check engine light FORD SUPER DUTY 2014 3.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2014, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2014 3.GPages: 458, PDF Size: 5.3 MB

Page 161 of 458

GENERAL INFORMATION

Note:

Occasional brake noise is normal. If

a metal-to-metal, continuous grinding or

continuous squeal sound is present, the

brake linings may be worn-out. Have the

system checked by an authorized dealer. If

your vehicle has continuous vibration or

shudder in the steering wheel while braking,

have it checked by an authorized dealer.

Note: Brake dust may accumulate on the

wheels, even under normal driving

conditions. Some dust is inevitable as the

brakes wear and does not contribute to

brake noise. See Cleaning the Alloy

Wheels (page 251). See

Warning Lamps and

Indicators (page 75).

Wet brakes result in reduced braking

efficiency. Gently press the brake pedal a

few times when driving from a car wash or

standing water to dry the brakes.

Brake Over Accelerator

In the event the accelerator pedal

becomes stuck or entrapped, apply steady

and firm pressure to the brake pedal to

slow the vehicle and reduce engine power.

If you experience this condition, apply the

brakes and bring your vehicle to a safe

stop. Move the transmission selector lever

to position

P, switch the engine off and

apply the parking brake. Inspect the

accelerator pedal for any interference. If

none are found and the condition persists,

have your vehicle towed to the nearest

authorized dealer. Brake Assist

Brake assist detects when you brake

rapidly by measuring the rate at which you

press the brake pedal. It provides

maximum braking efficiency as long as you

press the pedal, and can reduce stopping

distances in critical situations.

Anti-lock Brake System

This system helps you maintain steering

control during emergency stops by keeping

the brakes from locking.

This lamp momentarily

illuminates when you turn the

ignition on. If the light does not

illuminate during start up, remains on or

flashes, the system may be disabled. Have

the system checked by an authorized

dealer. If the system is disabled, normal

braking is still effective. If the

brake warning lamp illuminates

when you release the parking brake, have

the system checked by an authorized

dealer.

HINTS ON DRIVING WITH

ANTI-LOCK BRAKES

Note: When the system is operating, the

brake pedal will pulse and may travel

further. Maintain pressure on the brake

pedal. You may also hear a noise from the

system. This is normal.

The anti-lock braking system will not

eliminate the risks when:

• you drive too closely to the vehicle in

front of you

• your vehicle is hydroplaning

• you take corners too fast

• the road surface is poor.

