brake FORD SUPER DUTY 2009 2.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 418, PDF Size: 3.55 MB

Page 328 of 418

T-Type/Mini-Spare Tire Information (Harley Davidson only)

Your vehicle may be equipped with a temporary spare tire. This spare

tire is considered “temporary”. Replace the temporary spare with a tire

of the same size, speed rating, and load carrying capacity as the other

road tires as soon as possible.

When driving with the temporary spare tiredo not:

•Exceed 50 mph (80 km/h)

•Load the vehicle beyond maximum vehicle load rating listed on the

Safety Compliance Label

•Tow a trailer

•Use snow chains on the end of the vehicle with the temporary spare

tire

•Use more than one temporary spare tire at a time

Use of a temporary spare tire at any one wheel location can lead to

impairment of the following:

•Handling, stability and braking performance

•Comfort and noise

•Ground clearance and parking at curbs

•Winter weather driving capability

•Wet weather driving capability

Stopping and securing the vehicle

WARNING:To help prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block (in

both directions) the wheel that is diagonally opposite to the tire being

changed.

Refer to the instruction sheet (located in the glove box) for detailed tire

change instructions.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

328

Page 329 of 418

Park on a level surface, activate

hazard flashers and set the parking

brake.

•Automatic transmission: Place

gearshift lever in P (Park).

•Manual transmission: Place

gearshift lever in R (Reverse).

•Electronic Shift-On-the-Fly

(ESOF) 4x4: Place transfer case

in 4x4 HIGH or 4x4 LOW before

turning off the engine.

•Manual shift transfer case 4x4: Place transfer case in 4H or 4L.

Location of the spare tire and tools

If your vehicle is equipped with a spare tire, jack and associated tools,

refer to the following table for their locations:

Tool Location

Spare tire (pick-up trucks only) Under the vehicle, just forward of

the rear bumper

Jack Regular cab and Crew Cab:

Fastened to floor pan behind

rearmost seat on passenger side

SuperCab: Under rear bench seat

on passenger side

Jack handle, lug wrench, lug

wrench extension (only available

on Dual Rear Wheel [DRW]

