warning FORD SUPER DUTY 2015 3.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2015 3.GPages: 470, PDF Size: 18.24 MB

Page 201 of 470

Trailer Brakes

WARNING

Do not connect a trailer'shydraulic brake systemdirectly to your vehicle's brakesystem. Your vehicle may not haveenough braking power and yourchances of having a collisiongreatly increase.

Electric brakes and manual,automatic or surge-type trailerbrakes are safe if you install themproperly and adjust them to themanufacturer's specifications. Thetrailer brakes must meet local andfederal regulations.

The rating for the tow vehicle'sbraking system operation is atthe gross vehicle weight rating,not the gross combined weightrating.

Separate functioning brakesystems are required for safecontrol of towed vehicles andtrailers weighing more than1500 pounds (680 kilograms)when loaded.

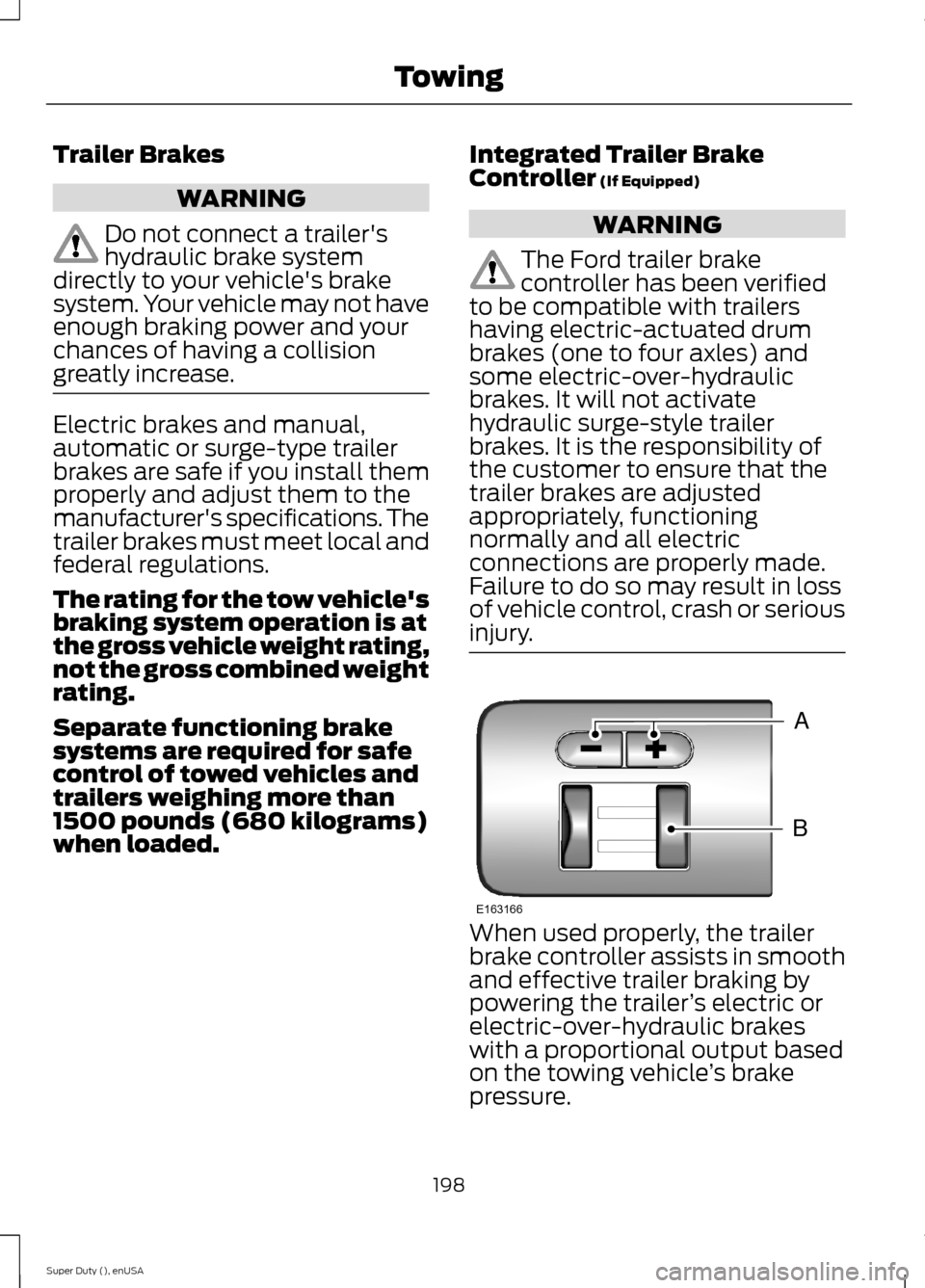

Integrated Trailer BrakeController (If Equipped)

WARNING

The Ford trailer brakecontroller has been verifiedto be compatible with trailershaving electric-actuated drumbrakes (one to four axles) andsome electric-over-hydraulicbrakes. It will not activatehydraulic surge-style trailerbrakes. It is the responsibility ofthe customer to ensure that thetrailer brakes are adjustedappropriately, functioningnormally and all electricconnections are properly made.Failure to do so may result in lossof vehicle control, crash or serious

injury.

