wheel FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 3 of 234

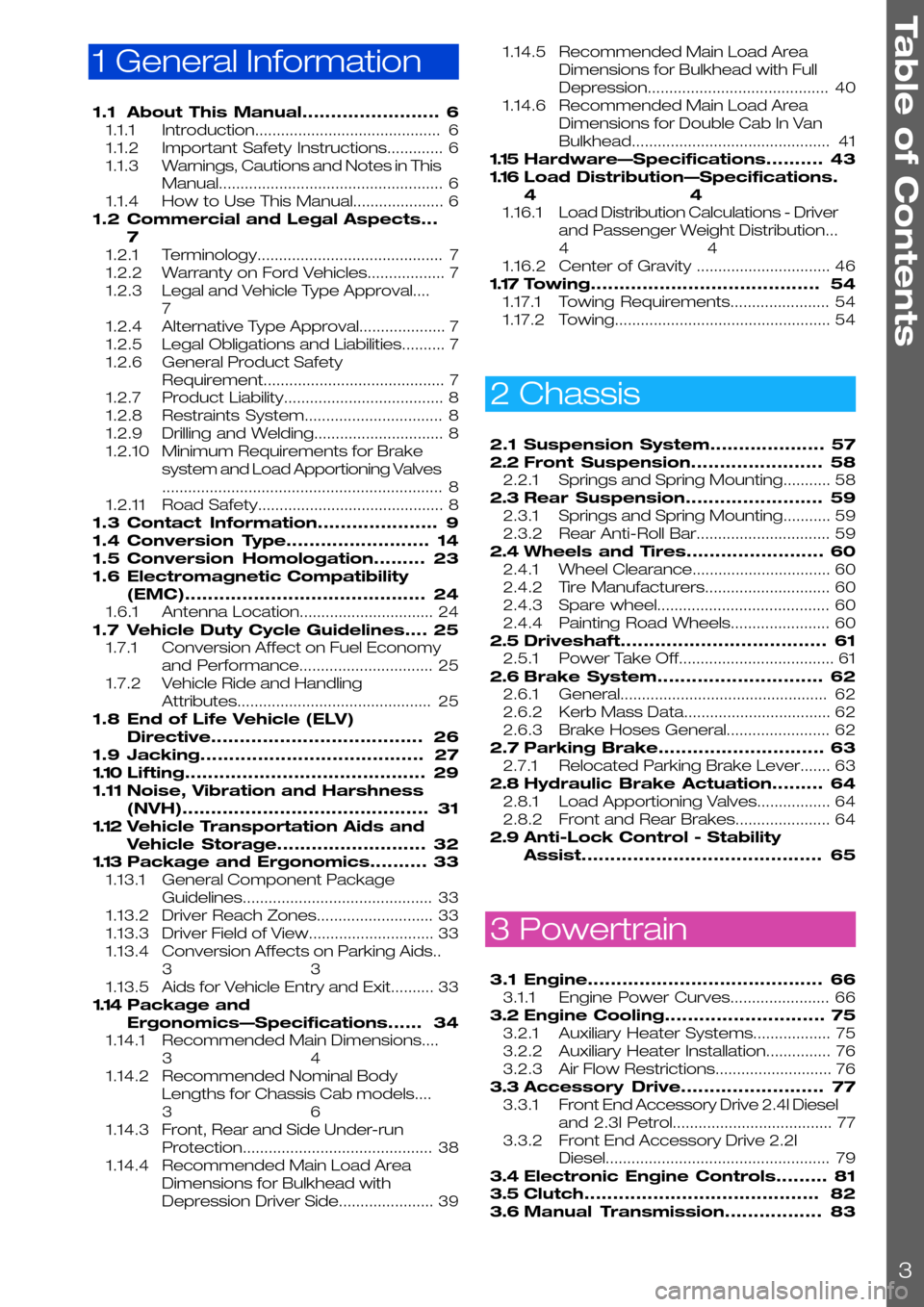

1 General Information

1.1About This Manual........................6

1.1.1Introduction...........................................6

1.1.2Important Safety Instructions.............6

1.1.3Warnings, Cautions and Notes in This

Manual....................................................6

1.1.4How to Use This Manual.....................6

1.2Commercial and Legal Aspects...

7

1.2.1Terminology...........................................7

1.2.2Warranty on Ford Vehicles..................7

1.2.3Legal and Vehicle Type Approval....

7

1.2.4Alternative Type Approval....................7

1.2.5Legal Obligations and Liabilities..........7

1.2.6General Product Safety

Requirement..........................................7

1.2.7Product Liability.....................................8

1.2.8Restraints System................................8

1.2.9Drilling and Welding..............................8

1.2.10Minimum Requirements for Brake

system and Load Apportioning Valves

.................................................................8

1.2.11Road Safety...........................................8

1.3Contact Information.....................9

1.4Conversion Type.........................14

1.5Conversion Homologation.........23

1.6Electromagnetic Compatibility

(EMC)..........................................24

1.6.1Antenna Location...............................24

1.7Vehicle Duty Cycle Guidelines....25

1.7.1Conversion Affect on Fuel Economy

and Performance...............................25

1.7.2Vehicle Ride and Handling

Attributes.............................................25

1.8End of Life Vehicle (ELV)

Directive.....................................26

1.9Jacking.......................................27

1.10Lifting..........................................29

1.11Noise, Vibration and Harshness

(NVH)...........................................31

1.12Vehicle Transportation Aids and

Vehicle Storage..........................32

1.13Package and Ergonomics..........33

1.13.1General Component Package

Guidelines............................................33

1.13.2Driver Reach Zones...........................33

1.13.3Driver Field of View.............................33

1.13.4Conversion Affects on Parking Aids..

