engine FORD SUPER DUTY 2010 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2010 2.GPages: 104, PDF Size: 0.63 MB

Page 39 of 104

Care should be taken whenever diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

the solution until it is run through the engine where it will be deposited

in the fuel injectors causing expensive-to-repair damage.

Diesel fuel dispensing nozzle fill rate

This truck is equipped with a fuel fill pipe which is able to accept fuel up

to 20 gallons per minute from an 11�8” fuel dispensing nozzle. Pumping fuel

at greater flow rates may result in premature nozzle shut-off or spitback.

Fuel filler cap

Your fuel tank filler cap has an indexed design with a 1/4 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it spins off.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The vehicle warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

WARNING:The fuel system may be under pressure. If the fuel

filler cap is venting vapor or if you hear a hissing sound, wait

until it stops before completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

WARNING:If you do not use the proper fuel filler cap,

excessive pressure or vacuum in the fuel tank may damage the

fuel system or cause the fuel cap to disengage in a collision, which may

result in possible personal injury.

Maintenance and Specifications

39

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 40 of 104

FUEL FILTER/WATER SEPARATOR

Fuel Conditioner Module (FCM - E-Series)

The vehicle is equipped with a Fuel Conditioning Module (FCM) located

on the driver-side of the vehicle next to the transmission case.

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 ml) of water accumulates in the module. If

water level is allowed to exceed this level, the water may be passed

through to the engine and may cause FIE (Fuel Injection Equipment)

damage.

Horizontal Fuel Conditioner Module (HFCM - F-Super Duty)

The vehicle is equipped with a Horizontal Fuel Conditioning Module

(HFCM) located on the frame-rail under the driver-side floorboard near

the transmission

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.13–0.16 pints (60–75 ml) of water accumulates in the

module. If water level is allowed to exceed this level, the water may be

passed through to the engine and may cause FIE (Fuel Injection

Equipment) damage.

DRAINING THE HFCM AND CHANGING THE ENGINE AND

VEHICLE FUEL FILTERS

Your vehicle is equipped with two fuel filters; one is mounted on top of

the engine.On F-Super Duty,the second filter, inside the HFCM, is

mounted inside the frame rail under the driver-side floorboard near the

transmission.On E-Series,the second filter, inside the FCM, is mounted

on the driver-side of the vehicle next to the transmission case.On all

vehicles,both filters should be replaced at the same time. Regular fuel

filter changes are an important part of engine maintenance; failing to

keep with the scheduled maintenance could lead to engine performance

issues and/or fuel injection system damage. Refer to theScheduled

maintenance guidechapter of this supplement for more information.

Refer toMotorcraft part numberslater in this chapter for the fuel filter

replacement part number. This part number includes filters and seals for

both the engine-mounted and frame-mounted filters.

