engine FORD TRANSIT 2017 5.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: TRANSIT, Model: FORD TRANSIT 2017 5.GPages: 484, PDF Size: 11.45 MB

Page 227 of 484

DRAINING THE FUEL FILTER

WATER TRAP - 3.2L POWER

STROKE DIESEL

WARNING

Do not dispose of fuel in the

household refuse or the public

sewage system. Use an authorized

waste disposal facility. Your vehicle is fitted with a diesel fuel

conditioner module located behind the fuel

tank.

A warning lamp will illuminate

and a message will be displayed

when approximately 3.38 fl oz

(100 ml) of water accumulates in the

module. If you allow the water level to

exceed this level, the water may pass

through to the engine and may cause fuel

injection equipment damage.

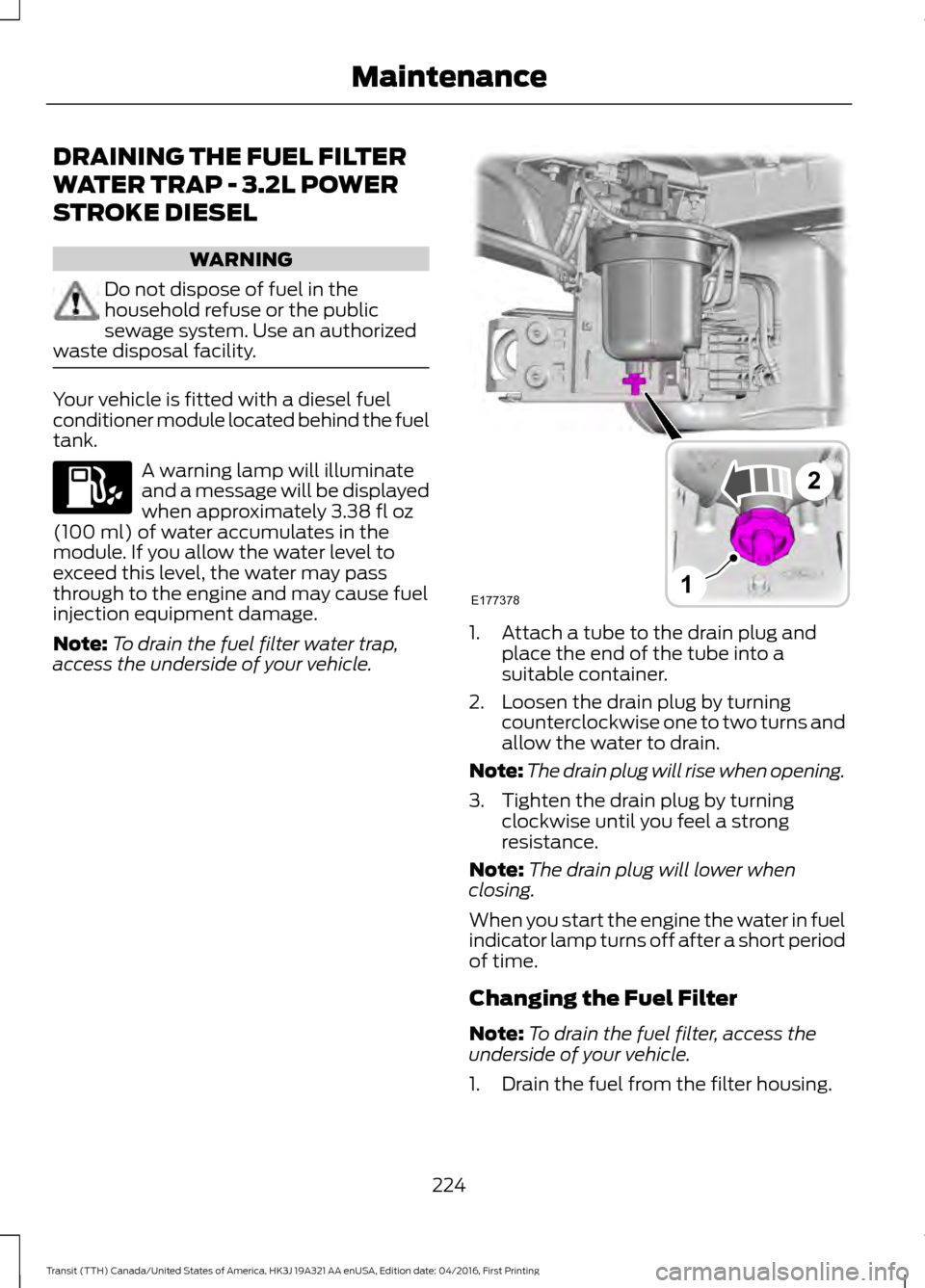

Note: To drain the fuel filter water trap,

access the underside of your vehicle. 1. Attach a tube to the drain plug and

place the end of the tube into a

suitable container.

2. Loosen the drain plug by turning counterclockwise one to two turns and

allow the water to drain.

Note: The drain plug will rise when opening.

3. Tighten the drain plug by turning clockwise until you feel a strong

resistance.

Note: The drain plug will lower when

closing.

When you start the engine the water in fuel

indicator lamp turns off after a short period

of time.

