ECU FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 4 of 234

3.7Exhaust System..........................86

3.7.1Extensions and Optional Exhausts....

86

3.7.2Exhaust Pipes and Supports.............86

3.7.3Exhaust Heat Shields..........................86

3.8Fuel System.................................88

4 Electrical

4.1Communications Network..........90

4.1.1CAN-Bus System Description and

Interface................................................90

4.1.2Central Junction Box (CJB)................91

4.1.3Circuit Diagram....................................93

4.2Module Communications

Network—Specifications.............94

4.2.1Circit Diagram......................................94

4.3Charging System.........................95

4.3.1General Information and Specific

Warnings...............................................95

4.3.2Power Management Settings...........95

4.3.3Electrical Conversions........................95

4.3.4Fitting of Equipment Containing an

Electric Motor.......................................97

4.3.5Vehicle Electrical Capacity -

Alternator..............................................97

4.3.6Charge Balance Guidelines...............97

4.3.7Circuit Diagrams..................................97

4.4Battery and Cables.....................98

4.4.1Battery Information.............................98

4.4.2Generator and Alternator.................103

4.5Climate Control System.............106

4.6Instrument Cluster.....................107

4.7Horn...........................................108

4.8Tachograph................................109

4.8.1Legislation...........................................109

4.8.2Tachograph Mounting.......................110

4.9Information and Entertainment

System - General

Information—Specifications.......112

4.9.1Radio Connector................................112

4.9.2Possible Accessories.........................113

4.10Cellular Phone............................115

4.11Exterior Lighting.........................116

4.11.1Reversing Lamps...............................116

4.11.2Additional External Lamps................116

4.11.3Lamps – Hazard / Direction

Indication..............................................117

4.11.4Lamps – Front and Rear Fog Lights....

117

4.11.5Lamps for Wide Vehicles...................117

4.11.6Electrically operated Door Mirrors....

117

4.12Interior Lighting..........................118

4.12.1Additional Internal Lamps .................118

4.12.2Additional 'Theatre Lighting' for rear

of vehicle interior................................118

4.13Fuses and Relays.......................119

4.13.1Wiring Specification............................119

4.13.2Auxiliary Fuses, Fuse Box and Relays

(Fuses - Standard).............................119

4.13.3Customer Connection Points..........120

4.13.4Special Vehicle Option Auxiliary Fuse

Box........................................................121

4.13.5Additional Ignition, Instrument Panel

Illumination and Air Conditioning On

Signals.................................................124

4.13.6Relays and Switches.........................127

4.13.7Windscreen wipers...........................130

4.14Special Conversions..................131

4.14.1Vehicle Speed Output (Signal).........131

4.14.2Engine Run Signal (D+ Alternative)....

132

4.14.3Connectors.........................................133

4.14.4Installation and Routing Guides.......134

4.14.5Electrics for Tow bar.........................136

4.14.6Ground Points....................................140

4.14.7Special Vehicle Options (SVO) and

Aftermarket Kits.................................146

4.14.8Additional Vehicle Signals / Features..

147

4.14.9Engine RPM (Revs Per Minute) Speed

Controller.............................................157

4.14.10Adding Connectors, Terminals and

Wiring...................................................162

5 Body and Paint

5.1Body...........................................175

5.1.1Body Structures - General

Information..........................................175

5.1.2Back Panel Removal.........................177

5.1.3Integrated Bodies and Conversions...

177

5.1.4Chassis Cab........................................179

5.1.5Cab Van Floor.....................................185

5.1.6Hydraulic Lifting Equipment for Van,

Bus, Kombi and Chassis Cab..........186

5.1.7Partitions (Bulkhead) - Driver and

Front Passenger(s) Protection on Van,

Bus and Kombi..................................192

5.1.8Racking Systems...............................194

5.1.9Front End Integrity for Cooling, Crash,

Aerodynamics and Lighting.............198

5.1.10Tipper Bodies.....................................199

5.1.11Tank and Dry Bulk Carriers...............199

5.2Body System - General

Information—Specifications......200

5.2.1Van Floor - Load Compartment Tie

Downs for Van ,Bus and Kombi.....200

5.3Body Closures..........................203

5.3.1Load Compartment Interior Lining....

203

5.3.2Security, Anti Theft and Locking

System Security ...............................203

5.4Rear View Mirrors.....................208

5.4.1Mirrors for Wide Vehicles.................208

5.5Seats.........................................209

5.5.1Rear Seat Fixings Positions - Kombi...