vehicles) and wheel chock (only

available on Single Rear Wheel

[SRW] vehicles equipped with a

diesel engine)Regular cab: Fastened to floor

behind driver seat

SuperCab: Fastened to floor under

rear seat

Crew Cab: Fastened to floor

behind rear seat at driver side

Key and spare tire lock In the glove box

Jack instruction sheet Under the jack tool kit

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

329

Page 331 of 418

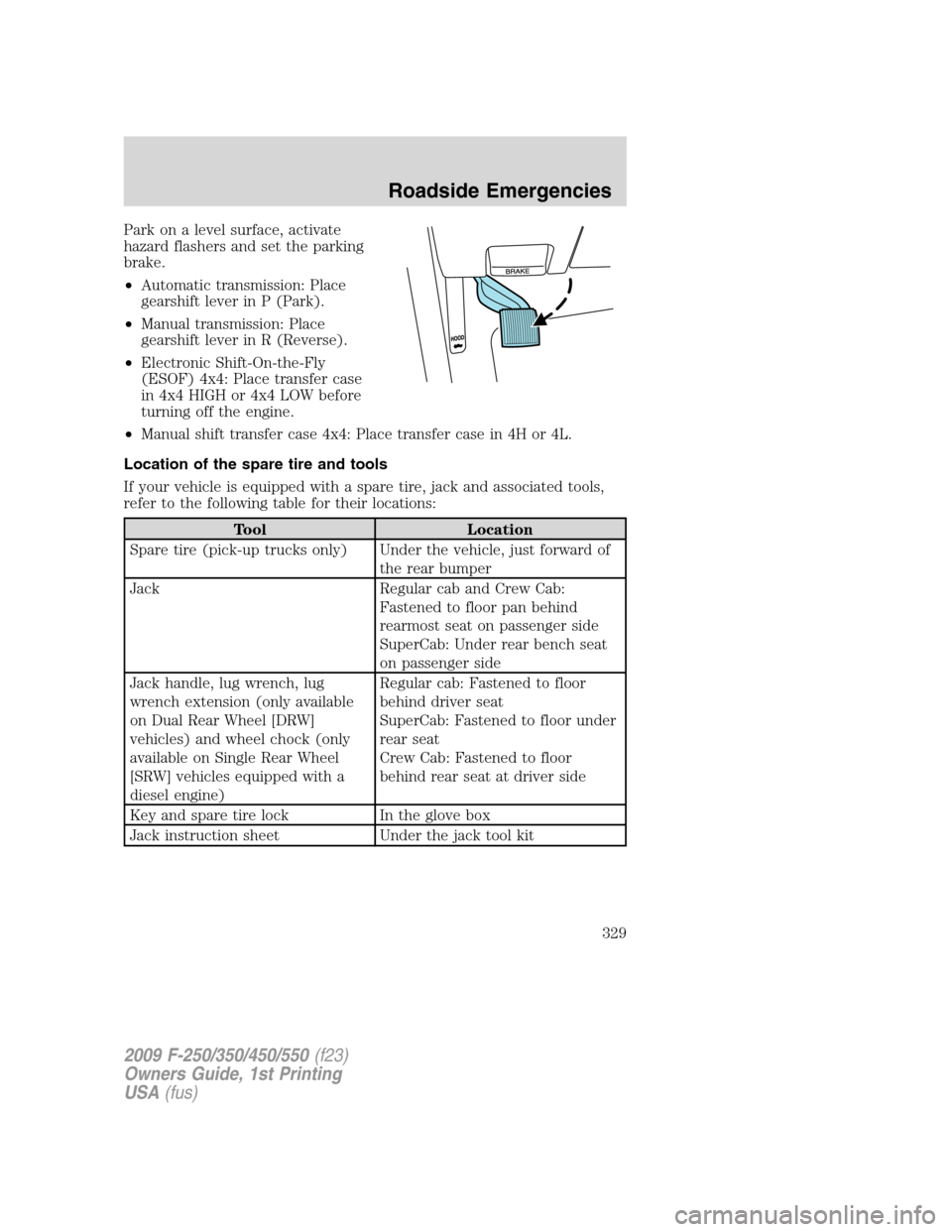

3. Fully insert the jack handle (with

one extension) through the bumper

hole and into the guide tube. The

key and lock will engage with a

slight push and counterclockwise

turn. Some resistance will be felt

when turning the jack handle

assembly.

4. Turn the handle counterclockwise

and lower the spare tire until you

can slide the tire rearward and the

cable is slack.

5. Remove the retainer through the center of the wheel.

Tire change procedure

WARNING:When one of the rear wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the transmission is in P (Park) (automatic

transmission) or R (Reverse) (manual transmission). To help prevent

the vehicle from moving when you change the tire, be sure that the

parking brake is set and the diagonally opposite wheel is blocked.

WARNING:To prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block (in

both directions) the wheel that is diagonally opposite (other side and

end of the vehicle) to the tire being changed.

WARNING:If the vehicle slips off the jack, you or someone else

could be seriously injured.

WARNING:Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack or changing the

wheel.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

331

Page 341 of 418

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, perscheduled maintenance information),