158

Super Duty (TFA) BrakesE144522 E144522

Page 167 of 458

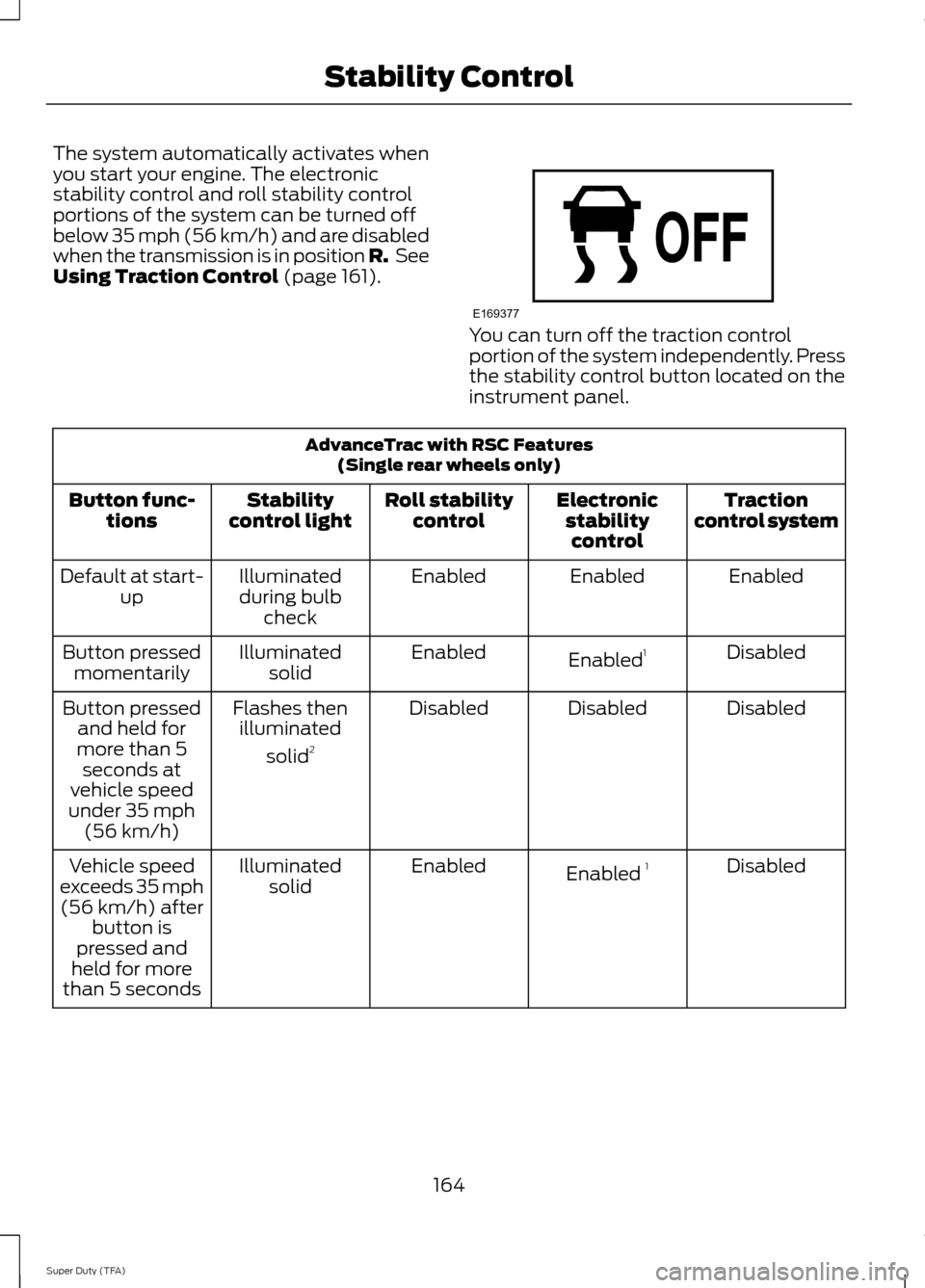

The system automatically activates when

you start your engine. The electronic

stability control and roll stability control

portions of the system can be turned off

below 35 mph (56 km/h) and are disabled

when the transmission is in position R.

See

Using Traction Control (page 161). You can turn off the traction control

portion of the system independently. Press

the stability control button located on the

instrument panel.

AdvanceTrac with RSC Features

(Single rear wheels only)

Traction

control system

Electronic

stabilitycontrol

Roll stability

control

Stability

control light

Button func-

tions

Enabled

Enabled

Enabled

Illuminated

during bulb check

Default at start-

up

Disabled

Enabled 1

Enabled

Illuminated

solid

Button pressed

momentarily

Disabled

Disabled

Disabled

Flashes then

illuminated

solid 2

Button pressed

and held for

more than 5 seconds at

vehicle speed

under 35 mph (56 km/h)

Disabled

Enabled 1

Enabled

Illuminated

solid

Vehicle speed

exceeds 35 mph (56 km/h) after button is

pressed and

held for more

than 5 seconds

164

Super Duty (TFA) Stability ControlE169377

Page 189 of 458

TRAILER SWAY CONTROL (IF

EQUIPPED) WARNING

Turning off trailer sway control

increases the risk of loss of vehicle

control, serious injury or death. Ford

does not recommend disabling this feature

except in situations where speed reduction

may be detrimental (such as hill climbing),

the driver has significant trailer towing

experience, and can control trailer sway

and maintain safe operation. Note:

This feature does not prevent trailer

sway, but reduces it once it begins.

Note: This feature cannot stop all trailers

from swaying.

