fuse box FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 129 of 234

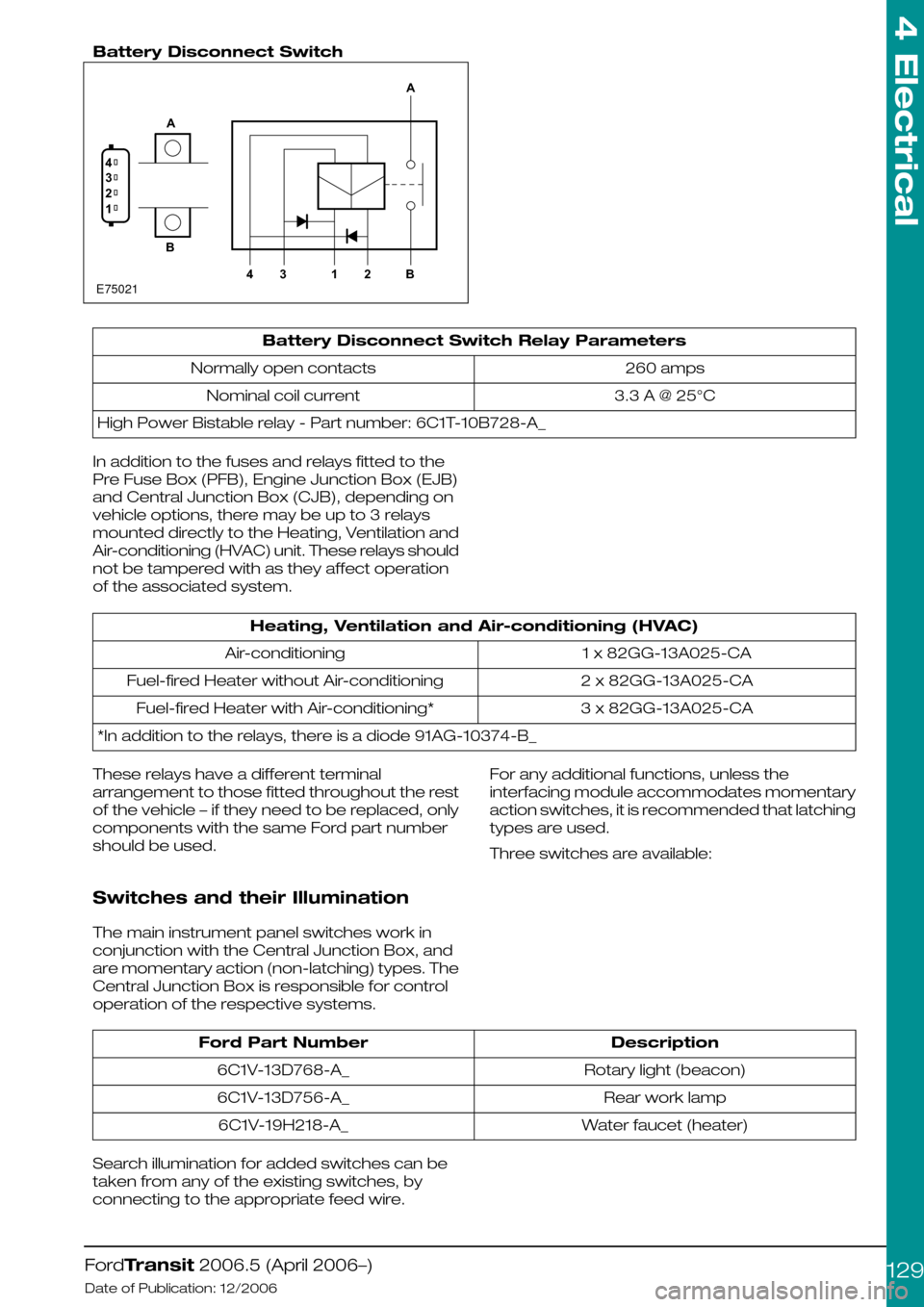

Battery Disconnect Switch

Battery Disconnect Switch Relay Parameters

260 ampsNormally open contacts

3.3 A @ 25°CNominal coil current

High Power Bistable relay - Part number: 6C1T-10B728-A_

In addition to the fuses and relays fitted to the

Pre Fuse Box (PFB), Engine Junction Box (EJB)

and Central Junction Box (CJB), depending on

vehicle options, there may be up to 3 relays

mounted directly to the Heating, Ventilation and

Air-conditioning (HVAC) unit. These relays should

not be tampered with as they affect operation

of the associated system.