When used properly, the trailerbrake controller assists in smoothand effective trailer braking bypowering the trailer’s electric orelectric-over-hydraulic brakeswith a proportional output basedon the towing vehicle’s brakepressure.

198Super Duty (), enUSATowingBAE163166

Page 204 of 470

gain setting is at a point justbelow trailer wheel lock-up. Iftowing a heavier trailer, trailerwheel lock-up may not beattainable even with themaximum gain setting of 10.

Initial Output Setting

The trailer brake controller letsyou customize how aggressivelythe trailer brakes engage. Thedefault value is set to “Light”. Werecommend this setting for themajority of trailers. If you are usingan EOH trailer with a high settingvoltage, or if you prefer to feelmore brake feedback from thetrailer, then select “Medium” or“Heavy”.

Trailer Brake Effort Setting

The trailer brake controller allowsthe user to customize howaggressively the trailer brakesengage. The default value is "Low"and is the recommended settingfor most trailers. If your trailer'sbrakes require more initial voltage,or if you prefer more aggressivetrailer braking, then select eitherthe "Medium" or the "High"setting.

Information Display WarningMessages

Note:An authorized dealer candiagnose the trailer brake controllerto determine exactly which trailerfault has occurred. However, yourFord warranty does not cover thisdiagnosis if the fault is with thetrailer.

TRAILER BRAKE MODULEFAULT

Displays in response to faultssensed by the trailer brakecontroller, accompanied by asingle tone. If this messageappears, contact an authorizeddealer as soon as possible fordiagnosis and repair. Thecontroller may still function, but

with degraded performance.

WIRING FAULT ON TRAILER

Displays when there is a shortcircuit on the electric brake outputwire.

If this message displays,accompanied by a single tone,with no trailer connected, theproblem is with your vehicle wiringbetween the trailer brakecontroller and the 7-pin connectorat the bumper.

201Super Duty (), enUSATowing

Page 206 of 470

•When you switch the engineoff, the controller output isdisabled and the display andmodule shut down. Thecontroller module and displayturn on when you switch theignition on.

•The trailer brake controller isonly a factory-installed ordealer-installed item. Ford isnot responsible for warranty orperformance of the controllerdue to misuse or customerinstallation.

Trailer Lamps

WARNING

Never connect any trailerlamp wiring to the vehicle'stail lamp wiring; this may damagethe electrical system resulting infire. Contact your authorizeddealer as soon as possible forassistance in proper trailer towwiring installation. Additionalelectrical equipment may berequired.

Trailer lamps are required on mosttowed vehicles. Make sure allrunning lights, brake lights, turnsignals and hazard lights areworking.

Using a Step Bumper (IfEquipped)

The rear bumper is equipped withan integral hitch and only requiresa ball with a one-inch (25.4millimeter) shank diameter. Thebumper has a 5000-pound (2268kilogram) trailer weight and a500-pound (227 kilogram) tongueweight capacity

If it is necessary to relocate thehitch ball position, you must installa frame-mounted trailer hitch.

Before Towing a Trailer

Practice turning, stopping andbacking up to get the feel of yourvehicle-trailer combination beforestarting on a trip. When turning,

make wider turns so the trailerwheels clear curbs and otherobstacles.

When Towing a Trailer

•Do not drive faster than 70mph (113 km/h) during the first500 miles (800 kilometers).

•Do not make full-throttlestarts.

•Check your hitch, electricalconnections and trailer wheel

lug nuts thoroughly after youhave traveled 50 miles (80kilometers).

203Super Duty (), enUSATowing

Page 208 of 470

Launching or Retrieving a Boator Personal Watercraft (PWC)

Note:Disconnect the wiring to thetrailer before backing the trailerinto the water.

Note:Reconnect the wiring to thetrailer after you remove the trailerfrom the water.

When backing down a rampduring boat launching or retrieval:

•Do not allow the static waterlevel to rise above the bottomedge of the rear bumper.