209

5.5.2Heated Seats.....................................210

5.6Glass, Frames and Mechanisms...

211

5.6.1Rear Windows....................................211

Table of Contents

4

Page 29 of 234

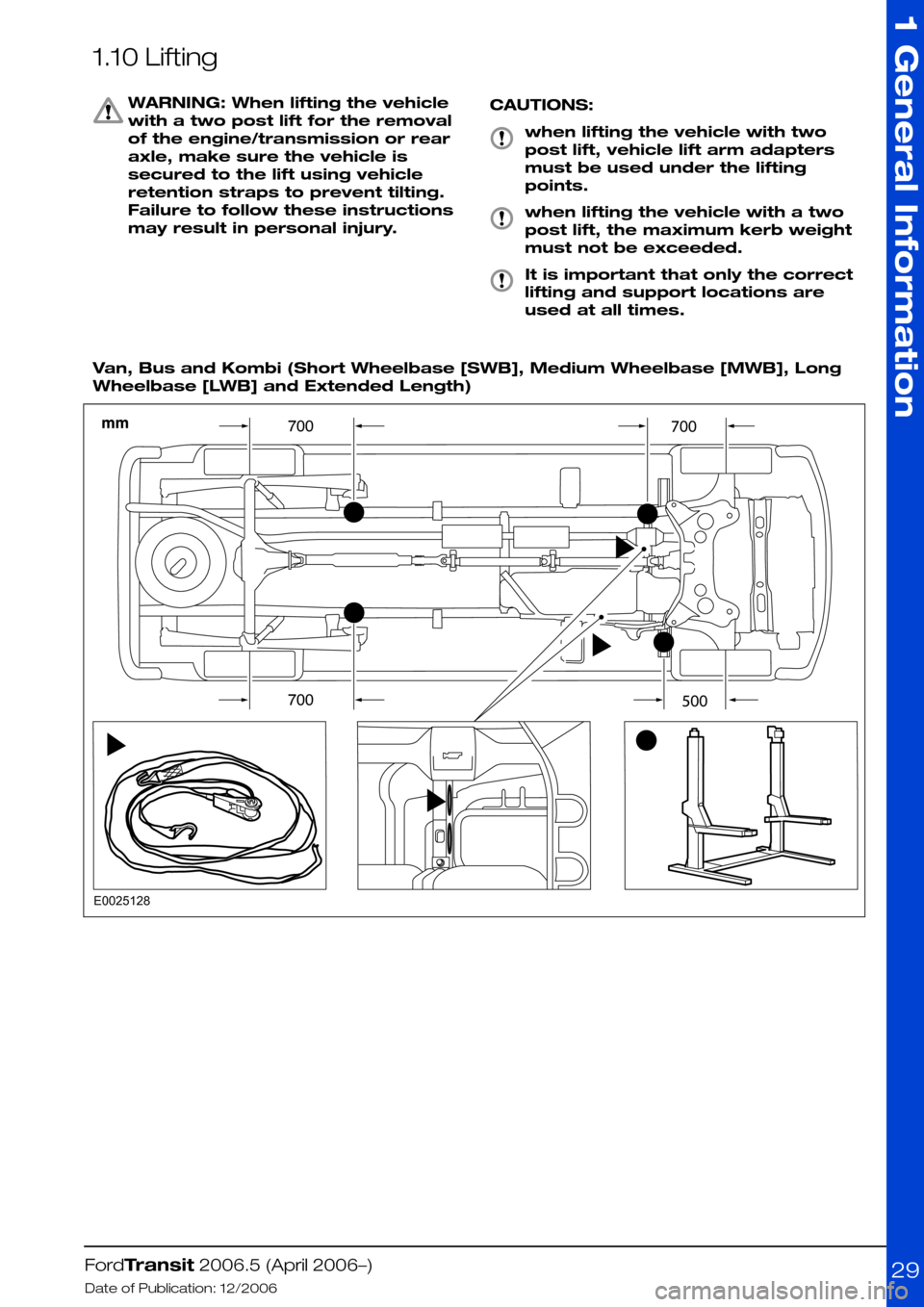

1.10 Lifting

WARNING: When lifting the vehicle

with a two post lift for the removal

of the engine/transmission or rear

axle, make sure the vehicle is

secured to the lift using vehicle

retention straps to prevent tilting.

Failure to follow these instructions

may result in personal injury.