Maintenance and Specifications

40

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 41 of 104

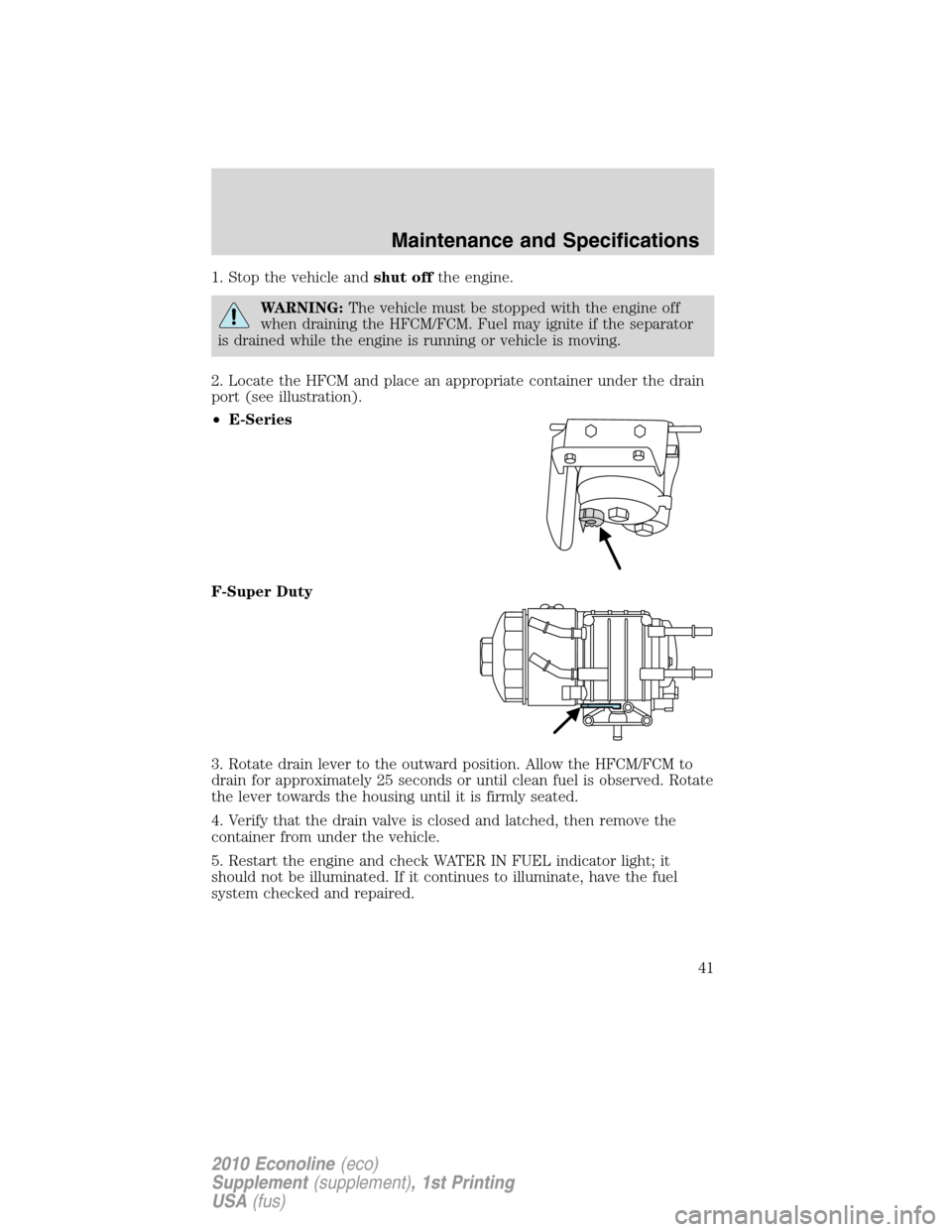

1. Stop the vehicle andshut offthe engine.

WARNING:The vehicle must be stopped with the engine off

when draining the HFCM/FCM. Fuel may ignite if the separator

is drained while the engine is running or vehicle is moving.

2. Locate the HFCM and place an appropriate container under the drain

port (see illustration).

•E-Series

F-Super Duty

3. Rotate drain lever to the outward position. Allow the HFCM/FCM to

drain for approximately 25 seconds or until clean fuel is observed. Rotate

the lever towards the housing until it is firmly seated.

4. Verify that the drain valve is closed and latched, then remove the

container from under the vehicle.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