Changing the Fuel Filter

Note: To drain the fuel filter, access the

underside of your vehicle.

1. Drain the fuel from the filter housing.

224

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Maintenance E177378

2

1

Page 228 of 484

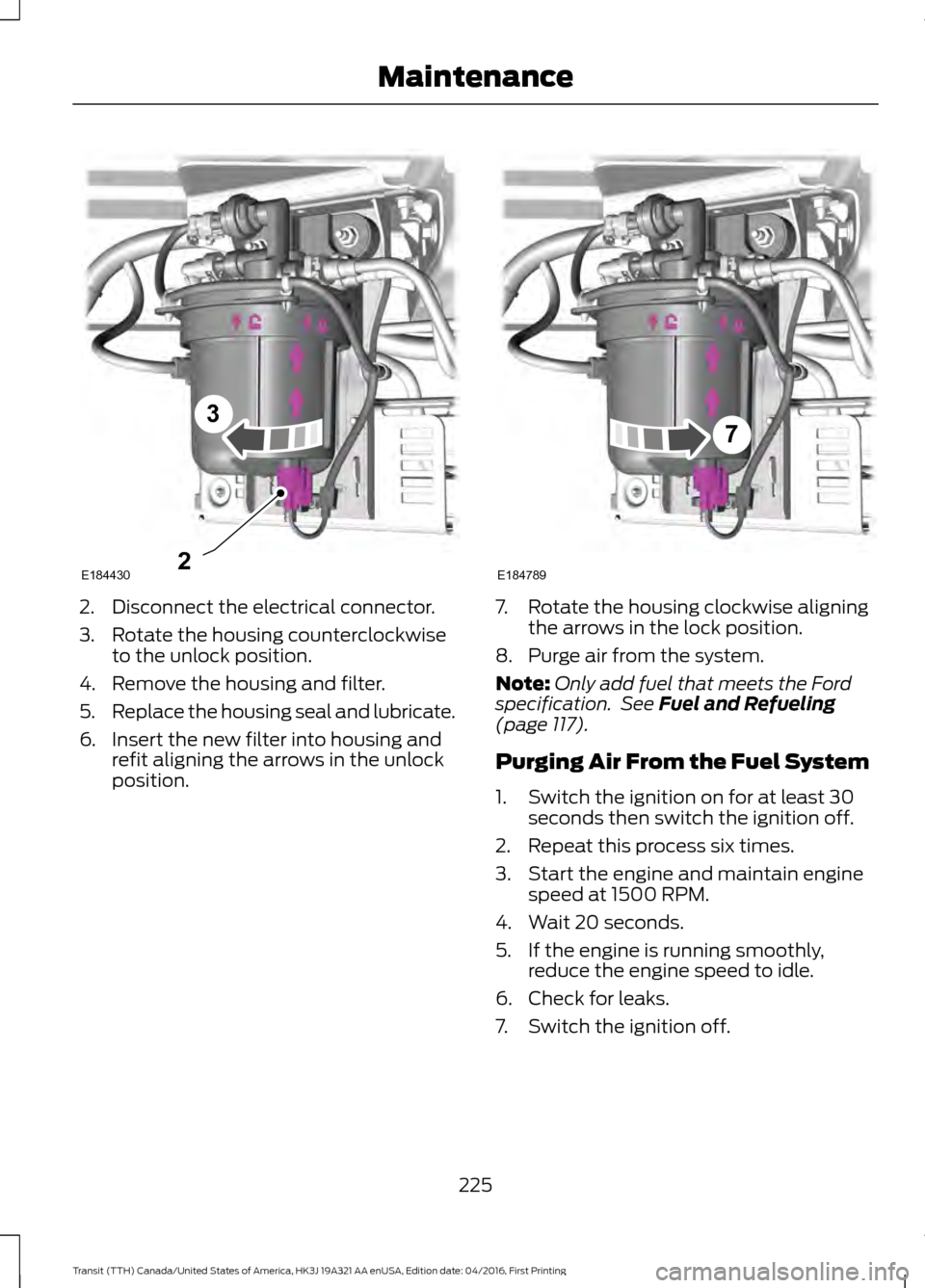

2. Disconnect the electrical connector.

3. Rotate the housing counterclockwise

to the unlock position.

4. Remove the housing and filter.

5. Replace the housing seal and lubricate.

6. Insert the new filter into housing and refit aligning the arrows in the unlock

position. 7. Rotate the housing clockwise aligning

the arrows in the lock position.

8. Purge air from the system.

Note: Only add fuel that meets the Ford

specification. See Fuel and Refueling

(page 117).

