WIRING HARNESS FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 75 of 234

3.2 Engine Cooling

3.2.1 Auxiliary Heater Systems

WARNINGS:

Ford coolant additives are

necessary for the complete function

of the system. Only use ford

approved or equivalent specification

component, to withstand any

detrimental effects on the materials.

Do not mount components in front

of the grille or in an area of air flow

around the engine, which could

affect the engine cooling.

CAUTIONS:

Only make connections into the

heater hose between the front cab

heater and water pump return inlet.

Do not exceed the vehicle's original

coolant volume by more than 10%

Only use the manufactures

recommended (or equivalent

specification) coolant

additives/anti-freeze. Do not mix

coolant types.

•Coolant flow to cab heater must have priority

over flow to auxiliary heater or hand wash

facility.

•Coolant tube routing must be below the base

of the degas bottle.

•Use aluminum or plastic tee junction with

swaged or beaded ends to prevent hose blow

off. Reconnect original coolant tube as shown

in view E74570 (in this section) with standard

Ford water hose clip or suitable equivalent

specification clip. Ensure interference fit

between hose and 'T' joint.

•Tube routing must be secured to the body

structure or suitable brackets avoiding

electrical components or wires, hot or moving

parts and brake or fuel system components

•Hose must be heat sleeved with appropriate

material if within 100mm of exhaust

components (for example, manifold or

exhaust gas recirculating).

•The vertical clearance between the critical

cooling components (radiator, fan shroud and

radiator brackets) and both the hood inner

and outer (assembly) panels at design position

shall not be less than 15mm.

•There shall be a minimum clearance of 7mm

between the engine assembly and flexible

components (for example, hoses or wiring

harnesses) affixed to front end sheet metal

hardware, under a maximum engine torque

roll condition.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

75

Page 97 of 234

•Before disconnecting the battery, check

availability of radio key code.

•Fuses – when auxiliary electrical systems are

to be added to the vehicle it is mandatory that

the additional circuit design includes the

necessary fuses.

•The Special Vehicle Option auxiliary fuse box

is recommended.

Refer to: 4.13 Fuses and Relays (page 119).

4.3.4 Fitting of Equipment

Containing an Electric Motor

WARNINGS:

When equipment containing an

electrical motor is connected, it

must be connected via a blocking

diode or relay to prevent “back

Electro Motive Force (EMF)” being

applied to the auxiliary terminal.

When electric motors are to be

fitted, account must be taken of the

potentially high currents that a

motor can draw.

CAUTION: The following must be

observed:

•All motors must be driven via relays with

contacts rated at least 3 times the maximum

rated current of the motor.

•All motor supply circuits must be individually

fused with the proper fuse rating for the

motor.

•All power wiring must be rated for at least 3

times the rating of the motor and installed as

far away as possible from any existing vehicle

wiring.

•All motors fitted should be fully suppressed to

ensure electrical interference does not affect

the vehicle systems.

•Add EMC emissions statement to CE

approval.

4.3.5 Vehicle Electrical Capacity

- Alternator

WARNING: Do not cut into the

alternator wires or use the

alternator as a source to obtain a

'D+ Signal'

An engine run signal is available from the Central

Junction Box by installing a T-piece jumper

harness (Ford Part Number 6C1V-14A411-F_).

Refer to: 4.14 Special Conversions (page 131).

4.3.6 Charge Balance Guidelines

The base vehicle is fitted with a 150A alternator.

It is recommended to conduct a charge balance

calculation in case the conversion comprises a

high number of electrical consumers or high

electrical consumption is expected.

4.3.7 Circuit Diagrams

For circuit diagrams for Auxiliary Fuse Box

Connections and Standard Ford relays.

Refer to: 4.13 Fuses and Relays (page 119).

Full vehicle wiring and circuit diagrams are in the

Ford Workshop Manual.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

97

Page 100 of 234

Pull-in us actuvated within 70 ms of switching to

key position II

Pull-out is activated when switching to key

position I, or 0, and in key position II when no

engine run signal is sensed within 120 secs.

It is not possible to change state within 500 ms.

Removal of the Battery Disconnect

Switch (on twin battery models) and

wiring of batteries in parallel for high

current applications.

For vehicles equipped with a twin battery system,

wiring of the two batteries in parallel is not

recommended. If higher current is required,

680Ah batteries can be fitted (or a deep cycle

battery in lieu of the non-start relevant battery

only). Where a single passenger seat is fitted,

further batteries (1 or 2) can be installed in the

pedestal and added in parallel to the

non-start-relevant battery, although due

consideration then needs to be given to

increased current availability in the event of a

short circuit. Additional batteries should not be

installed under a passenger bench seat.

if this requirement is imperative, it would be

possible to disconnect the battery disconnect

switch and put the start-relevant and

non-start-relevant batteries in parallel using a

shorting bar (available from the Ford Delerships,

part number 6C1T-14A439-A*). There is one

important consideration when replacing the

battery disconnect switch with a shorting bar:

•Where the vehicle is configured for

twin-battery operation, the Central Junction

Box will detect if the battery disconnect switch

is missing (or has been removed), or the

mating connector short-circuited, and although

the vehicle will be functional, Diagnostic

Trouble Codes will be generated that will

flag-up during service. Hence if a shorting bar

is fitted, the vehicle needs to be reconfigured

(via the Dealership and Dealership Hotline).

