suspension FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 3 of 234

1 General Information

1.1About This Manual........................6

1.1.1Introduction...........................................6

1.1.2Important Safety Instructions.............6

1.1.3Warnings, Cautions and Notes in This

Manual....................................................6

1.1.4How to Use This Manual.....................6

1.2Commercial and Legal Aspects...

7

1.2.1Terminology...........................................7

1.2.2Warranty on Ford Vehicles..................7

1.2.3Legal and Vehicle Type Approval....

7

1.2.4Alternative Type Approval....................7

1.2.5Legal Obligations and Liabilities..........7

1.2.6General Product Safety

Requirement..........................................7

1.2.7Product Liability.....................................8

1.2.8Restraints System................................8

1.2.9Drilling and Welding..............................8

1.2.10Minimum Requirements for Brake

system and Load Apportioning Valves

.................................................................8

1.2.11Road Safety...........................................8

1.3Contact Information.....................9

1.4Conversion Type.........................14

1.5Conversion Homologation.........23

1.6Electromagnetic Compatibility

(EMC)..........................................24

1.6.1Antenna Location...............................24

1.7Vehicle Duty Cycle Guidelines....25

1.7.1Conversion Affect on Fuel Economy

and Performance...............................25

1.7.2Vehicle Ride and Handling

Attributes.............................................25

1.8End of Life Vehicle (ELV)

Directive.....................................26

1.9Jacking.......................................27

1.10Lifting..........................................29

1.11Noise, Vibration and Harshness

(NVH)...........................................31

1.12Vehicle Transportation Aids and

Vehicle Storage..........................32

1.13Package and Ergonomics..........33

1.13.1General Component Package

Guidelines............................................33

1.13.2Driver Reach Zones...........................33

1.13.3Driver Field of View.............................33

1.13.4Conversion Affects on Parking Aids..

33

1.13.5Aids for Vehicle Entry and Exit..........33

1.14Package and

Ergonomics—Specifications......34

1.14.1Recommended Main Dimensions....

34

1.14.2Recommended Nominal Body

Lengths for Chassis Cab models....

36

1.14.3Front, Rear and Side Under-run

Protection............................................38

1.14.4Recommended Main Load Area

Dimensions for Bulkhead with

Depression Driver Side......................39

1.14.5Recommended Main Load Area

Dimensions for Bulkhead with Full

Depression..........................................40

1.14.6Recommended Main Load Area

Dimensions for Double Cab In Van

Bulkhead..............................................41

1.15Hardware—Specifications..........43

1.16Load Distribution—Specifications.

44

1.16.1Load Distribution Calculations - Driver

and Passenger Weight Distribution...

44

1.16.2Center of Gravity ...............................46

1.17Towing........................................54

1.17.1Towing Requirements.......................54

1.17.2Towing..................................................54

2 Chassis

2.1Suspension System....................57

2.2Front Suspension.......................58

2.2.1Springs and Spring Mounting...........58

2.3Rear Suspension........................59

2.3.1Springs and Spring Mounting...........59

2.3.2Rear Anti-Roll Bar...............................59

2.4Wheels and Tires........................60

2.4.1Wheel Clearance................................60

2.4.2Tire Manufacturers.............................60

2.4.3Spare wheel........................................60

2.4.4Painting Road Wheels.......................60

2.5Driveshaft....................................61

2.5.1Power Take Off....................................61

2.6Brake System.............................62

2.6.1General................................................62

2.6.2Kerb Mass Data..................................62

2.6.3Brake Hoses General........................62

2.7Parking Brake.............................63

2.7.1Relocated Parking Brake Lever.......63

2.8Hydraulic Brake Actuation.........64

2.8.1Load Apportioning Valves.................64

2.8.2Front and Rear Brakes......................64

2.9Anti-Lock Control - Stability

Assist..........................................65

3 Powertrain

3.1Engine.........................................66

3.1.1Engine Power Curves.......................66

3.2Engine Cooling............................75

3.2.1Auxiliary Heater Systems..................75

3.2.2Auxiliary Heater Installation...............76

3.2.3Air Flow Restrictions...........................76

3.3Accessory Drive.........................77

3.3.1Front End Accessory Drive 2.4l Diesel

and 2.3l Petrol.....................................77

3.3.2Front End Accessory Drive 2.2l

Diesel....................................................79

3.4Electronic Engine Controls.........81

3.5Clutch.........................................82

3.6Manual Transmission.................83

Table of Contents

3

Page 33 of 234

1.13 Package and Ergonomics

1.13.1 General Component

Package Guidelines

WARNING: Do not modify, drill, cut

or weld any suspension

components, specifically the

steering gear system, subframe or

anti-roll bars, springs or shock

absorbers including mounting

brackets.