Heating, Ventilation and Air-conditioning (HVAC)

1 x 82GG-13A025-CAAir-conditioning

2 x 82GG-13A025-CAFuel-fired Heater without Air-conditioning

3 x 82GG-13A025-CAFuel-fired Heater with Air-conditioning*

*In addition to the relays, there is a diode 91AG-10374-B_

These relays have a different terminal

arrangement to those fitted throughout the rest

of the vehicle – if they need to be replaced, only

components with the same Ford part number

should be used.

Switches and their Illumination

The main instrument panel switches work in

conjunction with the Central Junction Box, and

are momentary action (non-latching) types. The

Central Junction Box is responsible for control

operation of the respective systems.

For any additional functions, unless the

interfacing module accommodates momentary

action switches, it is recommended that latching

types are used.

Three switches are available:

DescriptionFord Part Number

Rotary light (beacon)6C1V-13D768-A_

Rear work lamp6C1V-13D756-A_

Water faucet (heater)6C1V-19H218-A_

Search illumination for added switches can be

taken from any of the existing switches, by

connecting to the appropriate feed wire.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

129E750211234AB4312BA

Page 130 of 234

4.13.7 Windscreen wipers

NOTE: Power to wiper motors is limited by the

size of the wiring and associated relays. If any

alternative wiper installation is made, it must have

a specification equivalent to Ford components.

Refer to: 5.6 Glass, Frames and Mechanisms

(page 211).

The base wiper system should not be tampered

with (controlled by Central Junction Box and

multiplex architecture).

Headlamp wash – such installations would need

to be controlled via an external timer relay. The

Special Vehicle Option Auxiliary Fuse Box should

be utilized.

Heated washer jets – aftermarket systems should

be fitted via an ignition feed, via an additional relay.

The Special Vehicle Option Auxiliary Fuse Box

should be utilized.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

130

Page 133 of 234

The fitment of the Special Vehicle Option auxiliary

box will provide a power source for the relay

(although connection to the engine run pin is still

required).

Where connections are already made to the

engine run signal, it is vital that these connections

remain connected. In this instance, a suitable 'Y'

Jumper link should be used to tap out of the

connection.

Refer to: 4.13 Fuses and Relays (page 119).

If a positive (+12V) engine run signal is required,

this is possible by using the relay contacts to ‘pull

in’ 12V (preferably an ignition feed, KL15)