CAUTIONS:

when lifting the vehicle with two

post lift, vehicle lift arm adapters

must be used under the lifting

points.

when lifting the vehicle with a two

post lift, the maximum kerb weight

must not be exceeded.

It is important that only the correct

lifting and support locations are

used at all times.

Van, Bus and Kombi (Short Wheelbase [SWB], Medium Wheelbase [MWB], Long

Wheelbase [LWB] and Extended Length)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

29E0025128

Page 62 of 234

2.6 Brake System

2.6.1 General

The Brake System must be fully functional when

the vehicle conversion is completed. The vehicle

brake operating modes must be checked,

including warning system and parking brakes.

Brakes are certified to 71/320EEC and ECE R13

requirements as amended.

WARNING: Do not restrict the airflow

and cooling to the brake system

CAUTION: Spoilers and wheel covers

must not affect the brake cooling

performance.

NOTE: Do not obstruct the view of the brake

fluid reservoir level

NOTE: The donor vehicle brake fluid reservoir is

translucent so that it is possible to check the level

of fluid without opening the reservoir which will

reduce the risk of contamination.

The brake fluid reservoir must remain accessible

for servicing and for adding brake fluid.

2.6.2 Kerb Mass Data

NOTE: For further information please contact

your local National Sales Company representative,

or Local Ford Dealer. If they are unable to help

you then please contact the Vehicle Converter

Advisory Service at [email protected].

2.6.3 Brake Hoses General

CAUTION: Make sure that the front

and rear brake hoses are not

twisted and are correctly located

away from body and chassis

components.

Front and rear brake hoses must not rub, chafe

or rest on body or chassis components. There

must be clearance under all operating conditions,

between full compression and extension and full

lock to lock.

Brake lines must not be used to support or

secure any other component.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

62

Page 75 of 234

3.2 Engine Cooling

3.2.1 Auxiliary Heater Systems

WARNINGS:

Ford coolant additives are

necessary for the complete function

of the system. Only use ford

approved or equivalent specification

component, to withstand any

detrimental effects on the materials.

Do not mount components in front

of the grille or in an area of air flow

around the engine, which could

affect the engine cooling.

CAUTIONS:

Only make connections into the

heater hose between the front cab

heater and water pump return inlet.

Do not exceed the vehicle's original

coolant volume by more than 10%

Only use the manufactures

recommended (or equivalent

specification) coolant

additives/anti-freeze. Do not mix

coolant types.

•Coolant flow to cab heater must have priority

over flow to auxiliary heater or hand wash

facility.

•Coolant tube routing must be below the base

of the degas bottle.

•Use aluminum or plastic tee junction with

swaged or beaded ends to prevent hose blow

off. Reconnect original coolant tube as shown

in view E74570 (in this section) with standard

Ford water hose clip or suitable equivalent

specification clip. Ensure interference fit

between hose and 'T' joint.

•Tube routing must be secured to the body

structure or suitable brackets avoiding

electrical components or wires, hot or moving

parts and brake or fuel system components

•Hose must be heat sleeved with appropriate

material if within 100mm of exhaust

components (for example, manifold or

exhaust gas recirculating).

•The vertical clearance between the critical

cooling components (radiator, fan shroud and

radiator brackets) and both the hood inner

and outer (assembly) panels at design position

shall not be less than 15mm.

•There shall be a minimum clearance of 7mm

between the engine assembly and flexible

components (for example, hoses or wiring

harnesses) affixed to front end sheet metal

hardware, under a maximum engine torque

roll condition.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

75

Page 88 of 234

3.8 Fuel System

WARNINGS:

Do not cut into the original fuel

supply lines

Make sure that the modified vehicle

complies with all relevant legal

requirements.

For auxiliary applications requiring a fuel supply,

it is advisable to use the auxiliary fuel supply port

as shown in the figure below.

•The auxiliary fuel supply port is mounted on

the top of the fuel sender unit located on the

top of the fuel tank, for applications such as

an auxiliary heater or fuel fired hand wash

facility.

•Ensure that a suitable fuel shut-off is fitted in

any unique system.

•Refit the Ford hose assembly from the fuel

pump to the fuel line.

•The tube and/or line must be routed

independently and secured to the body

structure or to suitable brackets.

CAUTION: Make sure that sufficient

clearance is maintained for all

driving conditions to all hot and

moving components.

