transmission FORD SUPER DUTY 2014 3.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2014, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2014 3.GPages: 458, PDF Size: 5.3 MB

Page 219 of 458

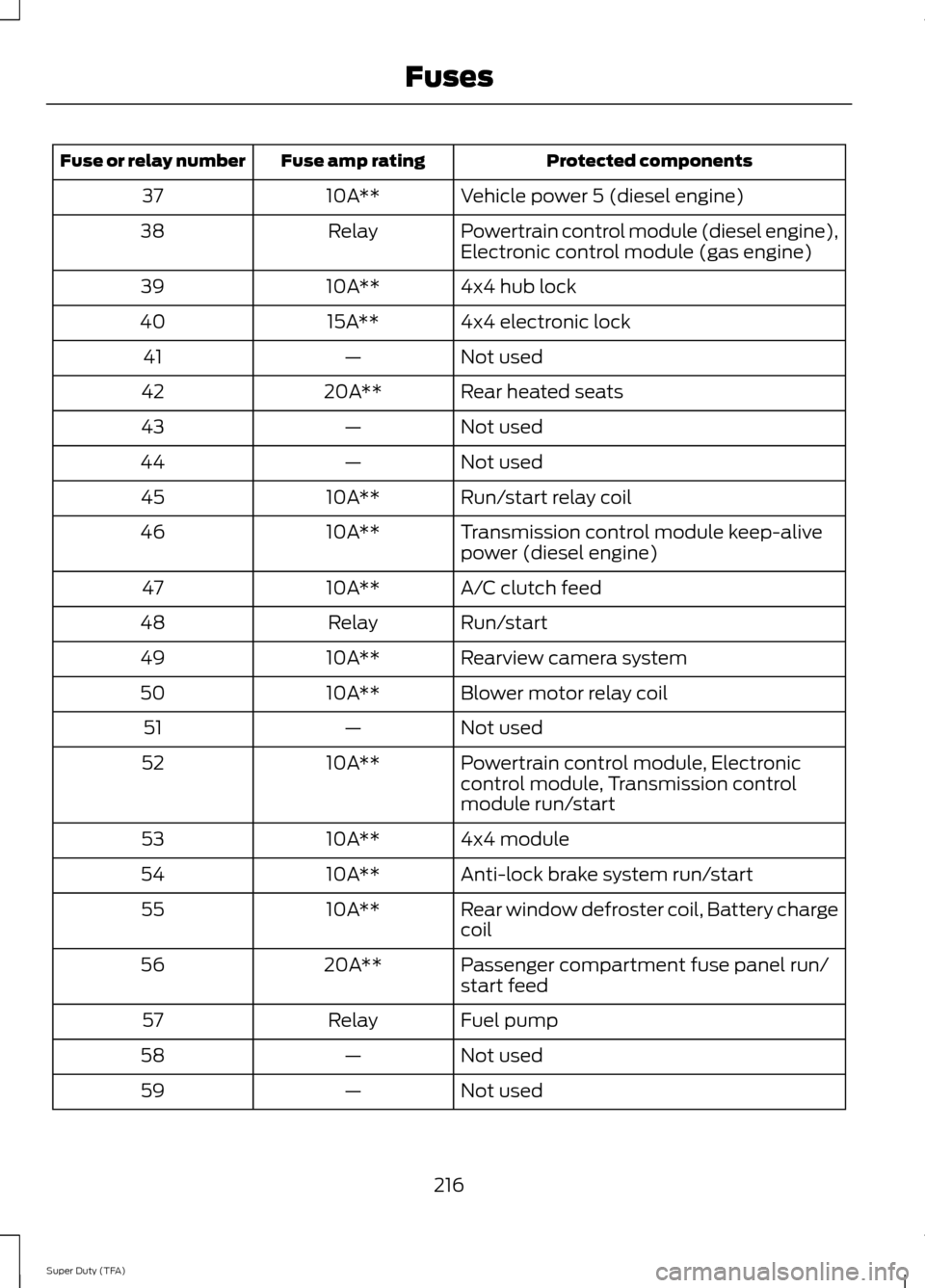

Protected components

Fuse amp rating

Fuse or relay number

Vehicle power 5 (diesel engine)

10A**

37

Powertrain control module (diesel engine),

Electronic control module (gas engine)

Relay

38

4x4 hub lock

10A**

39

4x4 electronic lock

15A**

40

Not used

—

41

Rear heated seats

20A**

42

Not used

—

43

Not used

—

44

Run/start relay coil

10A**

45

Transmission control module keep-alive

power (diesel engine)

10A**

46

A/C clutch feed

10A**

47

Run/start

Relay

48

Rearview camera system

10A**

49

Blower motor relay coil

10A**

50

Not used

—

51

Powertrain control module, Electronic

control module, Transmission control

module run/start

10A**

52

4x4 module

10A**

53

Anti-lock brake system run/start

10A**

54

Rear window defroster coil, Battery charge

coil

10A**

55

Passenger compartment fuse panel run/

start feed

20A**

56

Fuel pump

Relay

57

Not used

—

58

Not used

—

59

216

Super Duty (TFA) Fuses

Page 226 of 458

2. Go to the front of the vehicle and

locate the secondary release lever,

which is located under the front of the

hood, to your right of the center of the

vehicle (driver's side), toward the

headlight.

3. Release the hood latch by pushing the secondary release lever to your left,

toward the center of the vehicle.

4. Raise the hood. 5.

To close the hood, lower the hood and

allow it to drop the last 8 to 11 inches

(20 to 30 centimeters).

Note: Make sure that the hood is closed

properly.