The Vehicle Converter has to ensure that

sufficient clearance is maintained under all drive

conditions to moving components such as axles,

fans, steering, brake system etc.

The Vehicle Converter is responsible for all

installed components during the conversion. The

durability has to be confirmed by appropriate test

procedures.

1.13.2 Driver Reach Zones

Controls and/or equipment required to be used

while driving should be located within easy reach

of the driver so as not to impair driver control

1.13.3 Driver Field of View

WARNING: Make sure that the

modified vehicle complies with all

relevant legal requirements.

1.13.4 Conversion Affects on

Parking Aids

WARNING: Ensure that monitors

mounted in the cabin meet the

interior package and safety

requirements

On conversions requiring a rear camera, the

reverse signal may be taken as described in the

electrical section, described in reversing lamps.

Refer to: 4.11 Exterior Lighting (page 116).

1.13.5 Aids for Vehicle Entry and

Exit

Steps

WARNINGS:

Make sure that the modified vehicle

complies with all relevant legal

requirements.

If this modification alters the

homologated dimensions, a new

approval may be necessary.

CAUTION: Make sure that

reinforcements are installed to

maintain the integrity of the original

body structure.

Steps can be ordered as an option on the base

vehicle. Please check for availability.

Where additional steps are installed the required

ground clearance line is to be maintained.

The Vehicle Converter must make sure that a

movable step is set in the stored position when

the vehicle is running. The step surface must be

non-slip.

Grab Handles

WARNING: Make sure that the

location of the no-drill zones are

checked before drilling.

CAUTION: Make sure that

reinforcements are installed to

maintain the integrity of the original

body structure.

Grab handles can be ordered as an option on

the base vehicle. Please check for availability.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

33

Page 57 of 234

2.1 Suspension System

WARNING: Do not modify, drill, cut

or weld any suspension

components, specifically the

steering gear system, subframe or

anti-roll bars, springs or shock

absorbers including mounting

brackets.

CAUTION: Modifications to the

suspension system can cause a

deterioration of the vehicle handling

characteristics and durability.

NOTE: For detailed information please contact

the Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

57

Page 58 of 234

2.2 Front Suspension

2.2.1 Springs and Spring Mounting

WARNING: Do not modify, drill, cut

or weld any suspension

components, specifically the

steering gear system, subframe or

anti-roll bars, springs or shock

absorbers including mounting

brackets.

CAUTIONS:

When carrying out welding work the

springs must be covered to protect

them against weld splatter.

Do not touch springs with welding

electrodes or welding tongs.

Make sure that components

loosened or removed and reinstalled

are properly reassembled and the

torque set in accordance with

manufactures requirements.

NOTE: Do not modify the wheelbase or add any

type of frame extension to vehicles fitted with

Interactive Vehicle Dynamics (IVD)

NOTE: Do not damage the surface or corrosion

protection of the spring during disassembly and

installation.

NOTE: For detailed information please contact

the Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

58

Page 59 of 234

2.3 Rear Suspension

2.3.1 Springs and Spring

Mounting

WARNING: Do not modify, drill, cut

or weld any suspension

components, specifically the

steering gear system, sub-frame or

anti-roll bars, springs or shock

absorbers including mounting

brackets.

CAUTIONS:

When carrying out welding work the

springs must be covered to protect

them against weld splatter.

Do not touch springs with welding

electrodes or welding tongs.

Make sure that components

loosened or removed and reinstalled

are properly reassembled and the

torque set in accordance with

manufactures requirements.

NOTE: Do not modify the wheelbase or add any

type of frame extension to vehicles fitted with

Interactive Vehicle Dynamics (IVD)

NOTE: Do not damage the surface or corrosion

protection of the spring during disassembly and

installation.

NOTE: For detailed information please contact

the Vehicle Converter Advisory Service at

[email protected].