Maintenance and Specifications

41

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 43 of 104

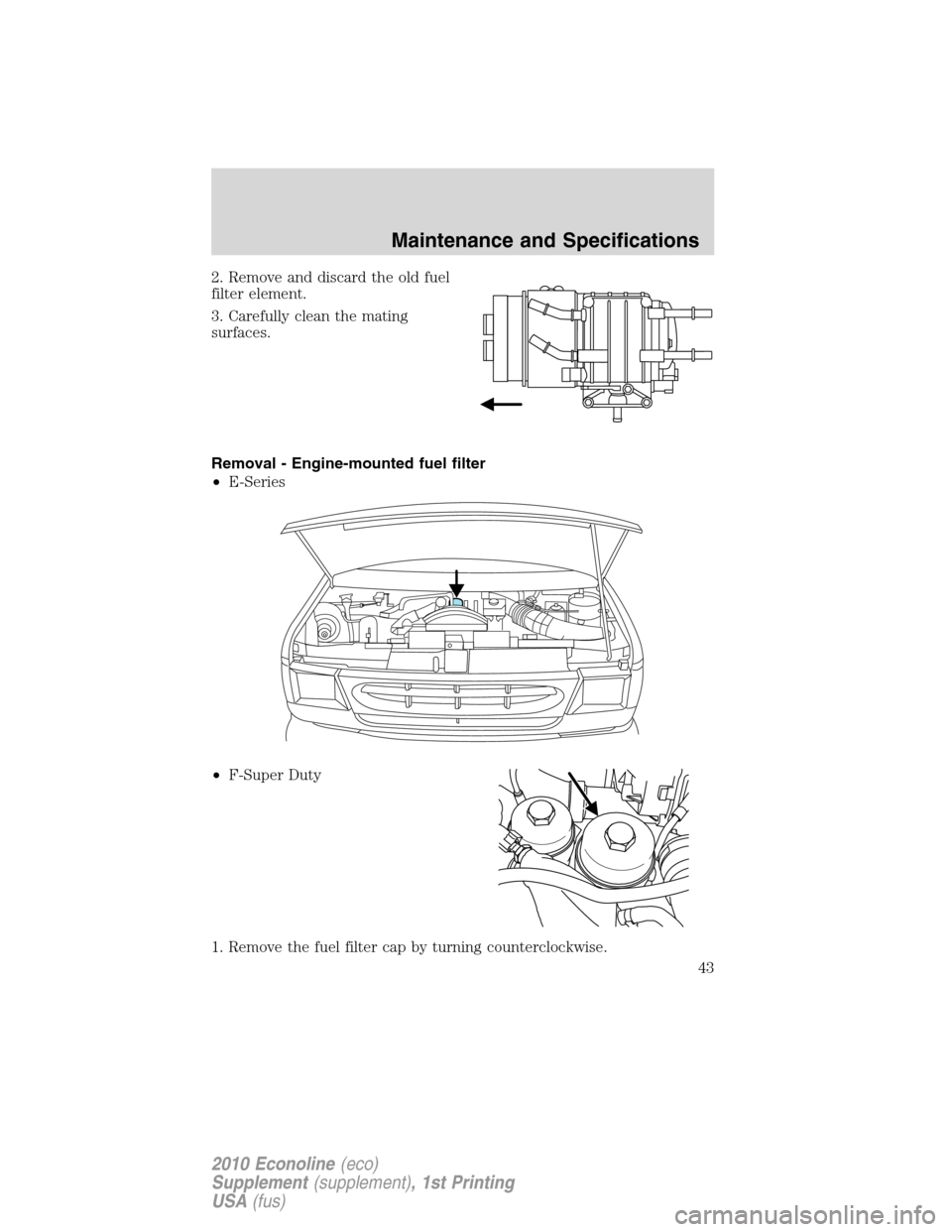

2. Remove and discard the old fuel

filter element.

3. Carefully clean the mating

surfaces.

Removal - Engine-mounted fuel filter

•E-Series

•F-Super Duty

1. Remove the fuel filter cap by turning counterclockwise.

Maintenance and Specifications

43

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 44 of 104

2. Remove and discard the old fuel filter element.

3. Carefully clean the mating surfaces.

Installation - both

The engine will not run properly if the fuel filter is not installed

in housing.

1. Install the new fuel filter and cap seal into the fuel filter housing.

Refer toMotorcraft part numberslater in this chapter for the fuel filter

part number.

2. Tighten cap onto fuel filter housing slowly, allowing fuel to soak into

the fuel filter element. Tighten cap until it contacts the housing.

Turn the ignition key to on for 30 seconds, then turn it to off. Do this a

total of six times in a row to purge any trapped air from the fuel system.

Replace the filter bowl O-ring with new seal (included in filter kit) every

time you service the filter.

After filter service, a no start or rough running engine may indicate that

air is entering the system through the filter bowl seal or drain. Make sure

the drain lever is pointing rearward and stowed against the HFCM case.

Using a fuel which has more than average impurities may require

the fuel filter to be replaced more frequently than the service

interval specifies.

ENGINE OIL

Checking the engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

3. Allow at least20 minutesafter engine shutdown to ensure that the

oil contained in the upper parts of the engine has returned to the oil

pan.

4. Protecting yourself from engine heat, pull out the dipstick, wipe it

clean and reinsert fully.