NOTE: Do not fasten anything to existing

electrical components or wires

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

88

Page 92 of 234

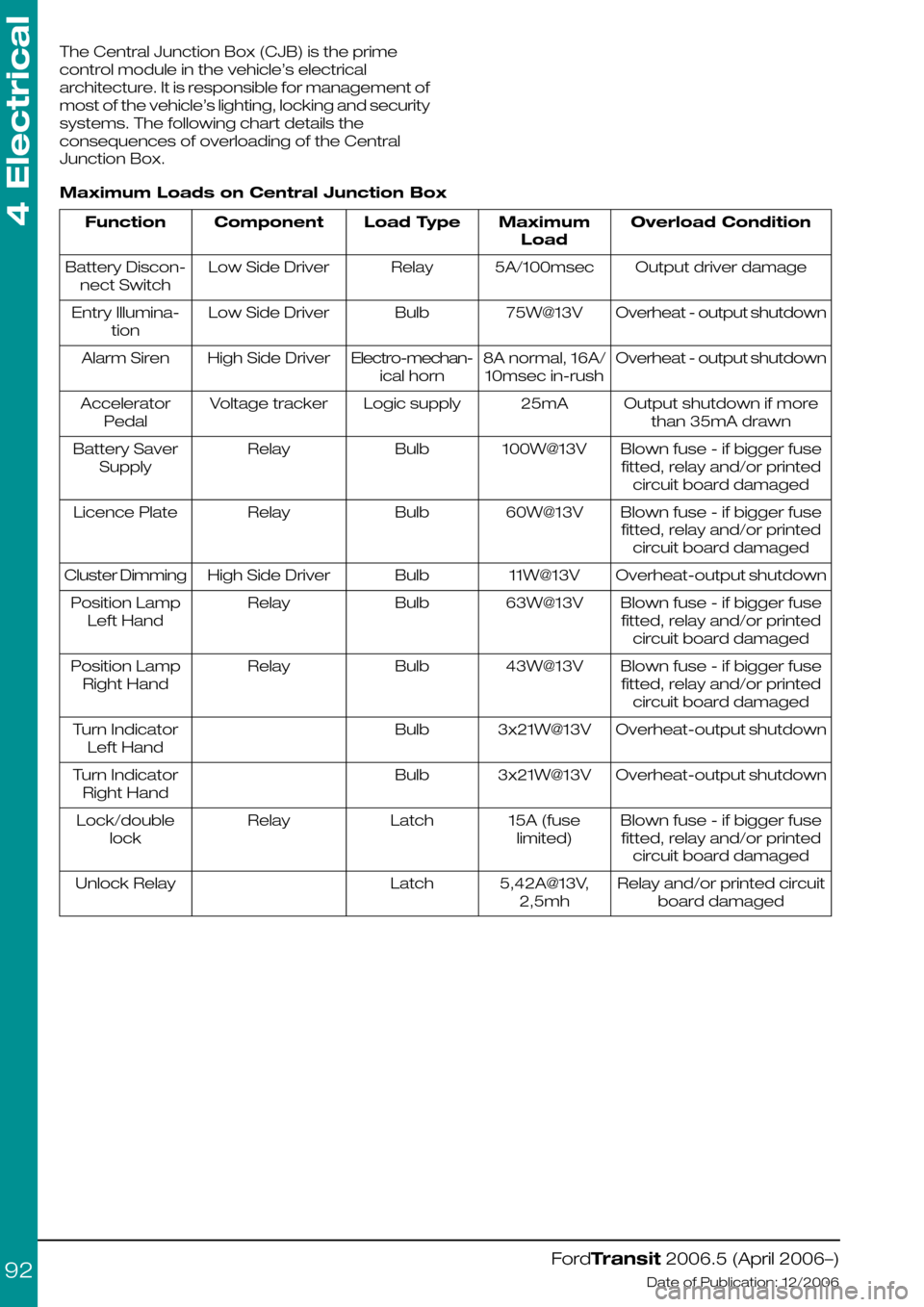

The Central Junction Box (CJB) is the prime

control module in the vehicle’s electrical

architecture. It is responsible for management of

most of the vehicle’s lighting, locking and security

systems. The following chart details the

consequences of overloading of the Central

Junction Box.

