FORD SUPER DUTY 2010 2.G Diesel Supplement Manual

Manufacturer: FORD, Model Year: 2010, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2010 2.GPages: 104, PDF Size: 0.63 MB

Page 21 of 104

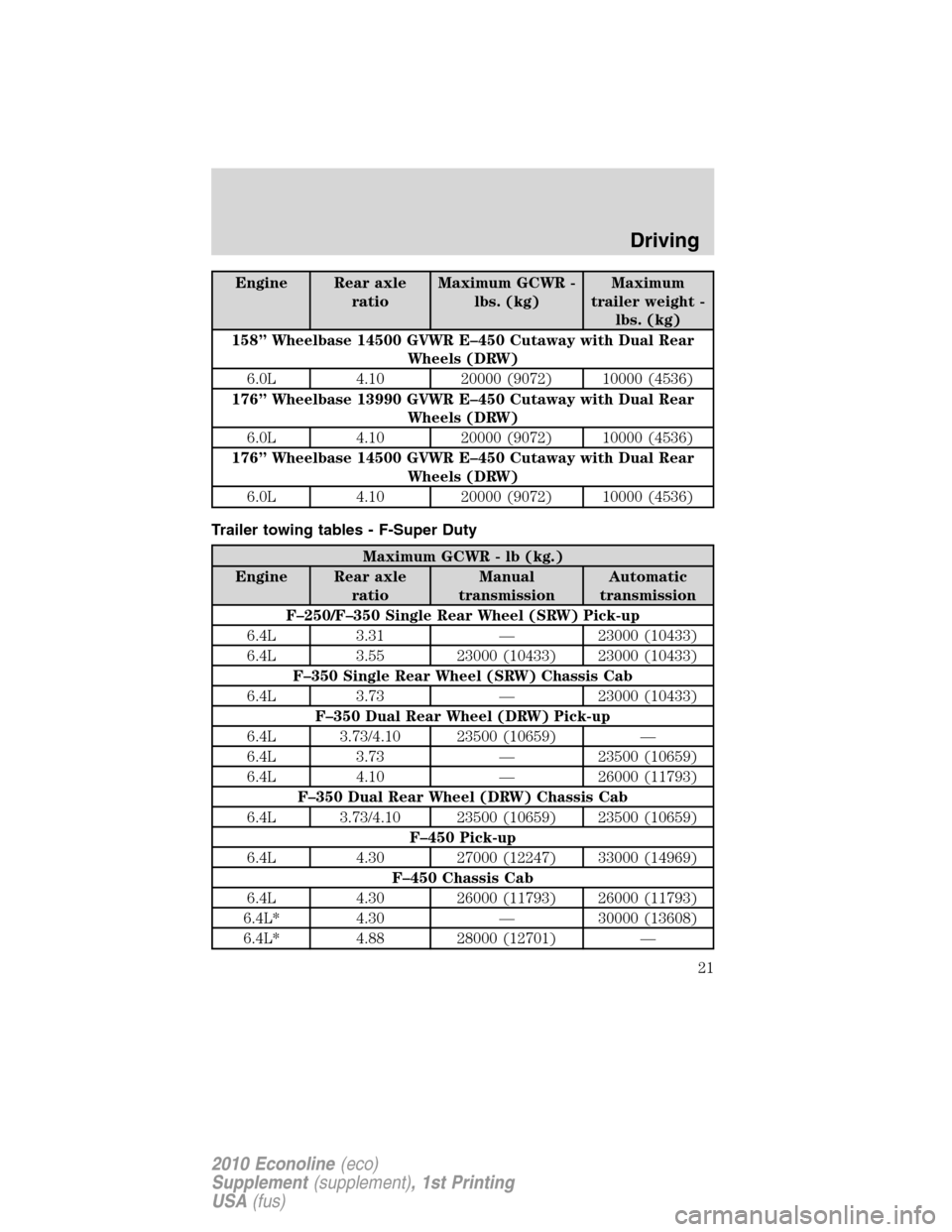

Engine Rear axle

ratioMaximum GCWR -

lbs. (kg)Maximum

trailer weight -

lbs. (kg)

158” Wheelbase 14500 GVWR E–450 Cutaway with Dual Rear

Wheels (DRW)

6.0L 4.10 20000 (9072) 10000 (4536)

176” Wheelbase 13990 GVWR E–450 Cutaway with Dual Rear

Wheels (DRW)

6.0L 4.10 20000 (9072) 10000 (4536)

176” Wheelbase 14500 GVWR E–450 Cutaway with Dual Rear

Wheels (DRW)

6.0L 4.10 20000 (9072) 10000 (4536)

Trailer towing tables - F-Super Duty

Maximum GCWR - lb (kg.)