Maintenance and Specifications

44

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 45 of 104

5. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

6. Maintain the oil level between MIN and MAX or the ADD and

OPERATING RANGE on the dipstick by adding oil as required. The

distance from MIN to MAX or ADD to OPERATING RANGE on the

dipstick represents 2.0 quarts (1.9L). Do not overfill. If the oil level

exceeds MAX or OPERATING RANGE, oil consumption may result.

Engine oil specifications

To help achieve acceptable engine performance and durability, it is

important that only engine oils of good quality are used in your diesel

engine and it is changed at the recommended interval. For normal or

severe service, use Motorcraft oil or an equivalent oil conforming to Ford

specification WSS-M2C171–E or API service categories CJ-4 or CJ-4/SM.

It is important to use these oils because they are compatible with the

emission control equipment of your vehicle to meet the more stringent

emission standards.

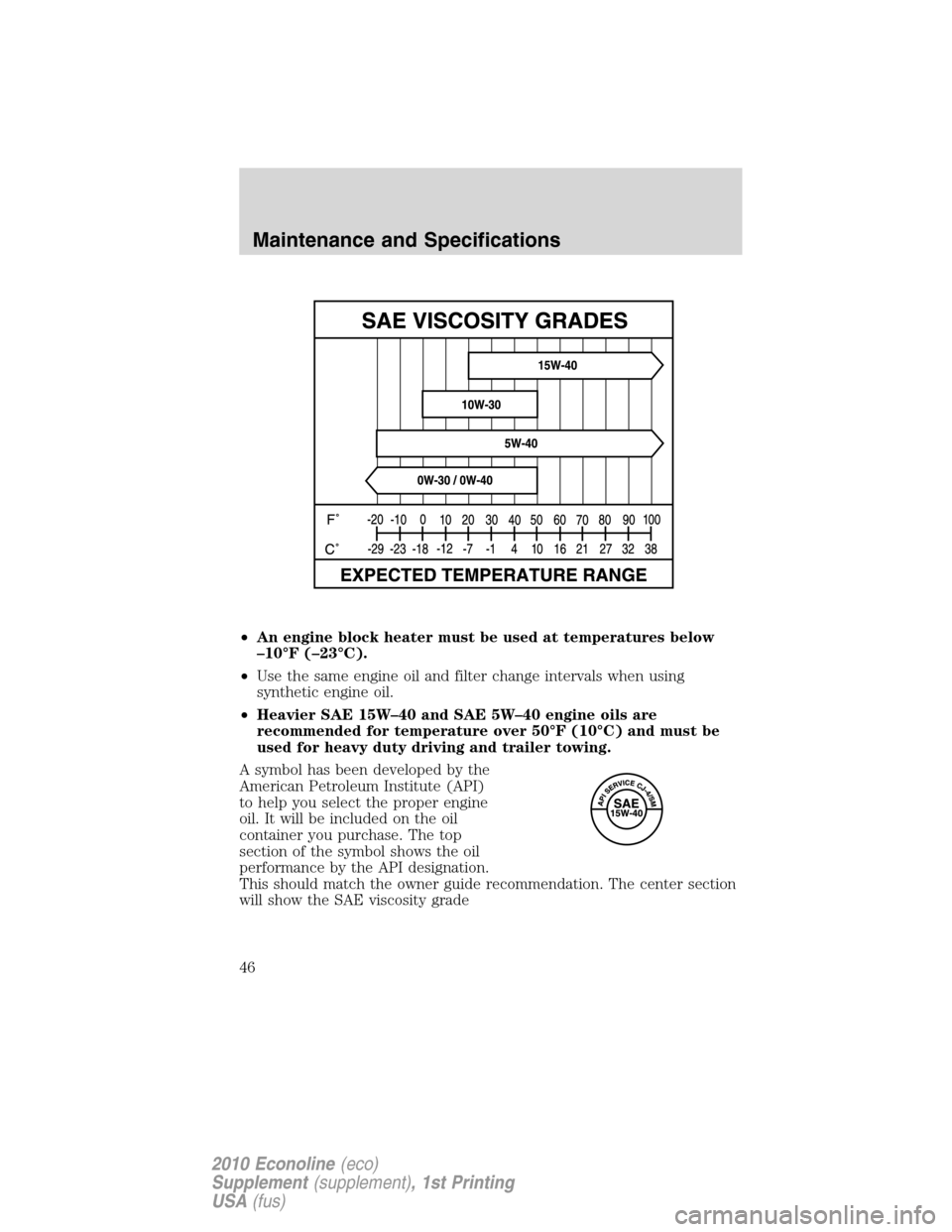

The use of correct oil viscosities for diesel engines is important for

satisfactory operation. Determine which oil viscosity best suits the

temperature range you expect to encounter for the next service interval

from the following SAE viscosity grade chart.

Maintenance and Specifications

45

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 46 of 104

•An engine block heater must be used at temperatures below

–10°F (–23°C).

•Use the same engine oil and filter change intervals when using

synthetic engine oil.

•Heavier SAE 15W–40 and SAE 5W–40 engine oils are

recommended for temperature over 50°F (10°C) and must be

used for heavy duty driving and trailer towing.

A symbol has been developed by the

American Petroleum Institute (API)

to help you select the proper engine

oil. It will be included on the oil

container you purchase. The top

section of the symbol shows the oil

performance by the API designation.

This should match the owner guide recommendation. The center section

will show the SAE viscosity grade

Maintenance and Specifications