Single to Dual Battery Conversion

For vehicles equipped with a single battery, it is

possible to upgrade to a twin battery system -

the connector for the battery disconnect switch

is present on all vehicles. In addition to

reconfiguring the vehicle for twin battery

operation (at a Dealership), the following battery

cables and components are required:

DescriptionPart Number

start relevant battery negative to vehicle ground point cable (right hand)

replaces C_ part

6C1T-14301-A_

start relevant battery negative to vehicle ground point cable (lefthand)

replaces D_ part

6C1T-14301-E_

start relevant battery negative to non-start relevant battery negative cable6C1T-14280-E_

pre-fuse box bus bar to non-start-relevant battery positive cable6C1T-14300-D_

Battery disconnect switch6C1T-10B728-A_

If a requirement exists (camper conversions for

example), it may be viable to order vehicles

installed with a single battery, a battery disconnect

switch, and a kit of harnesses – detailed above –

to be fitted by the installer.

Where required, e.g. for camper conversions,

gas-sealed battery boxes (with exterior venting)

are available. Ford part numbers:

6C1T-10N669-A_ (lefthand); 6C1T-10N669-B_

(right hand); 6C1T-10N725-A_ (lid).

The battery disconnect switch isolates the

auxiliary battery/batteries from the rest of the

base vehicle electrical system when the engine

is stopped.

The battery disconnect switch, together with

associated wiring and hardware, can be fitted as

part of an accessory kit (available from your local

Ford dealer) in the pre-fuse box.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

