clock FORD SUPER DUTY 2015 3.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2015 3.GPages: 84, PDF Size: 13.36 MB

Page 21 of 84

Note:

If you drain the diesel fuel conditioner

module while the system is running air will

enter into the fuel system. The engine will

not operate properly if air enters the system.

Note: With fuel tank levels above 3⁄4 tank

it may be necessary to loosen the bowl 3

turns before opening the drain. This will

actuate an anti-siphon valve at the fuel and

water separator inlet and prevent the fuel

from siphoning out of the tank.

Note: A loose drain valve can allow air to

enter the fuel system and cause drivetrain

issues. The engine will not operate properly.

Be sure that you fully tighten the drain valve.

1. Stop your vehicle and shut off the engine.

2. Locate the diesel fuel conditioner module and place an appropriate

container under the drain port. 3.

Rotate the drain counterclockwise until

the O-ring is visible. Allow the diesel

fuel conditioner module to drain for

approximately 25 seconds or until

clean fuel is observed. Rotate the drain

clockwise to tighten it. If no liquid

drains, there may be a clog in the drain.

Have the conditioner module serviced

by an authorized dealer.

4. Make sure that you fully tighten the drain valve and then remove the

container from under your vehicle. 5. Restart the engine. If the WATER IN

FUEL DRAIN FILTER or WATER IN FUEL

DRAIN FILTER SEE MANUAL message

and light continues to illuminate, have

the fuel system checked and repaired.

Low Fuel Pressure

The engine is equipped with a low fuel

pressure detection system. Here are some

possible causes if a low fuel pressure

message appears in the information

display:

• Cold start or during cold operation

(below 32°F (0°C): If the low fuel

pressure message appears during a

cold start or up to 10 minutes after the

initial cold start, monitor the

information display. If the low fuel

pressure message disappears and does

not re-appear after the engine has fully

warmed up, waxed or gelled fuel is

what most likely caused the message.

Do not use alcohol based additives to

correct fuel gelling. This may result in

damage to the fuel injectors and

systems. Use an anti-gel additive. See

Technical Specifications (page 57).

Note: Your customer warranty may be void

from using additives that do not meet or

exceed Ford specifications. If the low fuel

pressure message persistently appears after

re-fueling during the cold start and cold

operation conditions defined previously and

then disappear when the engine has fully

warmed up, consider different fuel sources.

18

Super Duty (TFA) , enUSA Fuel and RefuelingE163360

Page 22 of 84

•

Low fuel operation: If the low fuel

pressure message appears when your

vehicle is warm and during low fuel

tank level operation (near empty),

refuel your vehicle. If the message

reappears after fueling, see below. If

the message does not come back, the

low fuel pressure condition was due to

low fuel levels in the fuel tank.

• Normal operation: If the low fuel

pressure message appears during

normal operation when the engine is

fully warm, and fuel level is not low,

you must change the fuel filters

regardless of the maintenance

schedule interval.

• If replacement of the fuel filter does

not remedy the low fuel pressure

message during normal operation as

defined above, take the vehicle to an

authorized dealer.

Changing the Engine-Mounted and

Diesel Fuel Conditioner Module Fuel

Filters

Your vehicle is equipped with two fuel

filters. The first filter mounts on top of the

engine on the driver ’s side. The second

filter, inside the diesel fuel conditioner

module, is mounted on the frame rail under

the driver ’s side floorboard near the

transmission. You should replace both

filters at the same time. Regular fuel filter

changes are an important part of engine

maintenance; failing to keep with the

scheduled maintenance could lead to

engine performance issues and fuel

injection system damage. Refer to the

scheduled maintenance information of this

supplement for more information. See

General Maintenance Information

(page 59). Refer to Motorcraft part numbers in the

Capacities and Specifications chapter for

the fuel filter replacement part number.

See Motorcraft Parts (page 55). This part

number includes filters and seals for both

the engine-mounted and frame-mounted

filters.

