FORD TRANSIT 2017 5.G Owners Manual

Manufacturer: FORD, Model Year: 2017, Model line: TRANSIT, Model: FORD TRANSIT 2017 5.GPages: 484, PDF Size: 11.45 MB

Page 271 of 484

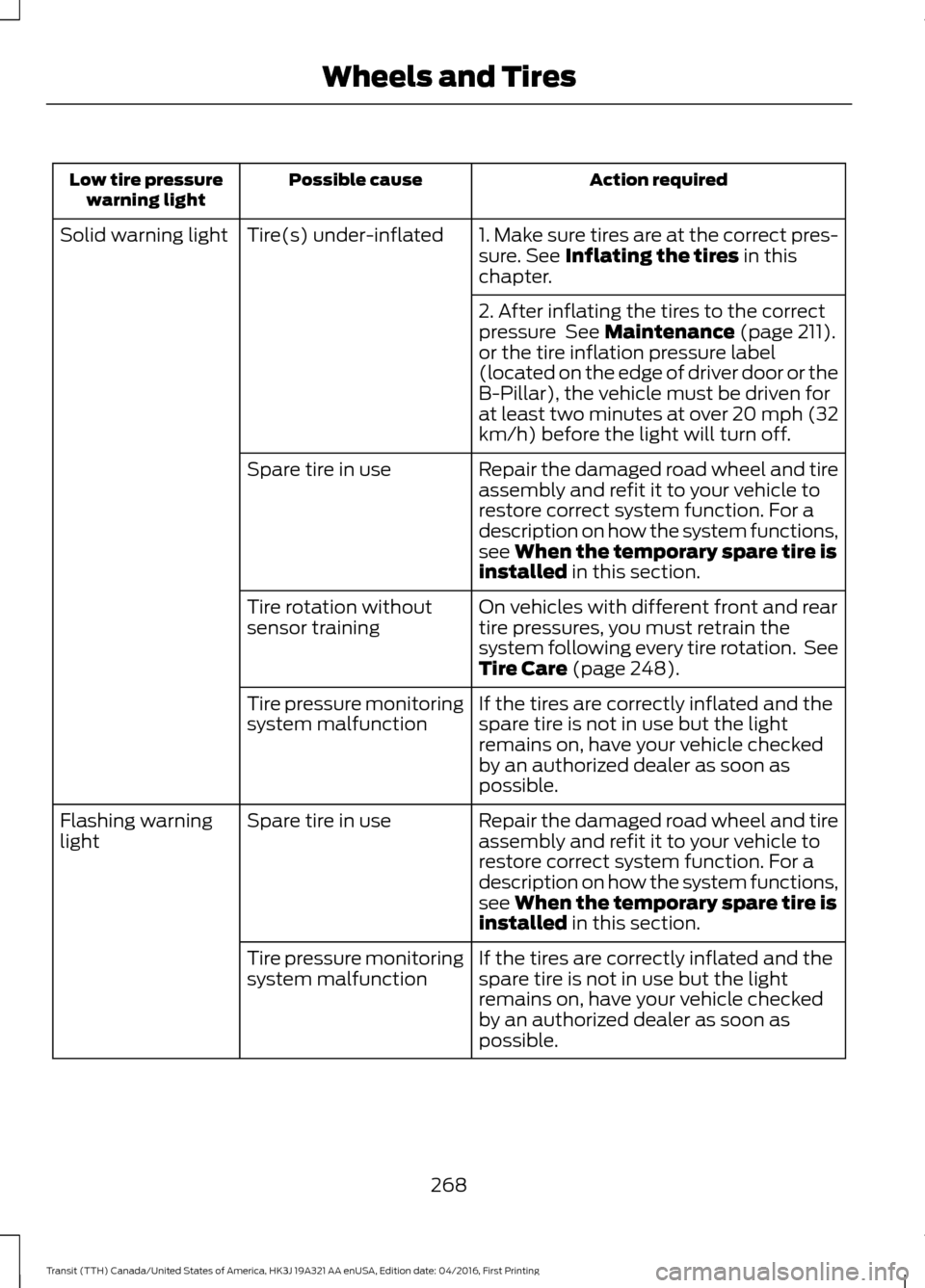

Action required

Possible cause

Low tire pressure

warning light

1. Make sure tires are at the correct pres-

sure. See Inflating the tires in this

chapter.