33

1.13.5Aids for Vehicle Entry and Exit..........33

1.14Package and

Ergonomics—Specifications......34

1.14.1Recommended Main Dimensions....

34

1.14.2Recommended Nominal Body

Lengths for Chassis Cab models....

36

1.14.3Front, Rear and Side Under-run

Protection............................................38

1.14.4Recommended Main Load Area

Dimensions for Bulkhead with

Depression Driver Side......................39

1.14.5Recommended Main Load Area

Dimensions for Bulkhead with Full

Depression..........................................40

1.14.6Recommended Main Load Area

Dimensions for Double Cab In Van

Bulkhead..............................................41

1.15Hardware—Specifications..........43

1.16Load Distribution—Specifications.

44

1.16.1Load Distribution Calculations - Driver

and Passenger Weight Distribution...

44

1.16.2Center of Gravity ...............................46

1.17Towing........................................54

1.17.1Towing Requirements.......................54

1.17.2Towing..................................................54

2 Chassis

2.1Suspension System....................57

2.2Front Suspension.......................58

2.2.1Springs and Spring Mounting...........58

2.3Rear Suspension........................59

2.3.1Springs and Spring Mounting...........59

2.3.2Rear Anti-Roll Bar...............................59

2.4Wheels and Tires........................60

2.4.1Wheel Clearance................................60

2.4.2Tire Manufacturers.............................60

2.4.3Spare wheel........................................60

2.4.4Painting Road Wheels.......................60

2.5Driveshaft....................................61

2.5.1Power Take Off....................................61

2.6Brake System.............................62

2.6.1General................................................62

2.6.2Kerb Mass Data..................................62

2.6.3Brake Hoses General........................62

2.7Parking Brake.............................63

2.7.1Relocated Parking Brake Lever.......63

2.8Hydraulic Brake Actuation.........64

2.8.1Load Apportioning Valves.................64

2.8.2Front and Rear Brakes......................64

2.9Anti-Lock Control - Stability

Assist..........................................65

3 Powertrain