Purging Air From the Fuel System

1. Switch the ignition on for at least 30 seconds then switch the ignition off.

2. Repeat this process six times.

3. Start the engine and maintain engine speed at 1500 RPM.

4. Wait 20 seconds.

5. If the engine is running smoothly, reduce the engine speed to idle.

6. Check for leaks.

7. Switch the ignition off.

225

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing MaintenanceE1844302

3 E184789

7

Page 229 of 484

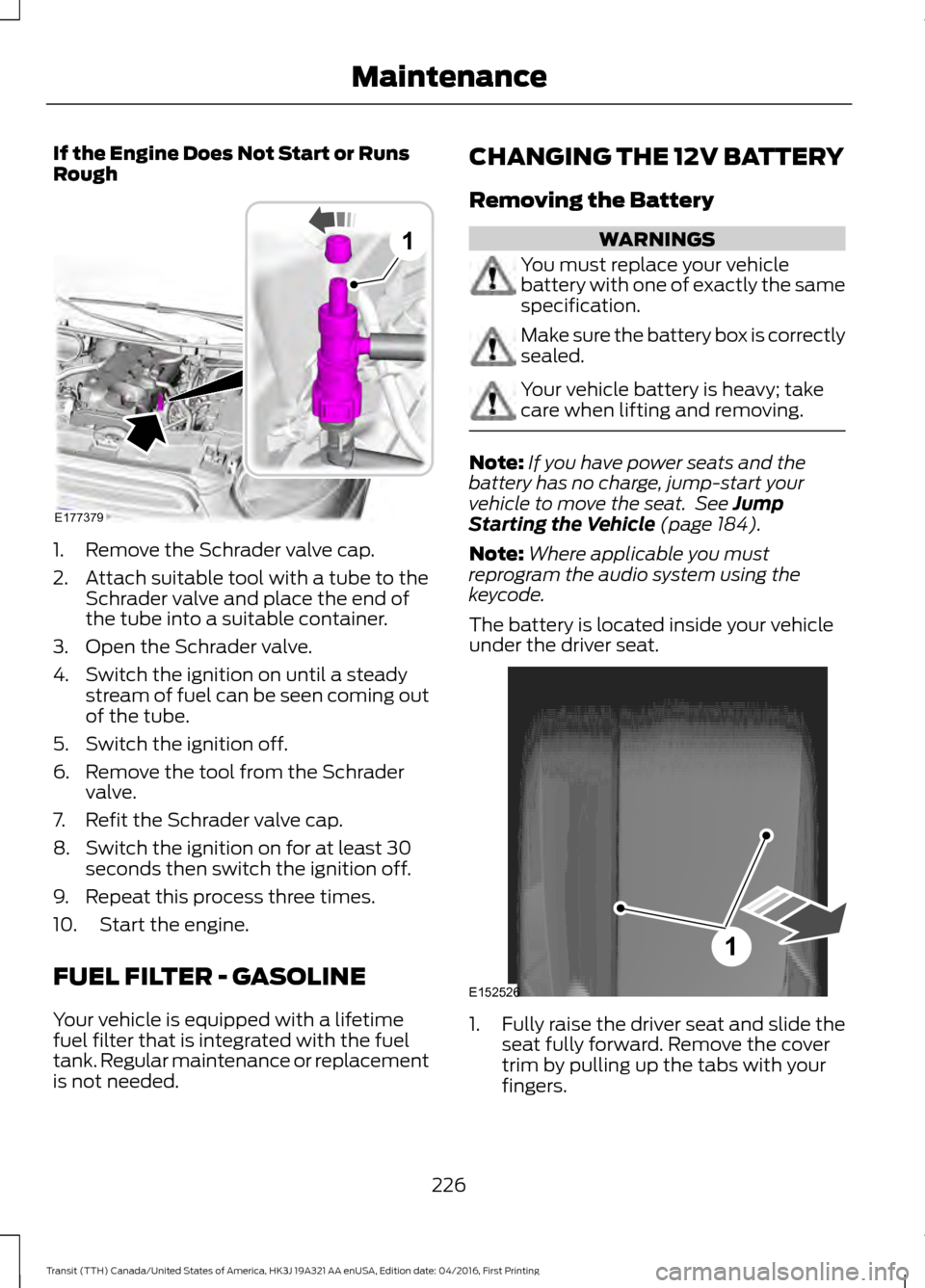

If the Engine Does Not Start or Runs

Rough

1. Remove the Schrader valve cap.

2. Attach suitable tool with a tube to the

Schrader valve and place the end of

the tube into a suitable container.

3. Open the Schrader valve.

4. Switch the ignition on until a steady stream of fuel can be seen coming out

of the tube.

5. Switch the ignition off.

6. Remove the tool from the Schrader valve.

7. Refit the Schrader valve cap.

8. Switch the ignition on for at least 30 seconds then switch the ignition off.

9. Repeat this process three times.

10. Start the engine.

FUEL FILTER - GASOLINE

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed. CHANGING THE 12V BATTERY

Removing the Battery WARNINGS

You must replace your vehicle

battery with one of exactly the same

specification.

Make sure the battery box is correctly

sealed.

Your vehicle battery is heavy; take

care when lifting and removing.

Note:

If you have power seats and the

battery has no charge, jump-start your

vehicle to move the seat. See Jump

Starting the Vehicle (page 184).

Note: Where applicable you must

reprogram the audio system using the

keycode.

The battery is located inside your vehicle

under the driver seat. 1.

Fully raise the driver seat and slide the

seat fully forward. Remove the cover

trim by pulling up the tabs with your

fingers.