100

Page 110 of 234

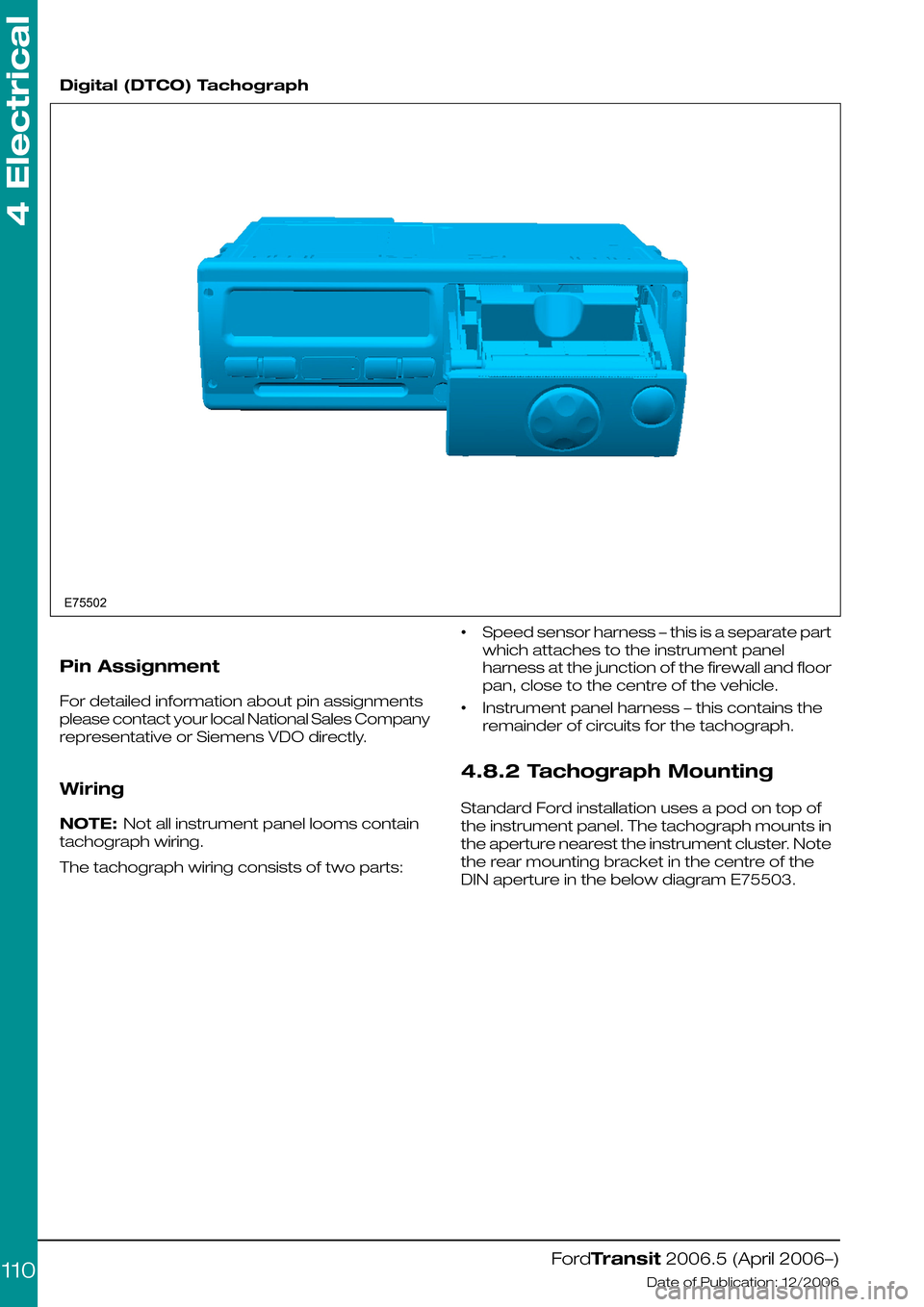

Digital (DTCO) Tachograph

Pin Assignment

For detailed information about pin assignments

please contact your local National Sales Company

representative or Siemens VDO directly.

Wiring

NOTE: Not all instrument panel looms contain

tachograph wiring.

The tachograph wiring consists of two parts:

•Speed sensor harness – this is a separate part

which attaches to the instrument panel

harness at the junction of the firewall and floor

pan, close to the centre of the vehicle.

•Instrument panel harness – this contains the

remainder of circuits for the tachograph.

4.8.2 Tachograph Mounting

Standard Ford installation uses a pod on top of

the instrument panel. The tachograph mounts in

the aperture nearest the instrument cluster. Note

the rear mounting bracket in the centre of the

DIN aperture in the below diagram E75503.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

110E75502

Page 113 of 234

Connector B

Mono -7Mono +1

Radio Remote Control Ground8Switched Accessory +2

Auxiliary Left -9Auxiliary Left +3

Auxiliary Right -10Auxiliary Right +4

-11Phone Transceiver Active5

-12Radio Remote Control +6

Connector C

-7-1

-8-2

-9-3

-10-4

Auxiliary 2 Right11Auxiliary 2 Left5

-12Audio Ground6

Fuse Relay

no fuse is fitted to the radio1

no fuse is fitted to the radio2

4.9.2 Possible Accessories

Electric Antenna- Activation line, pin B2

(Switched Accessory +) is switched: 0 Volts when

the radio is switched off and +12 Volts when the

radio is switched on.

Auxiliary Input- Accepts a line-out from a

personal stereo or digital media player. This can

be supported by left channel pin C5 (+) and right

channel pin C11 (+) with a common ground, pin

C6, wired to a jack plug socket.

Audio Mute- There is a requirement under the

Health and Safety Machinery Directive to mute

the radio when machinery is in operation - this is

necessary to hear audible alarms and signals.

Pin B5 (C3-5 on the electrical schematic) on the

FAKRA interface should be used for this. In order

to avoid electrical issues due to leakage, and to

ensure connector compatibility, a connector

insert and a pre-crimped wire and terminal are

available as part of a wiring accessory kit, should

be used (Kit Part number KT6C1V-14A411-L*).

NOTE: When this line is pulled low (ground),

radio / CD sound is muted. However, there is no

wire present in the harness as this function is

normally communicated through the CAN bus.

Refer to: 4.14 Special Conversions (page 131).

(Adding Connectors, Terminals and Wiring)

After Market Hands Free Telephone Kit

(Non CAN-based)- Power should be supplied

via a fused battery line and activated by the

accessory line, pin A16. The mute line from the

phone is connected to Phone Transceiver Active,

pin B5. The audio output from the phone kit

should be fed into pins B1 (+) and B7 (–). The

phone audio is then amplified and diverted

through vehicle speakers.

Refer to: 4.14 Special Conversions (page 131).

Adding Connectors, Terminals and Wiring (for

Phone Transceiver Active / Speaker Terminals

and Wires).

After Market Audio / Navigation (Non

CAN-based)- Power should be supplied via a

fused battery line and activated by accessory

line, pin A16. Auxiliary input is connected as per

above.

NOTE: Note: Vehicle speed and reverse are

now CAN messages and supplied via the vehicle

multimedia bus, A9 (+) and A10 (-). There is no

hard wired Vehicle Speed Signal or reverse signal

available.