Engine Rear axle

ratioManual

transmissionAutomatic

transmission

F–250/F–350 Single Rear Wheel (SRW) Pick-up

6.4L 3.31 — 23000 (10433)

6.4L 3.55 23000 (10433) 23000 (10433)

F–350 Single Rear Wheel (SRW) Chassis Cab

6.4L 3.73 — 23000 (10433)

F–350 Dual Rear Wheel (DRW) Pick-up

6.4L 3.73/4.10 23500 (10659) —

6.4L 3.73 — 23500 (10659)

6.4L 4.10 — 26000 (11793)

F–350 Dual Rear Wheel (DRW) Chassis Cab

6.4L 3.73/4.10 23500 (10659) 23500 (10659)

F–450 Pick-up

6.4L 4.30 27000 (12247) 33000 (14969)

F–450 Chassis Cab

6.4L 4.30 26000 (11793) 26000 (11793)

6.4L* 4.30 — 30000 (13608)

6.4L* 4.88 28000 (12701) —

Driving

21

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 22 of 104

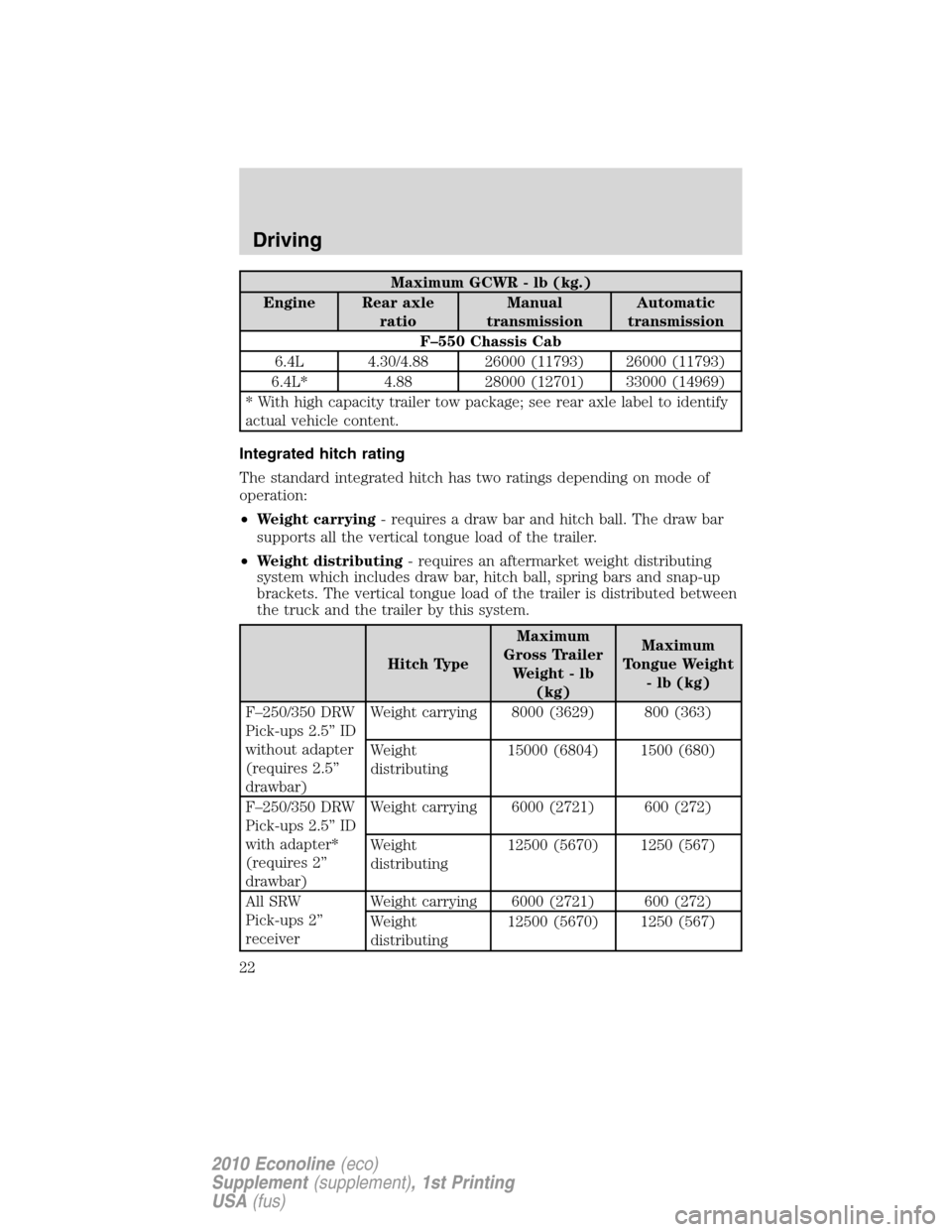

Maximum GCWR - lb (kg.)

Engine Rear axle

ratioManual

transmissionAutomatic

transmission

F–550 Chassis Cab

6.4L 4.30/4.88 26000 (11793) 26000 (11793)

6.4L* 4.88 28000 (12701) 33000 (14969)

* With high capacity trailer tow package; see rear axle label to identify

actual vehicle content.

Integrated hitch rating

The standard integrated hitch has two ratings depending on mode of

operation:

•Weight carrying- requires a draw bar and hitch ball. The draw bar

supports all the vertical tongue load of the trailer.