Note: In some cases, if vehicle speed is too

high, the system may activate multiple

times, gradually reducing vehicle speed.

This feature applies your vehicle brakes at

individual wheels and, if necessary, reduces

engine power. If the trailer begins to sway,

the stability control light flashes and the

message

TRAILER SWAY REDUCE

SPEED appears in the information display.

The first thing to do is slow your vehicle

down, then pull safely to the side of the

road and check for proper tongue load and

trailer load distribution. See

Load

Carrying (page 174). RECOMMENDED TOWING

WEIGHTS

Note:

Do not exceed a trailer weight of

5000 pounds (2268 kilograms) when

towing with, or by, bumper only.

Note: Make sure to take into consideration

trailer frontal area. Do not exceed 60 feet 2

(5.6 meters 2

) trailer frontal area.

Note: Exceeding this limitation may

significantly reduce the performance of your

towing vehicle. Selecting a trailer with a low

aerodynamic drag and rounded front design

helps optimize performance and fuel

economy.

Note: For high altitude operation, reduce

the gross combined weight by 2% per 1000

feet (300 meters) starting at the 1000 foot

(300 meter) elevation point.

Note: Certain states require electric trailer

brakes for trailers over a specified weight.

Be sure to check state regulations for this

specified weight. The maximum trailer

weights listed may be limited to this

specified weight, as your vehicle's electrical

system may not include the wiring

connector needed to use electric trailer

brakes.

Your vehicle may tow a class I, II, III and IV

trailer or fifth-wheel trailer provided the

maximum trailer weight is less than or

equal to the maximum trailer weight listed

for your vehicle configuration on the

following chart.

186

Super Duty (TFA) Towing

Page 196 of 458

Trailer Lamps

WARNING

Never connect any trailer lamp wiring

to the vehicle's tail lamp wiring; this

may damage the electrical system

resulting in fire. Contact your authorized

dealer as soon as possible for assistance

in proper trailer tow wiring installation.

Additional electrical equipment may be

required. Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, turn signals and hazard lights are

working.

Using a Step Bumper (If Equipped)

The rear bumper is equipped with an

integral hitch and only requires a ball with

a one-inch (25.4 millimeter) shank

diameter. The bumper has a 5000-pound

(2268 kilogram) trailer weight and a

500-pound (227 kilogram) tongue weight

capacity

If it is necessary to relocate the hitch ball

position, you must install a frame-mounted

trailer hitch.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

When Towing a Trailer

•

Do not drive faster than 70 mph (113

km/h) during the first 500 miles (800

kilometers).

• Do not make full-throttle starts. •

Check your hitch, electrical connections

and trailer wheel lug nuts thoroughly

after you have traveled 50 miles (80

kilometers).

• When stopped in congested or heavy

traffic during hot weather, place the

gearshift in position P to aid engine and

transmission cooling and to help A/C

performance.

• Turn off the speed control with heavy

loads or in hilly terrain. The speed

control may turn off automatically

when you are towing on long, steep

grades.

• Shift to a lower gear when driving down

a long or steep hill. Do not apply the

brakes continuously, as they may

overheat and become less effective.

• If your transmission is equipped with a

Grade Assist or Tow/Haul feature, use

this feature when towing. This provides

engine braking and helps eliminate

excessive transmission shifting for

optimum fuel economy and

transmission cooling.

• If your vehicle is equipped with

AdvanceTrac with RSC, this system

may turn on during typical cornering

maneuvers with a heavily loaded trailer.

This is normal. Turning the corner at a

slower speed while towing may reduce

this tendency.

• If you are towing a trailer frequently in

hot weather, hilly conditions, at the

gross combined weight rating (or any

combination of these factors), consider

refilling your rear axle with synthetic

gear lubricant (if the axle is not already

filled with it). See Capacities and

Specifications (page 292).