•Do not allow waves to breakhigher than 6 inches (15centimeters) above the bottomedge of the rear bumper.

Exceeding these limits may allowwater to enter vehiclecomponents:

•Causing internal damage to thecomponents.

•Affecting driveability,emissions, and reliability.

Replace the rear axle lubricantanytime the rear axle has beensubmerged in water. Water mayhave contaminated the rear axlelubricant, which is not normallychecked or changed unless a leakis suspected or other axle repair isrequired.

TOWING POINTS

WARNINGS

Using recovery hooks is dangerousand should only be done by a personfamiliar with proper vehicle recoverysafety practices. Improper use of recoveryhooks may cause hook failure or separationfrom the vehicle and could result in seriousinjury or death.

Always slowly remove the slack fromthe recovery strap prior to pulling.Failure to do so can introducesignificantly higher loads which can causethe recovery hooks to break off, or therecovery strap to fail which can causeserious injury or death.

Never link two straps together witha clevis pin. These heavy metalobjects could become projectiles ifthe strap breaks and can cause seriousinjury or death.

Your vehicle comes equipped withframe-mounted front recovery hooks.These hooks should never have a loadapplied to them greater than the grossvehicle weight rating of your vehicle.

Before using recovery hooks:

•Make sure all attaching points aresecure and capable of withstandingthe applied load.

•Never use chains, cables or tow strapswith metal hook ends.

•Only use recovery straps that have aminimum breaking strength two tothree times the gross vehicle weight ofthe stuck vehicle.

•Make sure the recovery strap is in goodcondition and free of visible cuts, tearsor damage.

205Super Duty (), enUSATowing

Page 212 of 470

•Transmissions give their best fueleconomy when operated in the topcruise gear and with steady pressureon the gas pedal.

•Four-wheel-drive operation (ifequipped) is less fuel efficient thantwo-wheel-drive operation.

•Close the windows for high-speeddriving.

DRIVING THROUGH WATER

Note:Driving through deep water abovethe recommended levels can cause vehicledamage.

If driving through deep or standing wateris unavoidable, proceed very slowly. Neverdrive through water that is higher than thebottom of the wheel rims (for cars) or thebottom of the hubs (for trucks).

When driving through water, traction orbrake capability may be limited. Also,water may enter your engine’s air intakeand severely damage your engine or yourvehicle may stall.

Once through the water, always dry thebrakes by moving your vehicle slowly whileapplying light pressure on the brake pedal.Wet brakes do not stop the vehicle asquickly as dry brakes.