or at any time that the spare tire is disturbed through service of other

components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

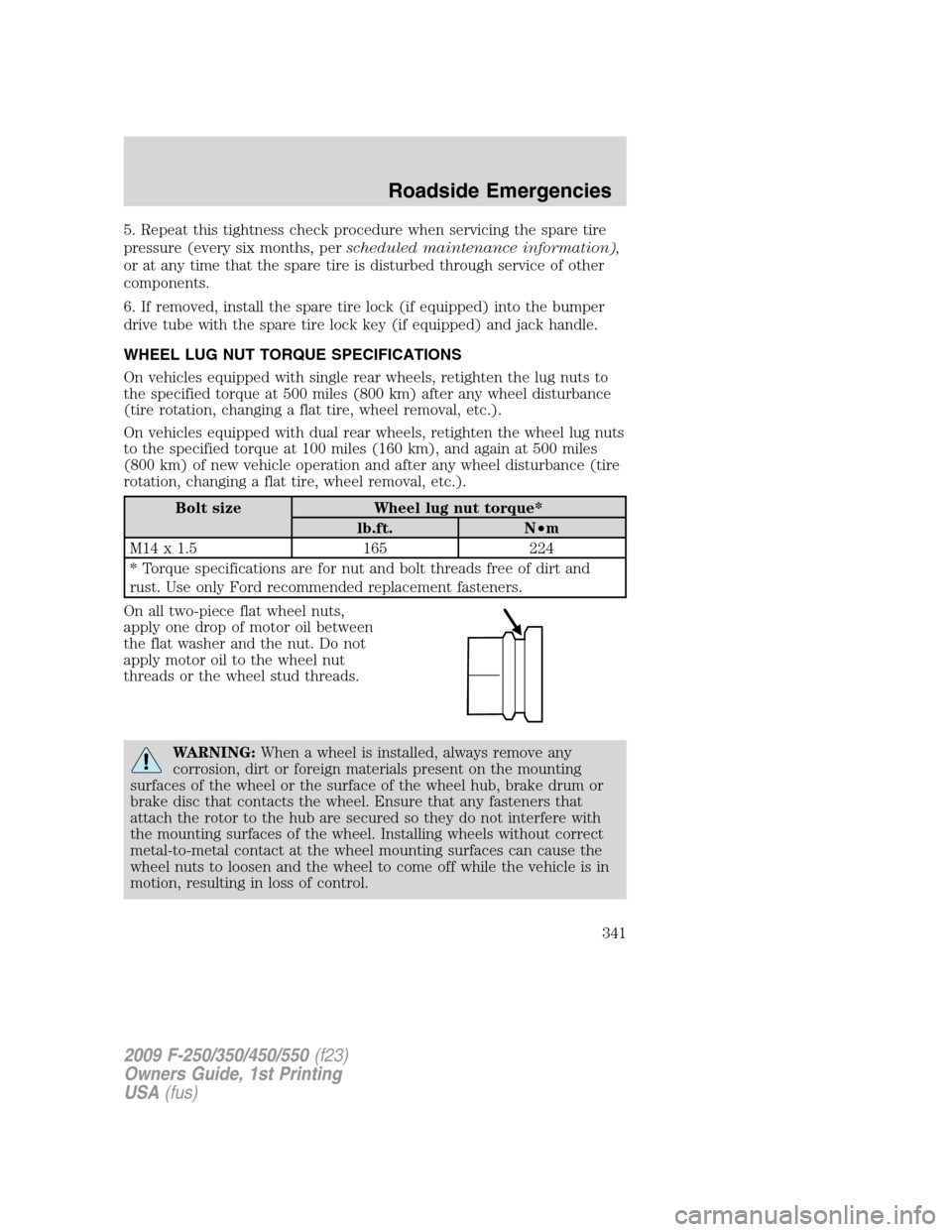

WHEEL LUG NUT TORQUE SPECIFICATIONS

On vehicles equipped with single rear wheels, retighten the lug nuts to

the specified torque at 500 miles (800 km) after any wheel disturbance

(tire rotation, changing a flat tire, wheel removal, etc.).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts

to the specified torque at 100 miles (160 km), and again at 500 miles

(800 km) of new vehicle operation and after any wheel disturbance (tire

rotation, changing a flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

lb.ft. N•m

M14 x 1.5 165 224

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut. Do not

apply motor oil to the wheel nut

threads or the wheel stud threads.

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Ensure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