2.3.2 Rear Anti-Roll Bar

Remove the rear anti-roll bar on Chassis Cabs,

except on:

•330 and 350 Front Wheel Drive Chassis Cabs

with Box Body or with another conversion that

gives a similar or higher Centre of Gravity

(CoG) height.

•Dual Rear Wheel Chassis Cabs with Box Body

or with another conversion that gives a similar

or higher Centre of Gravity (CoG) height

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

59

Page 60 of 234

2.4 Wheels and Tires

2.4.1 Wheel Clearance

The distance from the tire to the mudguard or

wheel arch must be sufficient, even if snow or

anti-skid chains are fitted and the suspension is

fully compressed allowing for axle twist as well.

Please consult the Vehicle Converter Advisory

Service [email protected] for clearance

requirements and data.

NOTE: Make sure that only approved wheels

and /or permissible tire sizes are fitted

For standard wheelhouse dimensions.

Refer to: 5.1 Body (page 175).

(Integral Bodies and Conversions)

2.4.2 Tire Manufacturers

Replacement tires should be of the same make,

size, tread pattern and load rating as the Original

Equipment Manufacturer. Under these conditions

the original tire label should be satisfactory,

however if the specified tires and/or inflation

pressures are changed then a new label should

be affixed over the original label.

2.4.3 Spare wheel

When converting or relocating the spare wheel,

access must be ensured.

2.4.4 Painting Road Wheels

CAUTION: Do not paint wheel clamp

surfaces in contact with other

wheels, brake drum or disc, hub and

holes, or surfaces under wheel nuts.

Any further treatment in these areas

may affect the wheel clamp

performance and the vehicle safety.

•Mask the wheel when changing the color or

repairing paint.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

60

Page 158 of 234

NOTE: A power take off layout can only be

implemented on vehicles fitted with an ABS

braking system. Manual braking systems employ

a transmission speed sensor to determine vehicle

speed & the RPM speed control software

contains vehicle speed restrictions which prohibit

RPM speed control operation if vehicle speed is

detected above very low levels (approx 2.5 mph).

A vehicle fitted with an ABS braking system

derives vehicle speed via the vehicles wheel

speed sensors, so the transmission can operate

normally without effecting RPM speed control

operation.

3 Modes of Operation

There are 3 principle modes in which this feature

can operate, they are:

1.3 speed mode – this provides the end user a

choice of up to 3 preset RPM values to select

from. The end user cannot easily override

these values so there is minimal risk of damage

to ancillary equipment due to it being run at

speeds it was not designed for. Very limited

vehicle speed is allowable while in this mode

(up to 2.5mph approx)

2.Variable speed mode – this provides the end

user with RPM speed ramp up & down

buttons. The end user is free to select RPM

values between 1300-3000rpm in 25rpm

steps. A single press results in a 25 rpm jump.

If a ramp button is held depressed by the end

user then the rate of change is 250rpm/sec.

Very limited vehicle speed is allowable while in

this mode (up to 2.5mph approx)

3.Idle up speed – this mode allows the engines

normal idle to be increased to any value (in 25

rpm steps) in the range 900-1200rpm. There

is not a vehicle speed restriction in this mode

as the intended use is to raise the engine idle

to reduce the likelihood of engine stall when

ancillary equipment is being run from the

engine during normal drive operations. Eg

refrigerator units used to keep the cargo bay

cool.

NOTE: Items 1) & 2) will be available from Nov

2006, while item 3) should be available from Jan

2007. Any latest generation diesel Transit can be

updated to include item 3) Idle up speed with a

simple calibration update once it becomes

available.

System Availability

This feature is built into the latest Powertrain

Control Module (PCM) software on all diesel

engine variants.

By default the feature is not enabled unless the

vehicle is specifically ordered with the feature

from the factory.

Vehicles which have not been ordered with this

feature may have the feature enabled at a dealer

via the IDS diagnostics system. The dealer should

charge for this service.

How to control this feature

A loop of wire (green/white) is provided in the

main electrical loom to permit control of the RPM

Speed Control software. Cutting this loop will

provide two wires to connect a control box to the

PCM.