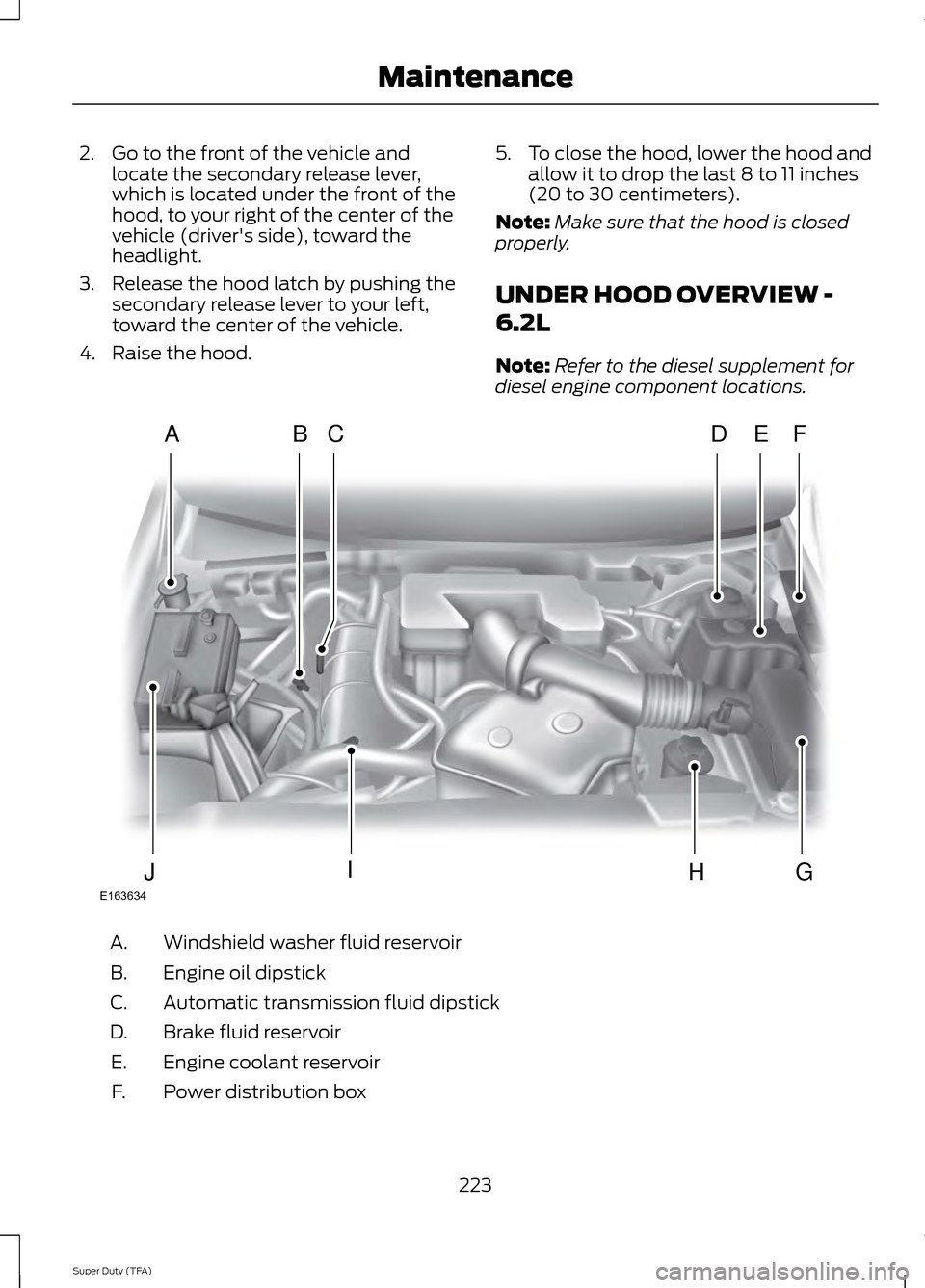

UNDER HOOD OVERVIEW -

6.2L

Note: Refer to the diesel supplement for

diesel engine component locations. Windshield washer fluid reservoir

A.

Engine oil dipstick

B.

Automatic transmission fluid dipstick

C.

Brake fluid reservoir

D.

Engine coolant reservoir

E.

Power distribution box

F.

223

Super Duty (TFA) MaintenanceE163634

ADFEBC

GHIJ

Page 227 of 458

Air filter assembly

G.

Power steering fluid reservoir

H.

Engine oil filler cap

I.

Battery

J.