Maximum Loads on Central Junction Box

Overload ConditionMaximum

Load

Load TypeComponentFunction

Output driver damage5A/100msecRelayLow Side DriverBattery Discon-

nect Switch

Overheat - output shutdown75W@13VBulbLow Side DriverEntry Illumina-

tion

Overheat - output shutdown8A normal, 16A/

10msec in-rush

Electro-mechan-

ical horn

High Side DriverAlarm Siren

Output shutdown if more

than 35mA drawn

25mALogic supplyVoltage trackerAccelerator

Pedal

Blown fuse - if bigger fuse

fitted, relay and/or printed

circuit board damaged

100W@13VBulbRelayBattery Saver

Supply

Blown fuse - if bigger fuse

fitted, relay and/or printed

circuit board damaged

60W@13VBulbRelayLicence Plate

Overheat-output shutdown11W@13VBulbHigh Side DriverCluster Dimming

Blown fuse - if bigger fuse

fitted, relay and/or printed

circuit board damaged

63W@13VBulbRelayPosition Lamp

Left Hand

Blown fuse - if bigger fuse

fitted, relay and/or printed

circuit board damaged

43W@13VBulbRelayPosition Lamp

Right Hand

Overheat-output shutdown3x21W@13VBulbTurn Indicator

Left Hand

Overheat-output shutdown3x21W@13VBulbTurn Indicator

Right Hand

Blown fuse - if bigger fuse

fitted, relay and/or printed

circuit board damaged

15A (fuse

limited)

LatchRelayLock/double

lock

Relay and/or printed circuit

board damaged

5,42A@13V,

2,5mh

LatchUnlock Relay

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

92

Page 106 of 234

4.5 Climate Control System

WARNING: Do not use propylene

glycol based coolant

•Never secure hoses or tubes to the

transmission fill or dip stick or to any fuel

system or brake component

•Do not route heater or refrigerant lines near or

directly over any exhaust system component,

including the exhaust manifolds.

•Avoid routing of hoses in the wheelhouse or

stone kick-up arch. However, if routing is

required in these areas, shield against stone

pecking as appropriate.

•Do not route hoses near sharp edges. Utilize

guards to protect against cutting or chafing.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