226

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing MaintenanceE177379

1 E152526

1

Page 240 of 484

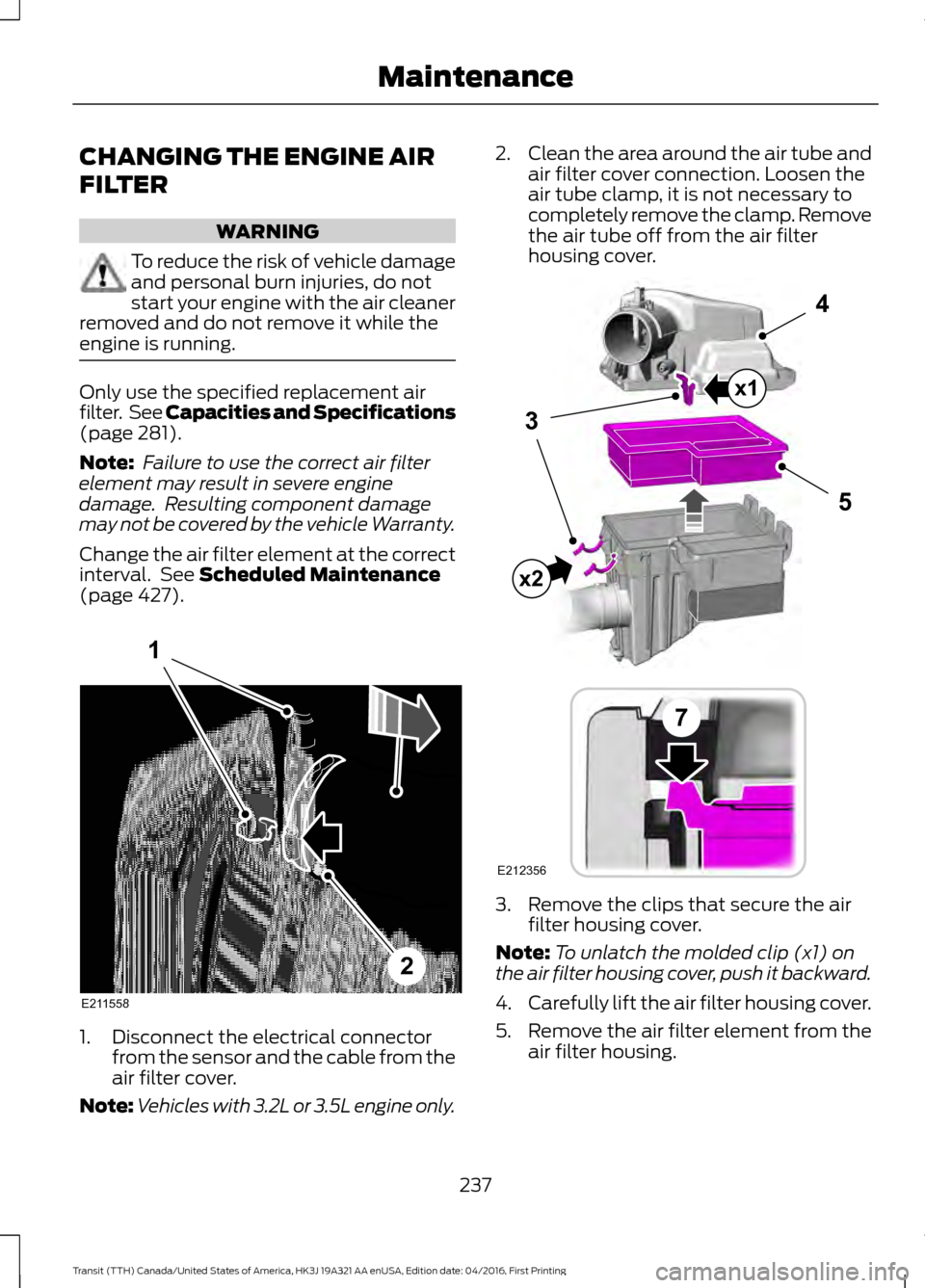

CHANGING THE ENGINE AIR

FILTER

WARNING

To reduce the risk of vehicle damage

and personal burn injuries, do not

start your engine with the air cleaner

removed and do not remove it while the

engine is running. Only use the specified replacement air

filter. See Capacities and Specifications

(page 281).

Note: Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage

may not be covered by the vehicle Warranty.

Change the air filter element at the correct

interval. See

Scheduled Maintenance

(page 427). 1. Disconnect the electrical connector

from the sensor and the cable from the

air filter cover.

Note: Vehicles with 3.2L or 3.5L engine only. 2.

Clean the area around the air tube and

air filter cover connection. Loosen the

air tube clamp, it is not necessary to

completely remove the clamp. Remove

the air tube off from the air filter

housing cover. 3. Remove the clips that secure the air

filter housing cover.

Note: To unlatch the molded clip (x1) on

the air filter housing cover, push it backward.

4. Carefully lift the air filter housing cover.

5. Remove the air filter element from the

air filter housing.

237

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing MaintenanceE211558

1

2 E212356

5

4

7

3

x1

x2

Page 241 of 484

6.

Wipe any dirt or debris from the air filter

housing and cover to make sure no dirt

gets in the engine and that you have a

good seal.

7. Install a new air filter element. Be careful not to crimp the filter element

edges between the air filter housing

and cover.