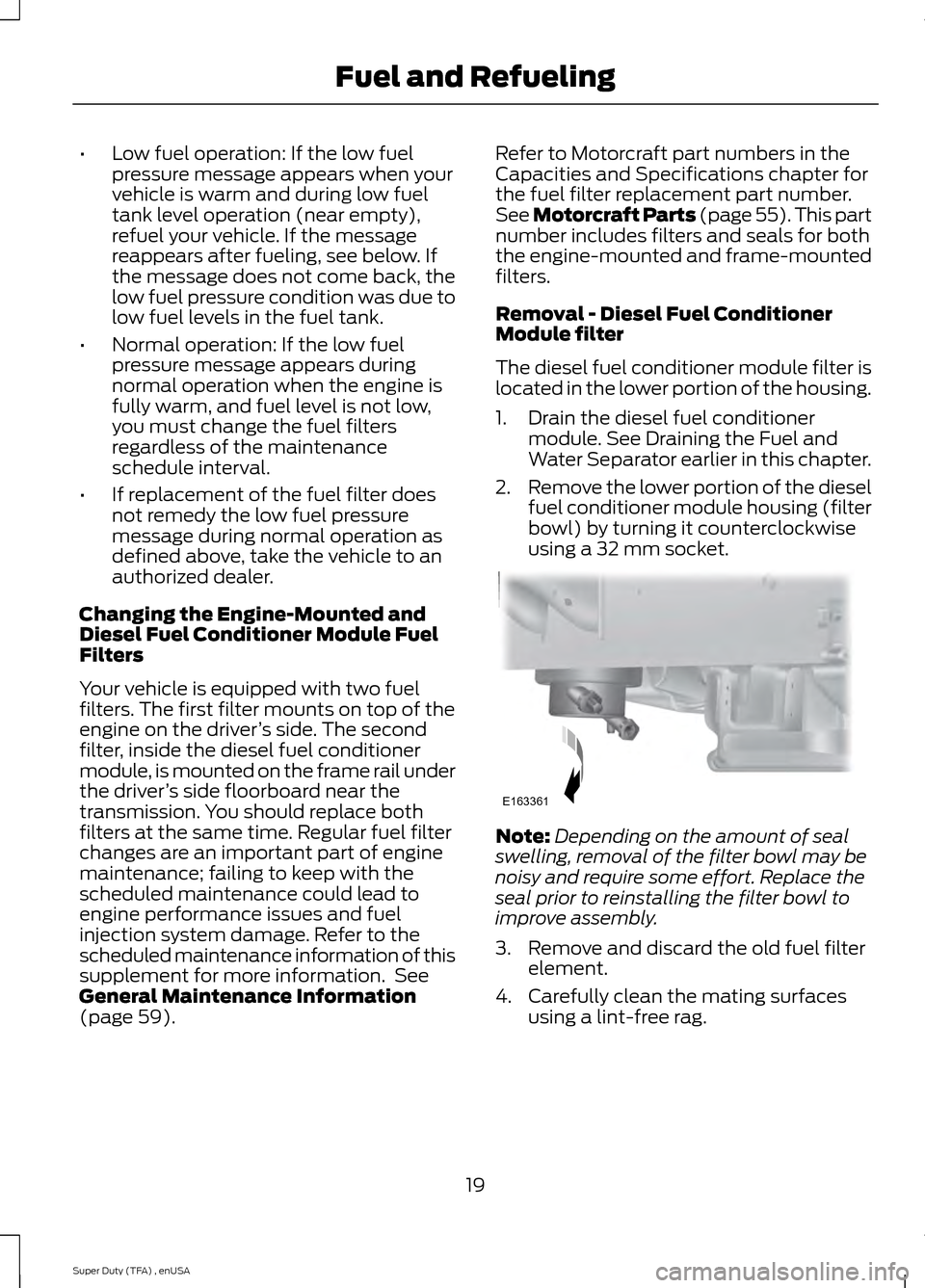

Removal - Diesel Fuel Conditioner

Module filter

The diesel fuel conditioner module filter is

located in the lower portion of the housing.