•Weight distributing- requires an aftermarket weight distributing

system which includes draw bar, hitch ball, spring bars and snap-up

brackets. The vertical tongue load of the trailer is distributed between

the truck and the trailer by this system.

Hitch TypeMaximum

Gross Trailer

Weight-lb

(kg)Maximum

Tongue Weight

- lb (kg)

F–250/350 DRW

Pick-ups 2.5” ID

without adapter

(requires 2.5”

drawbar)Weight carrying 8000 (3629) 800 (363)

Weight

distributing15000 (6804) 1500 (680)

F–250/350 DRW

Pick-ups 2.5” ID

with adapter*

(requires 2”

drawbar)Weight carrying 6000 (2721) 600 (272)

Weight

distributing12500 (5670) 1250 (567)

All SRW

Pick-ups 2”

receiverWeight carrying 6000 (2721) 600 (272)

Weight

distributing12500 (5670) 1250 (567)

Driving

22

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 23 of 104

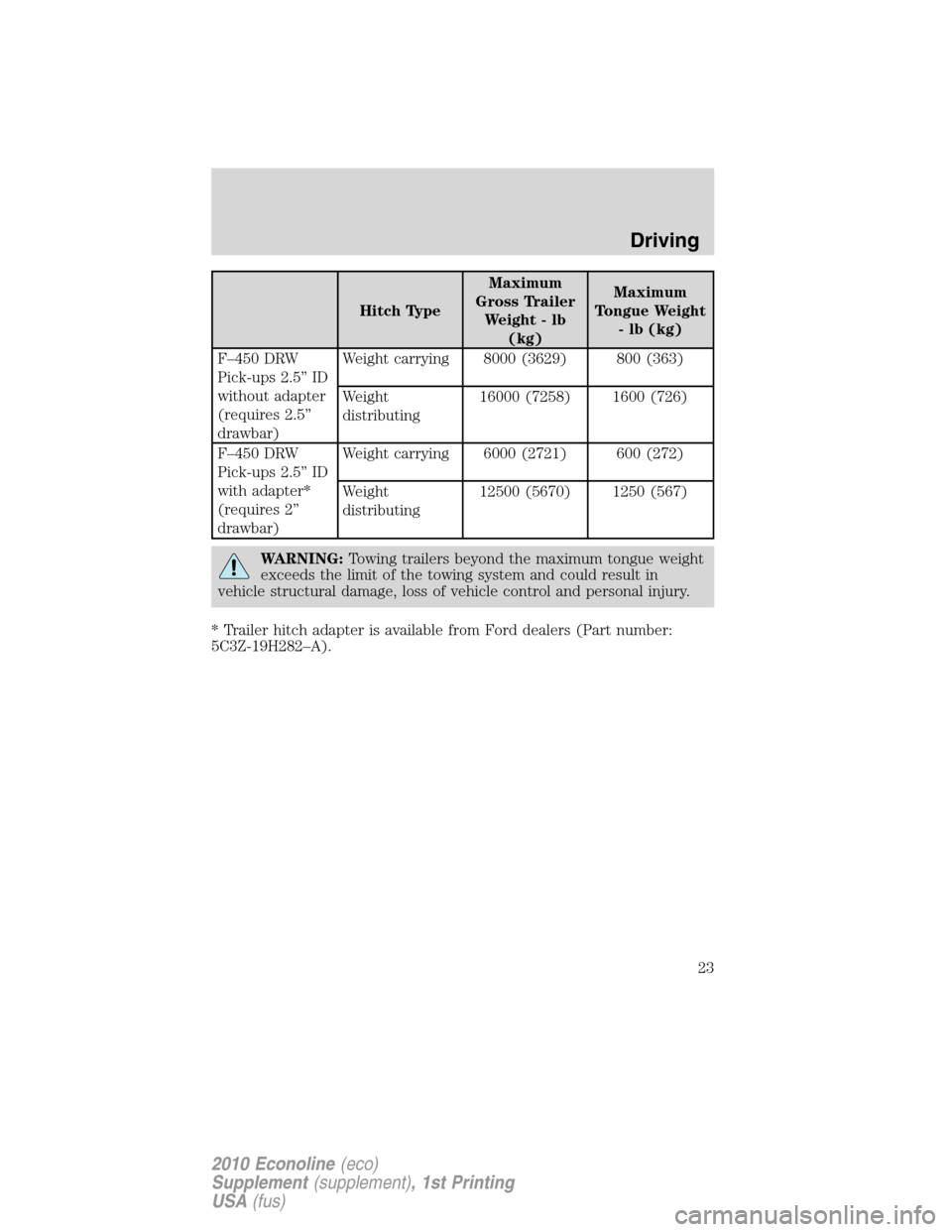

Hitch TypeMaximum

Gross Trailer

Weight-lb

(kg)Maximum

Tongue Weight

- lb (kg)

F–450 DRW

Pick-ups 2.5” ID

without adapter

(requires 2.5”

drawbar)Weight carrying 8000 (3629) 800 (363)

Weight

distributing16000 (7258) 1600 (726)

F–450 DRW

Pick-ups 2.5” ID

with adapter*

(requires 2”

drawbar)Weight carrying 6000 (2721) 600 (272)

Weight

distributing12500 (5670) 1250 (567)

WARNING:Towing trailers beyond the maximum tongue weight

exceeds the limit of the towing system and could result in

vehicle structural damage, loss of vehicle control and personal injury.