The control box needs to switch resistors into the

circuit across the two green/white wires which

formally formed the loop prior to being cut. This

sort of circuit is known as a resistance ladder. The

PCM software monitors the green/white wire

circuit & when certain resistances are detected

they are interpreted as various inputs which

control the feature. The switch box can be

located where it’s ideally required for the vehicle

conversion in question, rather than having to be

mounted on the Instrument Panel (IP). If the

converter chooses to locate the switch box in a

location which is subject to an adverse

environment then the converter should design

the switch box to withstand with these conditions.

How to locate the green/white loop

The main electrical loom enters the vehicle cab

from the engine bay on the left hand side of the

vehicle via a large diameter hole in the engine bay

/ cabin bulkhead. This hole is just above the left

hand front suspension turret. See following Figure

E88307

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

158

Page 230 of 234

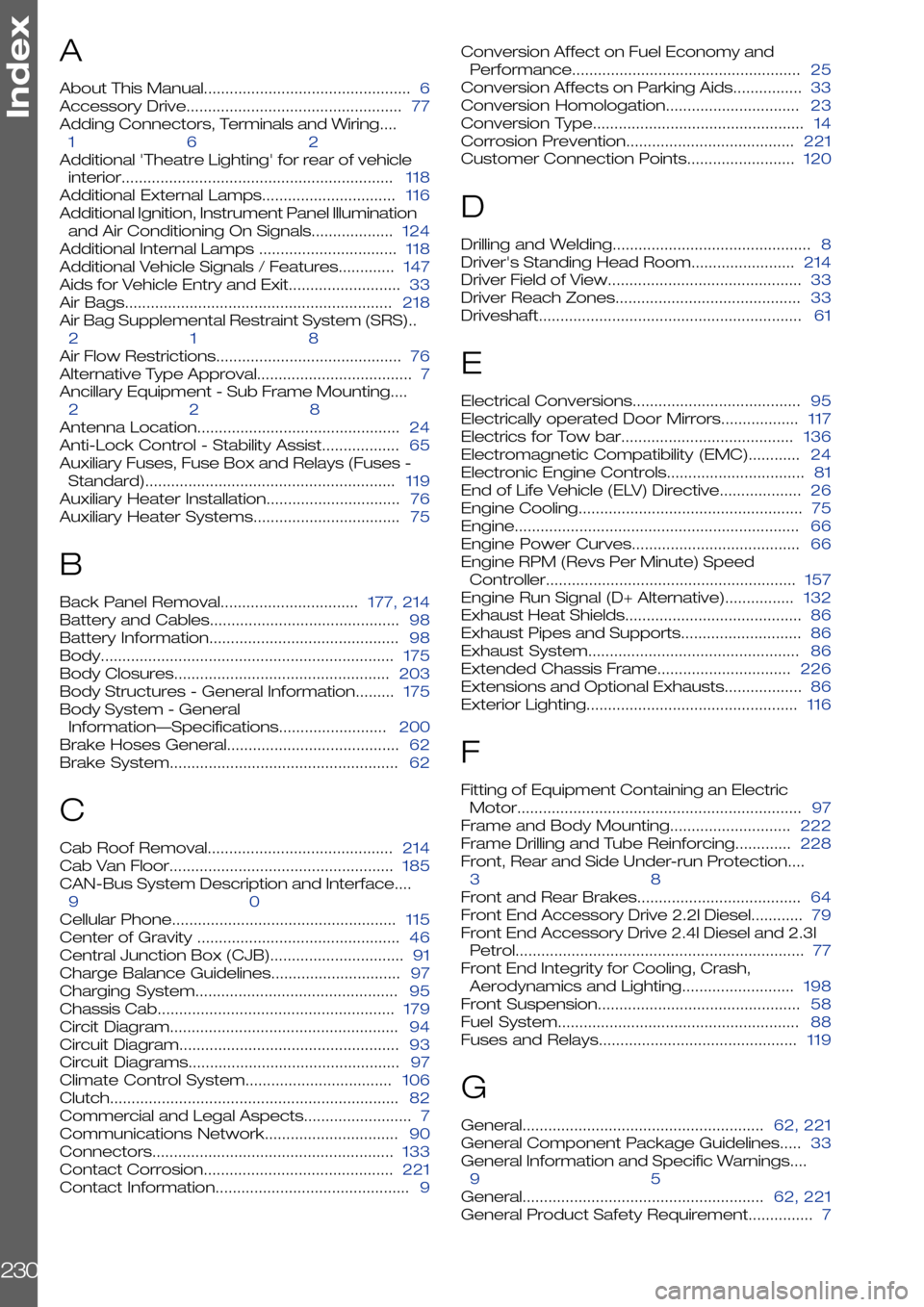

A

About This Manual................................................6

Accessory Drive..................................................77

Adding Connectors, Terminals and Wiring....