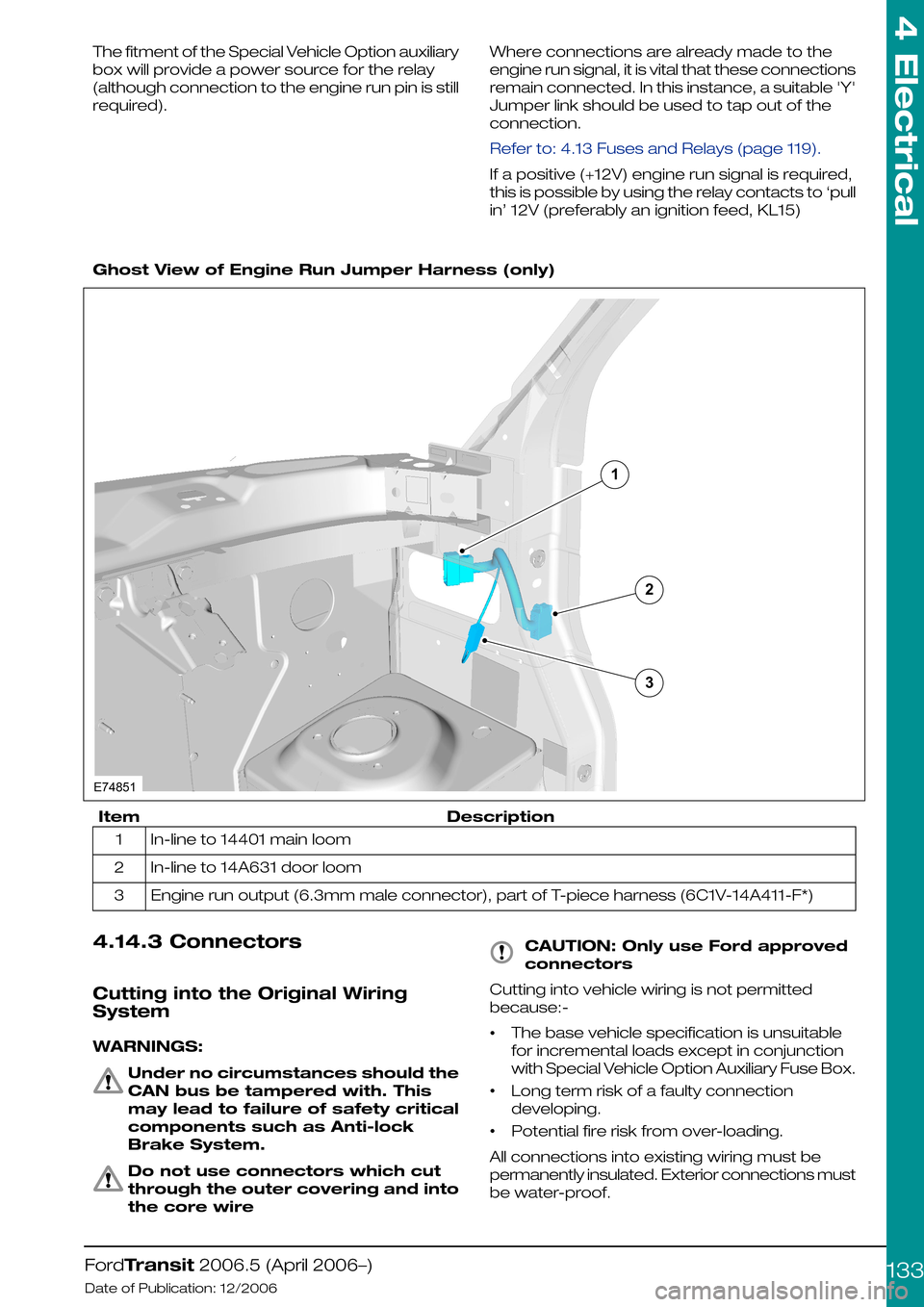

Ghost View of Engine Run Jumper Harness (only)

DescriptionItem

In-line to 14401 main loom1

In-line to 14A631 door loom2

Engine run output (6.3mm male connector), part of T-piece harness (6C1V-14A411-F*)3

4.14.3 Connectors

Cutting into the Original Wiring

System

WARNINGS:

Under no circumstances should the

CAN bus be tampered with. This

may lead to failure of safety critical

components such as Anti-lock

Brake System.

Do not use connectors which cut

through the outer covering and into

the core wire

CAUTION: Only use Ford approved

connectors

Cutting into vehicle wiring is not permitted

because:-

•The base vehicle specification is unsuitable

for incremental loads except in conjunction

with Special Vehicle Option Auxiliary Fuse Box.

•Long term risk of a faulty connection

developing.

•Potential fire risk from over-loading.