* Trailer hitch adapter is available from Ford dealers (Part number:

5C3Z-19H282–A).

Driving

23

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 24 of 104

JUMP STARTING YOUR VEHICLE (E-SERIES ONLY)

The following procedure is for E-Series vehicles only. F-Super

Duty vehicles equipped with the 6.4L diesel engine can be jump

started using the same procedure as a gasoline engine; refer to

yourOwner’s Guidefor the jump starting procedure.

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; damage to the

automatic transmission may result.

Preparing your vehicle

When the batteries are disconnected or new batteries are installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the batteries of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the passenger side of the disabled

vehicle making sure the two vehiclesdo nottouch. Set the parking

brake on both vehicles.

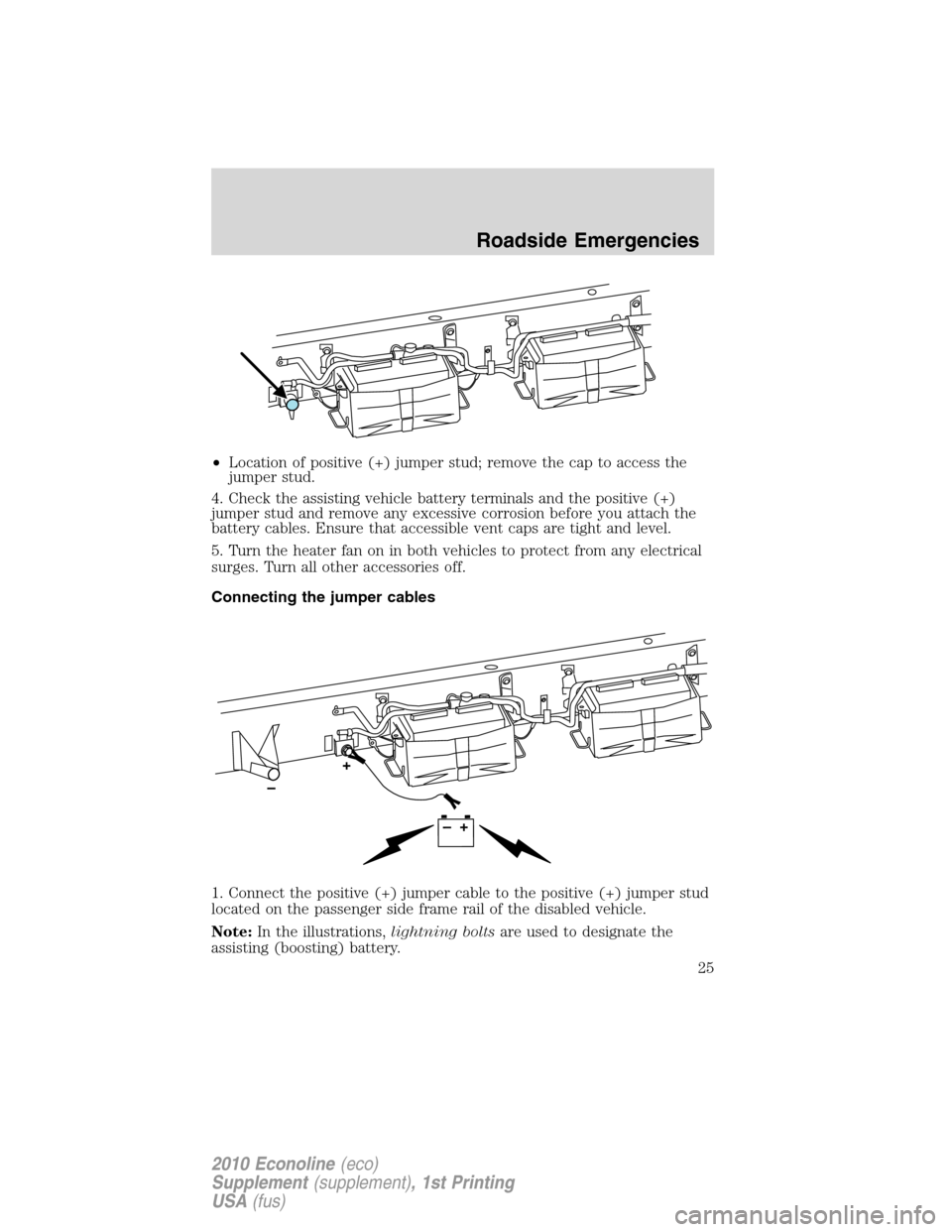

Note:This vehicle has two frame-mounted batteries located on the

passenger side frame rail, behind the front passenger door. A battery

positive (+) jumper stud is located on the frame rail behind the rear

most battery box.