341

Page 342 of 418

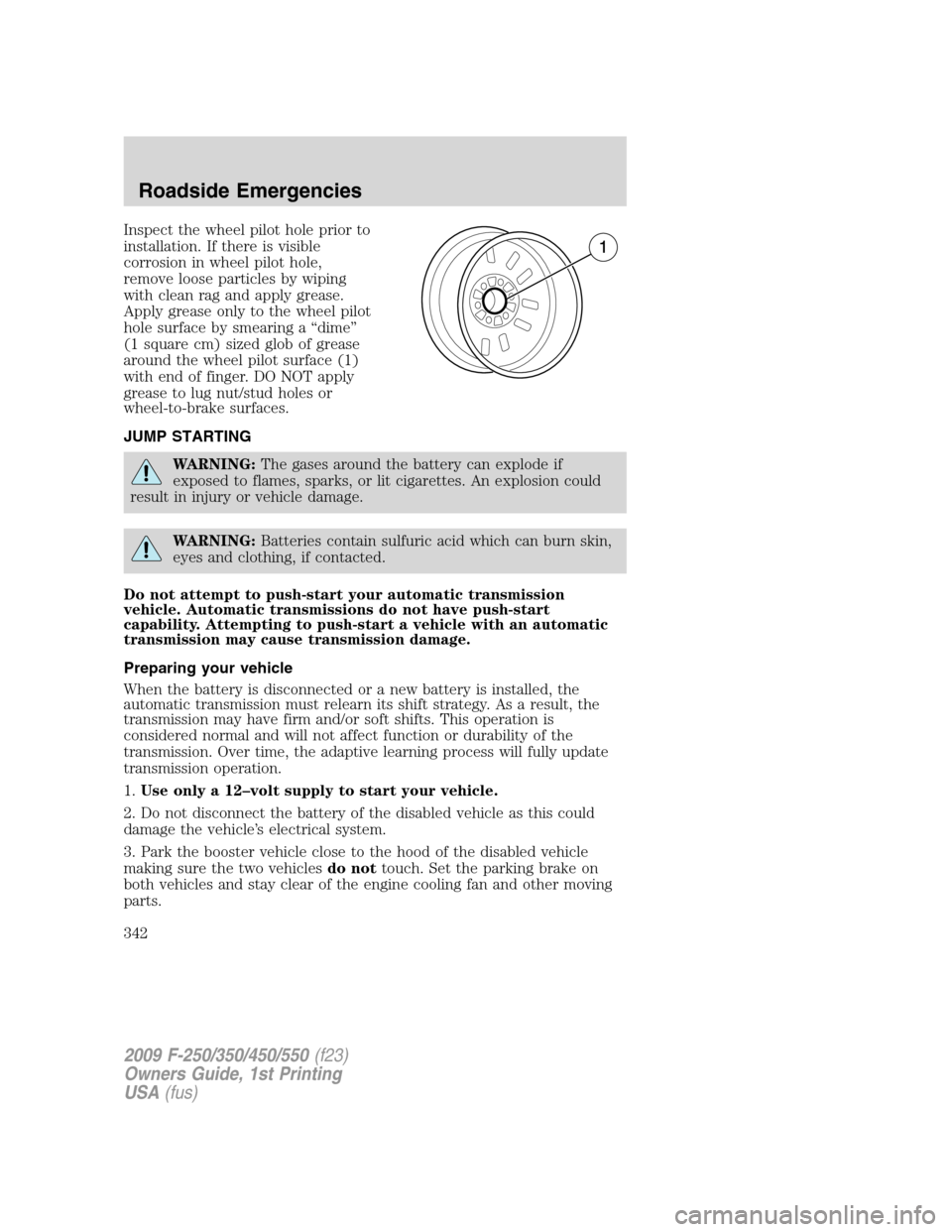

Inspect the wheel pilot hole prior to

installation. If there is visible

corrosion in wheel pilot hole,

remove loose particles by wiping

with clean rag and apply grease.

Apply grease only to the wheel pilot

hole surface by smearing a “dime”

(1 square cm) sized glob of grease

around the wheel pilot surface (1)

with end of finger. DO NOT apply

grease to lug nut/stud holes or

wheel-to-brake surfaces.

JUMP STARTING

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

342

Page 348 of 418

Note:Towing an ESOF 4x4 vehicle with the front wheels on the ground

without disengaging the front hubs may cause damage to the automatic

transmission.

Note:Towing a 4x2 or an ESOF 4x4 vehicle with the rear wheels on the

ground for more than 50 miles (80 km) and/or in excess of 35 mph

(56 km/h) may cause damage to the automatic transmission.

Note:On Dual Rear Wheel (DRW) vehicles, an outer rear wheel must be

removed prior to using a wheel lift wrecker.