193

Super Duty (TFA) Towing

Page 230 of 458

Adding Engine Coolant

WARNINGS

Do not add engine coolant when the

engine is hot. Steam and scalding

liquids released from a hot cooling

system can burn you badly. Also, you can

be burned if you spill coolant on hot engine

parts. Do not put engine coolant in the

windshield washer fluid container. If

sprayed on the windshield, engine

coolant could make it difficult to see

through the windshield. To reduce the risk of personal injury,

make sure the engine is cool before

unscrewing the coolant pressure

relief cap. The cooling system is under

pressure; steam and hot liquid can come

out forcefully when the cap is loosened

slightly. Do not add coolant further than the

MAX mark.

Note:

Do not use stop leak pellets, cooling

system sealants, or additives as they can

cause damage to the engine cooling or

heating systems. This damage would not

be covered under your vehicle ’s warranty.

Note: During normal vehicle operation, the

engine coolant may change color from

orange to pink or light red. As long as the

engine coolant is clear and uncontaminated,

this color change does not indicate the

engine coolant has degraded nor does it

require the engine coolant to be drained, the

system to be flushed, or the engine coolant

to be replaced. •

Do not mix different colors or types of

coolant in your vehicle. Make sure the

correct coolant is used. Mixing of

engine coolants may harm your

engine ’s cooling system. The use of an

improper coolant may harm engine and

cooling system components and may

void the warranty. Use prediluted

engine coolant meeting the Ford

specification. See Capacities and

Specifications (page 292).

• In case of emergency, a large amount

of water without engine coolant may

be added in order to reach a vehicle

service location. In this instance, the

cooling system must be drained,

chemically cleaned with Motorcraft®

Premium Cooling System Flush, and

refilled with engine coolant as soon as

possible. Water alone (without engine

coolant) can cause engine damage

from corrosion, overheating or freezing.

• Do not use alcohol, methanol, brine or

any engine coolants mixed with alcohol

or methanol antifreeze (coolant).

Alcohol and other liquids can cause

engine damage from overheating or

freezing.

• Do not add extra inhibitors or additives

to the coolant. These can be harmful

and compromise the corrosion

protection of the engine coolant.

Unscrew the cap slowly. Any pressure will

escape as you unscrew the cap.

Add prediluted engine coolant meeting the

Ford specification. See

Capacities and

Specifications (page 292).

Whenever coolant has been added, the

coolant level in the coolant reservoir

should be checked the next few times you

drive the vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level.

227

Super Duty (TFA) Maintenance

Page 233 of 458

•

the engine coolant temperature gauge

moves fully into the red (hot) area

• the coolant temperature warning light

illuminates

• the service engine soon indicator

illuminates. WARNING

Never remove the coolant reservoir

cap while the engine is running or hot.

1. Pull off the road as soon as safely

possible and place the vehicle in P

(Park).

2. Leave the engine running until the coolant temperature gauge needle

moves away from the H range. After

several minutes, if this does not

happen, follow the remaining steps.

3. Turn the engine off and wait for it to cool before checking the coolant level.

4. If the coolant level is normal, you may restart your engine and continue on.

5. If the coolant is low, add coolant, restart the engine and take your vehicle

to an authorized dealer. See Adding

engine coolant in this chapter for more

information. Refer to fail-safe cooling

for additional information.

AUTOMATIC TRANSMISSION

FLUID CHECK

Have an authorized dealer check and

change the transmission fluid and filter at

the correct service interval. See

Scheduled Maintenance (page 428).

Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components. Checking Automatic Transmission

Fluid (If Equipped)

For scheduled intervals of the fluid checks

and changes, See

Scheduled

Maintenance (page 428). Your

transmission does not consume fluid.

However, the fluid level should be checked

if the transmission is not working properly,

i.e., if the transmission slips or shifts slowly

or if you notice some sign of fluid leakage.

Automatic transmission fluid expands

when warmed. To obtain an accurate fluid

check, drive the vehicle until it is at normal

operating temperature (approximately

19 mi (30 km)

). Verify that the

transmission fluid temperature gauge,

located on the instrument cluster, is within

normal range.

1. Drive the vehicle

19 mi (30 km)until it

reaches normal operating temperature.

2. Park the vehicle on a level surface and

engage the parking brake.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Latch the gearshift lever in P and leave

the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag. If

necessary, refer to the Under Hood

Overview in this chapter for the

location of the dipstick.