46

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 47 of 104

Changing engine oil and filter

Change your oil and filter according to thescheduled maintenance

informationin this supplement. Change more frequently if your vehicle

operation includes extended periods of idling or low-speed operation,

driving for a long time in cold temperatures or driving short distances.

See the following sectionEngine lubrication for severe service

operationfor all severe duty restrictions.

Refer toMotorcraft part numberslater in this chapter for the engine oil

filter part number. This filter protects your engine by filtering harmful,

abrasive or sludge particles and particles significantly smaller than most

available “will-fit” filters.

To replace the filter,

1. Unscrew the oil filter cap and wait a few seconds for the oil to drain

through the built-in drain valve.Note:The filter should be changed

before reinstalling the oil pan drain plug.

2. Reinstall and tighten the oil filter cap.

WARNING:Do not handle a hot oil filter with bare hands.

WARNING:Continuous contact with USED motor oil has caused

cancer in laboratory mice. Protect your skin by washing with

soap and water.

Engine lubrication for severe service operation

The following severe service operating conditions require unique engine

maintenance procedures:

•frequent or extended idling (over 10 minutes per hour of normal

driving).

•if vehicle is operated in sustained ambient temperatures below -10°F

(-23°C) or above 100°F (38°C)

•frequent low speed operation, consistent heavy traffic less than

25 mph (40 km/h)

•operating in severe dust conditions.

•towing a trailer over 1,000 miles (1,600 km)

•sustained, high speed driving at Gross Vehicle Weight Rating

(maximum loaded weight for vehicle operation)

Maintenance and Specifications

47

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 48 of 104

•use of biodiesel, up to and including 5% Biodiesel (B5)

•use of high sulfur diesel fuel

If you are operating your vehicle under any of these conditions, change

engine oil and filter every 5,000 miles (8,000 km).