Ford Motor Company produces a towing manual for all authorized tow

truck operators. Have your tow truck operator refer to this manual for

proper hook-up and towing procedures for your vehicle.

If the vehicle is towed by other means or incorrectly, vehicle

damage may occur.

Emergency towing

In case of a roadside emergency with a disabled vehicle (without access

to wheel dollies, car hauling trailer, or flatbed transport vehicle) your

vehicle (regardless of transmission powertrain configuration) can be flat

towed (all wheels on the ground) under the following conditions:

•Vehicle is facing forward so that it is being towed in a forward

direction.

•Place the transmission in N (Neutral). Refer toBrake shift interlock

in theDrivingchapter for specific instructions if you cannot move the

gear shift lever into N (Neutral).

•Maximum speed is not to exceed 35 mph (56 km/h).

•Maximum distance is 50 miles (80 km).

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Roadside Emergencies

348

Page 358 of 418

•After polishing chrome bumpers, apply a coating of Motorcraft

Premium Liquid Wax (ZC-53-A), available from your authorized dealer,

or an equivalent quality product to help protect from environmental

effects.

WAXING

•Wash the vehicle first.

•Do not use waxes that contain abrasives; use Motorcraft Premium

Liquid Wax (ZC-53-A), which is available from your authorized dealer,

or an equivalent quality product.

•Do not allow paint sealant to come in contact with any non-body

(low-gloss black) colored trim, such as grained door handles, roof

racks, bumpers, side moldings, mirror housings or the windshield cowl

area. The paint sealant will “gray” or stain the parts over time.

PAINT CHIPS

Your authorized dealer has touch-up paint to match your vehicle’s color.

Take your color code (printed on a sticker in the driver’s door jamb) to

your authorized dealer to ensure you get the correct color.

•Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

•Always read the instructions before using the products.

ALUMINUM WHEELS AND WHEEL COVERS

Aluminum wheels and wheel covers are coated with a clearcoat paint

finish. In order to maintain their shine:

•Clean weekly with Motorcraft Wheel and Tire Cleaner (ZC-37-A),

which is available from your authorized dealer. Heavy dirt and brake

dust accumulation may require agitation with a sponge. Rinse

thoroughly with a strong stream of water.

•Never apply any cleaning chemical to hot or warm wheel rims or

covers.

•Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•To remove tar and grease, use Motorcraft Bug and Tar Remover

(ZC-42), available from your authorized dealer.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Cleaning

358

Page 367 of 418

SERVICE RECOMMENDATIONS

To help you service your vehicle, we providescheduled maintenance

informationwhich makes tracking routine service easy.

If your vehicle requires professional service, your authorized dealer can

provide the necessary parts and service. Check yourWarranty

Guide/Customer Information Guideto find out which parts and

services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

•Do not work on a hot engine.

•Make sure that nothing gets caught in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all open flames and other burning (cigarettes) material away

from the battery and all fuel related parts.

Working with the engine off

•Automatic transmission:

1. Set the parking brake and shift to P (Park).

2. Turn off the engine and remove the key.

3. Block the wheels.

•Manual transmission:

1. Set the parking brake, depress the clutch and place the gearshift in 1

(First).

2. Turn off the engine and remove the key.

3. Block the wheels.

Working with the engine on

•Automatic transmission:

1. Set the parking brake and shift to P (Park).

2. Block the wheels.

•Manual transmission:

1. Set the parking brake, depress the clutch pedal, place the gearshift in

N (Neutral), and release the clutch pedal.