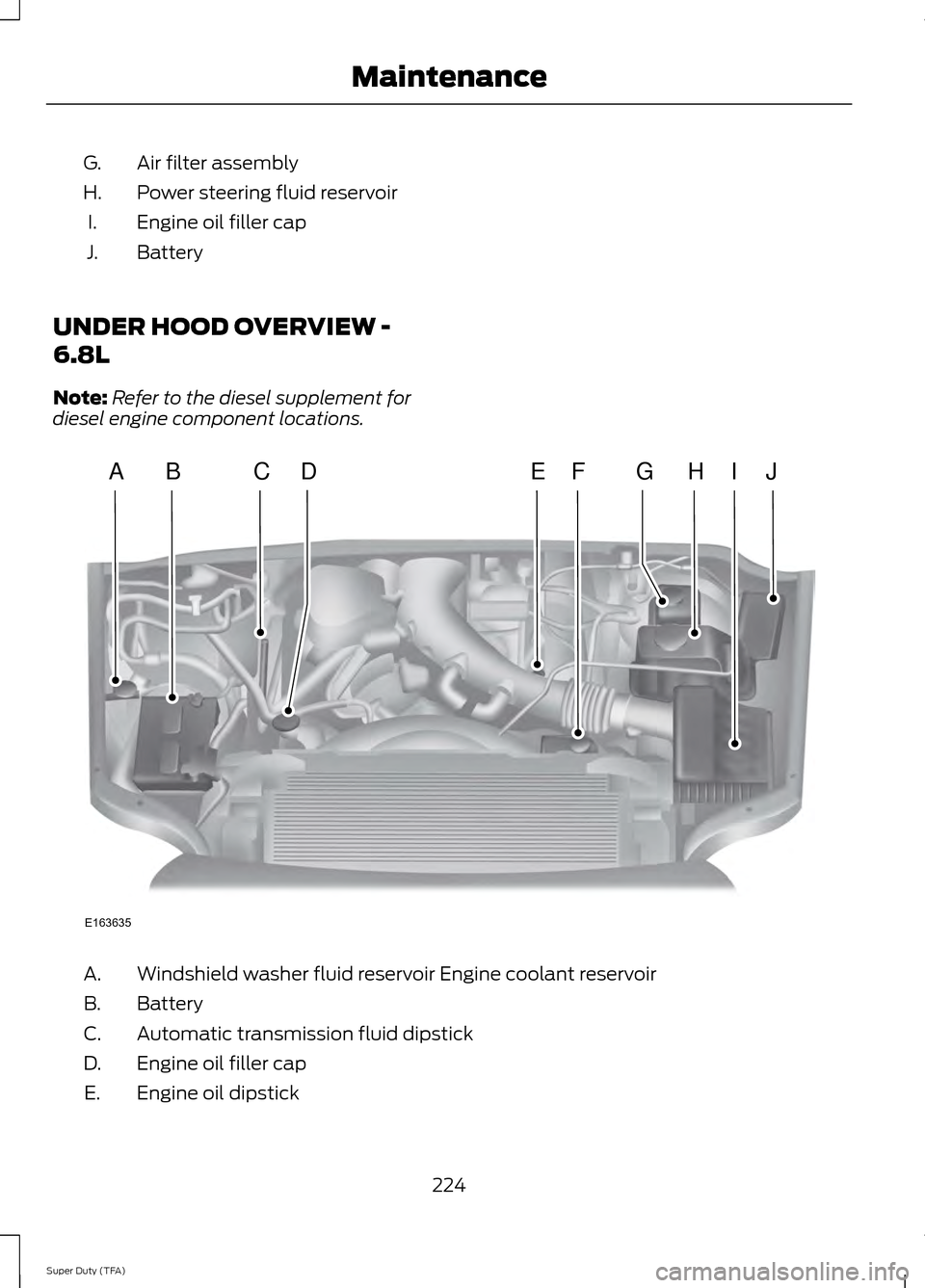

UNDER HOOD OVERVIEW -

6.8L

Note: Refer to the diesel supplement for

diesel engine component locations. Windshield washer fluid reservoir Engine coolant reservoir

A.

Battery

B.

Automatic transmission fluid dipstick

C.

Engine oil filler cap

D.

Engine oil dipstick

E.

224

Super Duty (TFA) MaintenanceE163635

ABCEHIJFDG

Page 233 of 458

•

the engine coolant temperature gauge

moves fully into the red (hot) area

• the coolant temperature warning light

illuminates

• the service engine soon indicator

illuminates. WARNING

Never remove the coolant reservoir

cap while the engine is running or hot.

1. Pull off the road as soon as safely

possible and place the vehicle in P

(Park).

2. Leave the engine running until the coolant temperature gauge needle

moves away from the H range. After

several minutes, if this does not

happen, follow the remaining steps.

3. Turn the engine off and wait for it to cool before checking the coolant level.

4. If the coolant level is normal, you may restart your engine and continue on.

5. If the coolant is low, add coolant, restart the engine and take your vehicle

to an authorized dealer. See Adding

engine coolant in this chapter for more

information. Refer to fail-safe cooling

for additional information.

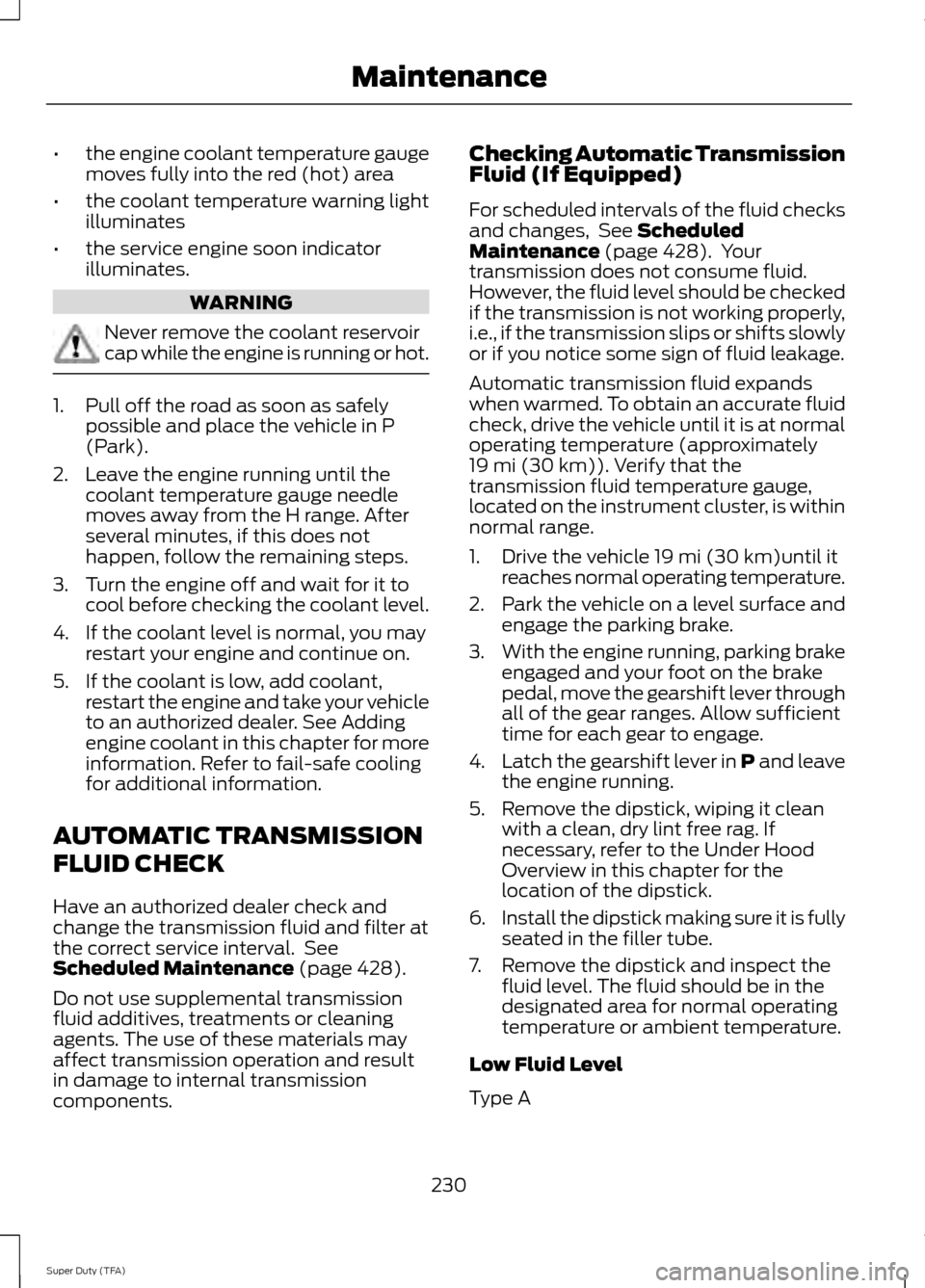

AUTOMATIC TRANSMISSION

FLUID CHECK

Have an authorized dealer check and

change the transmission fluid and filter at

the correct service interval. See

Scheduled Maintenance (page 428).

Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components. Checking Automatic Transmission

Fluid (If Equipped)

For scheduled intervals of the fluid checks

and changes, See

Scheduled

Maintenance (page 428). Your

transmission does not consume fluid.