8. Install the air filter housing cover.

Note: Make sure the front clips are fully

engaged and the molded clip on the air filter

housing cover is fully pushed down and

securely clicks into place.

9. Install the air tube onto the air filter cover. Tighten the air tube clamp until

you feel a strong resistance.

10. Reconnect the electrical connector to the sensor and the cable to the air

filter cover.

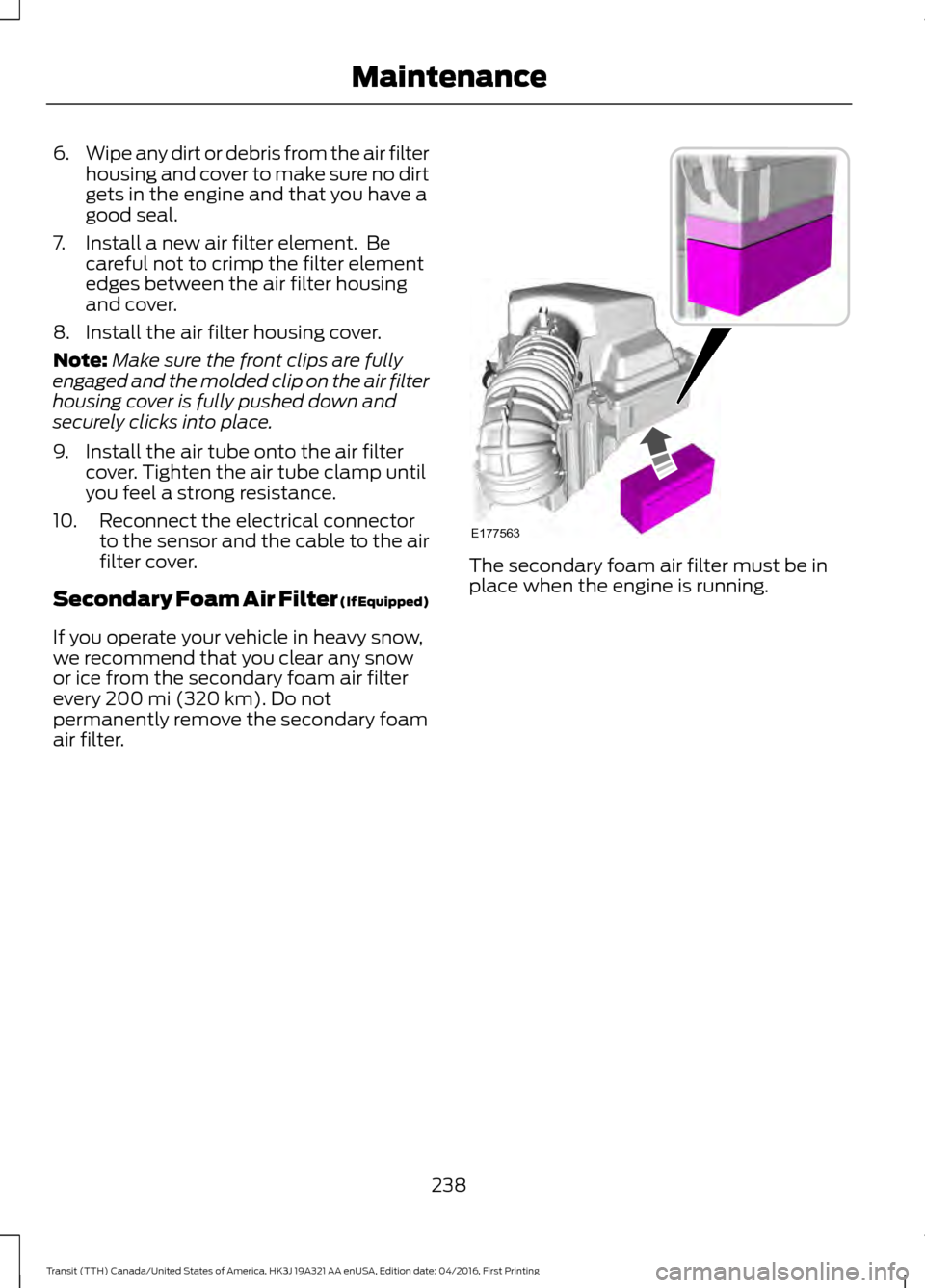

Secondary Foam Air Filter (If Equipped)

If you operate your vehicle in heavy snow,

we recommend that you clear any snow

or ice from the secondary foam air filter

every

200 mi (320 km). Do not

permanently remove the secondary foam

air filter. The secondary foam air filter must be in

place when the engine is running.