Roadside Emergencies

24

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 25 of 104

•Location of positive (+) jumper stud; remove the cap to access the

jumper stud.

4. Check the assisting vehicle battery terminals and the positive (+)

jumper stud and remove any excessive corrosion before you attach the

battery cables. Ensure that accessible vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) jumper stud

located on the passenger side frame rail of the disabled vehicle.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

Roadside Emergencies

25

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 26 of 104

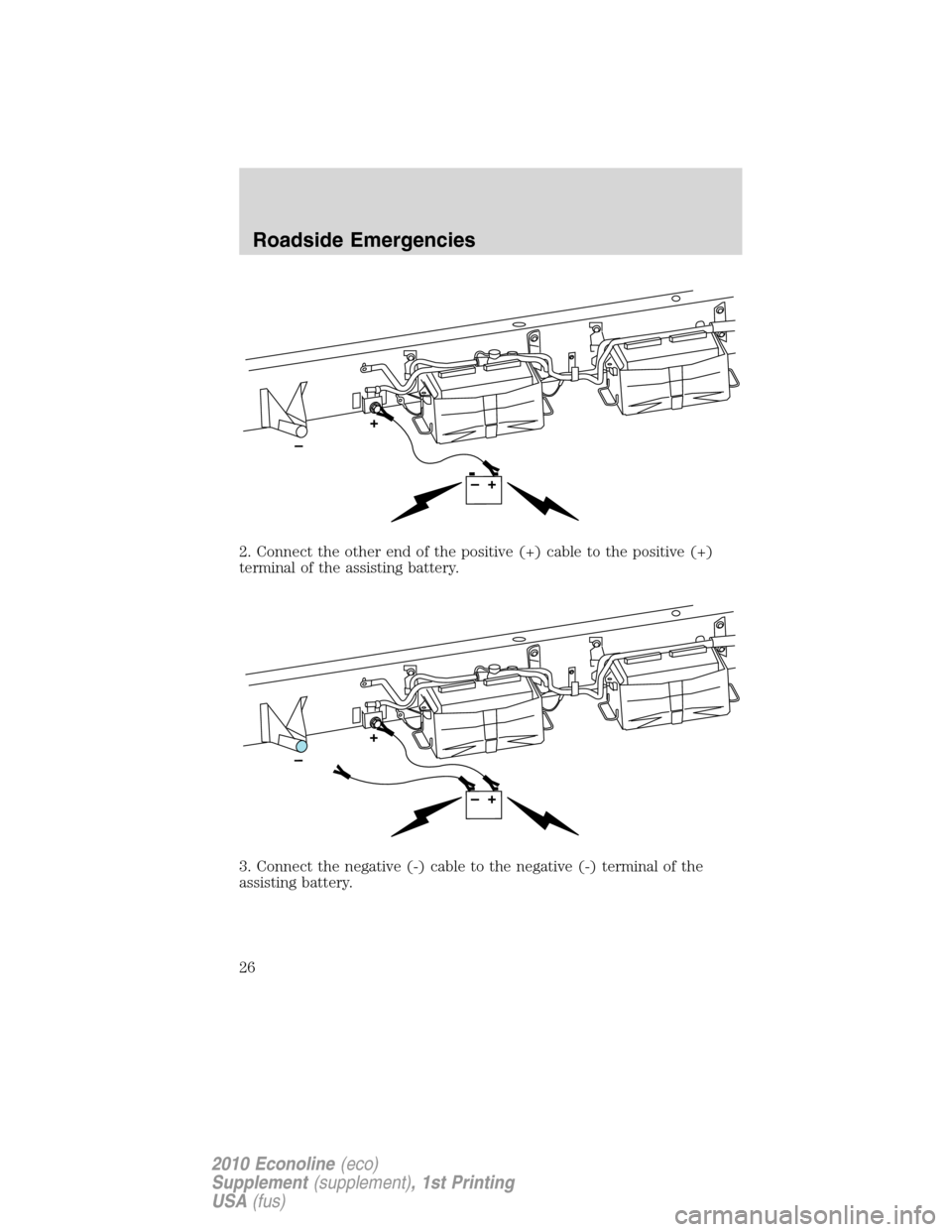