However, the fluid level should be checked

if the transmission is not working properly,

i.e., if the transmission slips or shifts slowly

or if you notice some sign of fluid leakage.

Automatic transmission fluid expands

when warmed. To obtain an accurate fluid

check, drive the vehicle until it is at normal

operating temperature (approximately

19 mi (30 km)

). Verify that the

transmission fluid temperature gauge,

located on the instrument cluster, is within

normal range.

1. Drive the vehicle

19 mi (30 km)until it

reaches normal operating temperature.

2. Park the vehicle on a level surface and

engage the parking brake.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Latch the gearshift lever in P and leave

the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag. If

necessary, refer to the Under Hood

Overview in this chapter for the

location of the dipstick.

6. Install the dipstick making sure it is fully

seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be in the

designated area for normal operating

temperature or ambient temperature.

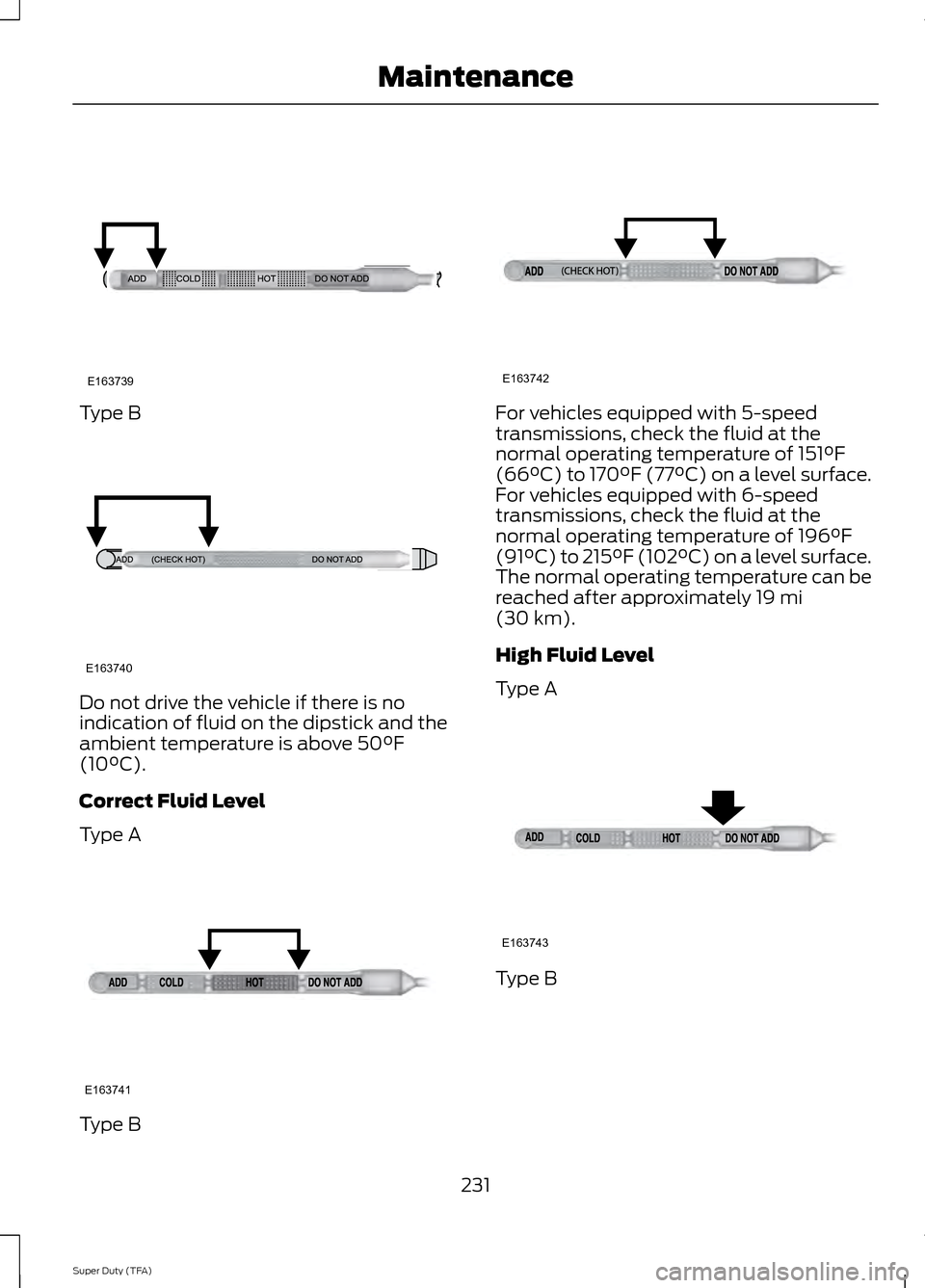

Low Fluid Level

Type A

230

Super Duty (TFA) Maintenance

Page 234 of 458

Type B

Do not drive the vehicle if there is no

indication of fluid on the dipstick and the

ambient temperature is above 50°F

(10°C).

Correct Fluid Level

Type A Type B For vehicles equipped with 5-speed

transmissions, check the fluid at the

normal operating temperature of

151°F

(66°C) to 170°F (77°C) on a level surface.

For vehicles equipped with 6-speed

transmissions, check the fluid at the

normal operating temperature of

196°F

(91°C) to 215°F (102°C) on a level surface.

The normal operating temperature can be

reached after approximately

19 mi

(30 km).