Additional Rear Speakers- Camper

vehicles, typically, are only equipped with

speakers in the front doors, in which case at

end-of-line the vehicle will be programmed for

just the front speakers and the fade function

disabled on the radios. If the radio is set for four

speakers, and those at the rear are absent, a

fault code will be flagged. The vehicle would need

reconfiguring at a Dealer once speakers are

installed. The radio will output 17W per channel

(left and right); a wire size with a CSA of 0.75 is

recommended.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

113

Page 114 of 234

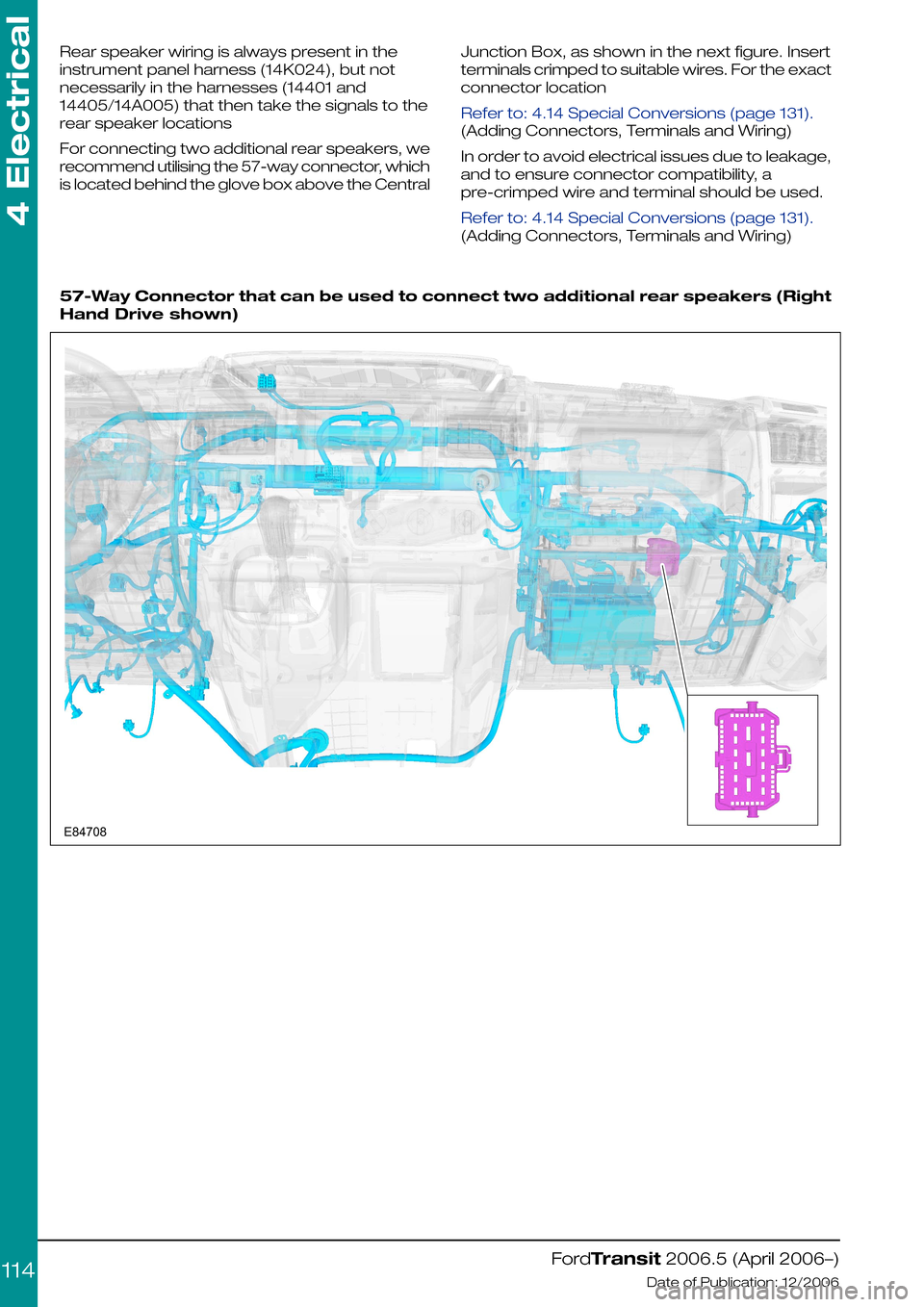

Rear speaker wiring is always present in the

instrument panel harness (14K024), but not

necessarily in the harnesses (14401 and

14405/14A005) that then take the signals to the

rear speaker locations

For connecting two additional rear speakers, we

recommend utilising the 57-way connector, which

is located behind the glove box above the Central

Junction Box, as shown in the next figure. Insert

terminals crimped to suitable wires. For the exact

connector location

Refer to: 4.14 Special Conversions (page 131).

(Adding Connectors, Terminals and Wiring)

In order to avoid electrical issues due to leakage,

and to ensure connector compatibility, a

pre-crimped wire and terminal should be used.

Refer to: 4.14 Special Conversions (page 131).

(Adding Connectors, Terminals and Wiring)