6. Install the dipstick making sure it is fully

seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be in the

designated area for normal operating

temperature or ambient temperature.

Low Fluid Level

Type A

230

Super Duty (TFA) Maintenance

Page 255 of 458

•

Touch-up exposed or primed metal to

prevent rust.

• Cover chrome and stainless steel parts

with a thick coat of auto wax to prevent

discoloration. Re-wax as necessary

when your vehicle is washed.

• Lubricate all hood, door and trunk lid

hinges, and latches with a light grade

oil.

• Cover interior trim to prevent fading.

• Keep all rubber parts free from oil and

solvents.

Engine

• The engine oil and filter should be

changed prior to storage, as used

engine oil contain contaminates that

may cause engine damage.

• Start the engine every 15 days. Run at

fast idle until it reaches normal

operating temperature

• With your foot on the brake, shift

through all the gears while the engine

is running.

Fuel system

• Fill the fuel tank with high-quality fuel

until the first automatic shutoff of the

fuel pump nozzle.

Note: During extended periods of vehicle

storage (30 days or more), fuel may

deteriorate due to oxidation. Add a quality

gas stabilizer product to your vehicle's fuel

system whenever actual or expected

storage periods exceed 30 days. Follow the

instructions on the additive label. your

vehicle should then be operated at idle

speed to circulate the additive throughout

the fuel system. Cooling system

•

Protect against freezing temperatures.

• When removing your vehicle from

storage, check coolant fluid level.

Confirm there are no cooling system

leaks, and fluid is at the recommended

level.

Battery

• Check and recharge as necessary. Keep

connections clean.

• If storing your vehicle for more than 30

days without recharging the battery, it

may be advisable to disconnect the

battery cables to ensure battery charge

is maintained for quick starting.

Note: If battery cables are disconnected, it

will be necessary to reset memory features.

Brakes

• Make sure brakes and parking brake

are fully released.

Tires

• Maintain recommended air pressure.

Miscellaneous

• Make sure all linkages, cables, levers

and pins under your vehicle are covered

with grease to prevent rust.

• Move vehicles at least 25 feet (8

meters) every 15 days to lubricate

working parts and prevent corrosion.

Removing Vehicle From Storage

When your vehicle is ready to come out of

storage, do the following:

• Wash your vehicle to remove any dirt

or grease film build-up on window

surfaces.

• Check windshield wipers for any

deterioration.

252

Super Duty (TFA) Vehicle Care

Page 432 of 458

Ford Motor Company has recommended

maintenance intervals for various parts

and component systems based upon

engineering testing. Ford Motor Company

relies upon this testing to determine the

most appropriate mileage for replacement

of oils and fluids to protect your vehicle at

the lowest overall cost to you and

recommends against maintenance

schedules that deviate from the scheduled

maintenance information.

We strongly recommend the use of only

genuine Ford, Motorcraft or

Ford-authorized re-manufactured

replacement parts engineered for your

vehicle.

Additives and Chemicals

This owner's manual and the Ford

Workshop Manual list the recommended

additives and chemicals for your vehicle.

We do not recommend using chemicals or

additives not approved by us as part of

your vehicle

’s normal maintenance. Please

consult your warranty information. Oils, Fluids and Flushing

In many cases, fluid discoloration is a

normal operating characteristic and, by

itself, does not necessarily indicate a

concern or that the fluid needs to be

changed. However, a qualified expert, such

as the factory-trained technicians at your

dealership, should inspect discolored fluids

that also show signs of overheating or

foreign material contamination

immediately.

Make sure to change your vehicle

’s oils and

fluids at the specified intervals or in

conjunction with a repair. Flushing is a

viable way to change fluid for many vehicle

sub-systems during scheduled

maintenance. It is critical that systems are

flushed only with new fluid that is the same

as that required to fill and operate the

system or using a Ford-approved flushing

chemical.

Owner Checks and Services

Make sure you perform the following basic

maintenance checks and inspections every

month or at six-month intervals. Check every month

Engine oil level.