All connections into existing wiring must be

permanently insulated. Exterior connections must

be water-proof.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

133132E74851

Page 146 of 234

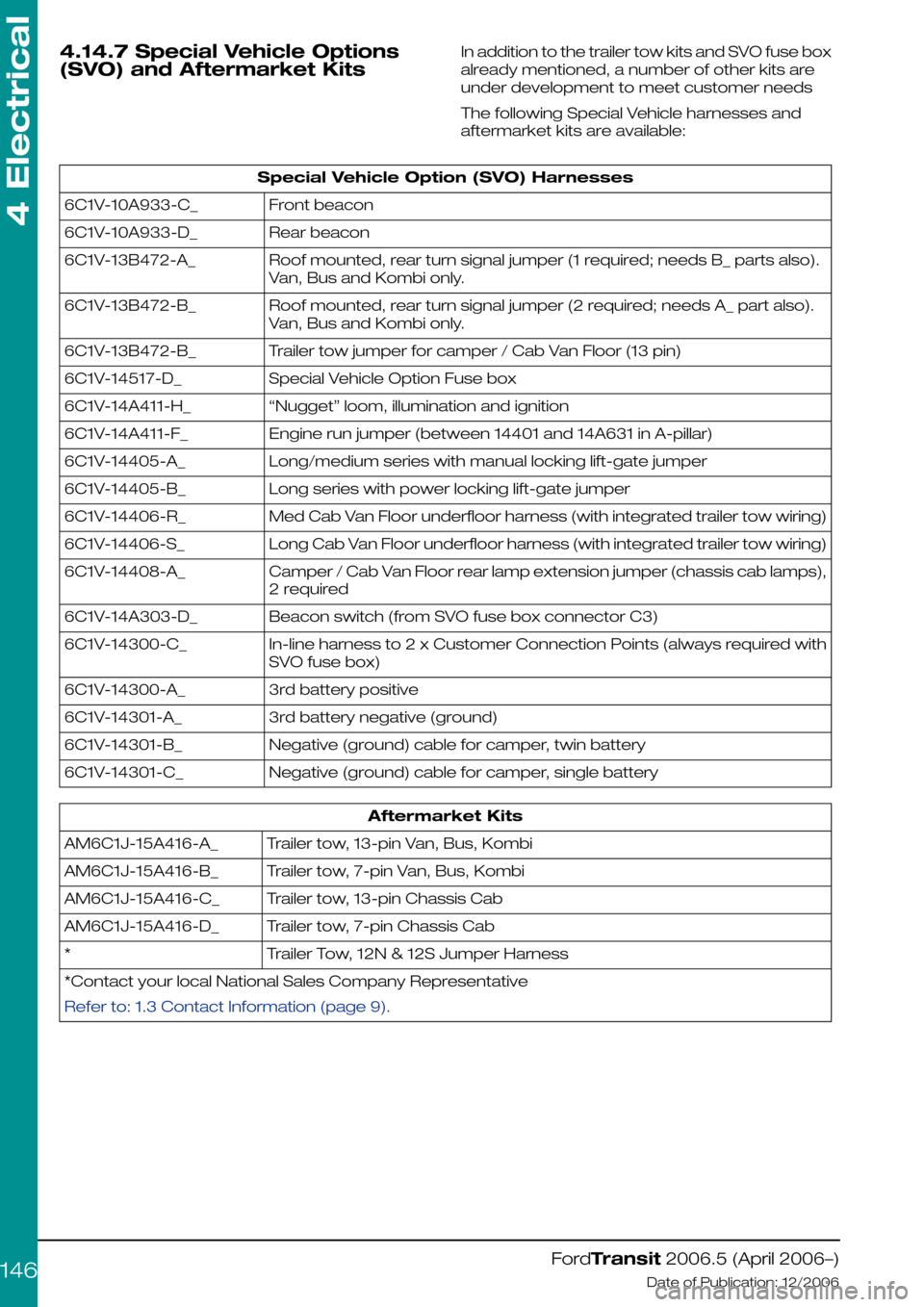

4.14.7 Special Vehicle Options

(SVO) and Aftermarket Kits

In addition to the trailer tow kits and SVO fuse box

already mentioned, a number of other kits are

under development to meet customer needs

The following Special Vehicle harnesses and

aftermarket kits are available:

Special Vehicle Option (SVO) Harnesses

Front beacon6C1V-10A933-C_

Rear beacon6C1V-10A933-D_

Roof mounted, rear turn signal jumper (1 required; needs B_ parts also).

Van, Bus and Kombi only.

6C1V-13B472-A_

Roof mounted, rear turn signal jumper (2 required; needs A_ part also).

Van, Bus and Kombi only.

6C1V-13B472-B_

Trailer tow jumper for camper / Cab Van Floor (13 pin)6C1V-13B472-B_

Special Vehicle Option Fuse box6C1V-14517-D_

“Nugget” loom, illumination and ignition6C1V-14A411-H_

Engine run jumper (between 14401 and 14A631 in A-pillar)6C1V-14A411-F_

Long/medium series with manual locking lift-gate jumper6C1V-14405-A_

Long series with power locking lift-gate jumper6C1V-14405-B_

Med Cab Van Floor underfloor harness (with integrated trailer tow wiring)6C1V-14406-R_

Long Cab Van Floor underfloor harness (with integrated trailer tow wiring)6C1V-14406-S_

Camper / Cab Van Floor rear lamp extension jumper (chassis cab lamps),

2 required

6C1V-14408-A_

Beacon switch (from SVO fuse box connector C3)6C1V-14A303-D_

In-line harness to 2 x Customer Connection Points (always required with

SVO fuse box)

6C1V-14300-C_

3rd battery positive6C1V-14300-A_

3rd battery negative (ground)6C1V-14301-A_

Negative (ground) cable for camper, twin battery6C1V-14301-B_

Negative (ground) cable for camper, single battery6C1V-14301-C_

Aftermarket Kits

Trailer tow, 13-pin Van, Bus, KombiAM6C1J-15A416-A_

Trailer tow, 7-pin Van, Bus, KombiAM6C1J-15A416-B_

Trailer tow, 13-pin Chassis CabAM6C1J-15A416-C_

Trailer tow, 7-pin Chassis CabAM6C1J-15A416-D_

Trailer Tow, 12N & 12S Jumper Harness*

*Contact your local National Sales Company Representative

Refer to: 1.3 Contact Information (page 9).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

146

Page 154 of 234

harness that provides roof-mounted rear turn

indicators, powered via relays. This should be

used in conjunction with SVO fusebox.