High Fluid Level

Type A Type B

231

Super Duty (TFA) MaintenanceE163739 E163740 E163741 E163742 E163743

Page 235 of 458

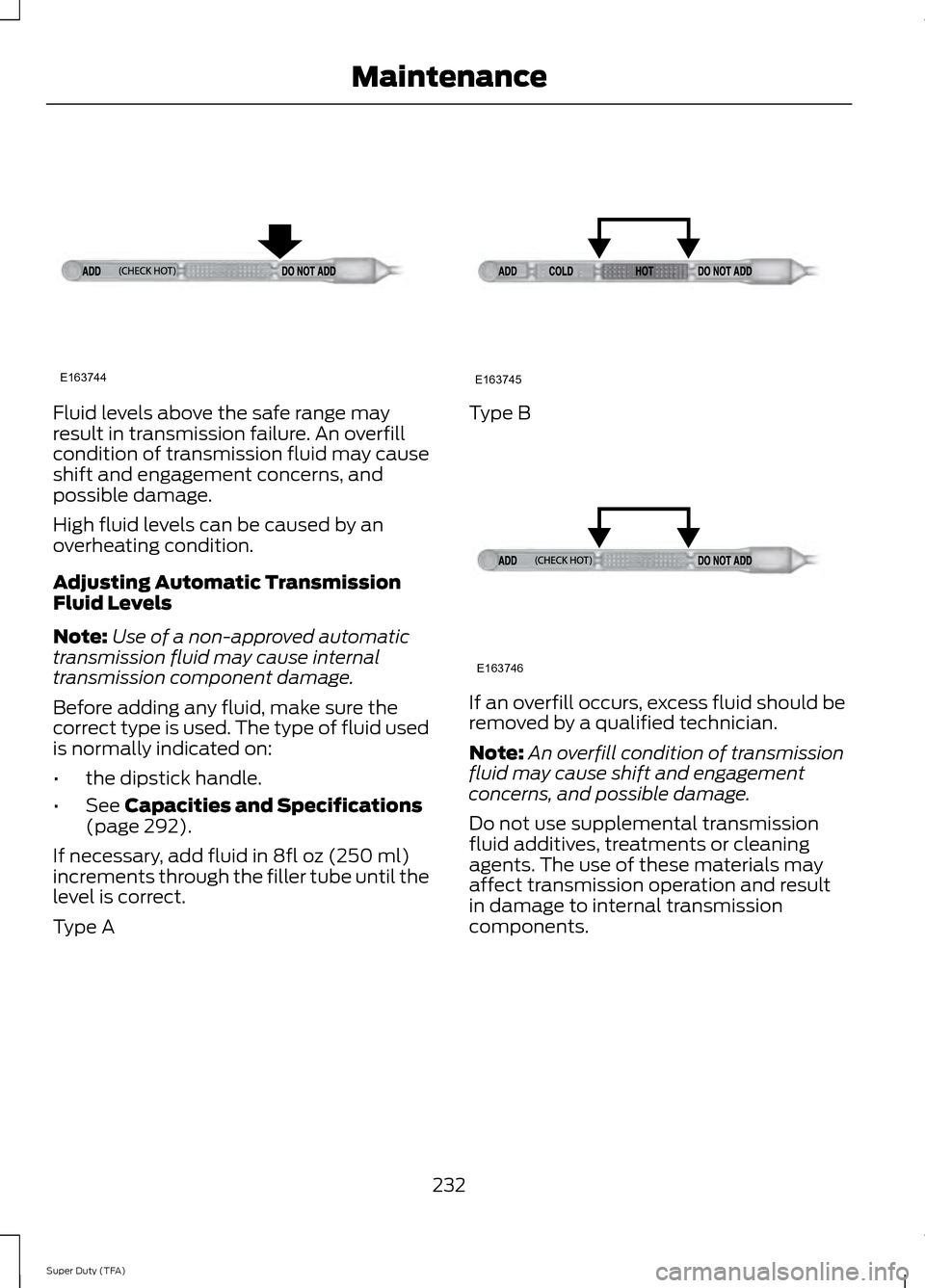

Fluid levels above the safe range may

result in transmission failure. An overfill

condition of transmission fluid may cause

shift and engagement concerns, and

possible damage.

High fluid levels can be caused by an

overheating condition.

Adjusting Automatic Transmission

Fluid Levels

Note:

Use of a non-approved automatic

transmission fluid may cause internal

transmission component damage.

Before adding any fluid, make sure the

correct type is used. The type of fluid used

is normally indicated on:

• the dipstick handle.

• See Capacities and Specifications

(page 292).

If necessary, add fluid in

8fl oz (250 ml)

increments through the filler tube until the

level is correct.

Type A Type B

If an overfill occurs, excess fluid should be

removed by a qualified technician.

Note:

An overfill condition of transmission

fluid may cause shift and engagement

concerns, and possible damage.

Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials may

affect transmission operation and result

in damage to internal transmission

components.