Function of all interior and exterior lights.

Tires (including spare) for wear and proper pressure. Windshield washer fluid level. Check every six months

Battery connections. Clean if necessary.

Body and door drain holes for obstructions. Clean if necessary. Cooling system fluid level and coolant strength.

Door weatherstrips for wear. Lubricate if necessary.

429

Super Duty (TFA) Scheduled Maintenance

Page 438 of 458

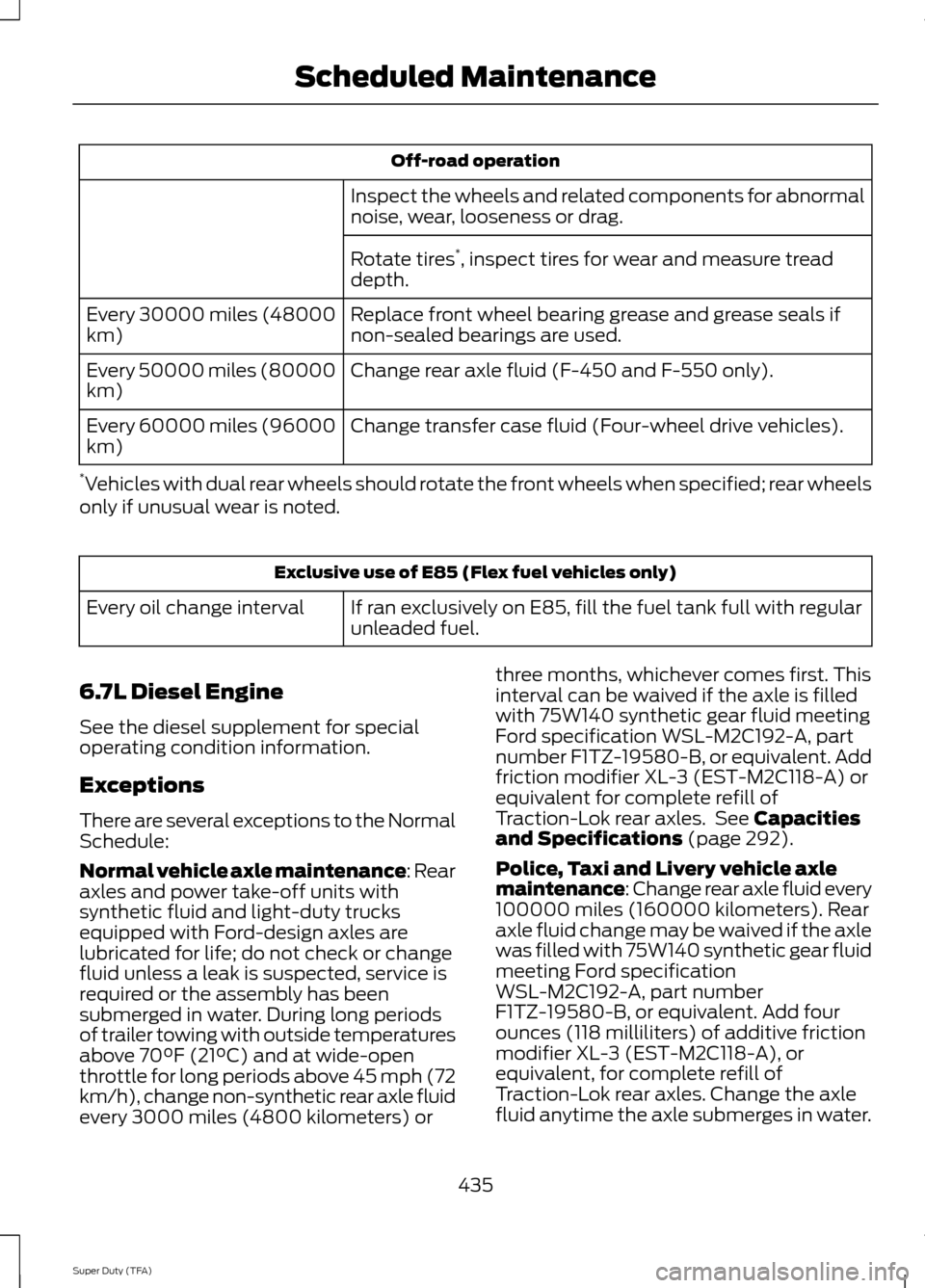

Off-road operation

Inspect the wheels and related components for abnormal

noise, wear, looseness or drag.