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

Roadside Emergencies

26

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 27 of 104

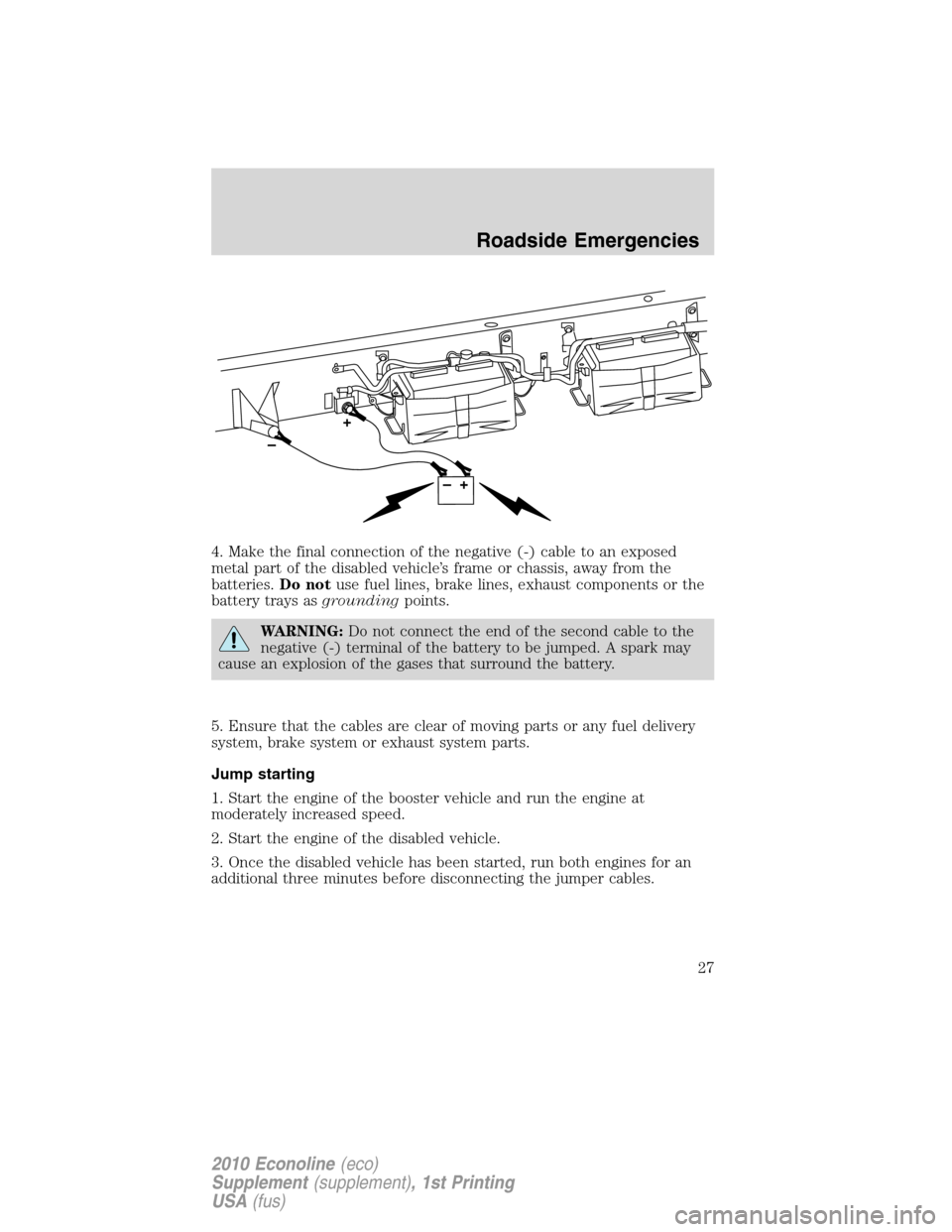

4. Make the final connection of the negative (-) cable to an exposed

metal part of the disabled vehicle’s frame or chassis, away from the

batteries.Do notuse fuel lines, brake lines, exhaust components or the

battery trays asgroundingpoints.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

5. Ensure that the cables are clear of moving parts or any fuel delivery

system, brake system or exhaust system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Roadside Emergencies