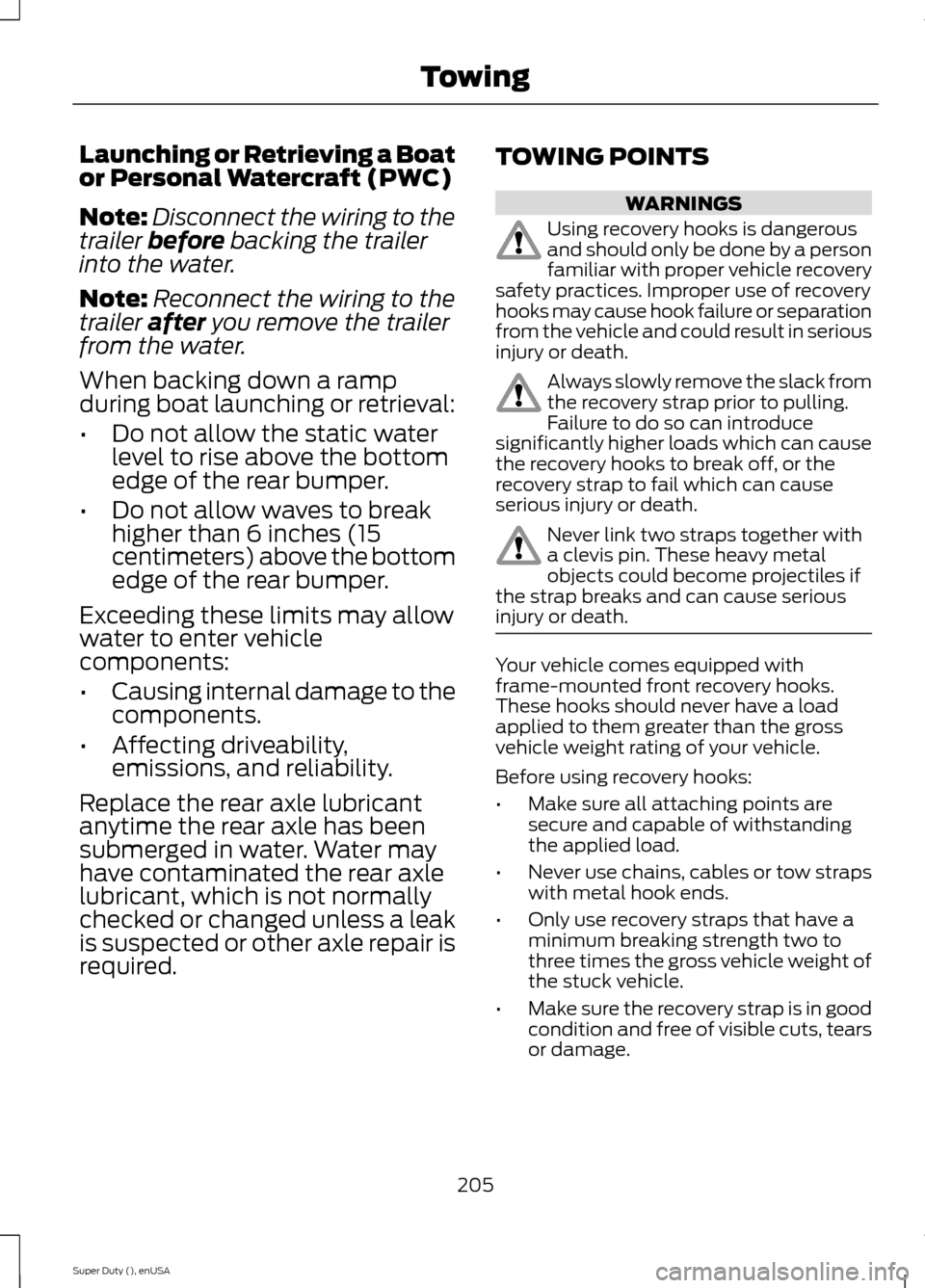

FLOOR MATS

WARNINGS

Always use floor mats that aredesigned to fit the foot well of yourvehicle, leaving the pedal areaunobstructed, and which can be firmlysecured to retention posts so that theycannot slip out of position and interferewith the pedals or impair safe operation ofyour vehicle in other ways.

Incorrectly fitted floor mats cancause the accelerator pedal tobecome stuck in the open position.This can cause loss of vehicle control.

Always correctly install the floormats to the retention posts so thatthey cannot slip out of position orobstruct pedal operation.

Do not place unsecured floor matsor any other covering in the foot well.

Do not place additional floor matsor any other covering on top of theoriginal floor mats. This will reducethe pedal clearance and interfere with thepedal operation.

Do not allow objects to fall orbecome trapped under the pedals ofyour vehicle. This can cause loss ofvehicle control.

Carry out regular inspections to makesure the floor mats are secure.

209Super Duty (), enUSADriving HintsE142667 E142666

Page 214 of 470

Follow the severe duty schedule in yourScheduled Maintenance information forengine oil and transmission fluid changeintervals.

Snowplowing with your AirbagEquipped Vehicle

WARNINGS

Do not attempt to service, repair, ormodify the airbag supplementalrestraint system (SRS) or its fuses.See your Ford or Lincoln Mercury dealer.

Additional equipment such assnowplow equipment may affect theperformance of the airbag sensorsincreasing the risk of injury. Please refer tothe Body Builders Layout Book forinstructions about the appropriateinstallation of additional equipment.

All occupants of the vehicle,including the driver, should alwaysproperly wear their safety belts, evenwhen provided with an airbagsupplemental restraint system (SRS).

Your vehicle is equipped with a driver andpassenger airbag supplemental restraintsystem. The supplemental restraint systemwill activate in certain frontal and offsetfrontal collisions when the vehicle sustainssufficient frontal deceleration.

Careless or high speed driving whileplowing snow that results in sufficientvehicle decelerations can deploy theairbag. Such driving also increases the riskof accidents

Never remove or defeat the trippingmechanisms designed into the snowremoval equipment by its manufacturer.Doing so may cause damage to the vehicleand the snow removal equipment as wellas possible airbag deployment.

Engine temperature while plowing

When driving with a plow, your engine mayrun at a higher temperature than normalbecause the attached snowplow blade willrestrict airflow to the radiator.

•If you are driving more than 14.91 mi(24 km) at temperatures abovefreezing, angle the plow blade eitherfull left or full right to providemaximum airflow to the radiator.

•If you are driving less than 14.91 mi(24 km) at speeds up to 44.7 mph(72 km/h) in cold weather, you will notneed to worry about blade position toprovide maximum airflow.