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Maintenance and Specifications

367

Page 369 of 418

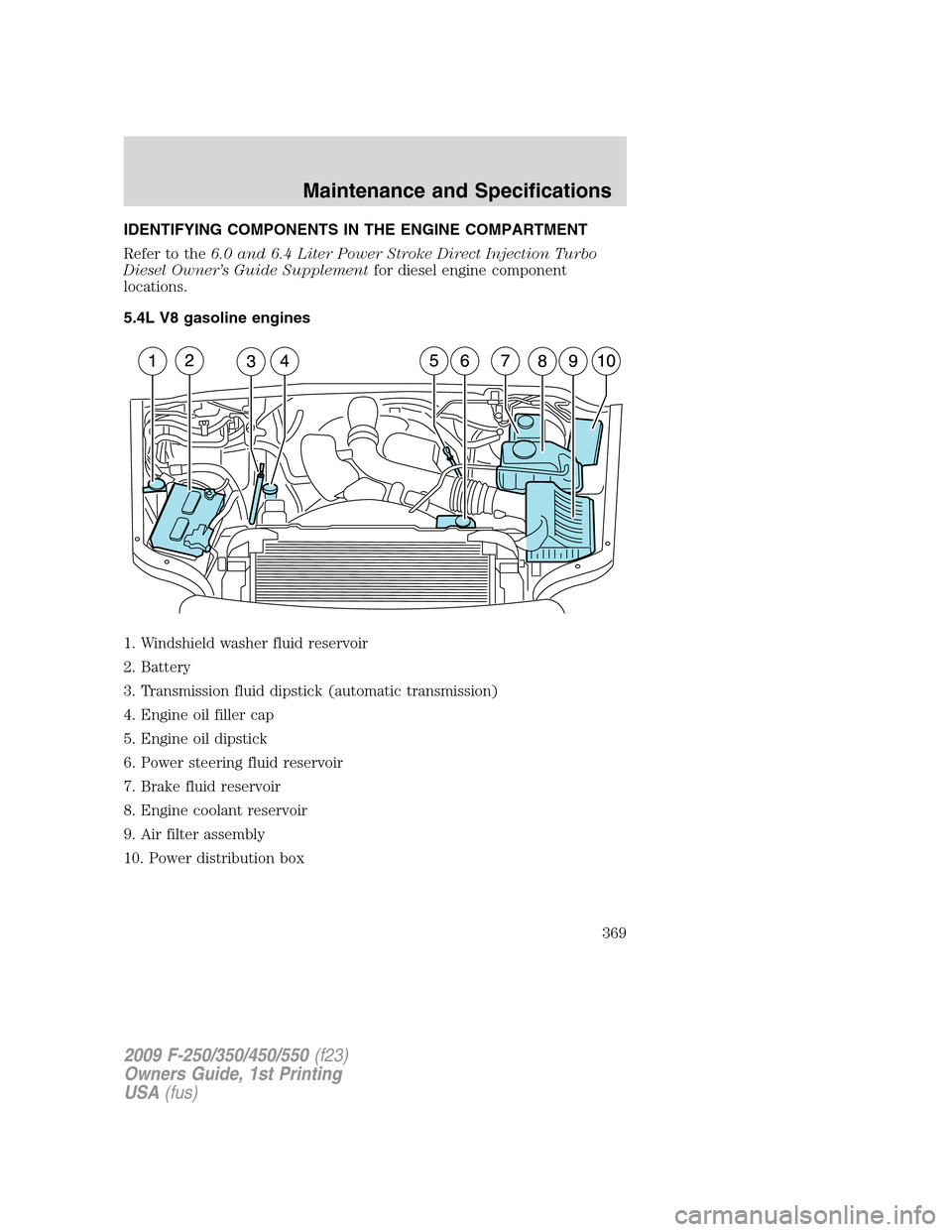

IDENTIFYING COMPONENTS IN THE ENGINE COMPARTMENT

Refer to the6.0 and 6.4 Liter Power Stroke Direct Injection Turbo

Diesel Owner’s Guide Supplementfor diesel engine component

locations.