238

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing MaintenanceE177563

Page 242 of 484

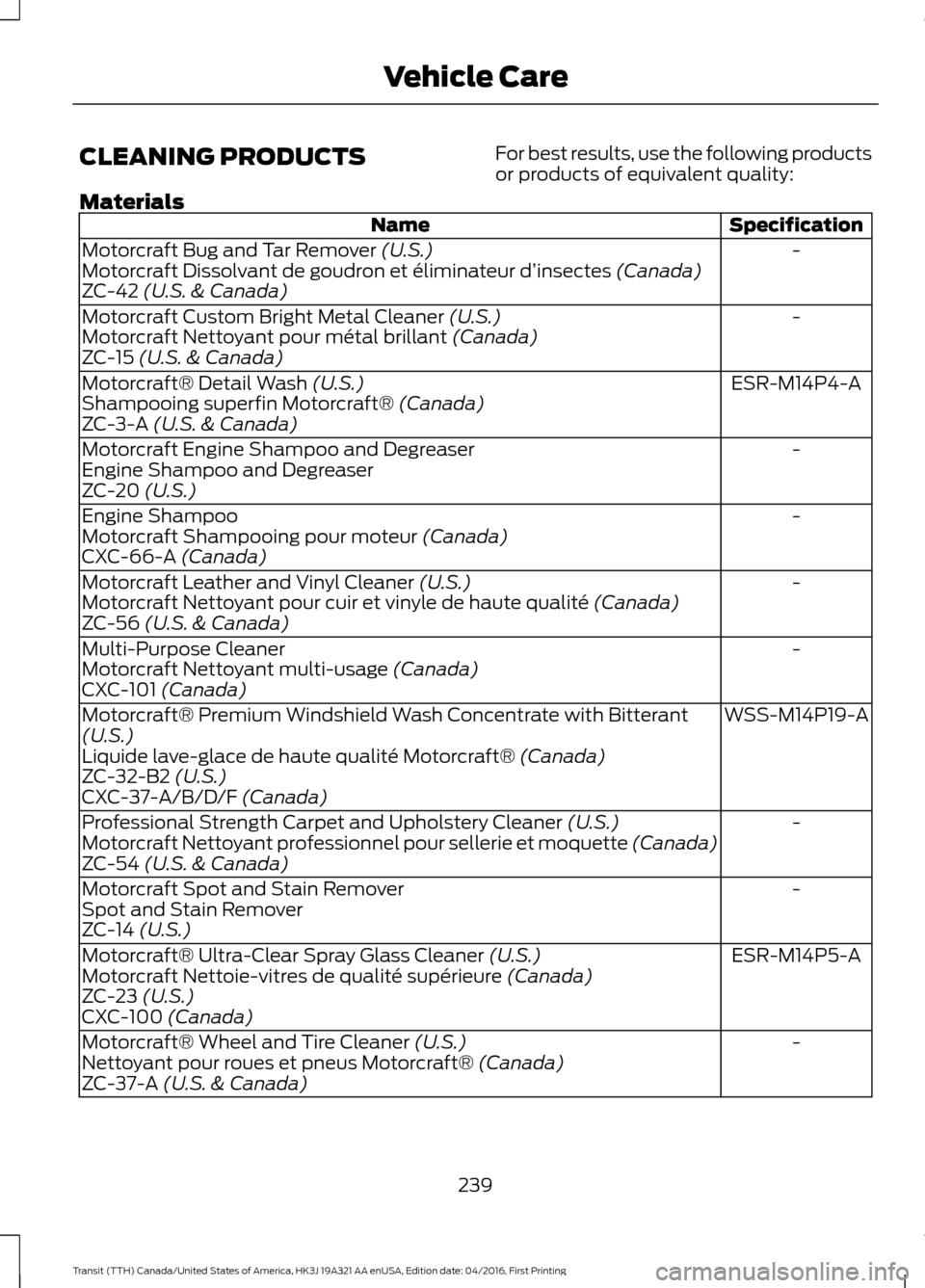

CLEANING PRODUCTS

For best results, use the following products

or products of equivalent quality:

Materials Specification

Name

-

Motorcraft Bug and Tar Remover (U.S.)

Motorcraft Dissolvant de goudron et éliminateur d ’insectes (Canada)

ZC-42 (U.S. & Canada)

-

Motorcraft Custom Bright Metal Cleaner

(U.S.)

Motorcraft Nettoyant pour métal brillant (Canada)

ZC-15 (U.S. & Canada)

ESR-M14P4-A

Motorcraft® Detail Wash

(U.S.)

Shampooing superfin Motorcraft® (Canada)

ZC-3-A (U.S. & Canada)

-

Motorcraft Engine Shampoo and Degreaser

Engine Shampoo and Degreaser

ZC-20

(U.S.)

-

Engine Shampoo

Motorcraft Shampooing pour moteur

(Canada)

CXC-66-A (Canada)

-

Motorcraft Leather and Vinyl Cleaner

(U.S.)

Motorcraft Nettoyant pour cuir et vinyle de haute qualité (Canada)

ZC-56 (U.S. & Canada)

-

Multi-Purpose Cleaner

Motorcraft Nettoyant multi-usage

(Canada)

CXC-101 (Canada)

WSS-M14P19-A

Motorcraft® Premium Windshield Wash Concentrate with Bitterant

(U.S.)

Liquide lave-glace de haute qualité Motorcraft®

(Canada)

ZC-32-B2 (U.S.)

CXC-37-A/B/D/F (Canada)

-

Professional Strength Carpet and Upholstery Cleaner

(U.S.)

Motorcraft Nettoyant professionnel pour sellerie et moquette (Canada)

ZC-54 (U.S. & Canada)

-

Motorcraft Spot and Stain Remover

Spot and Stain Remover

ZC-14

(U.S.)