Transmission operation whileplowing

WARNING

Do not spin the wheels at over34.2 mph (55 km/h). The tires mayfail and injure a passenger orbystander.

•Shift transfer case to 4L (4WD Low)when plowing in small areas at speedsbelow 5 mph (8 km/h).

•Shift transfer case to 4H (4WD High)when plowing larger areas or light snowat higher speeds. Do not exceed 15 mph(24 km/h).

•Do not shift the transmission from aforward gear to R (Reverse) until theengine is at idle and the wheels havestopped.

211Super Duty (), enUSADriving Hints

Page 216 of 470

HAZARD WARNING FLASHERS

Note:The hazard warning flashers willoperate when the ignition is in any positionor if the key is not in the ignition. If usedwhen the engine is not running, the batterywill lose charge. As a result, there may beinsufficient power to restart your engine.

In some models, the hazardflasher control is located on theinstrument panel.

In other models, this feature is located onthe steering column, just behind thesteering wheel.

Use your hazard warning flashers whenyour vehicle is creating a safety hazard forother motorists.

•Press the flasher control and all frontand rear direction indicators flash.

•Press the flasher control again to turnthem off.

FUEL SHUTOFF

WARNING

Failure to inspect and, if necessary,repair fuel leaks after a collision mayincrease the risk of fire and seriousinjury. Ford Motor Company recommendsthat the fuel system be inspected by anauthorized dealer after any collision.

In the event of a moderate to severecollision, this vehicle is equipped with afuel pump shut-off feature that stops theflow of fuel to the engine. Not every impactwill cause a shut-off.

Should your vehicle shut off after acollision, you may restart your vehicle. Forvehicles equipped with a key system:

1.Switch off the ignition.

2.Switch on the ignition.

3.Repeat Steps 1 and 2 to re-enable thefuel pump.

For vehicles equipped with a push buttonstart system:

1.Press the START/STOP button toswitch off the ignition.

2.Press the brake pedal and press theSTART/STOP button to start thevehicle.

3.Remove your foot from the brake pedaland press the START/STOP buttonto switch off the ignition.

4.You can either attempt to start theengine by pressing the brake pedal andthe START/STOP button, or switchon the ignition only by pressing theSTART/STOP button withoutpressing the brake pedal. Both waysre-enable the fuel system.

Note:When you try to restart your vehicleafter a fuel shutoff, the vehicle makes surethat various systems are safe to restart.Once your vehicle determines that thesystems are safe, then the vehicle will allowyou to restart.

Note:In the event that your vehicle doesnot restart after your third attempt, contactan authorized dealer.

213Super Duty (), enUSARoadside EmergenciesE142663 E161463

Page 217 of 470

JUMP STARTING THE VEHICLE

WARNINGS

The gases around the battery canexplode if exposed to flames, sparks,or lit cigarettes. An explosion couldresult in personal injury or vehicle damage.

Batteries contain sulfuric acid whichcan burn skin, eyes and clothing, ifcontacted.

Use only an adequate-sized cablewith insulated clamps.

Preparing Your Vehicle

Note:Do not attempt to push-start yourautomatic transmission vehicle. Automatictransmissions do not have push-startcapability. Attempting to push-start avehicle with an automatic transmission maycause transmission damage.

Note:Use only a 12-volt supply to start yourvehicle.

Note:Do not disconnect the battery of thedisabled vehicle as this could damage thevehicle's electrical system.