3.1Engine.........................................66

3.1.1Engine Power Curves.......................66

3.2Engine Cooling............................75

3.2.1Auxiliary Heater Systems..................75

3.2.2Auxiliary Heater Installation...............76

3.2.3Air Flow Restrictions...........................76

3.3Accessory Drive.........................77

3.3.1Front End Accessory Drive 2.4l Diesel

and 2.3l Petrol.....................................77

3.3.2Front End Accessory Drive 2.2l

Diesel....................................................79

3.4Electronic Engine Controls.........81

3.5Clutch.........................................82

3.6Manual Transmission.................83

Table of Contents

3

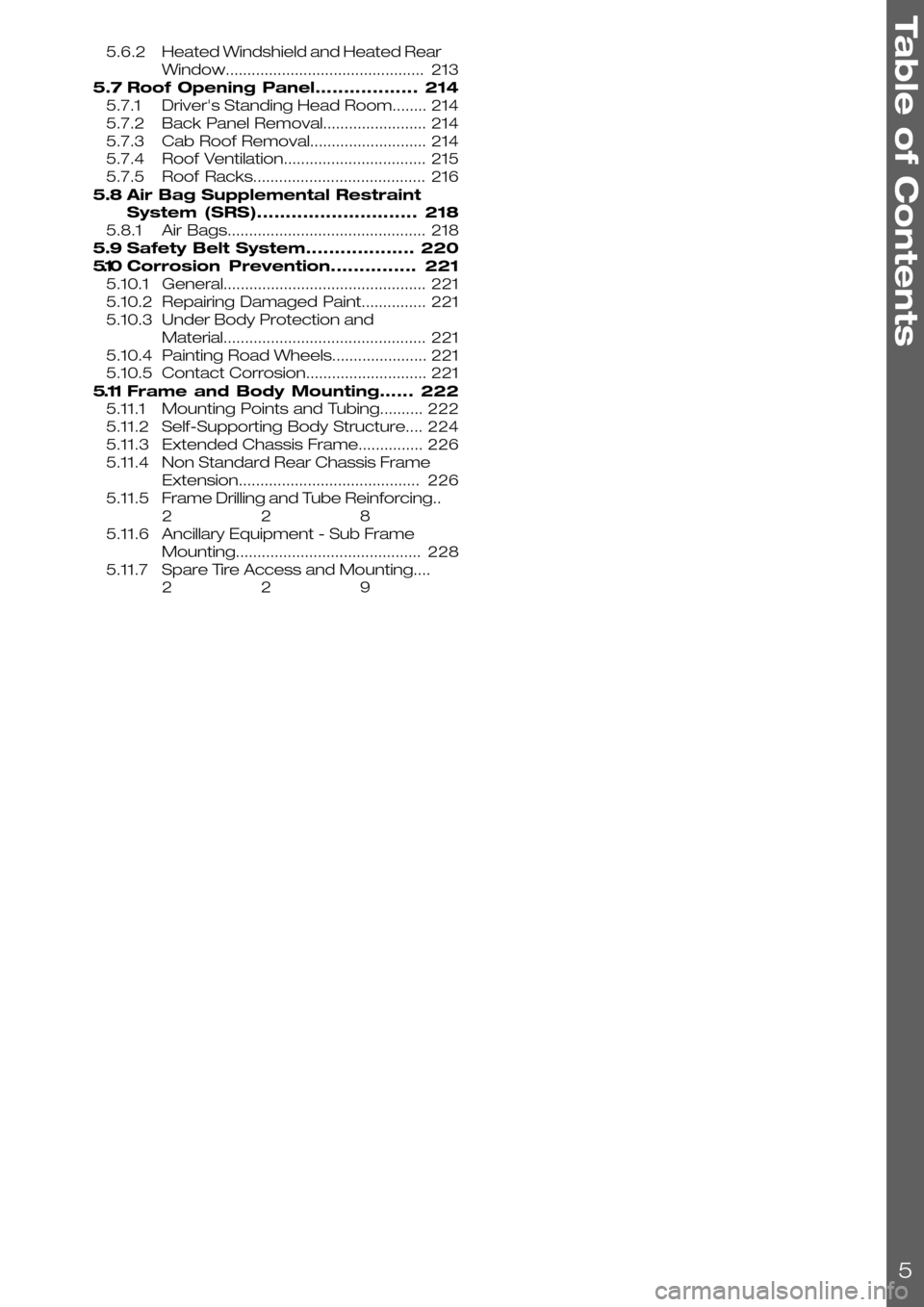

Page 5 of 234

5.6.2Heated Windshield and Heated Rear

Window..............................................213

5.7Roof Opening Panel..................214

5.7.1Driver's Standing Head Room........214

5.7.2Back Panel Removal........................214

5.7.3Cab Roof Removal...........................214

5.7.4Roof Ventilation.................................215

5.7.5Roof Racks........................................216

5.8Air Bag Supplemental Restraint

System (SRS)............................218

5.8.1Air Bags..............................................218

5.9Safety Belt System...................220

5.10Corrosion Prevention...............221

5.10.1General...............................................221

5.10.2Repairing Damaged Paint...............221

5.10.3Under Body Protection and

Material...............................................221

5.10.4Painting Road Wheels......................221

5.10.5Contact Corrosion............................221

5.11Frame and Body Mounting......222

5.11.1Mounting Points and Tubing..........222

5.11.2Self-Supporting Body Structure....224

5.11.3Extended Chassis Frame...............226

5.11.4Non Standard Rear Chassis Frame

Extension..........................................226

5.11.5Frame Drilling and Tube Reinforcing..

228

5.11.6Ancillary Equipment - Sub Frame

Mounting...........................................228

5.11.7Spare Tire Access and Mounting....

229

Table of Contents

5

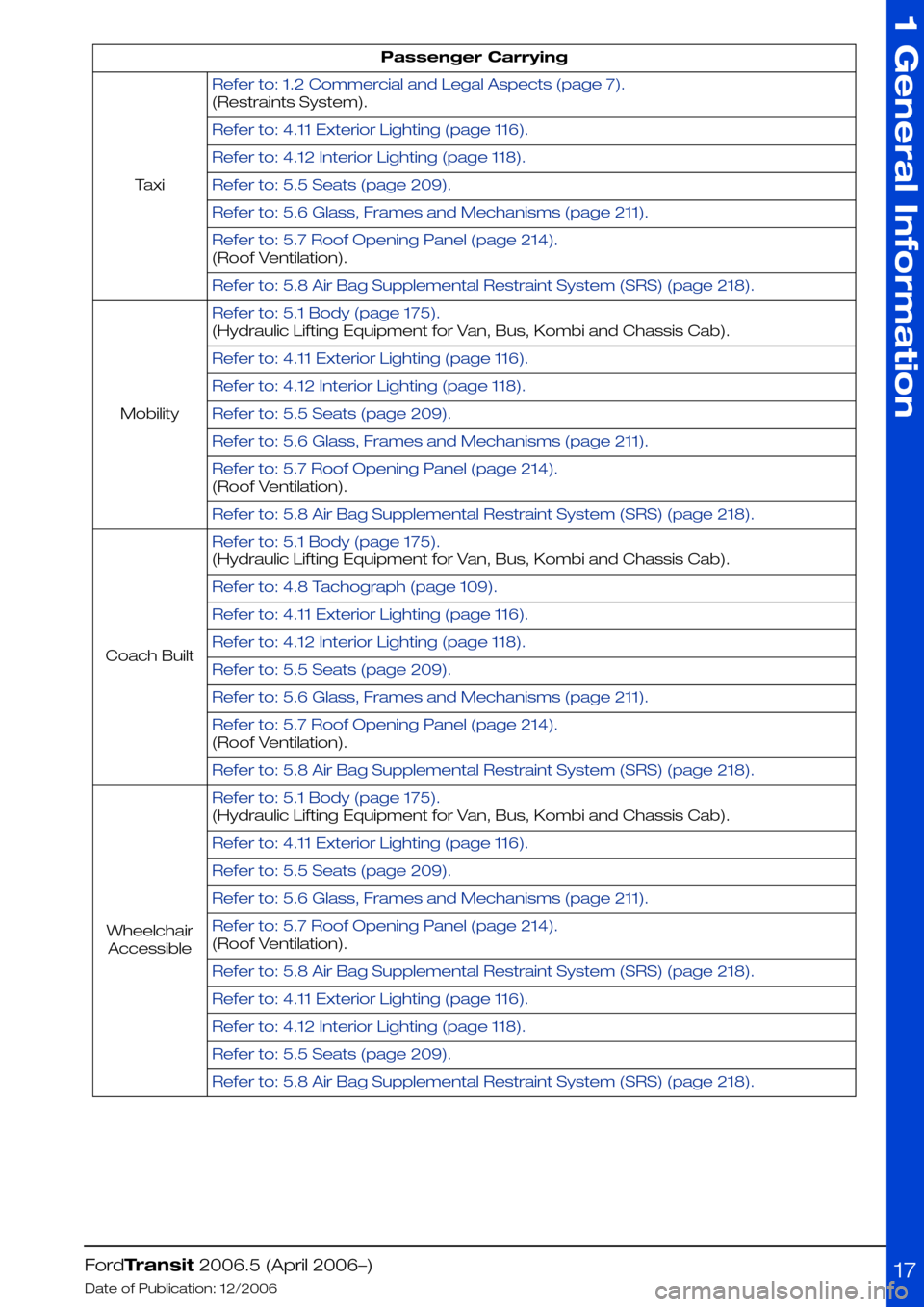

Page 17 of 234

Passenger Carrying

Refer to: 1.2 Commercial and Legal Aspects (page 7).