162

Additional 'Theatre Lighting' for rear of vehicle

interior...............................................................118

Additional External Lamps...............................116

Additional Ignition, Instrument Panel Illumination

and Air Conditioning On Signals...................124

Additional Internal Lamps ................................118

Additional Vehicle Signals / Features.............147

Aids for Vehicle Entry and Exit..........................33

Air Bags..............................................................218

Air Bag Supplemental Restraint System (SRS)..

218

Air Flow Restrictions...........................................76

Alternative Type Approval....................................7

Ancillary Equipment - Sub Frame Mounting....

228

Antenna Location...............................................24

Anti-Lock Control - Stability Assist..................65

Auxiliary Fuses, Fuse Box and Relays (Fuses -

Standard)..........................................................119

Auxiliary Heater Installation...............................76

Auxiliary Heater Systems..................................75

B

Back Panel Removal................................177, 214

Battery and Cables............................................98

Battery Information............................................98

Body....................................................................175

Body Closures..................................................203

Body Structures - General Information.........175

Body System - General

Information—Specifications.........................200

Brake Hoses General........................................62

Brake System.....................................................62

C

Cab Roof Removal...........................................214

Cab Van Floor....................................................185

CAN-Bus System Description and Interface....

90

Cellular Phone....................................................115

Center of Gravity ...............................................46

Central Junction Box (CJB)...............................91

Charge Balance Guidelines..............................97

Charging System...............................................95

Chassis Cab.......................................................179

Circit Diagram.....................................................94

Circuit Diagram...................................................93

Circuit Diagrams.................................................97

Climate Control System..................................106

Clutch...................................................................82

Commercial and Legal Aspects.........................7

Communications Network...............................90

Connectors........................................................133

Contact Corrosion............................................221

Contact Information.............................................9

Conversion Affect on Fuel Economy and

Performance.....................................................25

Conversion Affects on Parking Aids................33

Conversion Homologation...............................23

Conversion Type.................................................14

Corrosion Prevention.......................................221

Customer Connection Points.........................120

D

Drilling and Welding..............................................8

Driver's Standing Head Room........................214

Driver Field of View.............................................33

Driver Reach Zones...........................................33

Driveshaft.............................................................61

E

Electrical Conversions.......................................95

Electrically operated Door Mirrors..................117

Electrics for Tow bar........................................136

Electromagnetic Compatibility (EMC)............24

Electronic Engine Controls................................81

End of Life Vehicle (ELV) Directive...................26

Engine Cooling....................................................75

Engine..................................................................66

Engine Power Curves.......................................66

Engine RPM (Revs Per Minute) Speed

Controller..........................................................157

Engine Run Signal (D+ Alternative)................132

Exhaust Heat Shields.........................................86

Exhaust Pipes and Supports............................86

Exhaust System.................................................86

Extended Chassis Frame...............................226

Extensions and Optional Exhausts..................86

Exterior Lighting.................................................116

F

Fitting of Equipment Containing an Electric

Motor..................................................................97

Frame and Body Mounting............................222

Frame Drilling and Tube Reinforcing.............228

Front, Rear and Side Under-run Protection....

38

Front and Rear Brakes......................................64

Front End Accessory Drive 2.2l Diesel............79

Front End Accessory Drive 2.4l Diesel and 2.3l

Petrol...................................................................77

Front End Integrity for Cooling, Crash,

Aerodynamics and Lighting..........................198

Front Suspension...............................................58

Fuel System........................................................88

Fuses and Relays..............................................119

G

General........................................................62, 221

General Component Package Guidelines.....33

General Information and Specific Warnings....

95

General........................................................62, 221

General Product Safety Requirement...............7

Index

230

Page 231 of 234

Generator and Alternator...............................103

Glass, Frames and Mechanisms...................211

Ground Points..................................................140

H

Hardware—Specifications...............................43

Heated Seats...................................................210

Heated Windshield and Heated Rear Window.