27

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 28 of 104

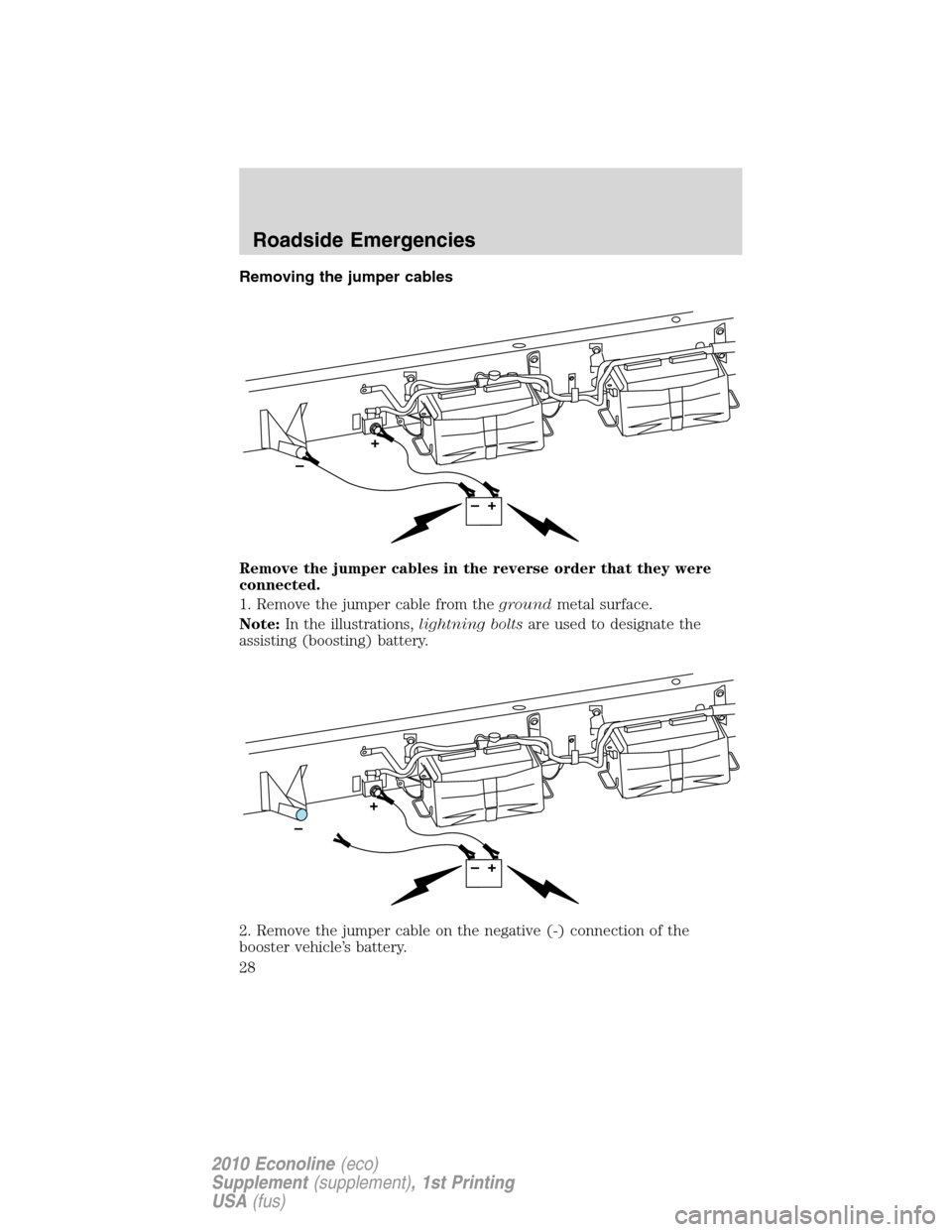

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

Roadside Emergencies

28

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 29 of 104

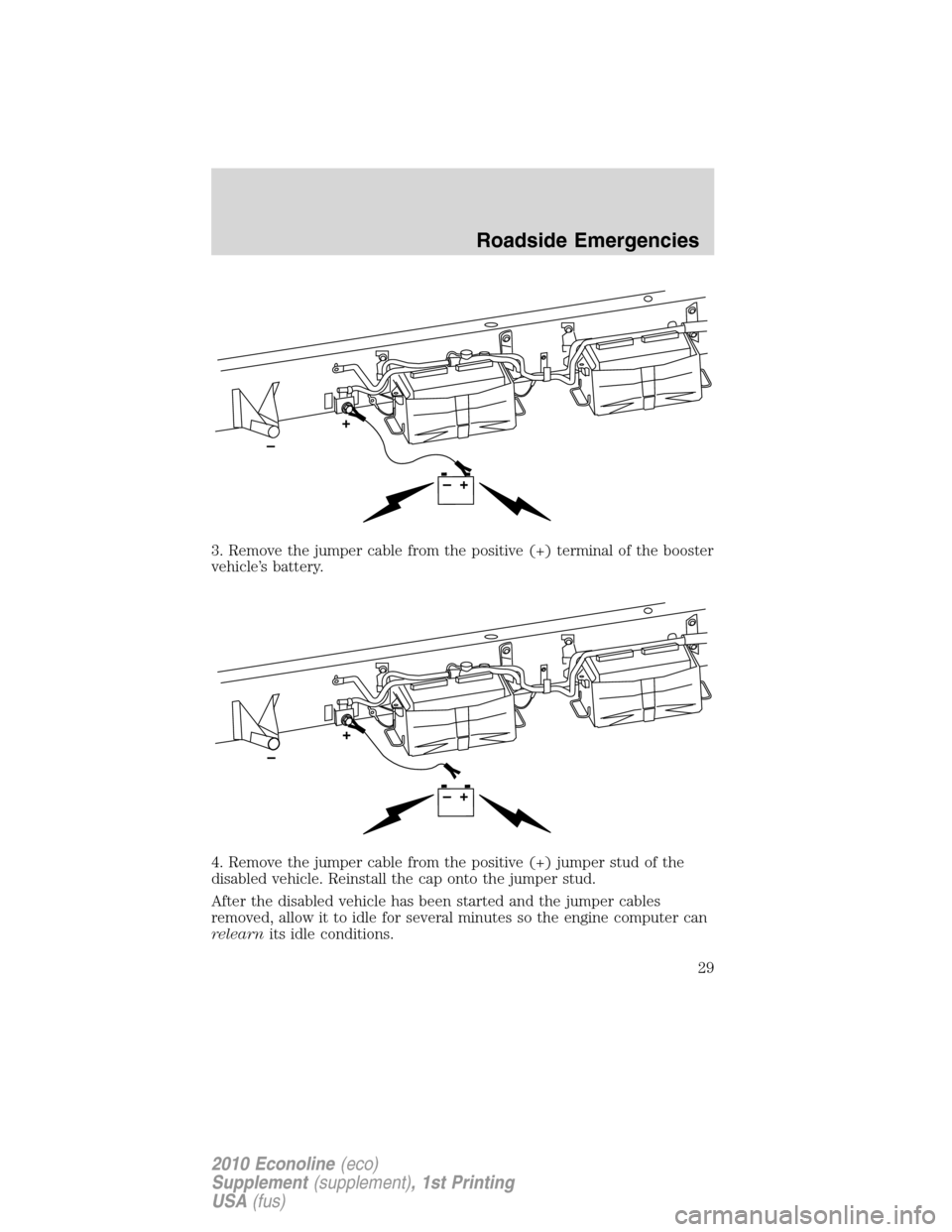

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) jumper stud of the