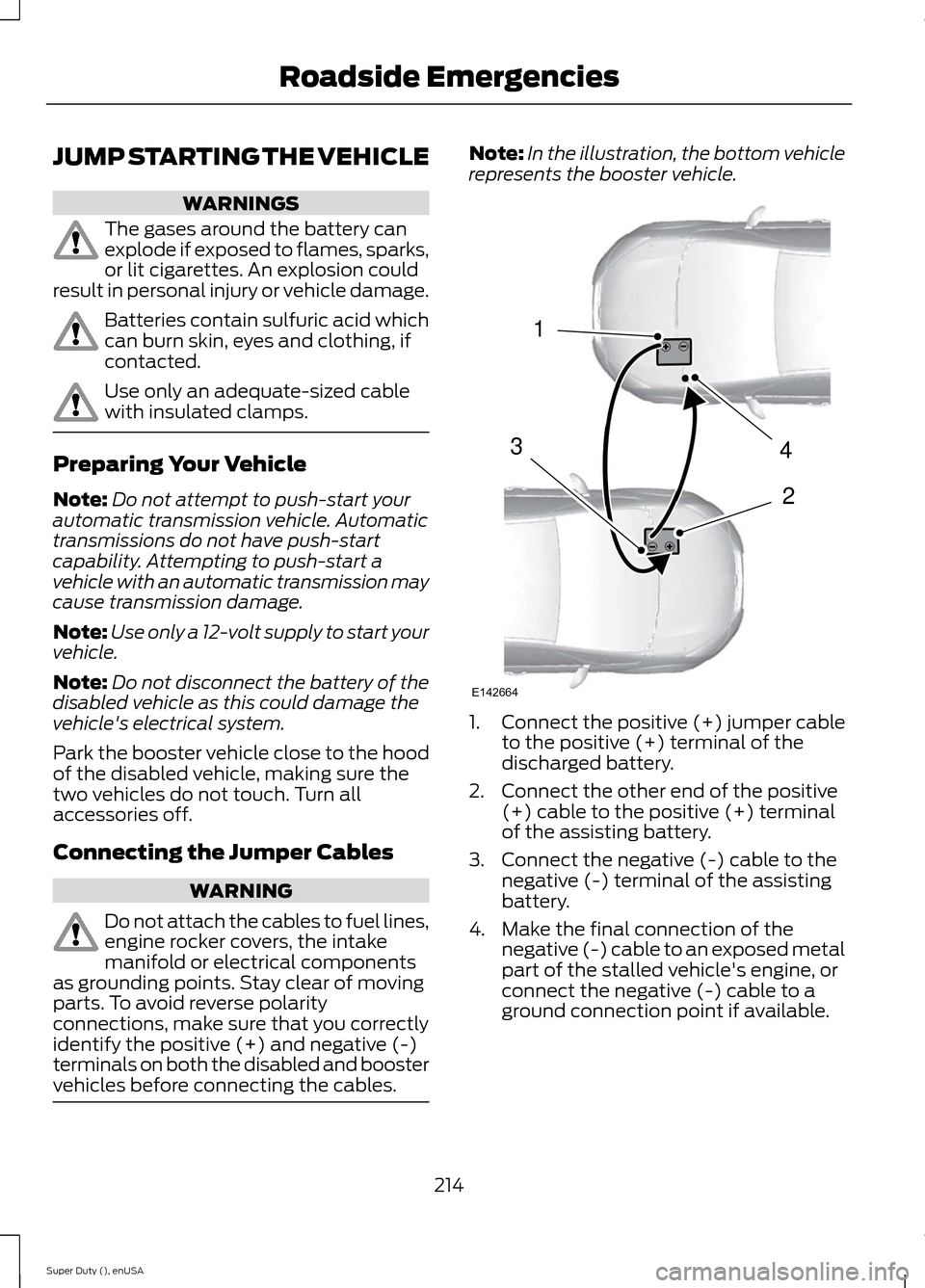

Park the booster vehicle close to the hoodof the disabled vehicle, making sure thetwo vehicles do not touch. Turn allaccessories off.

Connecting the Jumper Cables

WARNING

Do not attach the cables to fuel lines,engine rocker covers, the intakemanifold or electrical componentsas grounding points. Stay clear of movingparts. To avoid reverse polarityconnections, make sure that you correctlyidentify the positive (+) and negative (-)terminals on both the disabled and boostervehicles before connecting the cables.

Note:In the illustration, the bottom vehiclerepresents the booster vehicle.

1.Connect the positive (+) jumper cableto the positive (+) terminal of thedischarged battery.

2.Connect the other end of the positive(+) cable to the positive (+) terminalof the assisting battery.

3.Connect the negative (-) cable to thenegative (-) terminal of the assistingbattery.

4.Make the final connection of thenegative (-) cable to an exposed metalpart of the stalled vehicle's engine, orconnect the negative (-) cable to aground connection point if available.