232

Super Duty (TFA) MaintenanceE163744 E163745 E163746

Page 285 of 458

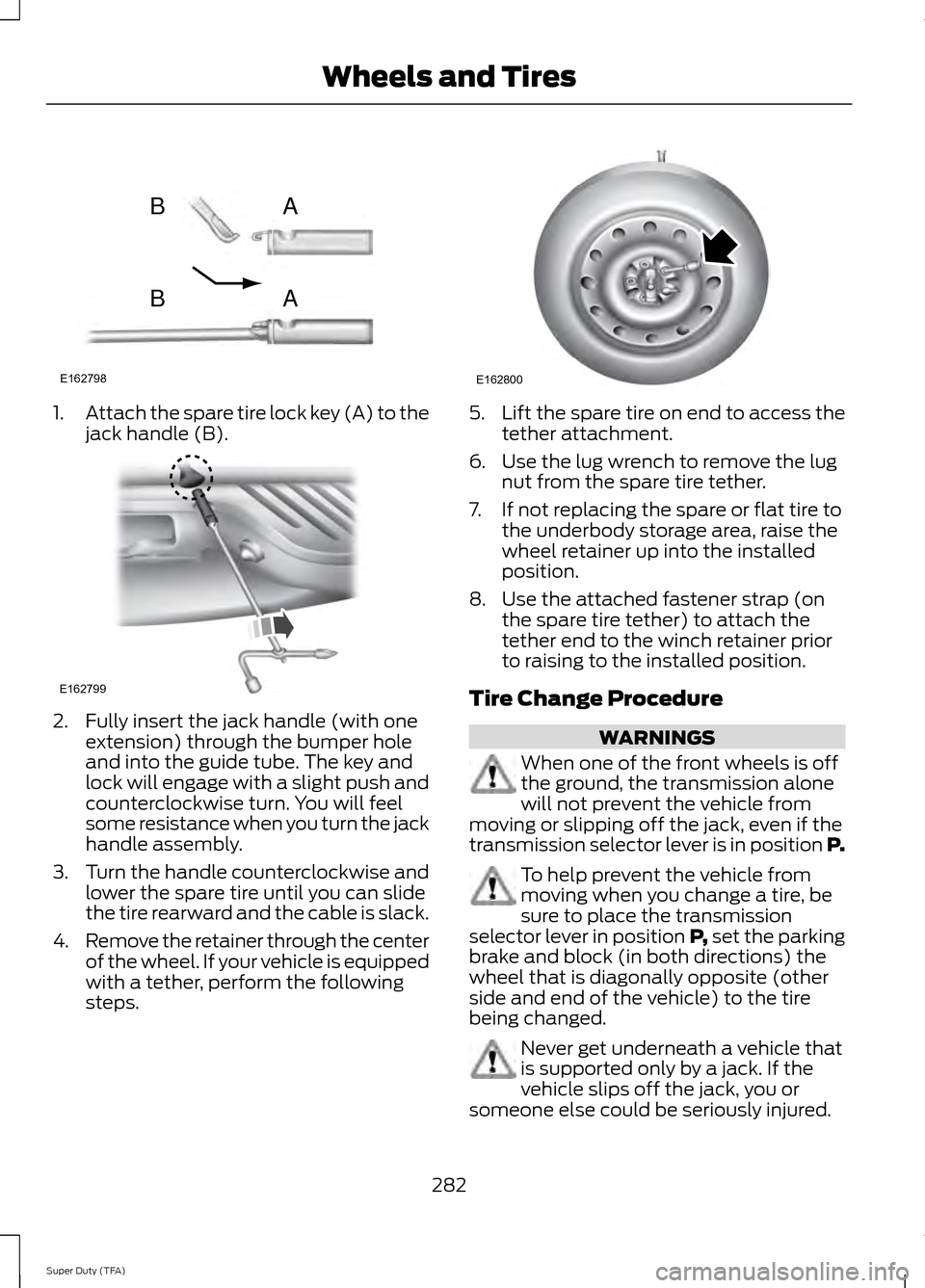

1.

Attach the spare tire lock key (A) to the

jack handle (B). 2. Fully insert the jack handle (with one

extension) through the bumper hole

and into the guide tube. The key and

lock will engage with a slight push and

counterclockwise turn. You will feel

some resistance when you turn the jack

handle assembly.

3. Turn the handle counterclockwise and

lower the spare tire until you can slide

the tire rearward and the cable is slack.

4. Remove the retainer through the center

of the wheel. If your vehicle is equipped

with a tether, perform the following

steps. 5.

Lift the spare tire on end to access the

tether attachment.

6. Use the lug wrench to remove the lug nut from the spare tire tether.

7. If not replacing the spare or flat tire to the underbody storage area, raise the

wheel retainer up into the installed

position.

8. Use the attached fastener strap (on the spare tire tether) to attach the

tether end to the winch retainer prior

to raising to the installed position.

Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent the vehicle from

moving or slipping off the jack, even if the

transmission selector lever is in position P. To help prevent the vehicle from

moving when you change a tire, be

sure to place the transmission

selector lever in position P, set the parking

brake and block (in both directions) the

wheel that is diagonally opposite (other

side and end of the vehicle) to the tire

being changed. Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured.

282

Super Duty (TFA) Wheels and TiresE162798

AB

AB E162799 E162800

Page 298 of 458

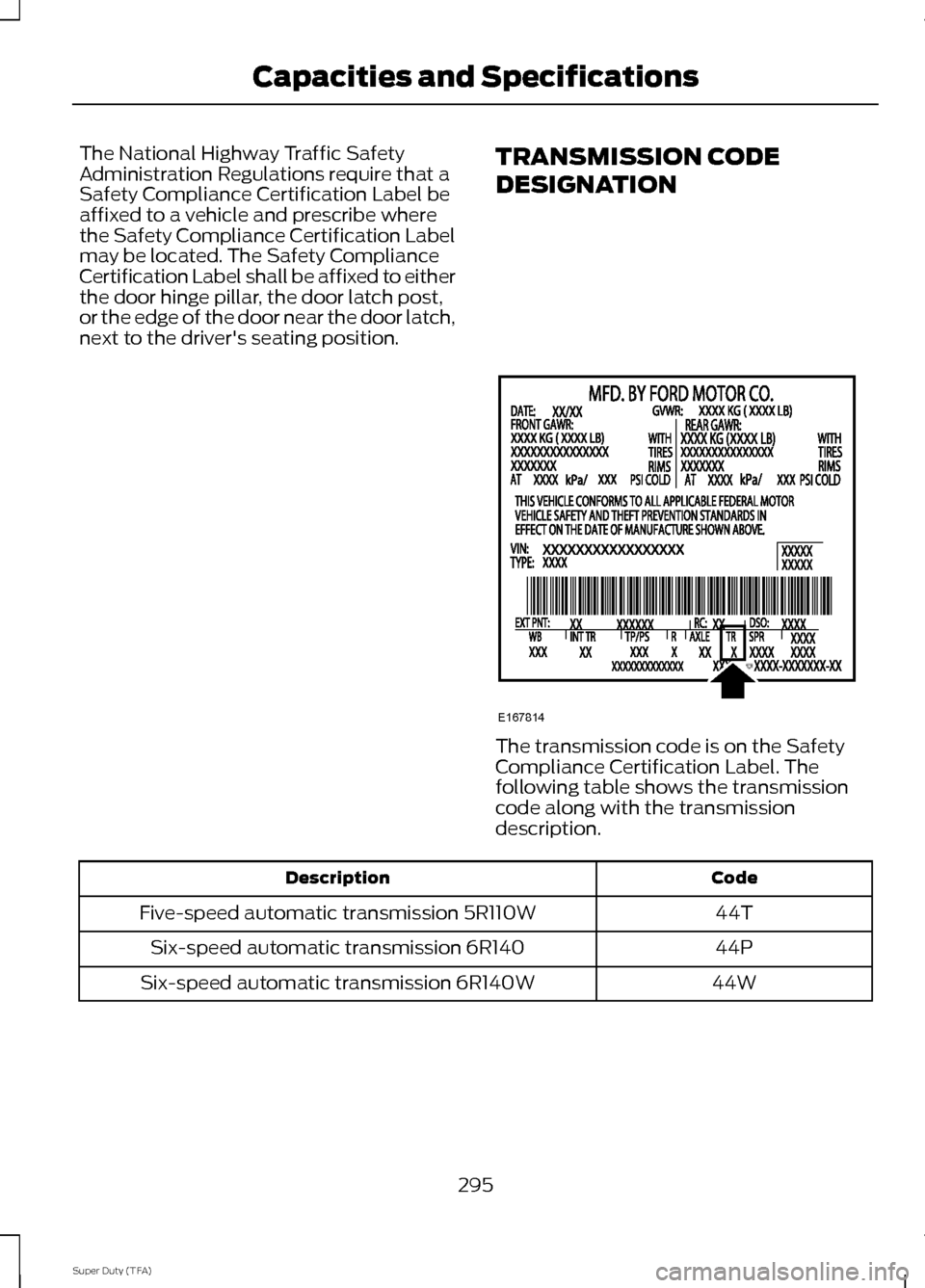

The National Highway Traffic Safety

Administration Regulations require that a

Safety Compliance Certification Label be

affixed to a vehicle and prescribe where

the Safety Compliance Certification Label

may be located. The Safety Compliance

Certification Label shall be affixed to either

the door hinge pillar, the door latch post,

or the edge of the door near the door latch,

next to the driver's seating position.