Taxi

(Restraints System).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 5.5 Seats (page 209).

Refer to: 5.6 Glass, Frames and Mechanisms (page 211).

Refer to: 5.7 Roof Opening Panel (page 214).

(Roof Ventilation).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

Refer to: 5.1 Body (page 175).

Mobility

(Hydraulic Lifting Equipment for Van, Bus, Kombi and Chassis Cab).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 5.5 Seats (page 209).

Refer to: 5.6 Glass, Frames and Mechanisms (page 211).

Refer to: 5.7 Roof Opening Panel (page 214).

(Roof Ventilation).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

Refer to: 5.1 Body (page 175).

Coach Built

(Hydraulic Lifting Equipment for Van, Bus, Kombi and Chassis Cab).

Refer to: 4.8 Tachograph (page 109).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 5.5 Seats (page 209).

Refer to: 5.6 Glass, Frames and Mechanisms (page 211).

Refer to: 5.7 Roof Opening Panel (page 214).

(Roof Ventilation).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

Refer to: 5.1 Body (page 175).

Wheelchair

Accessible

(Hydraulic Lifting Equipment for Van, Bus, Kombi and Chassis Cab).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 5.5 Seats (page 209).

Refer to: 5.6 Glass, Frames and Mechanisms (page 211).

Refer to: 5.7 Roof Opening Panel (page 214).

(Roof Ventilation).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 5.5 Seats (page 209).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

17

Page 25 of 234

1.7 Vehicle Duty Cycle Guidelines

It is necessary to take into account the customer

usage profile and the anticipated vehicle duty

cycles of the modified vehicle in order to choose

the appropriate specification of the base vehicle.

It is necessary to select the appropriate drive,

engine, gear ratio, gross vehicle mass, gross train

mass, axle plates and payloads of the base

vehicle to match the customer requirements.

Where possible make sure that the base vehicle

is ordered with any necessary plant fit options.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

A high numeric gear ratio is recommended for

vehicles with customer requirements for:

•high payload

•trailer tow

•frequent stop-and-go cycles

•high altitude and gradients

•terrain conditions such as found on building

and construction sites

Rear wheel drive is recommended for high

traction in combination with a high trailer weight

Front wheel drive is recommended for low

conversion weight

1.7.1 Conversion Affect on Fuel

Economy and Performance

Any conversion may effect the fuel consumption

and performance depending on the

aerodynamics and the weight added by the

conversion. The published information for fuel

consumption and performance of the base

vehicle therefore may not be valid. It is advisable

to control the weight, but without deteriorating

other vehicle attributes and functions (especially

those related to safety and durability).

1.7.2 Vehicle Ride and Handling

Attributes

CAUTION: Do not exceed the axle

plate, gross vehicle mass, trailer

plate and gross trailer mass limits.

Due to the displacement of the center of gravity

occurred by the conversion the ride and handling

attributes may be different to the base vehicle.