214Super Duty (), enUSARoadside Emergencies4213E142664

Page 218 of 470

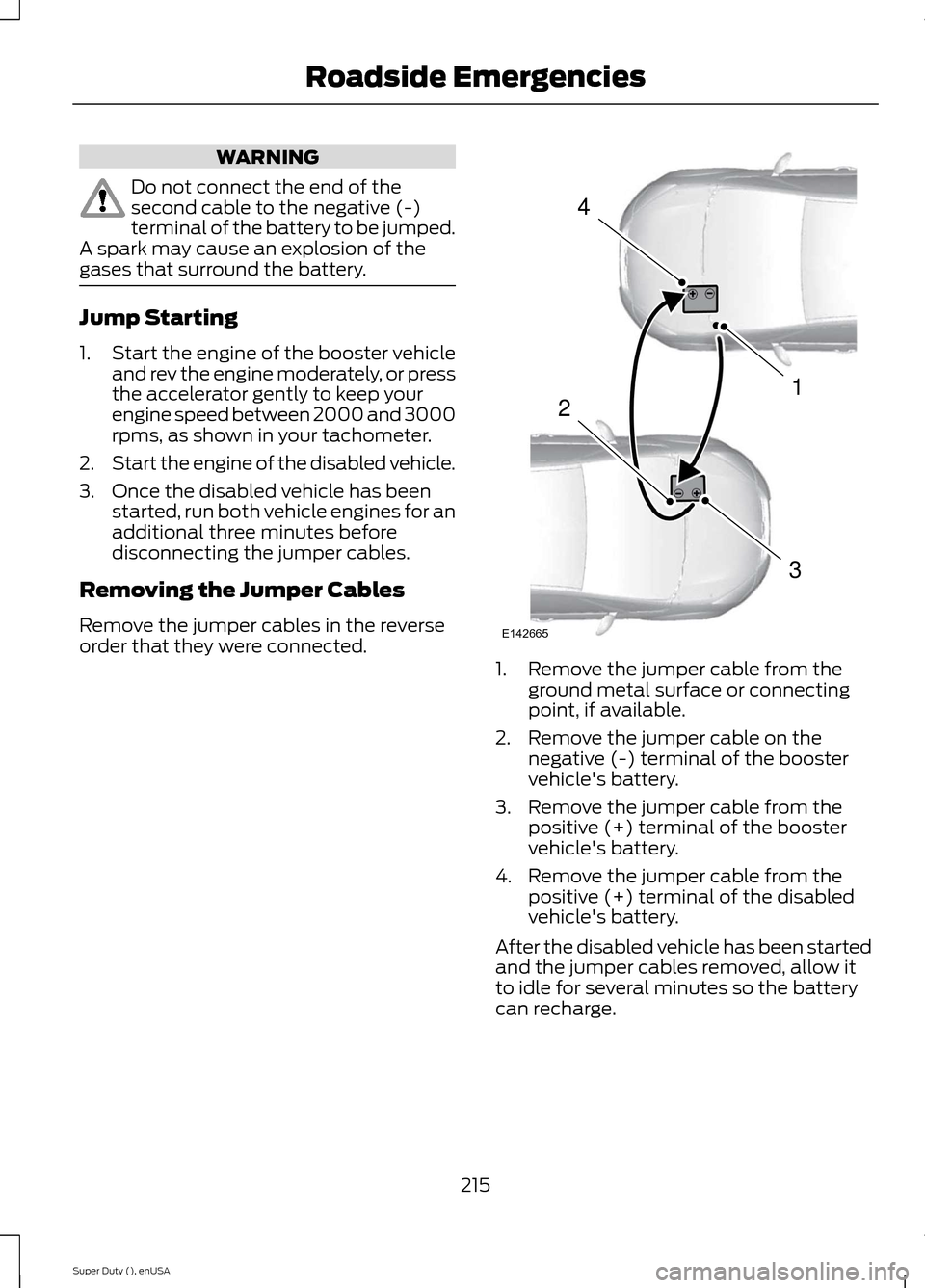

WARNING

Do not connect the end of thesecond cable to the negative (-)terminal of the battery to be jumped.A spark may cause an explosion of thegases that surround the battery.

Jump Starting

1.Start the engine of the booster vehicleand rev the engine moderately, or pressthe accelerator gently to keep yourengine speed between 2000 and 3000rpms, as shown in your tachometer.

2.Start the engine of the disabled vehicle.

3.Once the disabled vehicle has beenstarted, run both vehicle engines for anadditional three minutes beforedisconnecting the jumper cables.

Removing the Jumper Cables

Remove the jumper cables in the reverseorder that they were connected.1.Remove the jumper cable from theground metal surface or connectingpoint, if available.

2.Remove the jumper cable on thenegative (-) terminal of the boostervehicle's battery.

3.Remove the jumper cable from thepositive (+) terminal of the boostervehicle's battery.

4.Remove the jumper cable from thepositive (+) terminal of the disabledvehicle's battery.

After the disabled vehicle has been startedand the jumper cables removed, allow itto idle for several minutes so the batterycan recharge.