57-Way Connector that can be used to connect two additional rear speakers (Right

Hand Drive shown)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

114E84708

Page 125 of 234

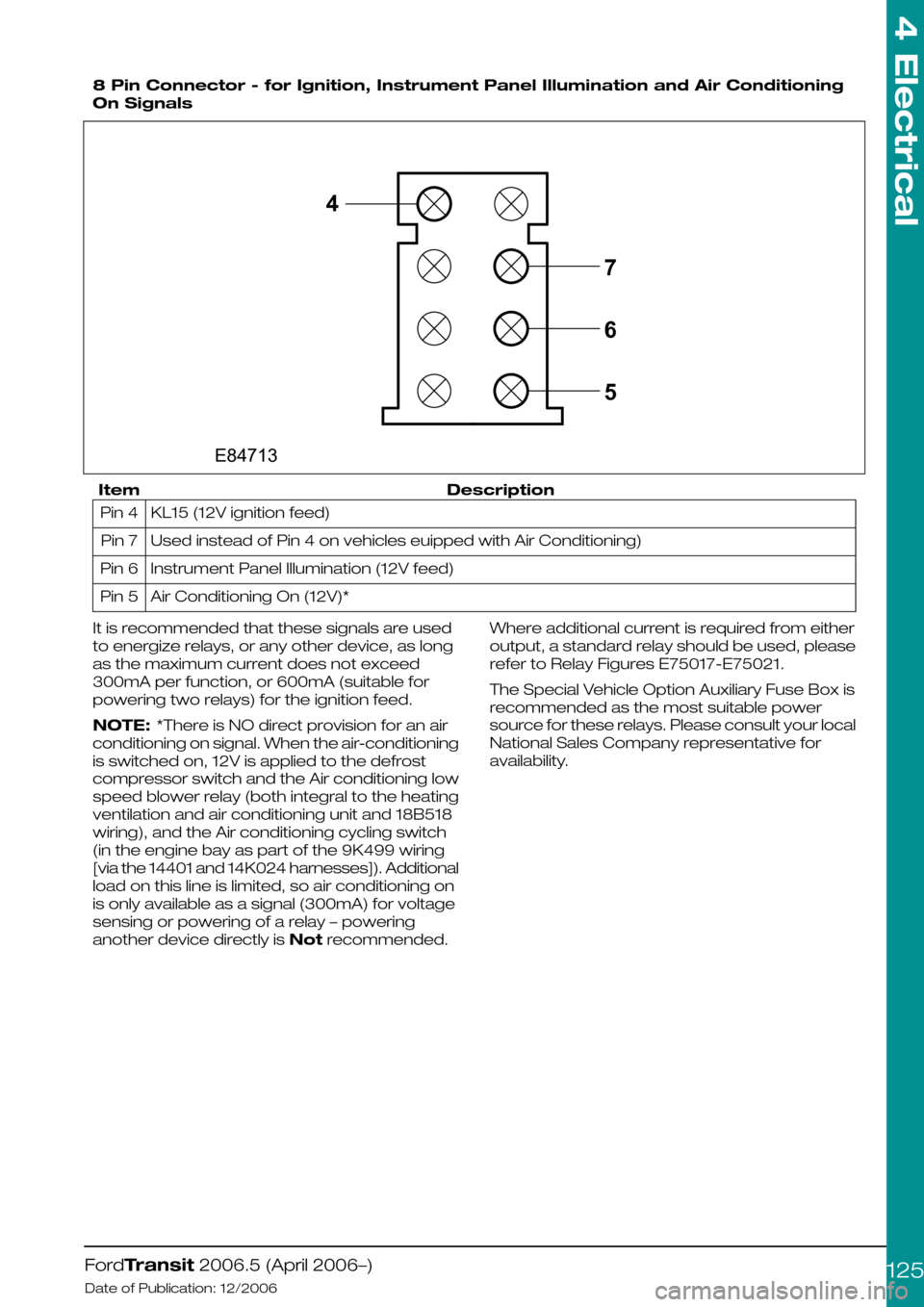

8 Pin Connector - for Ignition, Instrument Panel Illumination and Air Conditioning

On Signals

DescriptionItem

KL15 (12V ignition feed)Pin 4

Used instead of Pin 4 on vehicles euipped with Air Conditioning)Pin 7

Instrument Panel Illumination (12V feed)Pin 6

Air Conditioning On (12V)*Pin 5

It is recommended that these signals are used

to energize relays, or any other device, as long

as the maximum current does not exceed

300mA per function, or 600mA (suitable for

powering two relays) for the ignition feed.

NOTE: *There is NO direct provision for an air

conditioning on signal. When the air-conditioning

is switched on, 12V is applied to the defrost

compressor switch and the Air conditioning low

speed blower relay (both integral to the heating

ventilation and air conditioning unit and 18B518

wiring), and the Air conditioning cycling switch

(in the engine bay as part of the 9K499 wiring

[via the 14401 and 14K024 harnesses]). Additional

load on this line is limited, so air conditioning on

is only available as a signal (300mA) for voltage

sensing or powering of a relay – powering

another device directly is Not recommended.

Where additional current is required from either

output, a standard relay should be used, please

refer to Relay Figures E75017-E75021.