106

Page 131 of 234

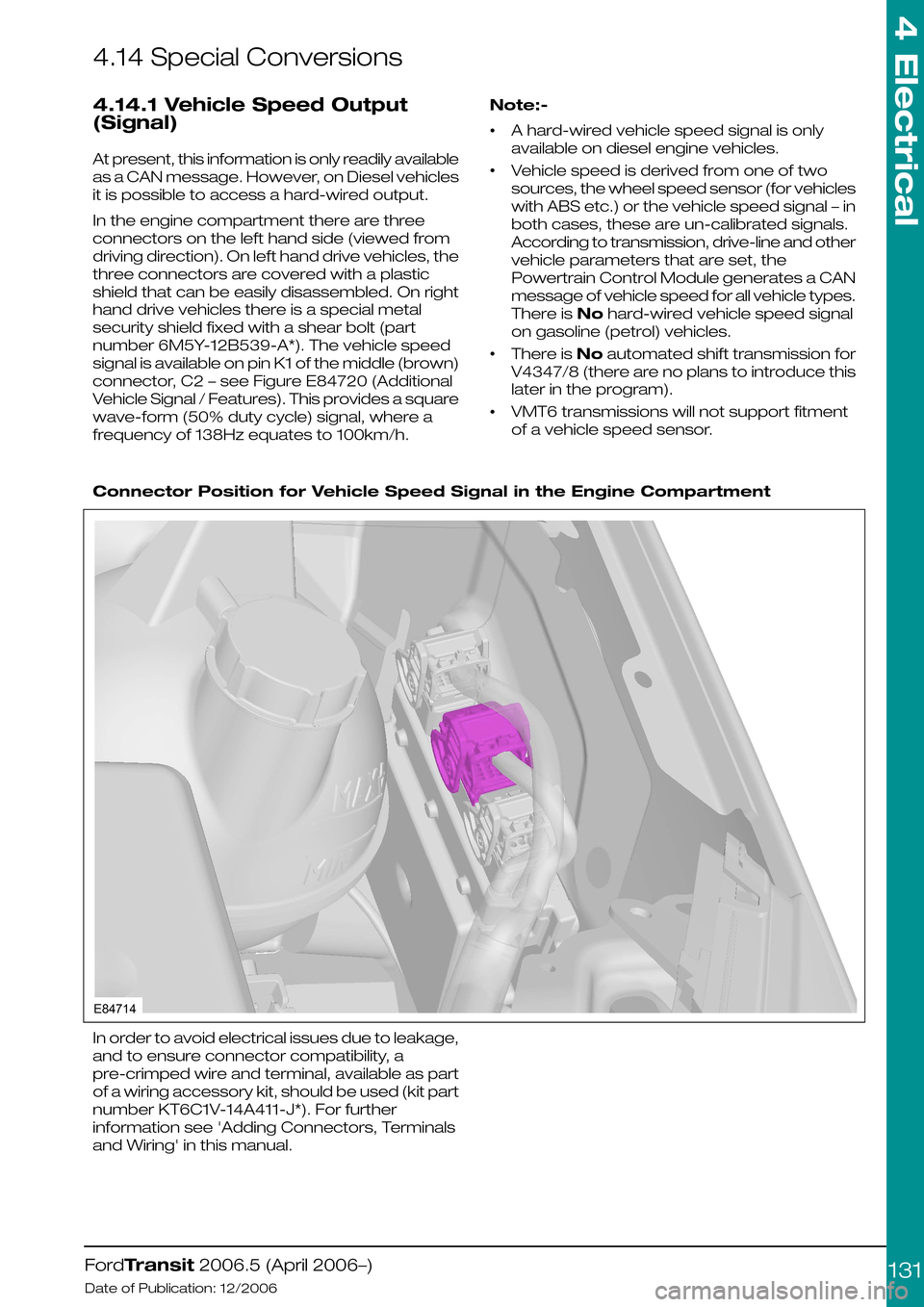

4.14 Special Conversions

4.14.1 Vehicle Speed Output

(Signal)

At present, this information is only readily available

as a CAN message. However, on Diesel vehicles

it is possible to access a hard-wired output.

In the engine compartment there are three

connectors on the left hand side (viewed from

driving direction). On left hand drive vehicles, the

three connectors are covered with a plastic

shield that can be easily disassembled. On right

hand drive vehicles there is a special metal

security shield fixed with a shear bolt (part

number 6M5Y-12B539-A*). The vehicle speed

signal is available on pin K1 of the middle (brown)

connector, C2 – see Figure E84720 (Additional

Vehicle Signal / Features). This provides a square

wave-form (50% duty cycle) signal, where a

frequency of 138Hz equates to 100km/h.

Note:-

•A hard-wired vehicle speed signal is only

available on diesel engine vehicles.

•Vehicle speed is derived from one of two

sources, the wheel speed sensor (for vehicles

with ABS etc.) or the vehicle speed signal – in

both cases, these are un-calibrated signals.

According to transmission, drive-line and other

vehicle parameters that are set, the

Powertrain Control Module generates a CAN

message of vehicle speed for all vehicle types.

There is No hard-wired vehicle speed signal

on gasoline (petrol) vehicles.

•There is No automated shift transmission for

V4347/8 (there are no plans to introduce this

later in the program).

•VMT6 transmissions will not support fitment

of a vehicle speed sensor.

Connector Position for Vehicle Speed Signal in the Engine Compartment

In order to avoid electrical issues due to leakage,

and to ensure connector compatibility, a

pre-crimped wire and terminal, available as part

of a wiring accessory kit, should be used (kit part

number KT6C1V-14A411-J*). For further

information see 'Adding Connectors, Terminals

and Wiring' in this manual.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

131E84714

Page 154 of 234

harness that provides roof-mounted rear turn

indicators, powered via relays. This should be

used in conjunction with SVO fusebox.

3.Chassis cab LED rear lamp cluster

replacement recommendations, especially

turn indicator relay implications – see lighting

load table. Generally the use of LED equivalent

lighting systems reduces the electrical load on

the vehicle; however, special care needs to

be taken with respect to any change to or

addition of turn indicator lights. Depending on

the current requirements of the LED(s)

compared to the bulb it is replacing, a ballast

resistor may be required, if not already

integrated into the LED lamp assembly.

Without this, bulb outage detection for turn

indicators will be affected, which is a legal

requirement.

Additional turn indicators must be powered

through relays (max 300mA), driven by existing

turn lights. The maximum load that the Central

Junction Box can drive is 3 x 21W per side (front,

rear and CAT 6 turn indicators); but even if the

vehicle is not fitted with the CAT 6 lights, the feeds

for these should not be used as the Central

Junction Box would need reconfiguring, which

could have safety as well as functional

implications.

4.Special Vehicle Option beacon switch: wiring

locations, circuit diagrams and max amperage

– see Special Vehicle Option fuse box

schematic (max current is 15A); there is

provision for the Special Vehicle Option beacon

switch in an empty switch location on the

instrument panel.