3.Chassis cab LED rear lamp cluster

replacement recommendations, especially

turn indicator relay implications – see lighting

load table. Generally the use of LED equivalent

lighting systems reduces the electrical load on

the vehicle; however, special care needs to

be taken with respect to any change to or

addition of turn indicator lights. Depending on

the current requirements of the LED(s)

compared to the bulb it is replacing, a ballast

resistor may be required, if not already

integrated into the LED lamp assembly.

Without this, bulb outage detection for turn

indicators will be affected, which is a legal

requirement.

Additional turn indicators must be powered

through relays (max 300mA), driven by existing

turn lights. The maximum load that the Central

Junction Box can drive is 3 x 21W per side (front,

rear and CAT 6 turn indicators); but even if the

vehicle is not fitted with the CAT 6 lights, the feeds

for these should not be used as the Central

Junction Box would need reconfiguring, which

could have safety as well as functional

implications.

4.Special Vehicle Option beacon switch: wiring

locations, circuit diagrams and max amperage

– see Special Vehicle Option fuse box

schematic (max current is 15A); there is

provision for the Special Vehicle Option beacon

switch in an empty switch location on the

instrument panel.

5.Rear loom connector detail location and supply

details for retro-fit loom extension for

example:- when extending a medium wheel

base, long wheel base or extended frame

overhang, what connectors do they use to

make a plug and play loom extension? – for

chassis cab vehicles, there is an Special

Vehicle Option extension loom for rear lamps

(part number 6C1V-14408-A*). There is not, at

present, a similar loom for Van, Bus and

Kombi's, although the appropriate mating

connector is now tooled, so this would be

possible.

Miscellaneous Systems

Handbrake on - Cluster Warning Light -

Unless the vehicle is specified with options that

drive the handbrake warning light (for example

ESP, Australia market), the components making

up this system are not fitted. We do not

recommend installation of this feature as an

aftermarket addition. There are several reasons

for this:

1.Not all circuits carry the requisite wire as a give

away:

•The wires might be part of the main vehicle

harness (14401) even if not used – for example

camper vehicles are normally ordered with

power mirrors, and the wires will be present

as a give-away.

•The seat pedestal harness (14K076), however,

is vehicle specific – if the handbrake is not part

of the specification, it will not be present or

give-away. This harness would need to be

changed to the compatible part that also

includes the handbrake warning light circuit.

2.The handbrake switch (part number

2F2T-15852-A*) together with its short jumper

harness (6C1T-15K857-A*) would need to be

obtained and fitted.

3.The handbrake warning light is in all clusters,

but unless the vehicle config. parameter

“parking brake switch” is set, the Central

Junction Box will not read this input, and hence

NO CAN message sent to the cluster.

Reconfiguration can only be done at a Ford

Dealer.

NOTE: If a vehicle already has a handbrake

warning light in the cluster, or one is installed as

per the Ford design, it is not possible to utilize the

wire from the handbrake switch as part of an

interlock circuit (this is a pull up resistor input that

provides a wetting current of 20mA – anything in

excess of this, for example through additional

circuitry, will almost certainly damage the Central

Junction Box). If there is no handbrake switch

installed, it would be possible to add one and

utilize this as part of a separate circuit, up to a

maximum current of 500mA through the switch.

Reverse Sensors (Rear Park Aid

Module)- The factory-fit option is a CAN-based

system, but for Van, Bus, and Kombi vehicles

only. Stand-alone systems can be installed (for

example for chassis cab conversions), but would

need to utilize the PTA line of the radio if muting

is required.

Fuel Fired Heater (FFH)- Add FFH: wiring is

only present (give-away) in certain harnesses.

There was an aftermarket kit available for this

system on current Transit, which could probably

be “updated” to suit V347/8.