215Super Duty (), enUSARoadside Emergencies4132E142665

Page 226 of 470

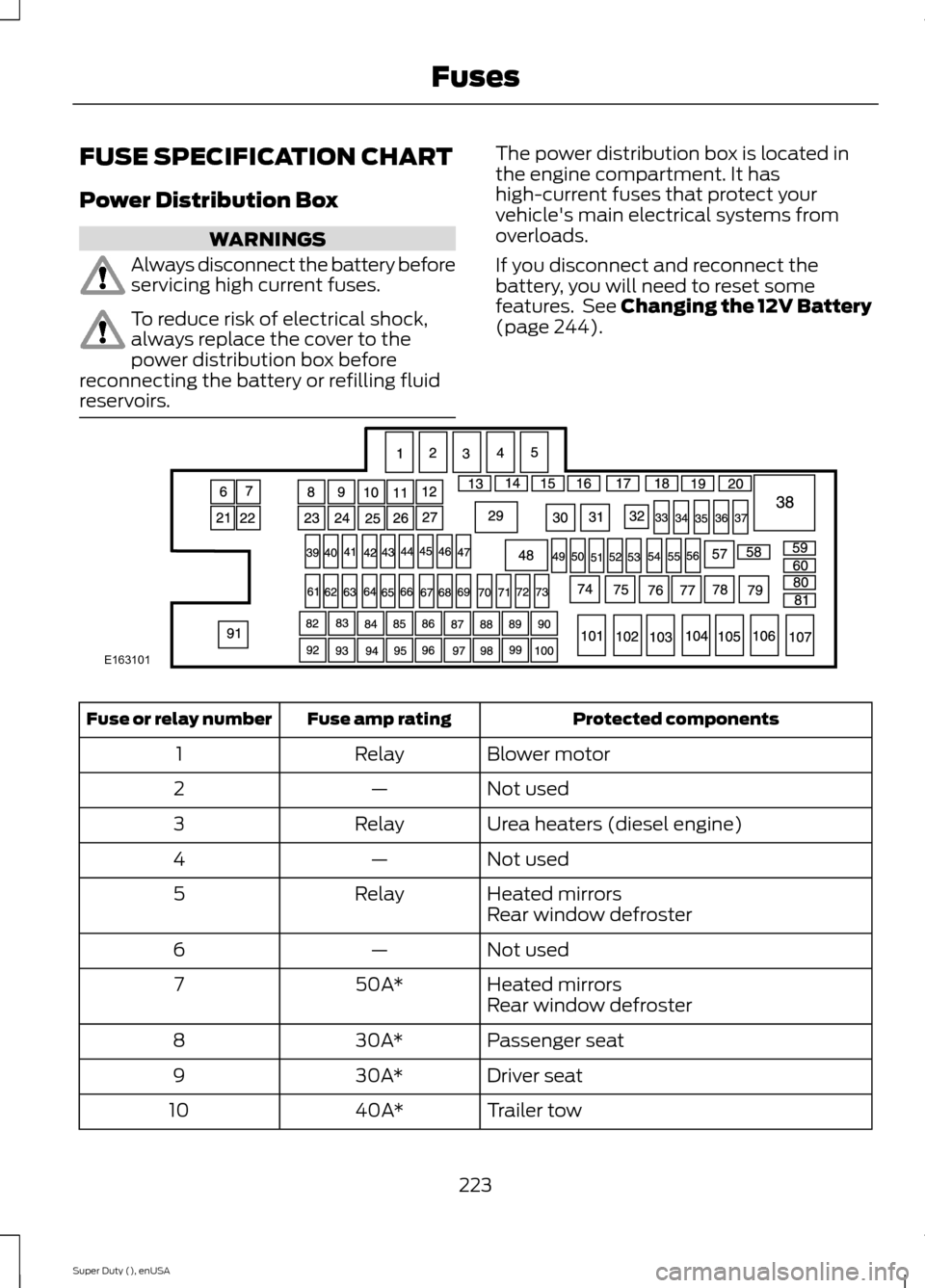

FUSE SPECIFICATION CHART

Power Distribution Box

WARNINGS

Always disconnect the battery beforeservicing high current fuses.

To reduce risk of electrical shock,always replace the cover to thepower distribution box beforereconnecting the battery or refilling fluidreservoirs.

The power distribution box is located inthe engine compartment. It hashigh-current fuses that protect yourvehicle's main electrical systems fromoverloads.

If you disconnect and reconnect thebattery, you will need to reset somefeatures. See Changing the 12V Battery(page 244).

Protected componentsFuse amp ratingFuse or relay number

Blower motorRelay1

Not used—2

Urea heaters (diesel engine)Relay3

Not used—4

Heated mirrorsRelay5Rear window defroster

Not used—6

Heated mirrors50A*7Rear window defroster

Passenger seat30A*8

Driver seat30A*9

Trailer tow40A*10

223Super Duty (), enUSAFusesE163101