NOTE: This vehicle should be evaluated for safe

operation prior to sale

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

25

Page 27 of 234

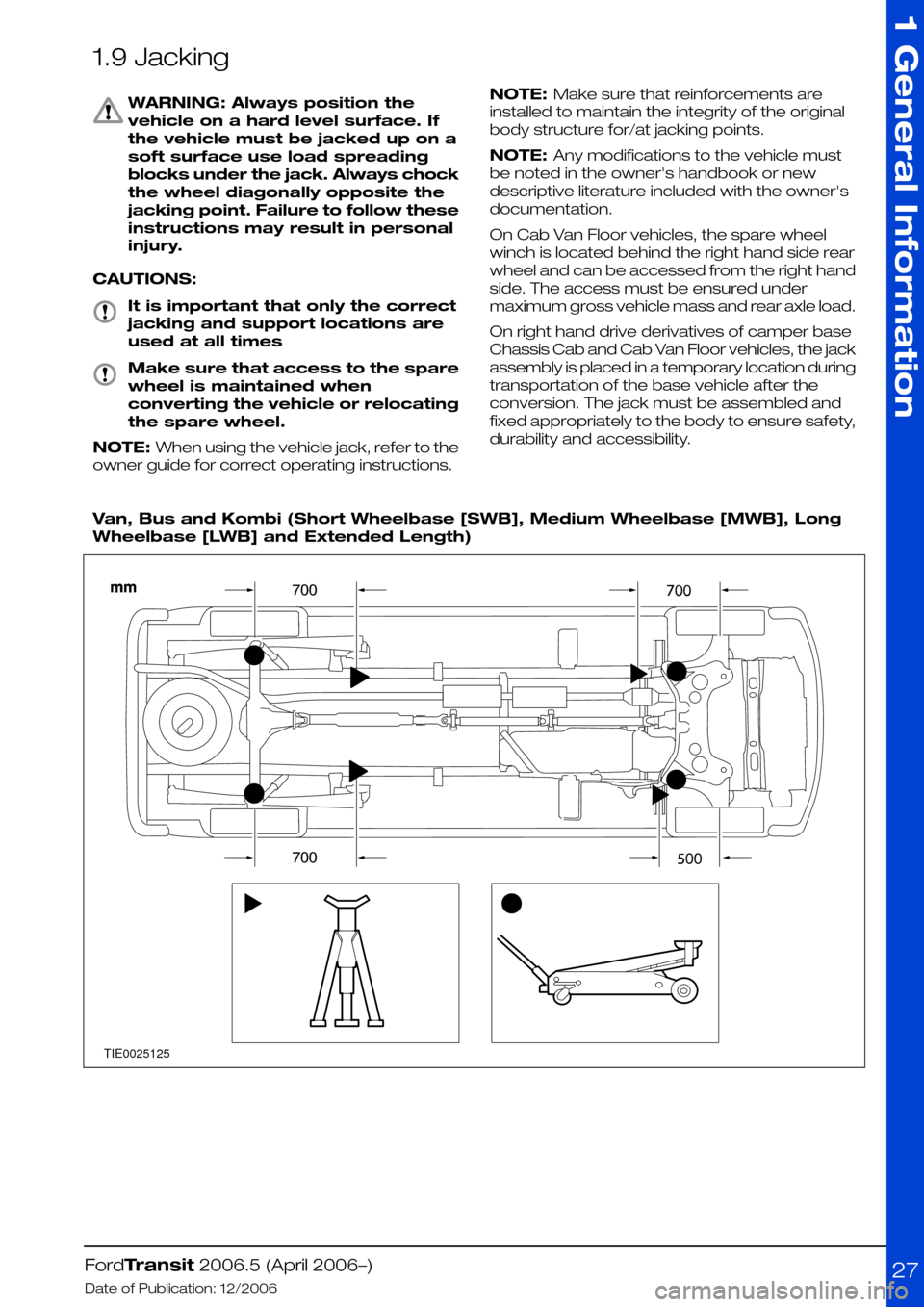

1.9 Jacking

WARNING: Always position the

vehicle on a hard level surface. If

the vehicle must be jacked up on a

soft surface use load spreading

blocks under the jack. Always chock

the wheel diagonally opposite the

jacking point. Failure to follow these

instructions may result in personal

injury.

CAUTIONS:

It is important that only the correct

jacking and support locations are

used at all times

Make sure that access to the spare

wheel is maintained when

converting the vehicle or relocating

the spare wheel.

NOTE: When using the vehicle jack, refer to the

owner guide for correct operating instructions.

NOTE: Make sure that reinforcements are

installed to maintain the integrity of the original

body structure for/at jacking points.

NOTE: Any modifications to the vehicle must

be noted in the owner's handbook or new

descriptive literature included with the owner's

documentation.

On Cab Van Floor vehicles, the spare wheel

winch is located behind the right hand side rear

wheel and can be accessed from the right hand

side. The access must be ensured under

maximum gross vehicle mass and rear axle load.

On right hand drive derivatives of camper base

Chassis Cab and Cab Van Floor vehicles, the jack

assembly is placed in a temporary location during

transportation of the base vehicle after the

conversion. The jack must be assembled and

fixed appropriately to the body to ensure safety,

durability and accessibility.

Van, Bus and Kombi (Short Wheelbase [SWB], Medium Wheelbase [MWB], Long

Wheelbase [LWB] and Extended Length)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