Fuel Fired Heater (FFH) - Programmable

FFH: this utilizes a timer/control module mounted

to the Instrument Panel, which necessitates

having the correct Instrument Panel harness

fitted. Retrofit of this would be a difficult.

For both systems, the appropriate 6C1T-14K132

harness would be required (suffix -A* for

Programmable FFH, and suffix –B* for Add FFH).

Central Locking

Locking is controlled by the Central Junction Box

module. There is current sensing on certain

locking circuit pins as part of the security system

– if these are tampered with, locking cannot be

guaranteed.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

154

Page 157 of 234

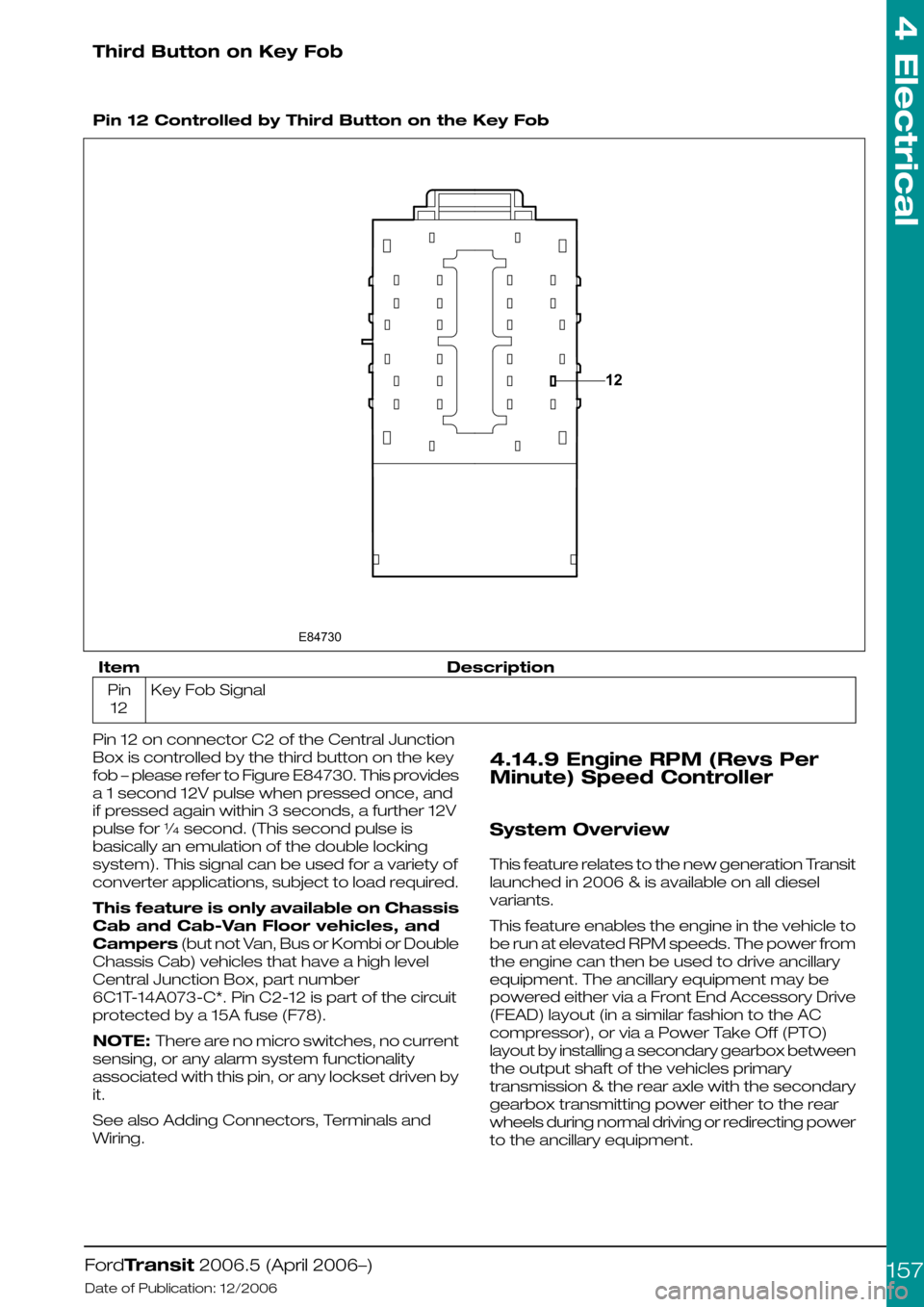

Third Button on Key Fob

Pin 12 Controlled by Third Button on the Key Fob

DescriptionItem

Key Fob SignalPin

12

Pin 12 on connector C2 of the Central Junction

Box is controlled by the third button on the key

fob – please refer to Figure E84730. This provides

a 1 second 12V pulse when pressed once, and

if pressed again within 3 seconds, a further 12V

pulse for ¼ second. (This second pulse is

basically an emulation of the double locking

system). This signal can be used for a variety of

converter applications, subject to load required.