1. Drain the diesel fuel conditioner

module. See Draining the Fuel and

Water Separator earlier in this chapter.

2. Remove the lower portion of the diesel

fuel conditioner module housing (filter

bowl) by turning it counterclockwise

using a 32 mm socket. Note:

Depending on the amount of seal

swelling, removal of the filter bowl may be

noisy and require some effort. Replace the

seal prior to reinstalling the filter bowl to

improve assembly.

3. Remove and discard the old fuel filter element.

4. Carefully clean the mating surfaces using a lint-free rag.

19

Super Duty (TFA) , enUSA Fuel and RefuelingE163361

Page 23 of 84

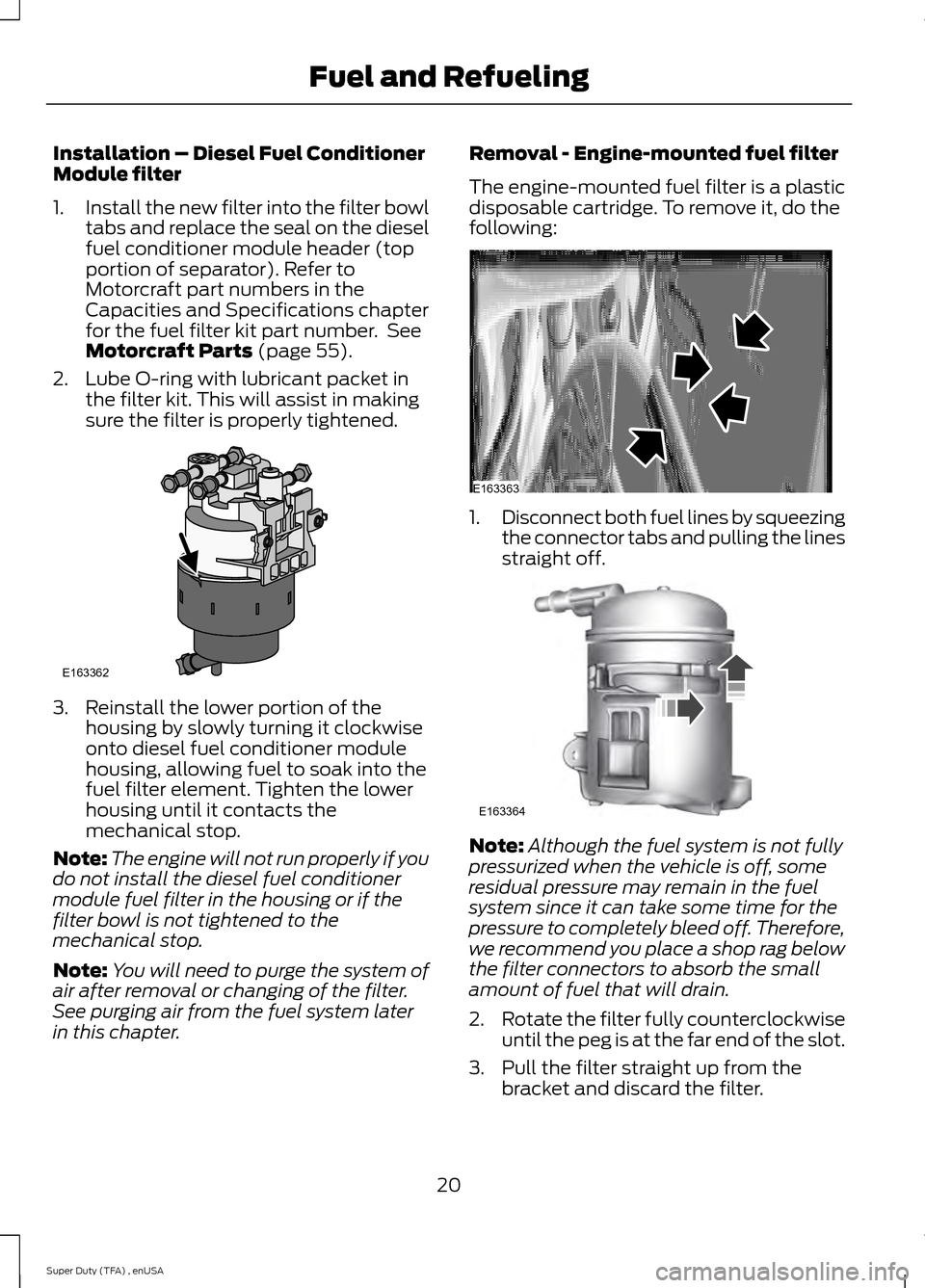

Installation – Diesel Fuel Conditioner

Module filter

1.

Install the new filter into the filter bowl

tabs and replace the seal on the diesel

fuel conditioner module header (top

portion of separator). Refer to

Motorcraft part numbers in the

Capacities and Specifications chapter

for the fuel filter kit part number. See

Motorcraft Parts (page 55).

2. Lube O-ring with lubricant packet in the filter kit. This will assist in making

sure the filter is properly tightened. 3. Reinstall the lower portion of the

housing by slowly turning it clockwise

onto diesel fuel conditioner module

housing, allowing fuel to soak into the

fuel filter element. Tighten the lower

housing until it contacts the

mechanical stop.

Note: The engine will not run properly if you

do not install the diesel fuel conditioner

module fuel filter in the housing or if the

filter bowl is not tightened to the

mechanical stop.

Note: You will need to purge the system of

air after removal or changing of the filter.