Rotate tires *

, inspect tires for wear and measure tread

depth.

Replace front wheel bearing grease and grease seals if

non-sealed bearings are used.

Every 30000 miles (48000

km)

Change rear axle fluid (F-450 and F-550 only).

Every 50000 miles (80000

km)

Change transfer case fluid (Four-wheel drive vehicles).

Every 60000 miles (96000

km)

* Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted. Exclusive use of E85 (Flex fuel vehicles only)

If ran exclusively on E85, fill the fuel tank full with regular

unleaded fuel.

Every oil change interval

6.7L Diesel Engine

See the diesel supplement for special

operating condition information.

Exceptions

There are several exceptions to the Normal

Schedule:

Normal vehicle axle maintenance: Rear

axles and power take-off units with

synthetic fluid and light-duty trucks

equipped with Ford-design axles are

lubricated for life; do not check or change

fluid unless a leak is suspected, service is

required or the assembly has been

submerged in water. During long periods

of trailer towing with outside temperatures

above 70°F (21°C) and at wide-open

throttle for long periods above 45 mph (72

km/h), change non-synthetic rear axle fluid

every 3000 miles (4800 kilometers) or three months, whichever comes first. This

interval can be waived if the axle is filled

with 75W140 synthetic gear fluid meeting

Ford specification WSL-M2C192-A, part

number F1TZ-19580-B, or equivalent. Add

friction modifier XL-3 (EST-M2C118-A) or

equivalent for complete refill of

Traction-Lok rear axles. See Capacities

and Specifications (page 292).

Police, Taxi and Livery vehicle axle

maintenance: Change rear axle fluid every

100000 miles (160000 kilometers). Rear

axle fluid change may be waived if the axle

was filled with 75W140 synthetic gear fluid

meeting Ford specification

WSL-M2C192-A, part number

F1TZ-19580-B, or equivalent. Add four

ounces (118 milliliters) of additive friction

modifier XL-3 (EST-M2C118-A), or

equivalent, for complete refill of

Traction-Lok rear axles. Change the axle

fluid anytime the axle submerges in water.