This feature is only available on Chassis

Cab and Cab-Van Floor vehicles, and

Campers (but not Van, Bus or Kombi or Double

Chassis Cab) vehicles that have a high level

Central Junction Box, part number

6C1T-14A073-C*. Pin C2-12 is part of the circuit

protected by a 15A fuse (F78).

NOTE: There are no micro switches, no current

sensing, or any alarm system functionality

associated with this pin, or any lockset driven by

it.

See also Adding Connectors, Terminals and

Wiring.

4.14.9 Engine RPM (Revs Per

Minute) Speed Controller

System Overview

This feature relates to the new generation Transit

launched in 2006 & is available on all diesel

variants.

This feature enables the engine in the vehicle to

be run at elevated RPM speeds. The power from

the engine can then be used to drive ancillary

equipment. The ancillary equipment may be

powered either via a Front End Accessory Drive

(FEAD) layout (in a similar fashion to the AC

compressor), or via a Power Take Off (PTO)

layout by installing a secondary gearbox between

the output shaft of the vehicles primary

transmission & the rear axle with the secondary

gearbox transmitting power either to the rear

wheels during normal driving or redirecting power

to the ancillary equipment.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

15712E84730

Page 230 of 234

A

About This Manual................................................6

Accessory Drive..................................................77

Adding Connectors, Terminals and Wiring....

162

Additional 'Theatre Lighting' for rear of vehicle

interior...............................................................118

Additional External Lamps...............................116

Additional Ignition, Instrument Panel Illumination

and Air Conditioning On Signals...................124

Additional Internal Lamps ................................118

Additional Vehicle Signals / Features.............147

Aids for Vehicle Entry and Exit..........................33

Air Bags..............................................................218

Air Bag Supplemental Restraint System (SRS)..

218

Air Flow Restrictions...........................................76

Alternative Type Approval....................................7

Ancillary Equipment - Sub Frame Mounting....

228

Antenna Location...............................................24

Anti-Lock Control - Stability Assist..................65

Auxiliary Fuses, Fuse Box and Relays (Fuses -

Standard)..........................................................119

Auxiliary Heater Installation...............................76

Auxiliary Heater Systems..................................75

B

Back Panel Removal................................177, 214

Battery and Cables............................................98

Battery Information............................................98

Body....................................................................175

Body Closures..................................................203

Body Structures - General Information.........175

Body System - General

Information—Specifications.........................200

Brake Hoses General........................................62

Brake System.....................................................62

C

Cab Roof Removal...........................................214

Cab Van Floor....................................................185

CAN-Bus System Description and Interface....

90

Cellular Phone....................................................115

Center of Gravity ...............................................46

Central Junction Box (CJB)...............................91

Charge Balance Guidelines..............................97

Charging System...............................................95

Chassis Cab.......................................................179

Circit Diagram.....................................................94

Circuit Diagram...................................................93

Circuit Diagrams.................................................97

Climate Control System..................................106

Clutch...................................................................82

Commercial and Legal Aspects.........................7

Communications Network...............................90

Connectors........................................................133

Contact Corrosion............................................221

Contact Information.............................................9

Conversion Affect on Fuel Economy and

Performance.....................................................25

Conversion Affects on Parking Aids................33

Conversion Homologation...............................23

Conversion Type.................................................14

Corrosion Prevention.......................................221

Customer Connection Points.........................120

D

Drilling and Welding..............................................8

Driver's Standing Head Room........................214

Driver Field of View.............................................33

Driver Reach Zones...........................................33

Driveshaft.............................................................61

E

Electrical Conversions.......................................95

Electrically operated Door Mirrors..................117

Electrics for Tow bar........................................136

Electromagnetic Compatibility (EMC)............24

Electronic Engine Controls................................81

End of Life Vehicle (ELV) Directive...................26

Engine Cooling....................................................75

Engine..................................................................66

Engine Power Curves.......................................66

Engine RPM (Revs Per Minute) Speed

Controller..........................................................157

Engine Run Signal (D+ Alternative)................132

Exhaust Heat Shields.........................................86

Exhaust Pipes and Supports............................86

Exhaust System.................................................86

Extended Chassis Frame...............................226

Extensions and Optional Exhausts..................86

Exterior Lighting.................................................116

F

Fitting of Equipment Containing an Electric

Motor..................................................................97

Frame and Body Mounting............................222

Frame Drilling and Tube Reinforcing.............228

Front, Rear and Side Under-run Protection....