See purging air from the fuel system later

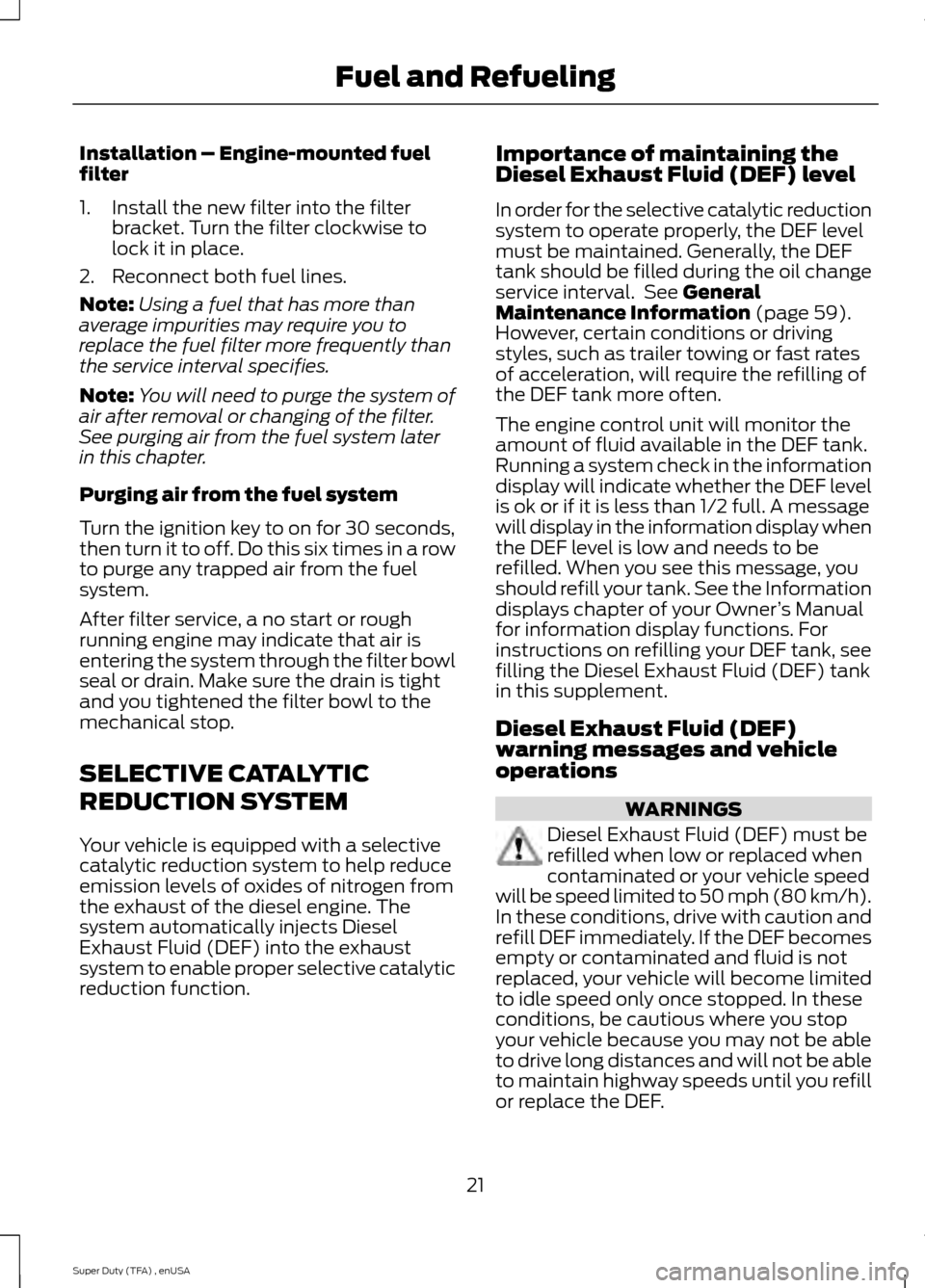

in this chapter. Removal - Engine-mounted fuel filter

The engine-mounted fuel filter is a plastic

disposable cartridge. To remove it, do the

following:

1.

Disconnect both fuel lines by squeezing

the connector tabs and pulling the lines

straight off. Note:

Although the fuel system is not fully

pressurized when the vehicle is off, some

residual pressure may remain in the fuel

system since it can take some time for the

pressure to completely bleed off. Therefore,

we recommend you place a shop rag below

the filter connectors to absorb the small

amount of fuel that will drain.

2. Rotate the filter fully counterclockwise

until the peg is at the far end of the slot.

3. Pull the filter straight up from the bracket and discard the filter.

20

Super Duty (TFA) , enUSA Fuel and RefuelingE163362 E163363 E163364

Page 24 of 84

Installation – Engine-mounted fuel

filter

1. Install the new filter into the filter

bracket. Turn the filter clockwise to

lock it in place.

2. Reconnect both fuel lines.

Note: Using a fuel that has more than

average impurities may require you to

replace the fuel filter more frequently than

the service interval specifies.

Note: You will need to purge the system of

air after removal or changing of the filter.

See purging air from the fuel system later

in this chapter.

Purging air from the fuel system

Turn the ignition key to on for 30 seconds,

then turn it to off. Do this six times in a row

to purge any trapped air from the fuel

system.

After filter service, a no start or rough

running engine may indicate that air is

entering the system through the filter bowl

seal or drain. Make sure the drain is tight

and you tightened the filter bowl to the

mechanical stop.

SELECTIVE CATALYTIC

REDUCTION SYSTEM

Your vehicle is equipped with a selective

catalytic reduction system to help reduce

emission levels of oxides of nitrogen from

the exhaust of the diesel engine. The

system automatically injects Diesel

Exhaust Fluid (DEF) into the exhaust

system to enable proper selective catalytic

reduction function. Importance of maintaining the

Diesel Exhaust Fluid (DEF) level

In order for the selective catalytic reduction

system to operate properly, the DEF level

must be maintained. Generally, the DEF

tank should be filled during the oil change

service interval. See General

Maintenance Information (page 59).