5.Rear loom connector detail location and supply

details for retro-fit loom extension for

example:- when extending a medium wheel

base, long wheel base or extended frame

overhang, what connectors do they use to

make a plug and play loom extension? – for

chassis cab vehicles, there is an Special

Vehicle Option extension loom for rear lamps

(part number 6C1V-14408-A*). There is not, at

present, a similar loom for Van, Bus and

Kombi's, although the appropriate mating

connector is now tooled, so this would be

possible.

Miscellaneous Systems

Handbrake on - Cluster Warning Light -

Unless the vehicle is specified with options that

drive the handbrake warning light (for example

ESP, Australia market), the components making

up this system are not fitted. We do not

recommend installation of this feature as an

aftermarket addition. There are several reasons

for this:

1.Not all circuits carry the requisite wire as a give

away:

•The wires might be part of the main vehicle

harness (14401) even if not used – for example

camper vehicles are normally ordered with

power mirrors, and the wires will be present

as a give-away.

•The seat pedestal harness (14K076), however,

is vehicle specific – if the handbrake is not part

of the specification, it will not be present or

give-away. This harness would need to be

changed to the compatible part that also

includes the handbrake warning light circuit.

2.The handbrake switch (part number

2F2T-15852-A*) together with its short jumper

harness (6C1T-15K857-A*) would need to be

obtained and fitted.

3.The handbrake warning light is in all clusters,

but unless the vehicle config. parameter

“parking brake switch” is set, the Central

Junction Box will not read this input, and hence

NO CAN message sent to the cluster.

Reconfiguration can only be done at a Ford

Dealer.

NOTE: If a vehicle already has a handbrake

warning light in the cluster, or one is installed as

per the Ford design, it is not possible to utilize the

wire from the handbrake switch as part of an

interlock circuit (this is a pull up resistor input that

provides a wetting current of 20mA – anything in

excess of this, for example through additional

circuitry, will almost certainly damage the Central

Junction Box). If there is no handbrake switch

installed, it would be possible to add one and

utilize this as part of a separate circuit, up to a

maximum current of 500mA through the switch.

Reverse Sensors (Rear Park Aid

Module)- The factory-fit option is a CAN-based

system, but for Van, Bus, and Kombi vehicles

only. Stand-alone systems can be installed (for

example for chassis cab conversions), but would

need to utilize the PTA line of the radio if muting

is required.

Fuel Fired Heater (FFH)- Add FFH: wiring is

only present (give-away) in certain harnesses.

There was an aftermarket kit available for this

system on current Transit, which could probably

be “updated” to suit V347/8.

Fuel Fired Heater (FFH) - Programmable

FFH: this utilizes a timer/control module mounted

to the Instrument Panel, which necessitates

having the correct Instrument Panel harness

fitted. Retrofit of this would be a difficult.

For both systems, the appropriate 6C1T-14K132

harness would be required (suffix -A* for

Programmable FFH, and suffix –B* for Add FFH).