ESR-M14P5-A

Motorcraft® Ultra-Clear Spray Glass Cleaner

(U.S.)

Motorcraft Nettoie-vitres de qualité supérieure (Canada)

ZC-23 (U.S.)

CXC-100 (Canada)

-

Motorcraft® Wheel and Tire Cleaner

(U.S.)

Nettoyant pour roues et pneus Motorcraft® (Canada)

ZC-37-A (U.S. & Canada)

239

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Vehicle Care

Page 244 of 484

When washing and waxing, park your

vehicle in a shaded area out of direct

sunlight. Always wash your vehicle before

applying wax.

•

Use a quality wax that does not contain

abrasives.

• Follow the manufacturer ’s instructions

to apply and remove the wax.

• Apply a small amount of wax in a

back-and-forth motion, not in circles.

• Do not allow wax to come in contact

with any non-body (low-gloss black)

colored trim. The wax will discolor or

stain the parts over time.

•Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should

feel smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal.

When washing:

• Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold

water to avoid cracking the engine

block or other engine components. •

Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine

Shampoo.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

• Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or

the area in and around these locations.

• Cover the battery, power distribution

box, and air filter assembly to prevent

water damage when cleaning the

engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

• Clean the windshield with a

non-abrasive glass cleaner. When

cleaning the interior of the windshield,

avoid getting any glass cleaner on the

instrument panel or door panels. Wipe

any glass cleaner off these surfaces

immediately.

• For windshields contaminated with

tree sap, chemicals, wax or bugs, clean

the entire windshield using steel wool

(no greater than 0000 grade) in a

circular motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

241

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Vehicle Care

Page 248 of 484

We engineer and test all motor vehicles

and their components for reliable, regular

driving. Under various conditions,

long-term storage may lead to degraded

engine performance or failure unless you

use specific precautions to preserve engine

components.

General

•

Store all vehicles in a dry, ventilated

place.

• Protect from sunlight, if possible.

• If vehicles are stored outside, they

require regular maintenance to protect

against rust and damage.

Body

• Wash your vehicle thoroughly to

remove dirt, grease, oil, tar or mud from

exterior surfaces, rear-wheel housing

and the underside of front fenders.

• Periodically wash your vehicle if it is

stored in exposed locations.

• Touch-up exposed or primed metal to

prevent rust.

• Cover chrome and stainless steel parts

with a thick coat of auto wax to prevent

discoloration. Re-wax as necessary

when you wash your vehicle.

• Lubricate all hood, door and luggage

compartment hinges and latches with

a light grade oil.

• Cover interior trim to prevent fading.

• Keep all rubber parts free from oil and

solvents. Engine

•

Change the engine oil and filter prior to

storage because used engine oil

contains contaminates which may

cause engine damage.

• Start the engine every 15 days for a

minimum of 15 minutes. Run at fast idle

with the climate controls set to defrost

until the engine reaches normal

operating temperature.

• With your foot on the brake, shift

through all the gears while the engine

is running.

• We recommend that you change the

engine oil before you use your vehicle

again.

Fuel system

• Fill the fuel tank with high-quality fuel

until the first automatic shutoff of the

fuel pump nozzle.

Cooling system

• Protect against freezing temperatures.

• When removing your vehicle from

storage, check coolant fluid level.

Confirm that there are no cooling

system leaks and that fluid is at the

recommended level.

Battery

• Check and recharge as necessary. Keep

connections clean.

• If storing your vehicle for more than 30

days without recharging the battery,

we recommend that you disconnect

the battery cables to maintain battery

charge for quick starting.

Note: It is necessary to reset memory

features if battery cables are disconnected.

245

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Vehicle Care

Page 273 of 484

Carrying Out the System Reset

Procedure

Read the entire procedure before carrying

out a system reset.

1. Drive your vehicle above 20 mph (32

km/h) for at least two minutes and

then park in a safe location where you

can easily get to all four tires and have

access to a tire inflation pump.

2. Switch the ignition off.

3. Switch the ignition on with the engine off.

4. Turn the hazard flashers on then off three times, this must be completed

within 10 seconds. If the reset mode

has been entered successfully, the horn

will chirp once and the system indicator

will flash. If this does not occur, repeat

the procedure from step 2. If after

repeated attempts to enter the reset

mode, the horn does not chirp and the

system indicator does not flash, have

your vehicle checked by an authorized

dealer as soon as possible.

5. Train the system sensors in the tires using the following reset sequence

starting with the left front tire and

following a clockwise order: Left front,

right front, right rear, left rear.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn chirps.

Note: The single horn chirp confirms that

the sensor identification code has been

learned by your vehicle for this position. If a

double horn chirp is heard, the reset

procedure was unsuccessful and must be

repeated.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn chirps.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn chirps. 9. Remove the valve cap from the valve

stem on the left rear tire. Decrease the

air pressure until the horn chirps.

Training is complete when the horn

chirps after the last system sensor (left

rear) has been trained and the system

indicator stops flashing.

10. Switch the ignition off. If two short horn chirps are heard, the reset

procedure was unsuccessful and

must be repeated.

Note: If after repeating the procedure two

short horn chirps are heard again, have your

vehicle checked by an authorized dealer as

soon as possible.