However, certain conditions or driving

styles, such as trailer towing or fast rates

of acceleration, will require the refilling of

the DEF tank more often.

The engine control unit will monitor the

amount of fluid available in the DEF tank.

Running a system check in the information

display will indicate whether the DEF level

is ok or if it is less than 1/2 full. A message

will display in the information display when

the DEF level is low and needs to be

refilled. When you see this message, you

should refill your tank. See the Information

displays chapter of your Owner ’s Manual

for information display functions. For

instructions on refilling your DEF tank, see

filling the Diesel Exhaust Fluid (DEF) tank

in this supplement.

Diesel Exhaust Fluid (DEF)

warning messages and vehicle

operations WARNINGS

Diesel Exhaust Fluid (DEF) must be

refilled when low or replaced when

contaminated or your vehicle speed

will be speed limited to 50 mph (80 km/h).

In these conditions, drive with caution and

refill DEF immediately. If the DEF becomes

empty or contaminated and fluid is not

replaced, your vehicle will become limited

to idle speed only once stopped. In these

conditions, be cautious where you stop

your vehicle because you may not be able

to drive long distances and will not be able

to maintain highway speeds until you refill

or replace the DEF.

21

Super Duty (TFA) , enUSA Fuel and Refueling

Page 28 of 84

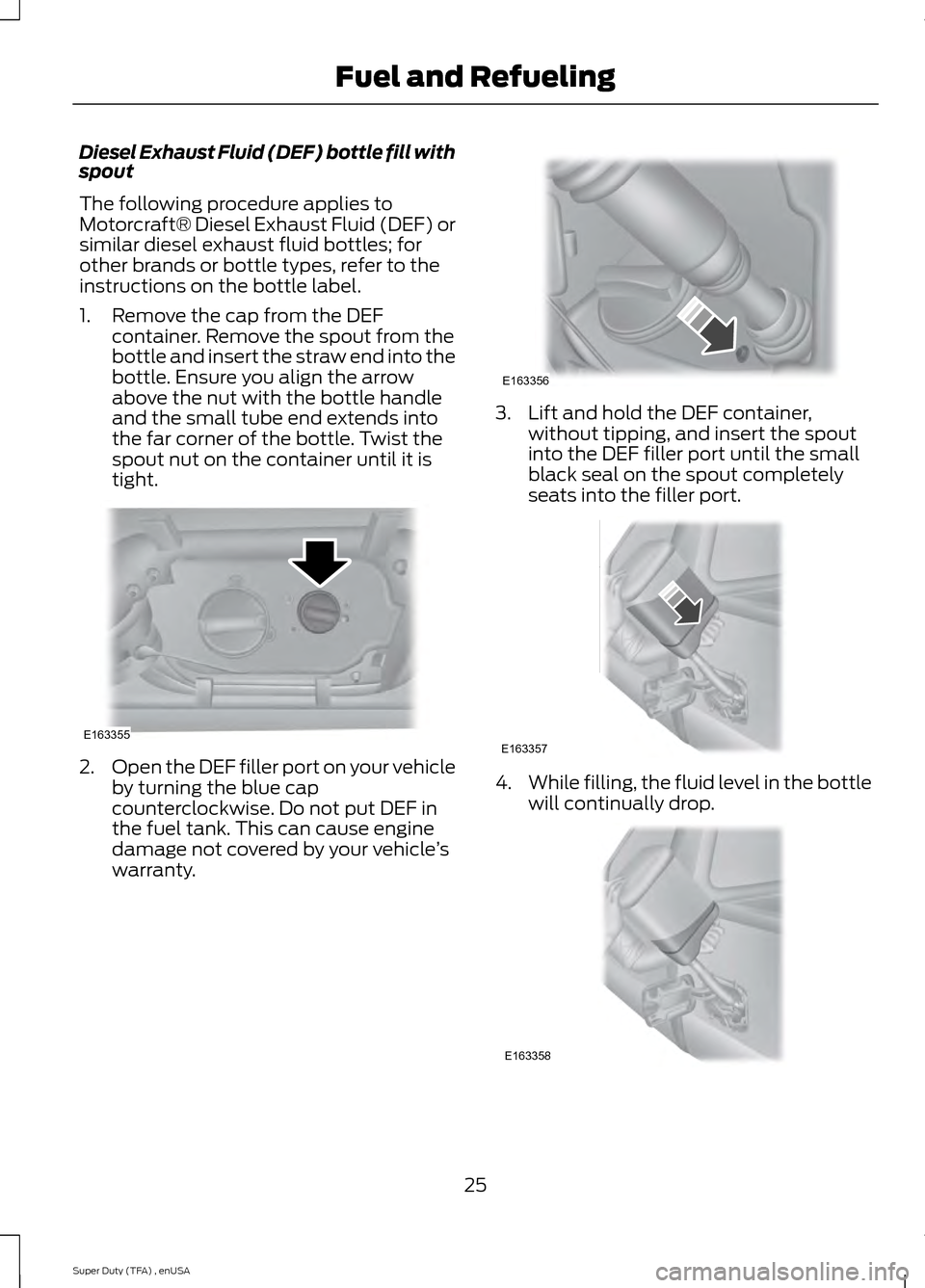

Diesel Exhaust Fluid (DEF) bottle fill with

spout

The following procedure applies to

Motorcraft® Diesel Exhaust Fluid (DEF) or

similar diesel exhaust fluid bottles; for

other brands or bottle types, refer to the

instructions on the bottle label.

1. Remove the cap from the DEF

container. Remove the spout from the