Central Locking

Locking is controlled by the Central Junction Box

module. There is current sensing on certain

locking circuit pins as part of the security system

– if these are tampered with, locking cannot be

guaranteed.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

154

Page 155 of 234

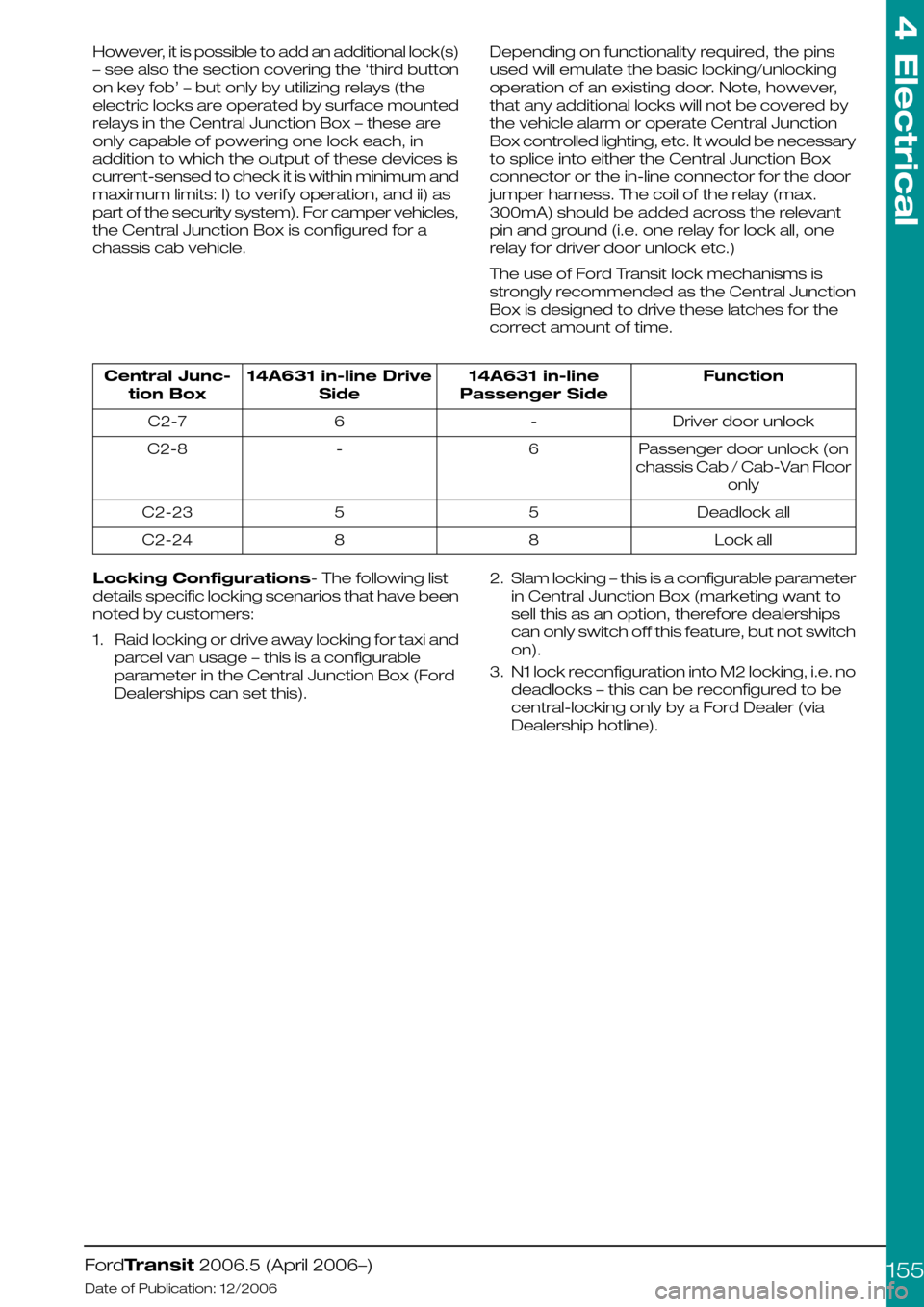

However, it is possible to add an additional lock(s)

– see also the section covering the ‘third button

on key fob’ – but only by utilizing relays (the

electric locks are operated by surface mounted

relays in the Central Junction Box – these are

only capable of powering one lock each, in

addition to which the output of these devices is

current-sensed to check it is within minimum and

maximum limits: I) to verify operation, and ii) as

part of the security system). For camper vehicles,

the Central Junction Box is configured for a

chassis cab vehicle.

Depending on functionality required, the pins

used will emulate the basic locking/unlocking

operation of an existing door. Note, however,

that any additional locks will not be covered by

the vehicle alarm or operate Central Junction

Box controlled lighting, etc. It would be necessary

to splice into either the Central Junction Box

connector or the in-line connector for the door

jumper harness. The coil of the relay (max.

300mA) should be added across the relevant

pin and ground (i.e. one relay for lock all, one

relay for driver door unlock etc.)

The use of Ford Transit lock mechanisms is

strongly recommended as the Central Junction

Box is designed to drive these latches for the

correct amount of time.

Function14A631 in-line

Passenger Side

14A631 in-line Drive

Side

Central Junc-

tion Box

Driver door unlock-6C2-7

Passenger door unlock (on

chassis Cab / Cab-Van Floor

only

6-C2-8

Deadlock all55C2-23

Lock all88C2-24

Locking Configurations- The following list

details specific locking scenarios that have been

noted by customers:

1.Raid locking or drive away locking for taxi and

parcel van usage – this is a configurable

parameter in the Central Junction Box (Ford

Dealerships can set this).

2.Slam locking – this is a configurable parameter

in Central Junction Box (marketing want to

sell this as an option, therefore dealerships

can only switch off this feature, but not switch

on).

3.N1 lock reconfiguration into M2 locking, i.e. no

deadlocks – this can be reconfigured to be

central-locking only by a Ford Dealer (via

Dealership hotline).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

155