disabled vehicle. Reinstall the cap onto the jumper stud.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

Roadside Emergencies

29

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 30 of 104

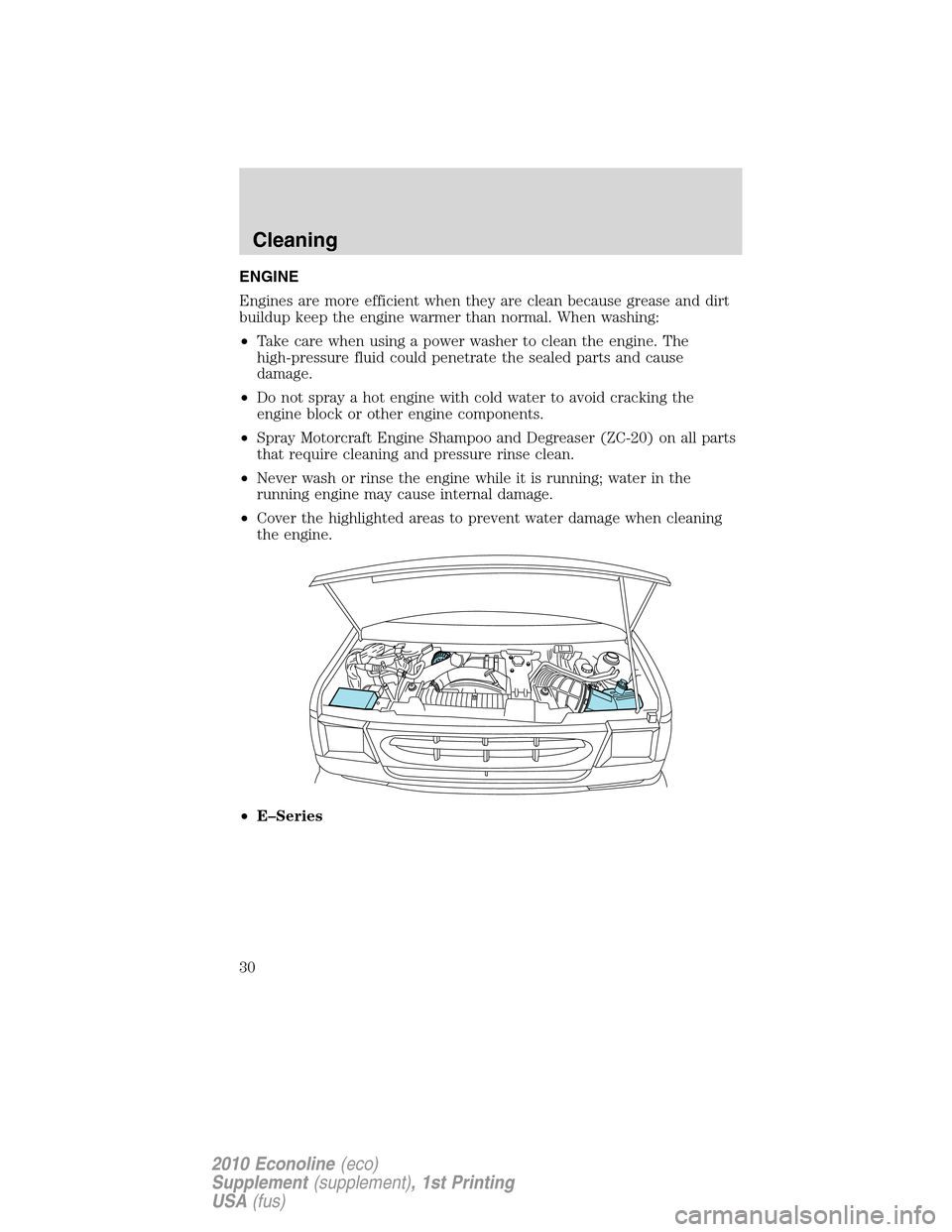

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

•Cover the highlighted areas to prevent water damage when cleaning

the engine.

•E–Series

Cleaning

30

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)