bottle and insert the straw end into the

bottle. Ensure you align the arrow

above the nut with the bottle handle

and the small tube end extends into

the far corner of the bottle. Twist the

spout nut on the container until it is

tight. 2.

Open the DEF filler port on your vehicle

by turning the blue cap

counterclockwise. Do not put DEF in

the fuel tank. This can cause engine

damage not covered by your vehicle ’s

warranty. 3. Lift and hold the DEF container,

without tipping, and insert the spout

into the DEF filler port until the small

black seal on the spout completely

seats into the filler port. 4.

While filling, the fluid level in the bottle

will continually drop. 25

Super Duty (TFA) , enUSA Fuel and RefuelingE163355 E163356 E163357 E163358

Page 33 of 84

Diesel fuel dispensing nozzle fill rate

Your truck is equipped with a fuel fill pipe

that is able to accept fuel up to 20 gallons

per minute from an 11⁄8 fuel-dispensing

nozzle. Pumping fuel at greater flow rates

may result in premature nozzle shut-off or

spit back.

Fuel filler cap

WARNINGS

The fuel system may be under

pressure. If the fuel filler cap is

venting vapor or if you hear a hissing

sound, wait until it stops before completely

removing the fuel filler cap. Otherwise, fuel

may spray out and injure you or others. If you do not use the proper fuel filler

cap, excessive pressure or vacuum

in the fuel tank may damage the fuel

system or cause the fuel cap to disengage

in a collision, which may result in possible

personal injury. Note:

If you must replace the fuel filler cap,

replace it with a fuel filler cap designed for

your vehicle. The vehicle warranty may be

void for any damage to the fuel tank or fuel

system if the correct genuine Ford or

Motorcraft® fuel filler cap is not used.