27TIE0025125

Page 29 of 234

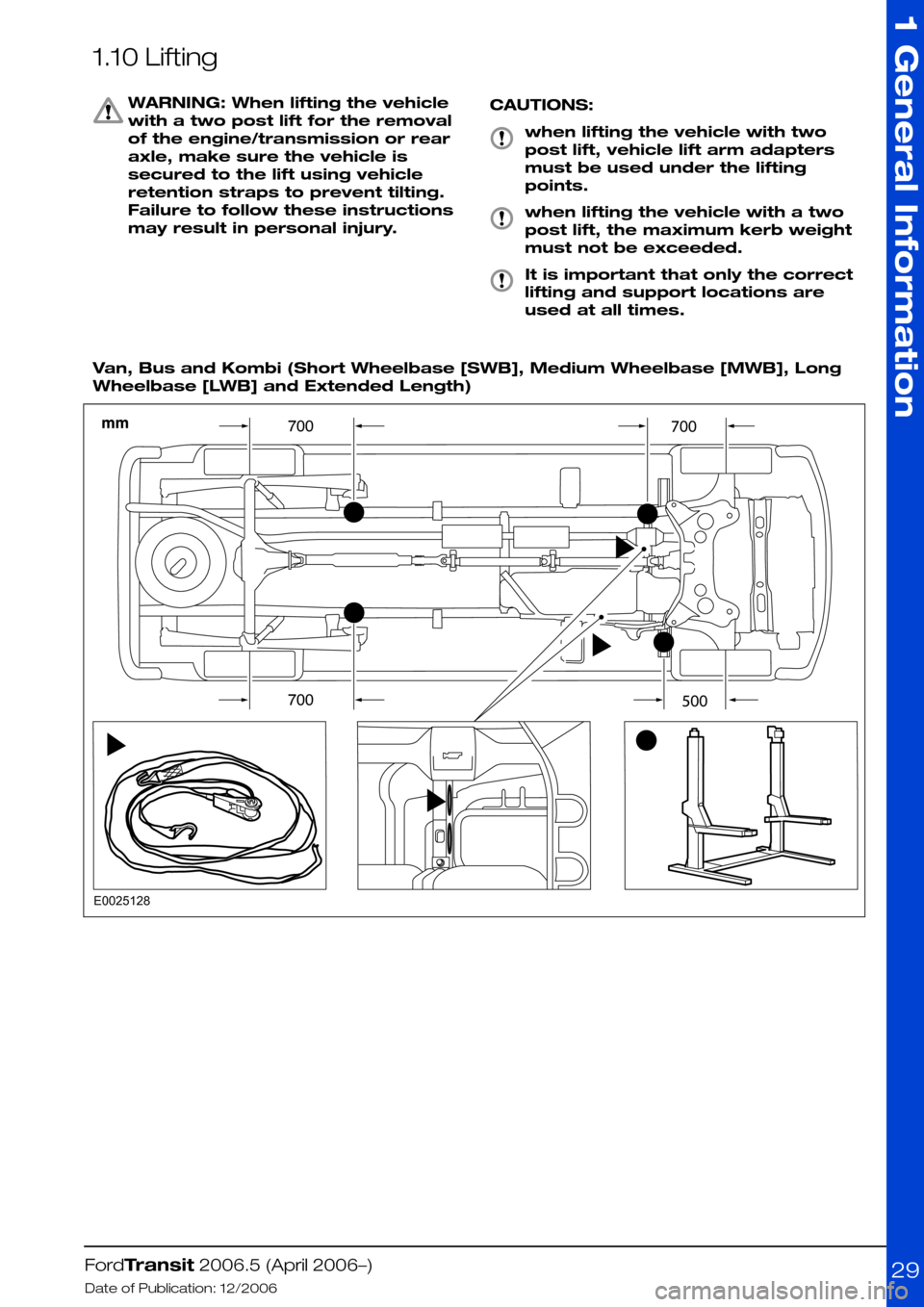

1.10 Lifting

WARNING: When lifting the vehicle

with a two post lift for the removal

of the engine/transmission or rear

axle, make sure the vehicle is

secured to the lift using vehicle

retention straps to prevent tilting.

Failure to follow these instructions

may result in personal injury.

CAUTIONS:

when lifting the vehicle with two

post lift, vehicle lift arm adapters

must be used under the lifting

points.

when lifting the vehicle with a two

post lift, the maximum kerb weight

must not be exceeded.

It is important that only the correct

lifting and support locations are

used at all times.

Van, Bus and Kombi (Short Wheelbase [SWB], Medium Wheelbase [MWB], Long

Wheelbase [LWB] and Extended Length)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

29E0025128

Page 32 of 234

1.12 Vehicle Transportation Aids and Vehicle Storage

CAUTIONS:

Disconnect the battery if the vehicle

is to be stored for more than 30

days.

Make sure that the protective covers

are not removed from an incomplete

vehicle until the conversion is

started.

Make sure that components

removed during conversion are kept

clean and dry.

Make sure that components

removed during conversion are

refitted to the same vehicle.

In addition:

•The windscreen wipers should be lifted off the

glass and set right up.

•All air intakes should be closed.

•Increase normal tyre pressure by 0.5 bar.

•The hand brake system should not be used.

•Apply suitable wheel chock to prevent roll

away.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

32

Page 34 of 234

1.14 Package and Ergonomics—Specifications

1.14.1 Recommended Main Dimensions

WARNING: Do not modify the

wheelbase or add any type of frame

extension to vehicles fitted with

Interactive Vehicle Dynamics

(IVD)/Electronic Stability Program

ESP

NOTE: Extreme rear overhang may encourage

unacceptable loading conditions, which could

unload the front axle producing unacceptable

handling and braking characteristics

NOTE: When extending the length of the

wheelbase during conversion, do not increase

the overall length more than 50% of the

wheelbase of the donor vehicle. The maximum

legal overhang of the donor vehicle is 60%.

If a conversion requires more than 50% overhang,

please contact one of the below.

NOTE: For further information please contact

your local National Sales Company representative,

or Local Ford Dealer. If they are unable to help

you then please contact the Vehicle Converter

Advisory Service at [email protected].

The Special Vehicle Option 2.3m body Width pack

includes long arm mirrors and side repeater

lamps. Please check for availability.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