38

Front and Rear Brakes......................................64

Front End Accessory Drive 2.2l Diesel............79

Front End Accessory Drive 2.4l Diesel and 2.3l

Petrol...................................................................77

Front End Integrity for Cooling, Crash,

Aerodynamics and Lighting..........................198

Front Suspension...............................................58

Fuel System........................................................88

Fuses and Relays..............................................119

G

General........................................................62, 221

General Component Package Guidelines.....33

General Information and Specific Warnings....

95

General........................................................62, 221

General Product Safety Requirement...............7

Index

230

Page 231 of 234

Generator and Alternator...............................103

Glass, Frames and Mechanisms...................211

Ground Points..................................................140

H

Hardware—Specifications...............................43

Heated Seats...................................................210

Heated Windshield and Heated Rear Window.

213

Horn...................................................................108

How to Use This Manual....................................6

Hydraulic Brake Actuation...............................64

Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab...........................................186

I

Important Safety Instructions............................6

Information and Entertainment System -

General Information—Specifications...........112

Installation and Routing Guides.....................134

Instrument Cluster...........................................107

Integrated Bodies and Conversions.............177

Interior Lighting.................................................118

Introduction..........................................................6

J

Jacking................................................................27

K

Kerb Mass Data.................................................62

L

Lamps for Wide Vehicles.................................117

Lamps – Front and Rear Fog Lights..............117

Lamps – Hazard / Direction Indication..........117

Legal and Vehicle Type Approval......................7

Legal Obligations and Liabilities.........................7

Legislation.........................................................109

Lifting...................................................................29

Load Apportioning Valves................................64

Load Compartment Interior Lining...............203

Load Distribution—Specifications...................44

Load Distribution Calculations - Driver and

Passenger Weight Distribution.....................44

M

Manual Transmission........................................83

Minimum Requirements for Brake system and

Load Apportioning Valves ...............................8

Mirrors for Wide Vehicles...............................208

Module Communications

Network—Specifications................................94

Mounting Points and Tubing.........................222

N

Noise, Vibration and Harshness (NVH)...........31

Non Standard Rear Chassis Frame Extension.

226

P

Package and Ergonomics—Specifications....

34

Package and Ergonomics...............................33

Painting Road Wheels..............................60, 221

Parking Brake....................................................63

Partitions (Bulkhead) - Driver and Front

Passenger(s) Protection on Van, Bus and

Kombi..............................................................192

Possible Accessories.......................................113

Power Management Settings.........................95

Power Take Off...................................................61

Product Liability....................................................8

R

Racking Systems.............................................194

Radio Connector..............................................112

Rear Anti-Roll Bar..............................................59

Rear Seat Fixings Positions - Kombi............209

Rear Suspension...............................................59

Rear View Mirrors...........................................208

Rear Windows..................................................211

Recommended Main Dimensions.................34

Recommended Main Load Area Dimensions

for Bulkhead with Depression Driver Side....

39

Recommended Main Load Area Dimensions

for Bulkhead with Full Depression................40

Recommended Main Load Area Dimensions

for Double Cab In Van Bulkhead...................41

Recommended Nominal Body Lengths for

Chassis Cab models......................................36

Relays and Switches.......................................127

Relocated Parking Brake Lever......................63

Repairing Damaged Paint..............................221

Restraints System...............................................8

Reversing Lamps.............................................116

Road Safety..........................................................8

Roof Opening Panel........................................214

Roof Racks.......................................................216

Roof Ventilation................................................215

S

Safety Belt System.........................................220

Seats.................................................................209

Security, Anti Theft and Locking System

Security ..........................................................203

Self-Supporting Body Structure...................224

Spare Tire Access and Mounting.................229

Spare wheel.......................................................60

Special Conversions........................................131

Special Vehicle Option Auxiliary Fuse Box....

121

Index

231