213

Horn...................................................................108

How to Use This Manual....................................6

Hydraulic Brake Actuation...............................64

Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab...........................................186

I

Important Safety Instructions............................6

Information and Entertainment System -

General Information—Specifications...........112

Installation and Routing Guides.....................134

Instrument Cluster...........................................107

Integrated Bodies and Conversions.............177

Interior Lighting.................................................118

Introduction..........................................................6

J

Jacking................................................................27

K

Kerb Mass Data.................................................62

L

Lamps for Wide Vehicles.................................117

Lamps – Front and Rear Fog Lights..............117

Lamps – Hazard / Direction Indication..........117

Legal and Vehicle Type Approval......................7

Legal Obligations and Liabilities.........................7

Legislation.........................................................109

Lifting...................................................................29

Load Apportioning Valves................................64

Load Compartment Interior Lining...............203

Load Distribution—Specifications...................44

Load Distribution Calculations - Driver and

Passenger Weight Distribution.....................44

M

Manual Transmission........................................83

Minimum Requirements for Brake system and

Load Apportioning Valves ...............................8

Mirrors for Wide Vehicles...............................208

Module Communications

Network—Specifications................................94

Mounting Points and Tubing.........................222

N

Noise, Vibration and Harshness (NVH)...........31

Non Standard Rear Chassis Frame Extension.

226

P

Package and Ergonomics—Specifications....

34

Package and Ergonomics...............................33

Painting Road Wheels..............................60, 221

Parking Brake....................................................63

Partitions (Bulkhead) - Driver and Front

Passenger(s) Protection on Van, Bus and

Kombi..............................................................192

Possible Accessories.......................................113

Power Management Settings.........................95

Power Take Off...................................................61

Product Liability....................................................8

R

Racking Systems.............................................194

Radio Connector..............................................112

Rear Anti-Roll Bar..............................................59

Rear Seat Fixings Positions - Kombi............209

Rear Suspension...............................................59

Rear View Mirrors...........................................208

Rear Windows..................................................211

Recommended Main Dimensions.................34

Recommended Main Load Area Dimensions

for Bulkhead with Depression Driver Side....

39

Recommended Main Load Area Dimensions

for Bulkhead with Full Depression................40

Recommended Main Load Area Dimensions

for Double Cab In Van Bulkhead...................41

Recommended Nominal Body Lengths for

Chassis Cab models......................................36

Relays and Switches.......................................127

Relocated Parking Brake Lever......................63

Repairing Damaged Paint..............................221

Restraints System...............................................8

Reversing Lamps.............................................116

Road Safety..........................................................8

Roof Opening Panel........................................214

Roof Racks.......................................................216

Roof Ventilation................................................215

S

Safety Belt System.........................................220

Seats.................................................................209

Security, Anti Theft and Locking System

Security ..........................................................203

Self-Supporting Body Structure...................224

Spare Tire Access and Mounting.................229

Spare wheel.......................................................60

Special Conversions........................................131

Special Vehicle Option Auxiliary Fuse Box....

121

Index

231

Page 232 of 234

Special Vehicle Options (SVO) and Aftermarket

Kits....................................................................146

Springs and Spring Mounting....................58, 59

Suspension System...........................................57

T

Tachograph Mounting......................................110

Tachograph.......................................................109

Tank and Dry Bulk Carriers..............................199

Terminology...........................................................7

Tipper Bodies....................................................199

Tire Manufacturers.............................................60

Towing Requirements.......................................54

Towing..................................................................54

U

Under Body Protection and Material.............221

V

Van Floor - Load Compartment Tie Downs for

Van ,Bus and Kombi......................................200

Vehicle Duty Cycle Guidelines..........................25

Vehicle Electrical Capacity - Alternator...........97

Vehicle Ride and Handling Attributes..............25

Vehicle Speed Output (Signal)........................131

Vehicle Transportation Aids and Vehicle

Storage..............................................................32

W

Warnings, Cautions and Notes in This Manual..

6

Warranty on Ford Vehicles..................................7

Wheel Clearance................................................60

Wheels and Tires................................................60

Windscreen wipers..........................................130

Wiring Specification...........................................119

Index

232