34

Page 36 of 234

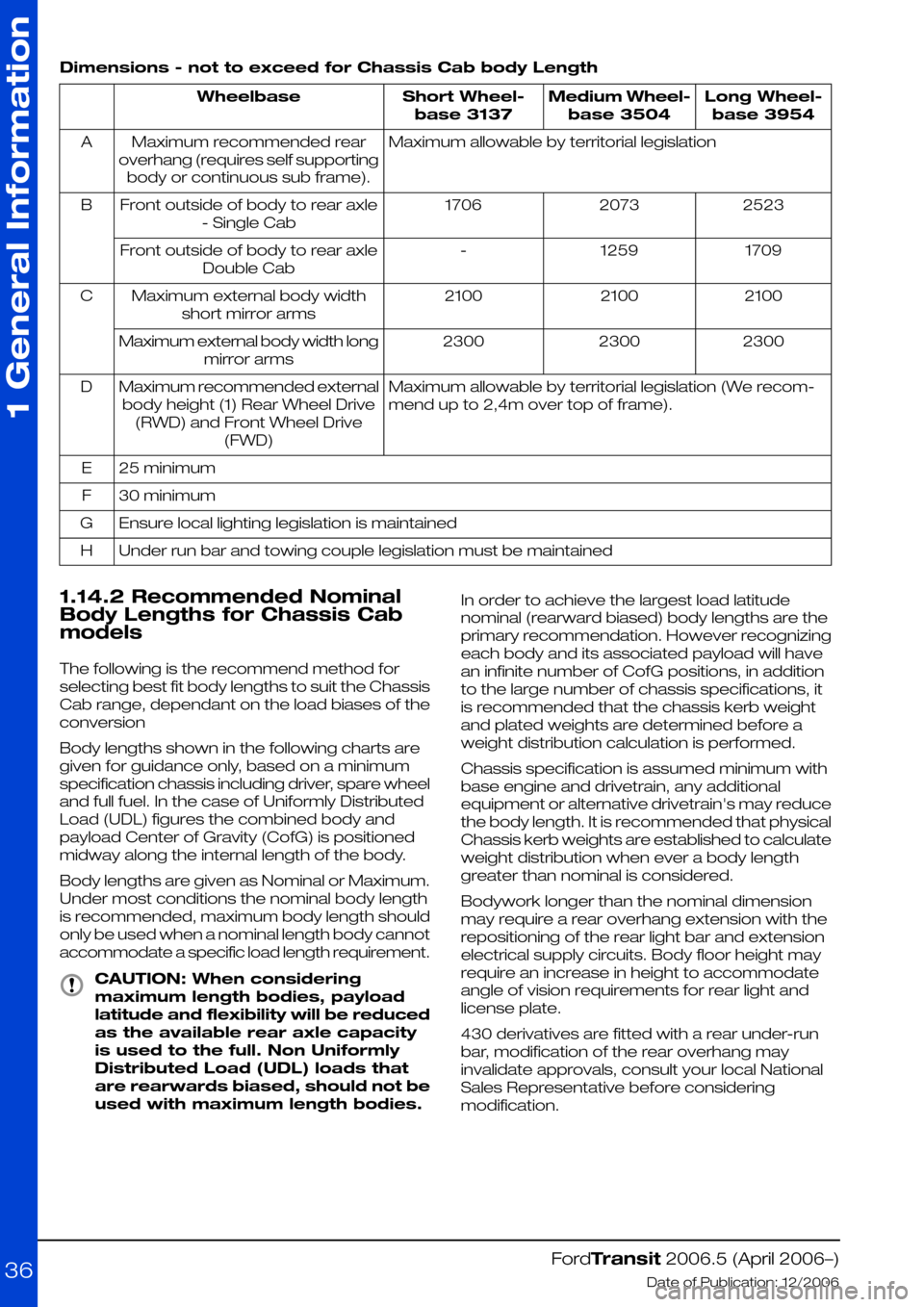

Dimensions - not to exceed for Chassis Cab body Length

Long Wheel-

base 3954

Medium Wheel-

base 3504

Short Wheel-

base 3137

Wheelbase

Maximum allowable by territorial legislationMaximum recommended rear

overhang (requires self supporting

body or continuous sub frame).

A

252320731706Front outside of body to rear axle

- Single Cab

B

17091259-Front outside of body to rear axle

Double Cab

210021002100Maximum external body width

short mirror arms

C

230023002300Maximum external body width long

mirror arms

Maximum allowable by territorial legislation (We recom-

mend up to 2,4m over top of frame).

Maximum recommended external

body height (1) Rear Wheel Drive

(RWD) and Front Wheel Drive

(FWD)

D

25 minimumE

30 minimumF

Ensure local lighting legislation is maintainedG

Under run bar and towing couple legislation must be maintainedH

1.14.2 Recommended Nominal

Body Lengths for Chassis Cab

models

The following is the recommend method for

selecting best fit body lengths to suit the Chassis

Cab range, dependant on the load biases of the

conversion

Body lengths shown in the following charts are

given for guidance only, based on a minimum

specification chassis including driver, spare wheel

and full fuel. In the case of Uniformly Distributed

Load (UDL) figures the combined body and

payload Center of Gravity (CofG) is positioned

midway along the internal length of the body.

Body lengths are given as Nominal or Maximum.

Under most conditions the nominal body length

is recommended, maximum body length should

only be used when a nominal length body cannot

accommodate a specific load length requirement.

CAUTION: When considering

maximum length bodies, payload

latitude and flexibility will be reduced

as the available rear axle capacity

is used to the full. Non Uniformly

Distributed Load (UDL) loads that

are rearwards biased, should not be

used with maximum length bodies.

In order to achieve the largest load latitude

nominal (rearward biased) body lengths are the

primary recommendation. However recognizing

each body and its associated payload will have

an infinite number of CofG positions, in addition

to the large number of chassis specifications, it

is recommended that the chassis kerb weight

and plated weights are determined before a

weight distribution calculation is performed.

Chassis specification is assumed minimum with

base engine and drivetrain, any additional

equipment or alternative drivetrain's may reduce

the body length. It is recommended that physical

Chassis kerb weights are established to calculate

weight distribution when ever a body length

greater than nominal is considered.

Bodywork longer than the nominal dimension

may require a rear overhang extension with the

repositioning of the rear light bar and extension

electrical supply circuits. Body floor height may

require an increase in height to accommodate

angle of vision requirements for rear light and

license plate.