AIR FILTER RESTRICTION GAUGE AND AIR FILTER

REPLACEMENT

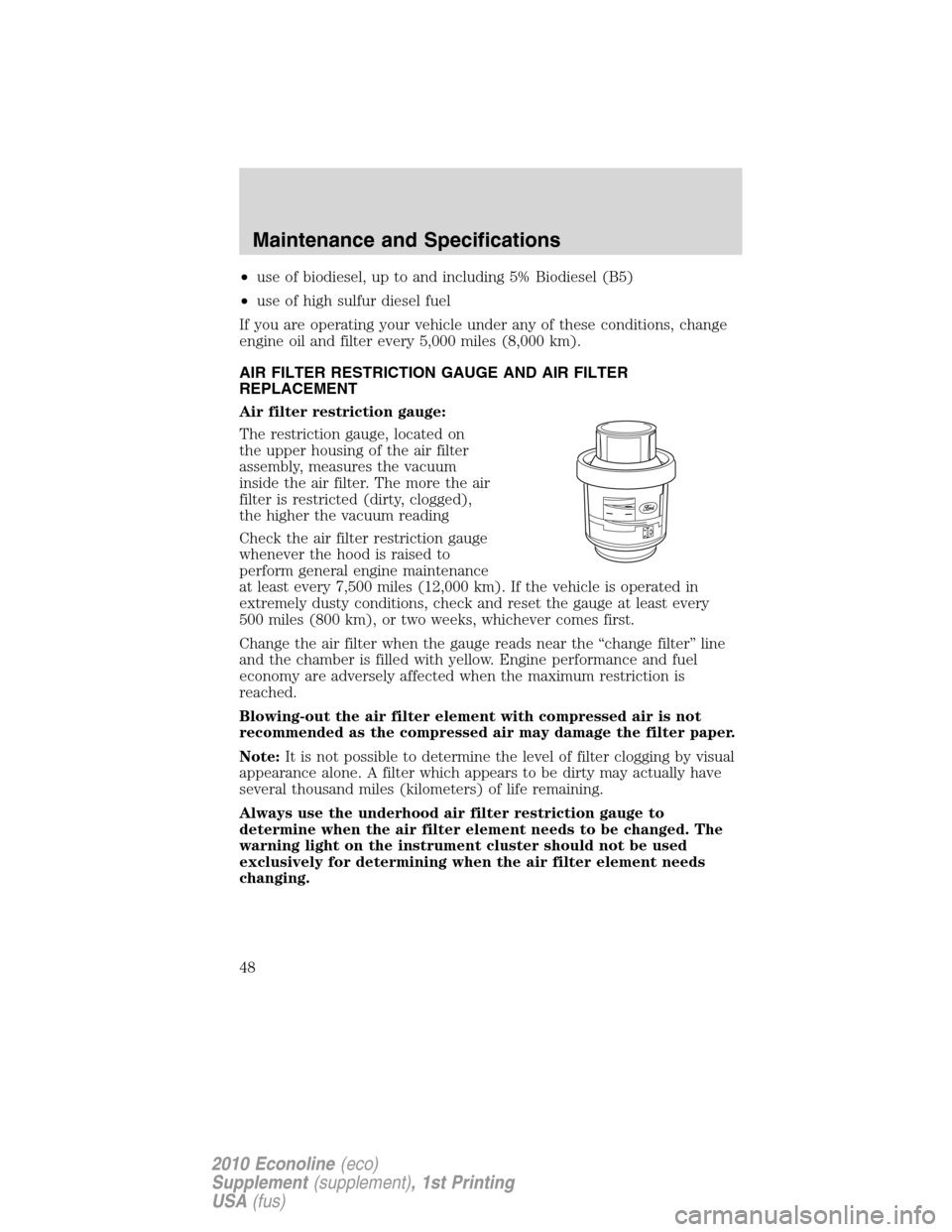

Air filter restriction gauge:

The restriction gauge, located on

the upper housing of the air filter

assembly, measures the vacuum

inside the air filter. The more the air

filter is restricted (dirty, clogged),

the higher the vacuum reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km). If the vehicle is operated in

extremely dusty conditions, check and reset the gauge at least every

500 miles (800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads near the “change filter” line

and the chamber is filled with yellow. Engine performance and fuel

economy are adversely affected when the maximum restriction is

reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

Maintenance and Specifications

48

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)