5.4L V8 gasoline engines

1. Windshield washer fluid reservoir

2. Battery

3. Transmission fluid dipstick (automatic transmission)

4. Engine oil filler cap

5. Engine oil dipstick

6. Power steering fluid reservoir

7. Brake fluid reservoir

8. Engine coolant reservoir

9. Air filter assembly

10. Power distribution box

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Maintenance and Specifications

369

Page 370 of 418

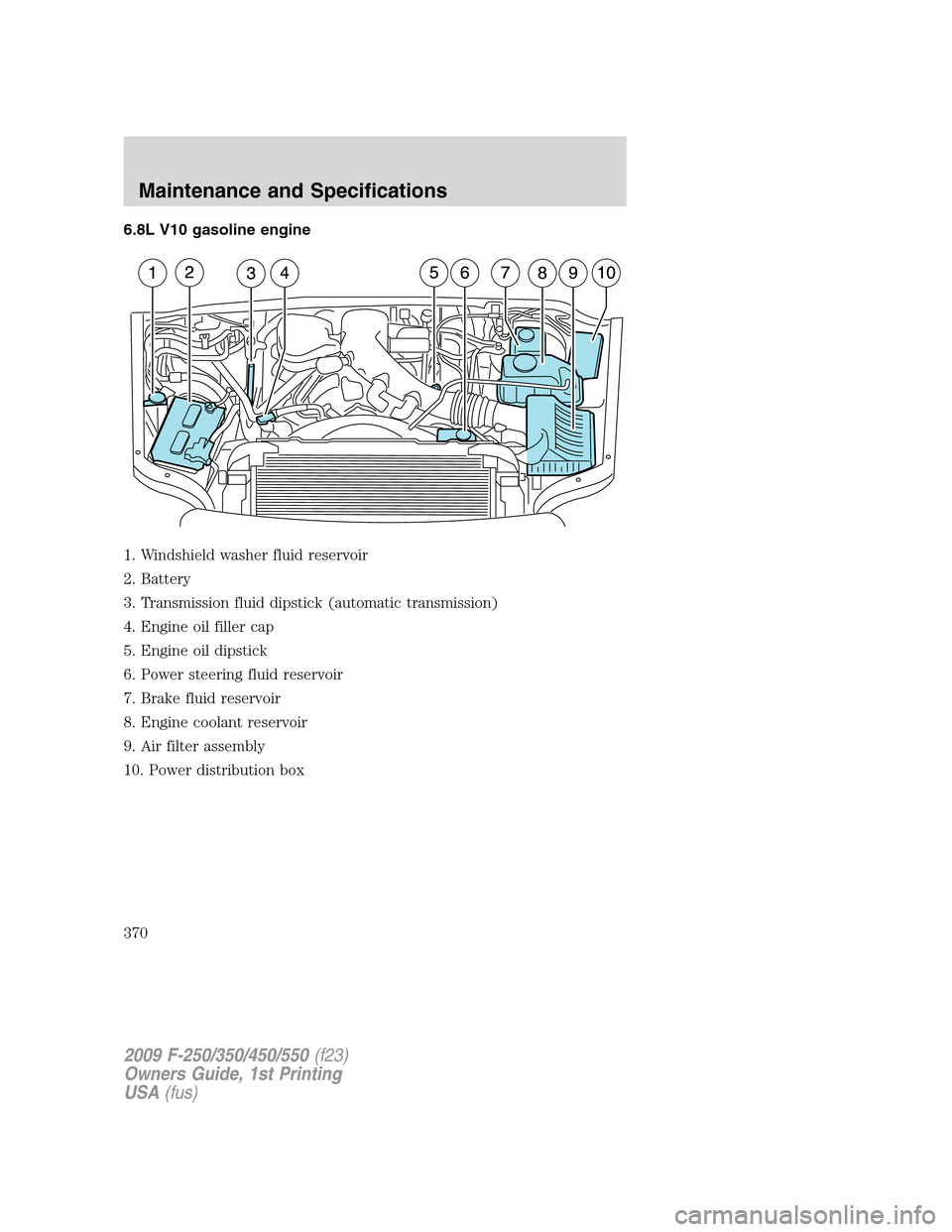

6.8L V10 gasoline engine

1. Windshield washer fluid reservoir

2. Battery

3. Transmission fluid dipstick (automatic transmission)

4. Engine oil filler cap

5. Engine oil dipstick

6. Power steering fluid reservoir

7. Brake fluid reservoir

8. Engine coolant reservoir

9. Air filter assembly

10. Power distribution box

2009 F-250/350/450/550(f23)

Owners Guide, 1st Printing

USA(fus)

Maintenance and Specifications

370