11. Set all four tires to the correct pressure See Maintenance (page

211). or the tire inflation pressure label

(located on the edge of driver door or

the B-Pillar).

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealant may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be

used. The tire pressure monitoring system

sensor and valve stem on the wheel must

be replaced by an authorized dealer after

use of the sealant. If the tire pressure monitor sensor

becomes damaged, it will no longer

function. See

Tire Pressure

Monitoring System (page 266). Note:

The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on this vehicle.

270

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and Tires

Page 284 of 484

ENGINE SPECIFICATIONS - 3.5L ECOBOOST™

3.5L V6 Ecoboost

Engine

214

Cubic inches

Minimum 87 octane

Required fuel

1-4-2-5-3-6

Firing order

Coil on plug

Ignition system

.030-.033 in. (.75-.85 mm)

Spark plug gap

10.0:1

Compression ratio

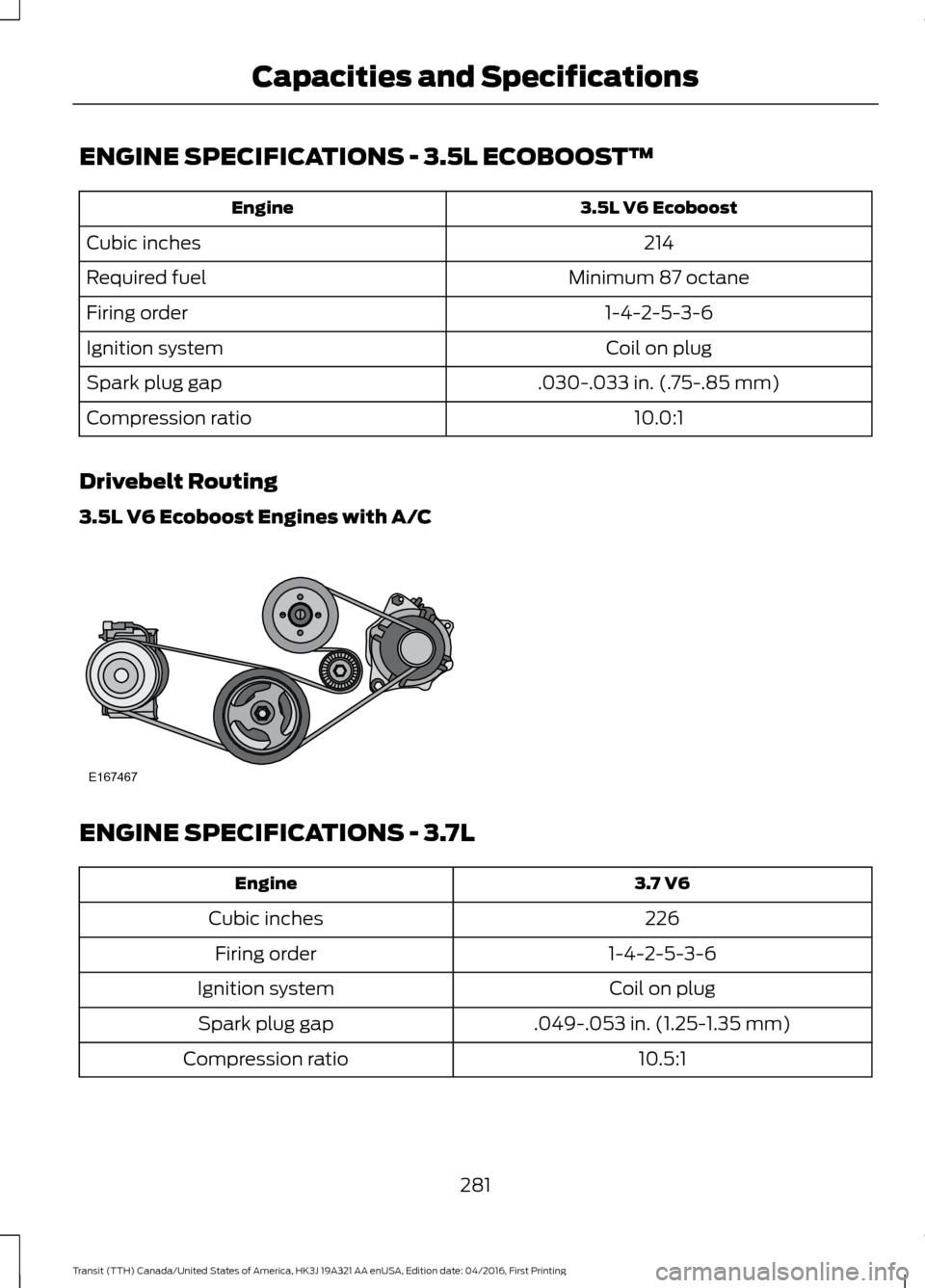

Drivebelt Routing

3.5L V6 Ecoboost Engines with A/C ENGINE SPECIFICATIONS - 3.7L

3.7 V6

Engine

226

Cubic inches

1-4-2-5-3-6

Firing order

Coil on plug

Ignition system

.049-.053 in. (1.25-1.35 mm)

Spark plug gap

10.5:1

Compression ratio

281

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Capacities and SpecificationsE167467