Page 49 of 104

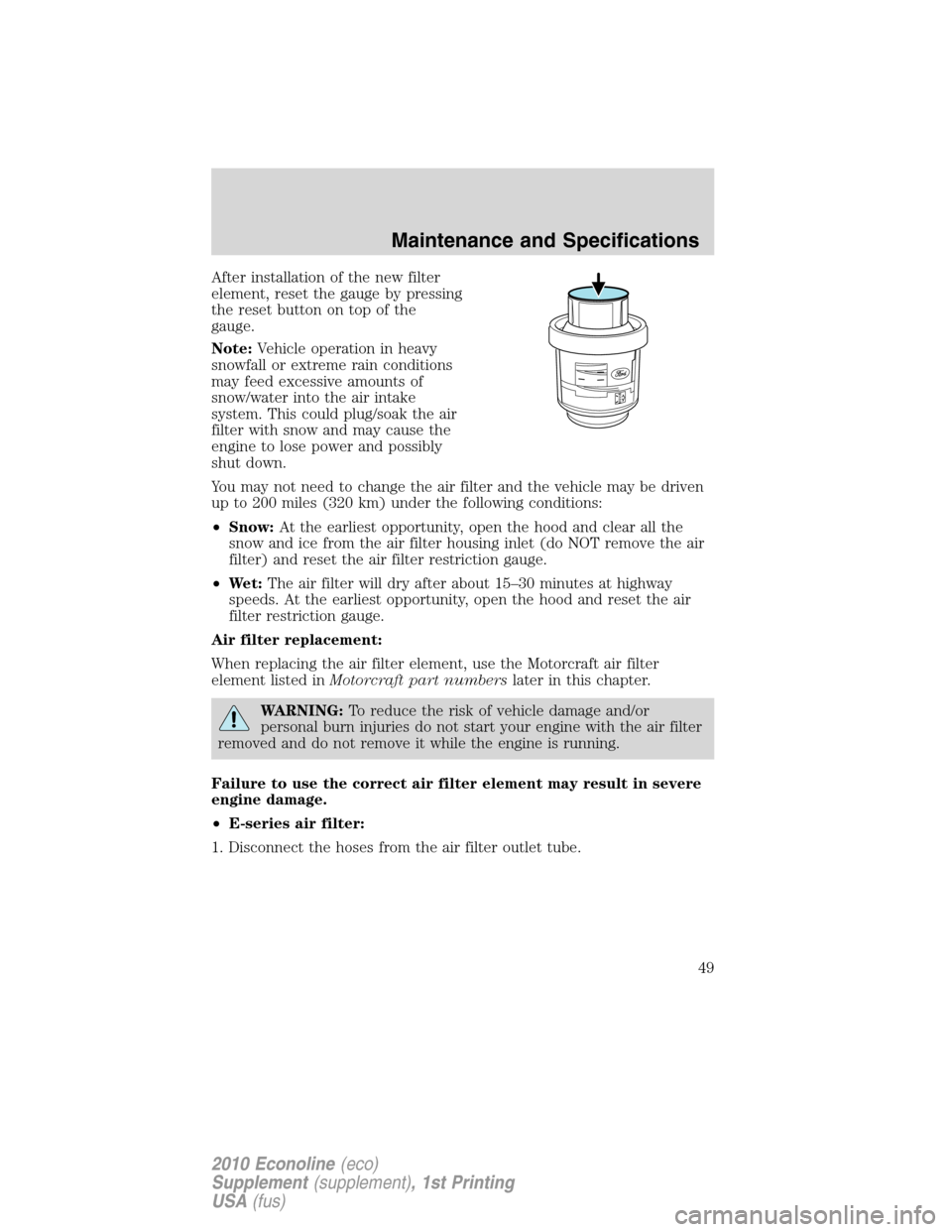

After installation of the new filter

element, reset the gauge by pressing

the reset button on top of the

gauge.

Note:Vehicle operation in heavy

snowfall or extreme rain conditions

may feed excessive amounts of

snow/water into the air intake

system. This could plug/soak the air

filter with snow and may cause the

engine to lose power and possibly

shut down.

You may not need to change the air filter and the vehicle may be driven

up to 200 miles (320 km) under the following conditions:

•Snow:At the earliest opportunity, open the hood and clear all the

snow and ice from the air filter housing inlet (do NOT remove the air

filter) and reset the air filter restriction gauge.

•Wet:The air filter will dry after about 15–30 minutes at highway

speeds. At the earliest opportunity, open the hood and reset the air

filter restriction gauge.

Air filter replacement:

When replacing the air filter element, use the Motorcraft air filter

element listed inMotorcraft part numberslater in this chapter.

WARNING:To reduce the risk of vehicle damage and/or

personal burn injuries do not start your engine with the air filter

removed and do not remove it while the engine is running.

Failure to use the correct air filter element may result in severe

engine damage.

•E-series air filter:

1. Disconnect the hoses from the air filter outlet tube.

Maintenance and Specifications

49

2010 Econoline(eco)

Supplement(supplement), 1st Printing

USA(fus)