The Special Vehicle Option Auxiliary Fuse Box is

recommended as the most suitable power

source for these relays. Please consult your local

National Sales Company representative for

availability.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

1254E84713765

Page 133 of 234

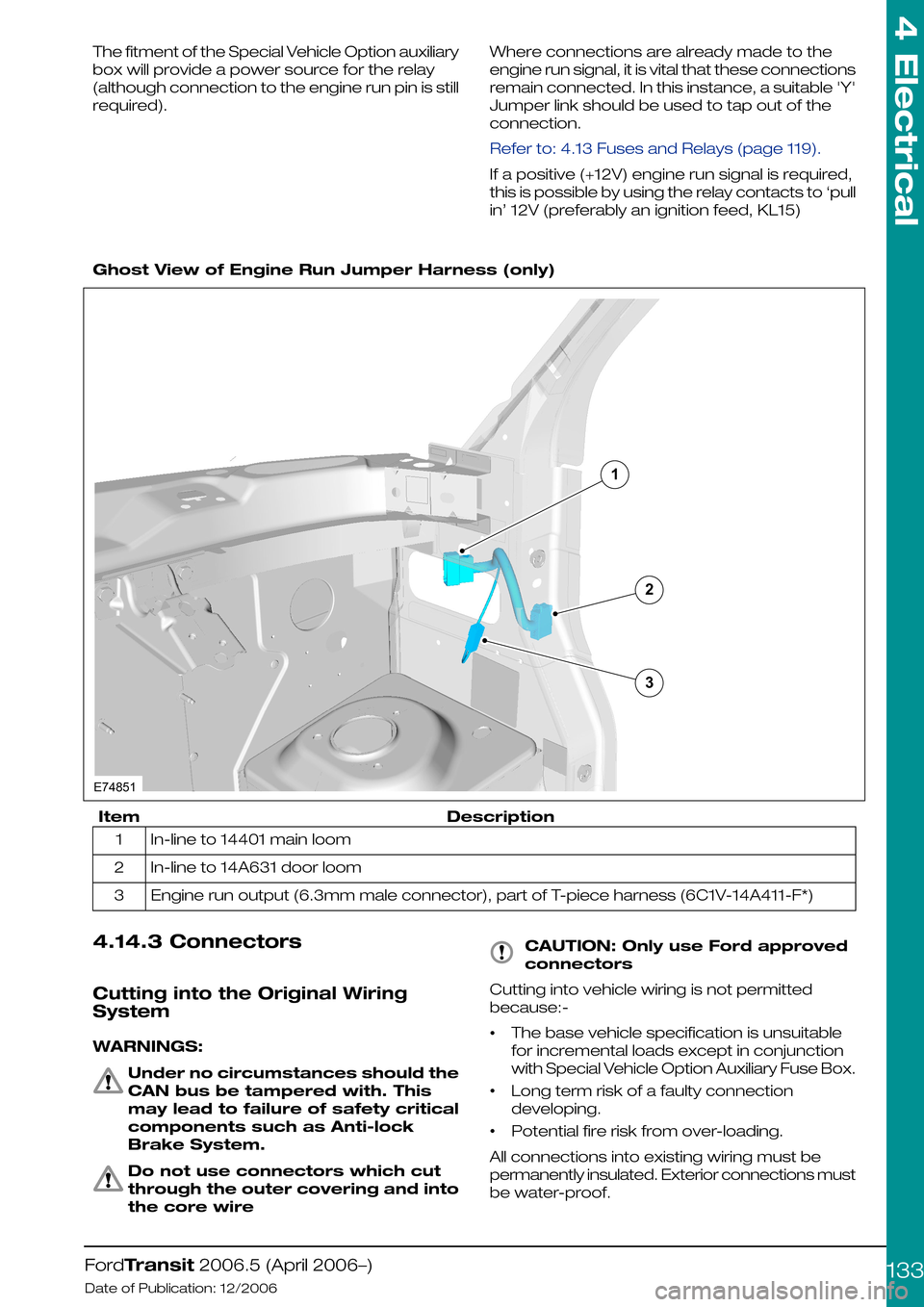

The fitment of the Special Vehicle Option auxiliary

box will provide a power source for the relay

(although connection to the engine run pin is still

required).

Where connections are already made to the

engine run signal, it is vital that these connections

remain connected. In this instance, a suitable 'Y'

Jumper link should be used to tap out of the

connection.

Refer to: 4.13 Fuses and Relays (page 119).

If a positive (+12V) engine run signal is required,

this is possible by using the relay contacts to ‘pull

in’ 12V (preferably an ignition feed, KL15)

Ghost View of Engine Run Jumper Harness (only)

DescriptionItem

In-line to 14401 main loom1

In-line to 14A631 door loom2

Engine run output (6.3mm male connector), part of T-piece harness (6C1V-14A411-F*)3

4.14.3 Connectors

Cutting into the Original Wiring

System

WARNINGS:

Under no circumstances should the

CAN bus be tampered with. This

may lead to failure of safety critical

components such as Anti-lock

Brake System.

Do not use connectors which cut

through the outer covering and into

the core wire

CAUTION: Only use Ford approved

connectors

Cutting into vehicle wiring is not permitted

because:-

•The base vehicle specification is unsuitable

for incremental loads except in conjunction

with Special Vehicle Option Auxiliary Fuse Box.

•Long term risk of a faulty connection

developing.

•Potential fire risk from over-loading.

All connections into existing wiring must be

permanently insulated. Exterior connections must

be water-proof.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

133132E74851

Page 134 of 234

Where wires are required to be extended, break

in points should only be at existing connector

points and only Ford approved connectors should

be used.

Ford approved link harnesses should be used.

Unused Connectors

The harnesses may have a number of unused

connectors – these are dedicated to other

features and options, e.g. heated seats, but are

not always present depending on level of

harness fitted. Ford do not recommend the use

of these connectors for any other purpose than

that intended by design.