TRANSMISSION CODE

DESIGNATION The transmission code is on the Safety

Compliance Certification Label. The

following table shows the transmission

code along with the transmission

description.

Code

Description

44T

Five-speed automatic transmission 5R110W

44P

Six-speed automatic transmission 6R140

44W

Six-speed automatic transmission 6R140W

295

Super Duty (TFA) Capacities and SpecificationsE167814

Page 300 of 458

Ford part number /

Ford specification

Ford part name or

equivalent

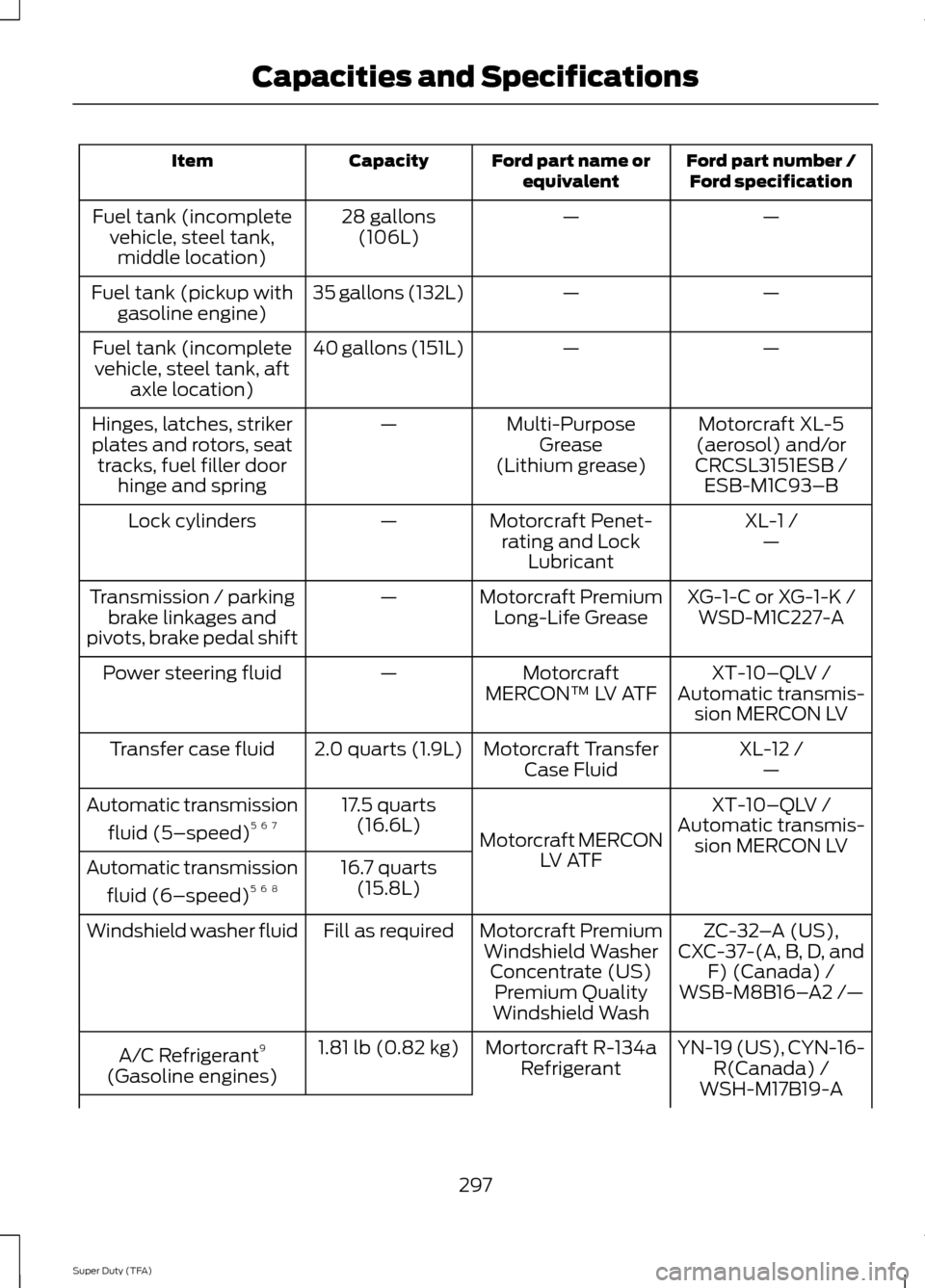

Capacity

Item

—

—

28 gallons

(106L)

Fuel tank (incomplete

vehicle, steel tank,middle location)

—

—

35 gallons (132L)

Fuel tank (pickup with

gasoline engine)

—

—

40 gallons (151L)

Fuel tank (incomplete

vehicle, steel tank, aft axle location)

Motorcraft XL-5

(aerosol) and/or

CRCSL3151ESB /

Multi-Purpose

Grease

(Lithium grease)

—

Hinges, latches, striker

plates and rotors, seat

tracks, fuel filler door hinge and spring ESB-M1C93–B

XL-1 /

Motorcraft Penet-

rating and Lock Lubricant

—

Lock cylinders

—

XG-1-C or XG-1-K /

Motorcraft Premium

Long-Life Grease

—

Transmission / parking

brake linkages and

pivots, brake pedal shift WSD-M1C227-A

XT-10–QLV /

Motorcraft

MERCON™ LV ATF

—

Power steering fluid

Automatic transmis-sion MERCON LV

XL-12 /

Motorcraft Transfer

Case Fluid

2.0 quarts (1.9L)

Transfer case fluid

—

XT-10–QLV /

Motorcraft MERCON LV ATF

17.5 quarts

(16.6L)

Automatic transmission

fluid (5–speed) 5 6 7

Automatic transmis-

sion MERCON LV

16.7 quarts (15.8L)

Automatic transmission

fluid (6–speed) 5 6 8

ZC-32–A (US),

Motorcraft Premium

Windshield Washer Concentrate (US)Premium Quality

Windshield Wash

Fill as required

Windshield washer fluid

CXC-37-(A, B, D, andF) (Canada) /

WSB-M8B16– A2 /—

YN-19 (US), CYN-16- R(Canada) /

Mortorcraft R-134a

Refrigerant

1.81 lb (0.82 kg)