430 derivatives are fitted with a rear under-run

bar, modification of the rear overhang may

invalidate approvals, consult your local National

Sales Representative before considering

modification.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

36

Page 37 of 234

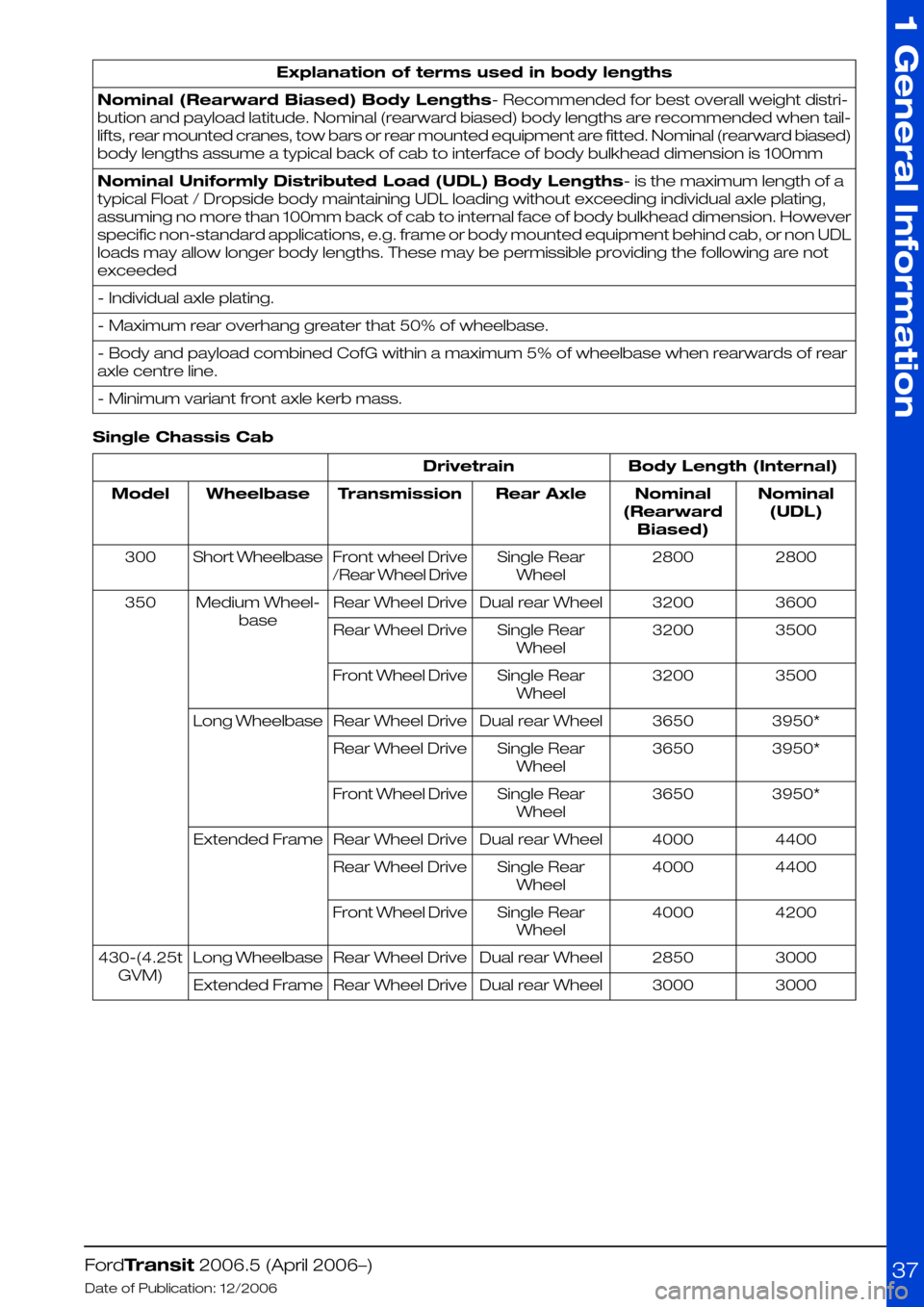

Explanation of terms used in body lengths

Nominal (Rearward Biased) Body Lengths- Recommended for best overall weight distri-

bution and payload latitude. Nominal (rearward biased) body lengths are recommended when tail-

lifts, rear mounted cranes, tow bars or rear mounted equipment are fitted. Nominal (rearward biased)

body lengths assume a typical back of cab to interface of body bulkhead dimension is 100mm

Nominal Uniformly Distributed Load (UDL) Body Lengths- is the maximum length of a

typical Float / Dropside body maintaining UDL loading without exceeding individual axle plating,

assuming no more than 100mm back of cab to internal face of body bulkhead dimension. However

specific non-standard applications, e.g. frame or body mounted equipment behind cab, or non UDL

loads may allow longer body lengths. These may be permissible providing the following are not

exceeded

- Individual axle plating.

- Maximum rear overhang greater that 50% of wheelbase.

- Body and payload combined CofG within a maximum 5% of wheelbase when rearwards of rear

axle centre line.

- Minimum variant front axle kerb mass.

Single Chassis Cab

Body Length (Internal)Drivetrain

Nominal

(UDL)

Nominal

(Rearward

Biased)

Rear AxleTransmissionWheelbaseModel

28002800Single Rear

Wheel

Front wheel Drive

/Rear Wheel Drive

Short Wheelbase300

36003200Dual rear WheelRear Wheel DriveMedium Wheel-

base

350

35003200Single Rear

Wheel

Rear Wheel Drive

35003200Single Rear

Wheel

Front Wheel Drive

3950*3650Dual rear WheelRear Wheel DriveLong Wheelbase

3950*3650Single Rear

Wheel

Rear Wheel Drive

3950*3650Single Rear

Wheel

Front Wheel Drive

44004000Dual rear WheelRear Wheel DriveExtended Frame

44004000Single Rear

Wheel

Rear Wheel Drive

42004000Single Rear

Wheel

Front Wheel Drive

30002850Dual rear WheelRear Wheel DriveLong Wheelbase430-(4.25t

GVM)30003000Dual rear WheelRear Wheel DriveExtended Frame

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

37