Power Outlet / Cigar Lighter

Both features adopt a 20A fusing strategy. With

a single battery system, continued loading of

these features will lead to battery drain, and risk

vehicle starting. If continuous power is required,

a second battery option should be installed and

the customer connection points, where fitted,

utilized.

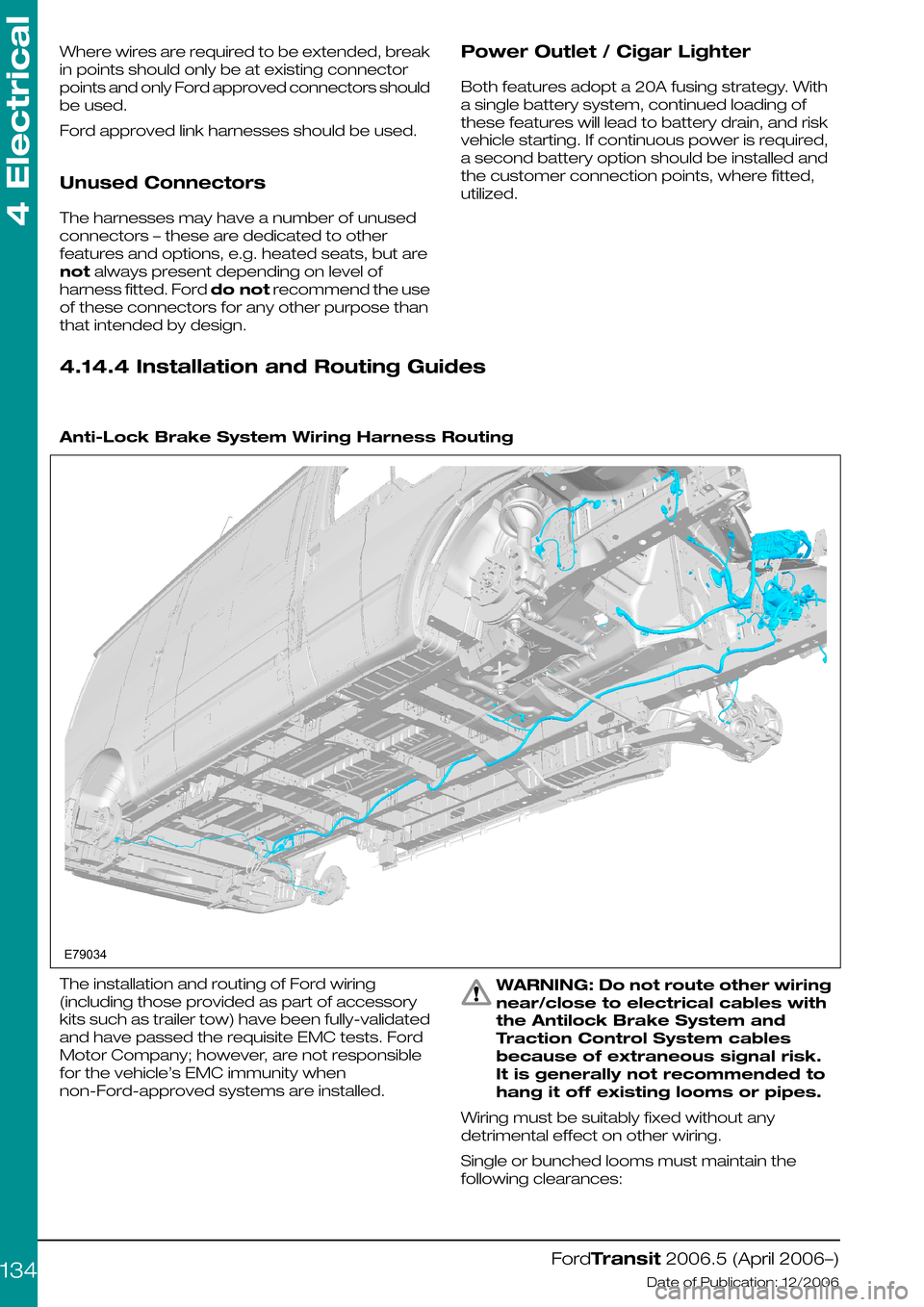

4.14.4 Installation and Routing Guides

Anti-Lock Brake System Wiring Harness Routing

The installation and routing of Ford wiring

(including those provided as part of accessory

kits such as trailer tow) have been fully-validated

and have passed the requisite EMC tests. Ford

Motor Company; however, are not responsible

for the vehicle’s EMC immunity when

non-Ford-approved systems are installed.

WARNING: Do not route other wiring

near/close to electrical cables with

the Antilock Brake System and

Traction Control System cables

because of extraneous signal risk.

It is generally not recommended to

hang it off existing looms or pipes.

Wiring must be suitably fixed without any

detrimental effect on other wiring.