435

Super Duty (TFA) Scheduled Maintenance

Page 457 of 458

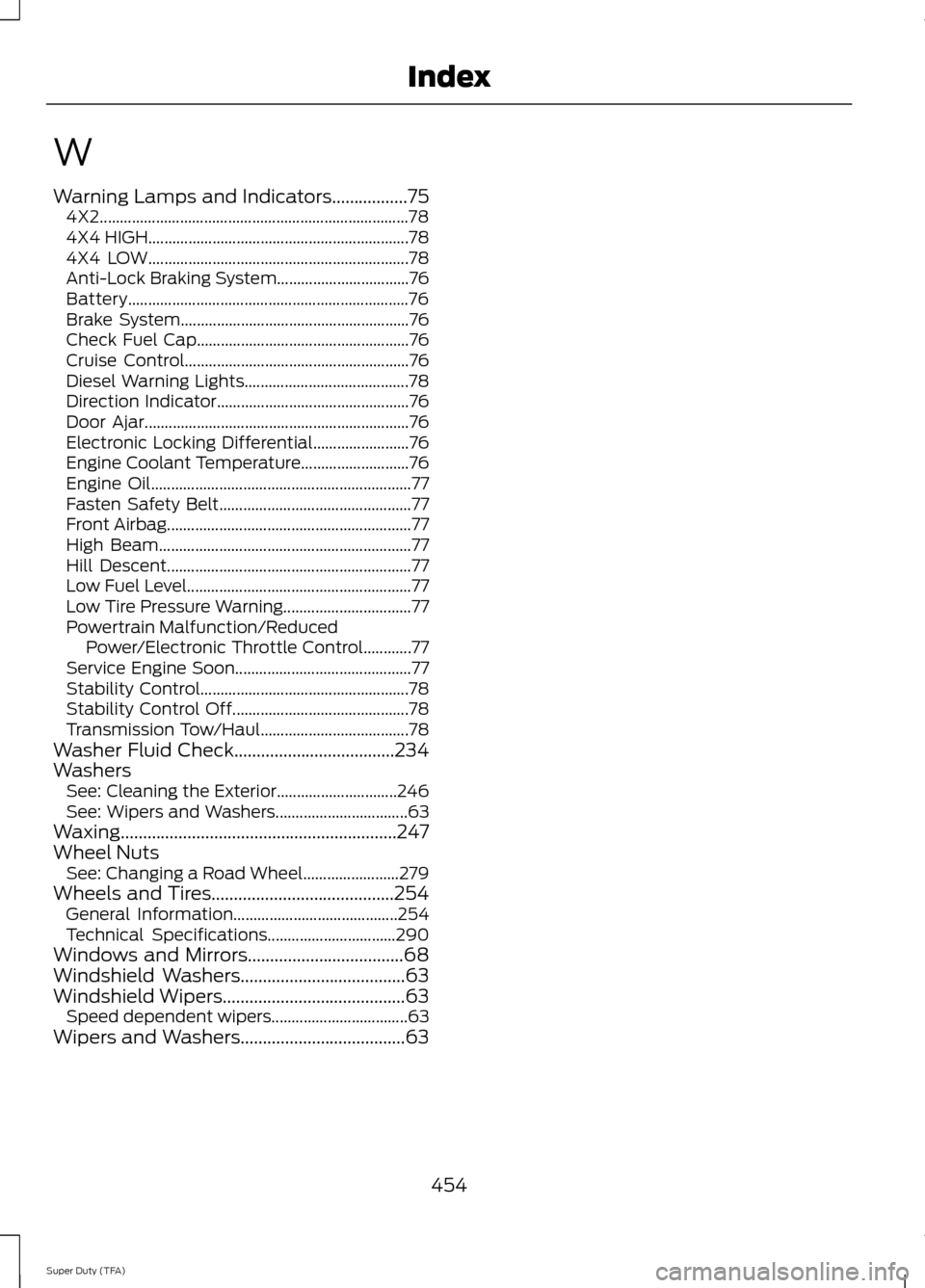

W

Warning Lamps and Indicators.................75

4X2........................................................................\

..... 78

4X4 HIGH................................................................. 78

4X4 LOW................................................................. 78

Anti-Lock Braking System................................. 76

Battery...................................................................... 76

Brake System......................................................... 76

Check Fuel Cap..................................................... 76

Cruise Control........................................................ 76

Diesel Warning Lights......................................... 78

Direction Indicator................................................ 76

Door Ajar.................................................................. 76

Electronic Locking Differential........................ 76

Engine Coolant Temperature........................... 76

Engine Oil................................................................. 77

Fasten Safety Belt................................................ 77

Front Airbag............................................................. 77

High Beam............................................................... 77

Hill Descent............................................................. 77

Low Fuel Level........................................................ 77

Low Tire Pressure Warning................................ 77

Powertrain Malfunction/Reduced Power/Electronic Throttle Control............77

Service Engine Soon............................................ 77

Stability Control.................................................... 78

Stability Control Off............................................ 78

Transmission Tow/Haul..................................... 78

Washer Fluid Check....................................234

Washers See: Cleaning the Exterior.............................. 246

See: Wipers and Washers................................. 63

Waxing..............................................................247

Wheel Nuts See: Changing a Road Wheel........................ 279

Wheels and Tires.........................................254 General Information......................................... 254

Technical Specifications................................ 290

Windows and Mirrors

...................................68

Windshield Washers.....................................63

Windshield Wipers.........................................63 Speed dependent wipers.................................. 63

Wipers and Washers.....................................63

454

Super Duty (TFA) Index