A/C Refrigerant 9

(Gasoline engines) WSH-M17B19-A

297

Super Duty (TFA) Capacities and Specifications

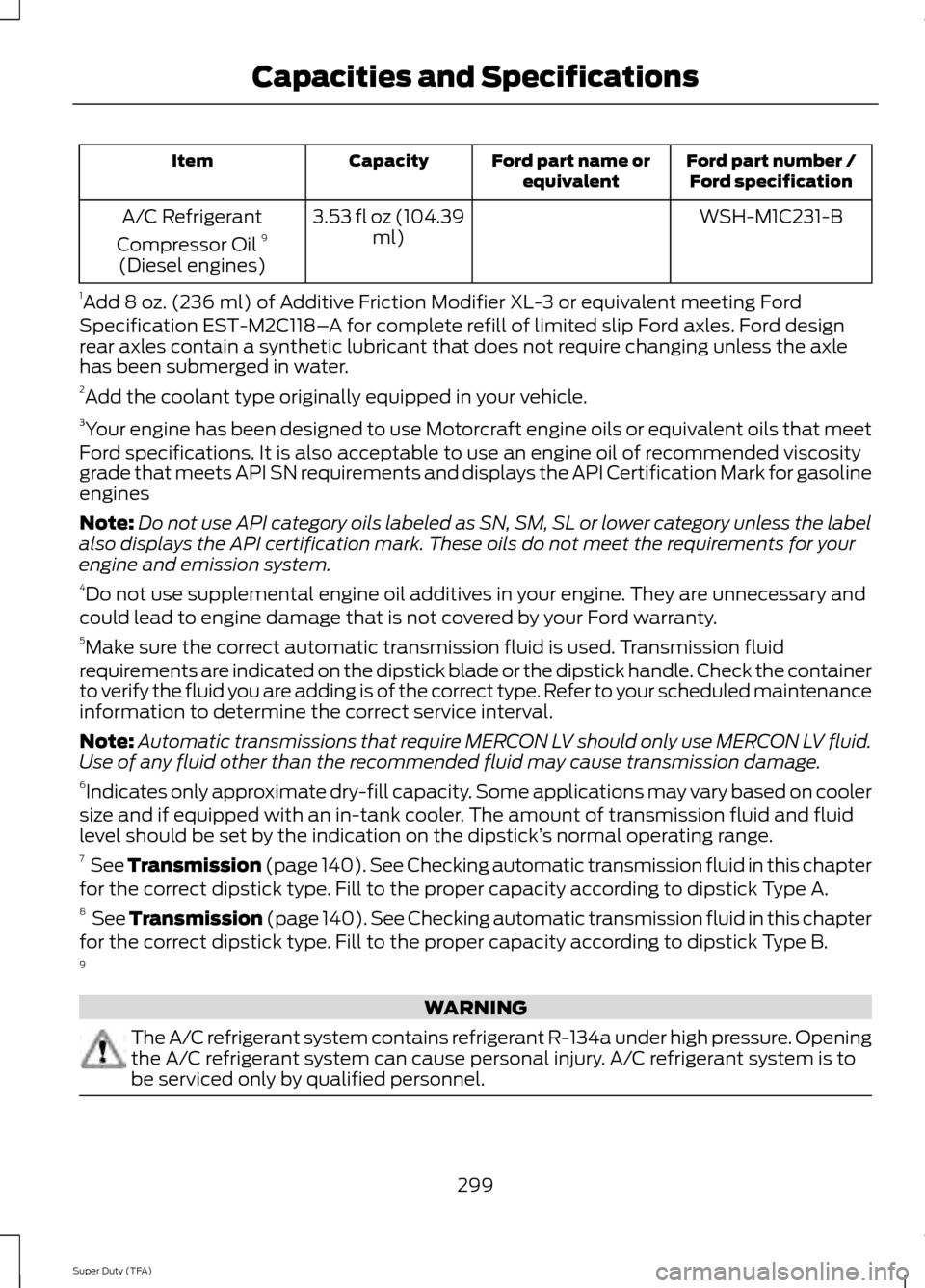

Page 302 of 458

Ford part number /

Ford specification

Ford part name or

equivalent

Capacity

Item

WSH-M1C231-B

3.53 fl oz (104.39

ml)

A/C Refrigerant

Compressor Oil 9

(Diesel engines)

1 Add 8 oz. (236 ml) of Additive Friction Modifier XL-3 or equivalent meeting Ford

Specification EST-M2C118– A for complete refill of limited slip Ford axles. Ford design

rear axles contain a synthetic lubricant that does not require changing unless the axle

has been submerged in water.

2 Add the coolant type originally equipped in your vehicle.

3 Your engine has been designed to use Motorcraft engine oils or equivalent oils that meet

Ford specifications. It is also acceptable to use an engine oil of recommended viscosity

grade that meets API SN requirements and displays the API Certification Mark for gasoline

engines

Note: Do not use API category oils labeled as SN, SM, SL or lower category unless the label

also displays the API certification mark. These oils do not meet the requirements for your

engine and emission system.

4 Do not use supplemental engine oil additives in your engine. They are unnecessary and

could lead to engine damage that is not covered by your Ford warranty.

5 Make sure the correct automatic transmission fluid is used. Transmission fluid

requirements are indicated on the dipstick blade or the dipstick handle. Check the container

to verify the fluid you are adding is of the correct type. Refer to your scheduled maintenance

information to determine the correct service interval.

Note: Automatic transmissions that require MERCON LV should only use MERCON LV fluid.

Use of any fluid other than the recommended fluid may cause transmission damage.

6 Indicates only approximate dry-fill capacity. Some applications may vary based on cooler

size and if equipped with an in-tank cooler. The amount of transmission fluid and fluid

level should be set by the indication on the dipstick’ s normal operating range.

7 See Transmission (page 140). See Checking automatic transmission fluid in this chapter

for the correct dipstick type. Fill to the proper capacity according to dipstick Type A.

8 See Transmission (page 140). See Checking automatic transmission fluid in this chapter

for the correct dipstick type. Fill to the proper capacity according to dipstick Type B.

9 WARNING

The A/C refrigerant system contains refrigerant R-134a under high pressure. Opening

the A/C refrigerant system can cause personal injury. A/C refrigerant system is to

be serviced only by qualified personnel.

299

Super Duty (TFA) Capacities and Specifications