Single or bunched looms must maintain the

following clearances:

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

134E79034

Page 136 of 234

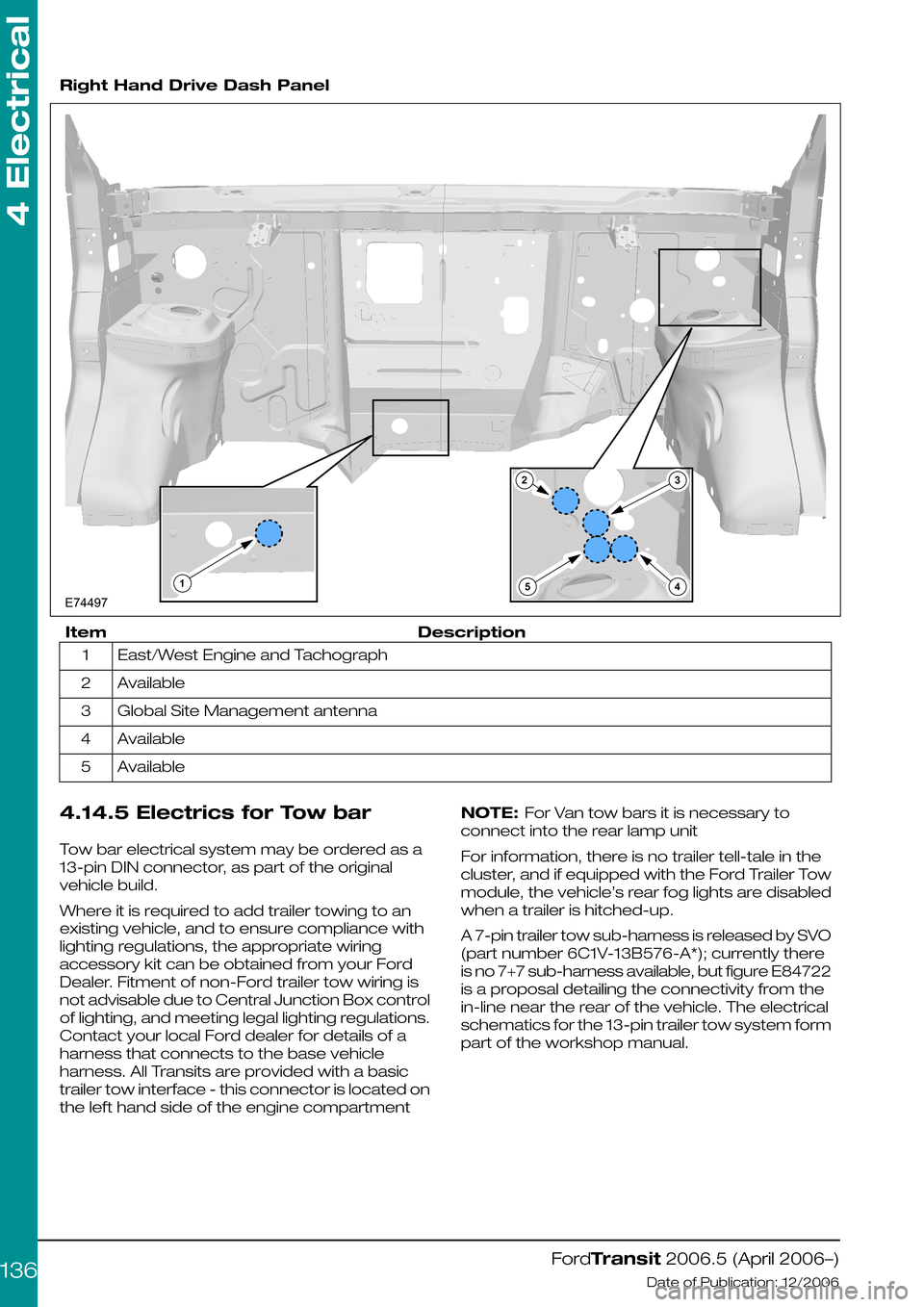

Right Hand Drive Dash Panel

DescriptionItem

East/West Engine and Tachograph1

Available2

Global Site Management antenna3

Available4

Available5

4.14.5 Electrics for Tow bar

Tow bar electrical system may be ordered as a

13-pin DIN connector, as part of the original

vehicle build.

Where it is required to add trailer towing to an

existing vehicle, and to ensure compliance with

lighting regulations, the appropriate wiring

accessory kit can be obtained from your Ford

Dealer. Fitment of non-Ford trailer tow wiring is

not advisable due to Central Junction Box control

of lighting, and meeting legal lighting regulations.

Contact your local Ford dealer for details of a

harness that connects to the base vehicle

harness. All Transits are provided with a basic

trailer tow interface - this connector is located on

the left hand side of the engine compartment

NOTE: For Van tow bars it is necessary to

connect into the rear lamp unit

For information, there is no trailer tell-tale in the

cluster, and if equipped with the Ford Trailer Tow

module, the vehicle’s rear fog lights are disabled

when a trailer is hitched-up.

A 7-pin trailer tow sub-harness is released by SVO

(part number 6C1V-13B576-A*); currently there

is no 7+7 sub-harness available, but figure E84722

is a proposal detailing the connectivity from the

in-line near the rear of the vehicle. The electrical

schematics for the 13-pin trailer tow system form

part of the workshop manual.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

4 Electrical

136E7449724513