Your fuel tank filler cap has an indexed

design with a 1/4 turn on/off feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it spins off.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the

cap with the notches on the filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once. EMISSION CONTROL SYSTEM

Diesel Exhaust System: Oxidation

Catalyst And Diesel Particulate

Filter System (If Equipped)

Your vehicle is equipped with a diesel

particulate filter. The diesel particulate

filter is an inline filter in the exhaust system

that reduces carbon emissions by trapping

exhaust particles before they reach the

tailpipe. The diesel particulate filter looks

similar to a traditional exhaust catalyst,

except larger, and is part of the exhaust

system under the vehicle. The filter couples

to a diesel oxidation catalyst that reduces

the amount of harmful exhaust emitted

from the tailpipe. As soot gathers in the

system, it begins to restrict the filter. You

need to periodically clean the soot that

gathers inside the filter. You can clean the

soot in two different ways, passive

regeneration and active regeneration. Both

methods occur automatically and require

no actions from the driver. During either

one of these regeneration methods, you

may notice a change in exhaust tone. At

certain times, the information display will

display various messages related to the

diesel particulate filter. See the Information

Displays chapter in the Owner Guide for

more information.

Passive regeneration

In passive regeneration, the exhaust

system temperature and constituents

automatically clean the filter, or reduce

the soot level, by burning (oxidizing) the

soot. Cleaning occurs naturally because of

normal engine operating conditions (at

varying levels, due to driving patterns).

30

Super Duty (TFA) , enUSA Fuel and Refueling

Page 50 of 84

For vehicles with overflow coolant systems

with a non-pressurized cap on the coolant

recovery system, add coolant to the

coolant recovery reservoir when the engine

is cool. Add prediluted engine coolant

(Motorcraft Orange Antifreeze/Coolant

Prediluted) to the FULL COLD level. For all

other vehicles which have a coolant degas

system with a pressurized cap, or if it is

necessary to remove the coolant pressure

relief cap on the radiator of a vehicle with

an overflow system, follow these steps to

add engine coolant.

1. Turn the engine off and let it cool.

2. When the engine is cool, wrap a thick

cloth around the coolant pressure relief

cap on the coolant reservoir (a

translucent plastic bottle). Slowly turn

cap counterclockwise until pressure

begins to release. When you are sure

that all the pressure has been released,

use the cloth to turn it

counterclockwise and remove the cap.

3. Fill the coolant reservoir slowly with prediluted engine coolant to within the

FULL COLD level, or between the MIN

and MAX marks (within the COLD FILL

RANGE), as listed on the engine

coolant reservoir. If you removed the

radiator cap in an overflow system, fill

the radiator until the coolant is visible

and radiator is almost full. If coolant is

added to bring the level within the

COLD FILL RANGE when the engine is

not cold, the system may remain under

filled.

4. Replace the cap. Turn until tightly installed. Cap must be tightly installed

to prevent coolant loss.

Whenever coolant has been added, the

coolant level in the coolant reservoir

should be checked the next few times you

drive the vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level. If you have to add more than 1.0 quart (1.0

liter) of engine coolant per month, have

your authorized dealer check the engine

cooling system. Your cooling system may

have a leak. Operating an engine with a

low level of coolant can result in engine

overheating and possible engine damage.

Engine and Secondary Cooling

System Refill Procedure

The following procedure should be used

when refilling the engine or secondary

cooling systems after it has been drained

or become extremely low.

1. Before you remove the cap, turn the

engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly turn cap

counterclockwise until pressure begins

to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure

has been released, use the cloth to turn

it counterclockwise and remove the

cap.

5. Slowly add prediluted engine coolant to the coolant reservoir until the

coolant level is within the COLD FILL

RANGE as listed on the reservoir.

6. Reinstall the pressure relief cap.

7. Start and run the engine at 2000 rpm for 2 minutes.

8. Shut engine off, and remove the pressure relief cap as previously

outlined.

9. If required, add prediluted engine coolant to the coolant reservoir until

the coolant level is within the COLD

FILL RANGE as listed on the reservoir.

47

Super Duty (TFA) , enUSA Maintenance