Tire(s) under-inflated

Solid warning light

2. After inflating the tires to the correct

pressure

See Maintenance (page 211).

or the tire inflation pressure label

(located on the edge of driver door or the

B-Pillar), the vehicle must be driven for

at least two minutes at over 20 mph (32

km/h) before the light will turn off.

Repair the damaged road wheel and tire

assembly and refit it to your vehicle to

restore correct system function. For a

description on how the system functions,

see

When the temporary spare tire is

installed in this section.

Spare tire in use

On vehicles with different front and rear

tire pressures, you must retrain the

system following every tire rotation. See

Tire Care

(page 248).

Tire rotation without

sensor training

If the tires are correctly inflated and the

spare tire is not in use but the light

remains on, have your vehicle checked

by an authorized dealer as soon as

possible.

Tire pressure monitoring

system malfunction

Repair the damaged road wheel and tire

assembly and refit it to your vehicle to

restore correct system function. For a

description on how the system functions,

see

When the temporary spare tire is

installed in this section.

Spare tire in use

Flashing warning

light

If the tires are correctly inflated and the

spare tire is not in use but the light

remains on, have your vehicle checked

by an authorized dealer as soon as

possible.

Tire pressure monitoring

system malfunction

268

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and Tires

Page 272 of 484

When Inflating the Tires

When inflating the tires (for example; at a

gas station), the system may not respond

immediately to the air added to the tires.

It may take up to two minutes of driving

over 20 mph (32 km/h) for the light to turn

off after you have filled your tires to the

recommended inflation pressure.

How Temperature Affects the Tire

Pressures

While driving in a normal manner, tire

pressures may increase up to 4 psi (0.3

bar) from a cold start situation. If the

vehicle is stationary overnight and the

temperature significantly lower than the

daytime temperature, tire pressures may

decrease up to 3 psi (0.2 bar) for a drop of

30°F (17°C) in ambient temperature. This

lower pressure value will be detected by

the system as being significantly lower

than the correct inflation pressure and the

warning light will illuminate.

If the warning light is on:

•

Check each tire to verify that none are

flat.

• If one or more tires are flat, repair as

necessary.

• Check the tire pressures and Inflate all

the tires to the correct pressure.

Tire Pressure Monitoring System

Reset Procedure

Carry out the tire pressure monitoring

system reset procedure after:

• Every tire rotation.

• Each tire replacement, only when the

sensor stays the same and does not

change.

Note: The tire pressure monitoring system

reset procedure will not work with a new

sensor until an authorized dealer programs

the new sensor. Overview WARNING

To determine the required

pressure(s) for your vehicle, see the

Safety Compliance Certification

Label (on the door hinge pillar, door-latch

post or the door edge that meets the

door-latch post, next to the driver seat) or

the Tire Label on the B-Pillar or the edge

of the driver door. To maintain your vehicle

’s load carrying

capability, this vehicle requires different

tire pressures in the front tires compared

to the rear tires. The system on your vehicle

is designed to illuminate the warning light

at different pressures for the front and rear

tires.

The tires need to be periodically rotated

to provide consistent performance and

maximum tire life, the system needs to

know when the tires have been rotated to

determine which set of tires are on the

front and rear axles. With this information,

the system can detect and correctly warn

of low tire pressures.

System Reset Tips:

• To reduce the chance of interference

from another vehicle, the system reset

procedure should be carried out at

least three feet (one meter) away from

another Ford vehicle undergoing the

system reset procedure.

• Do not wait more than two minutes

between resetting each tire sensor or

the system will time-out and the entire

procedure will have to be repeated on

all four wheels. A double horn chirp

indicates the need to repeat the

procedure.

269

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and Tires

Page 273 of 484

Carrying Out the System Reset

Procedure

Read the entire procedure before carrying

out a system reset.

1. Drive your vehicle above 20 mph (32

km/h) for at least two minutes and

then park in a safe location where you

can easily get to all four tires and have

access to a tire inflation pump.

2. Switch the ignition off.

3. Switch the ignition on with the engine off.

4. Turn the hazard flashers on then off three times, this must be completed

within 10 seconds. If the reset mode

has been entered successfully, the horn

will chirp once and the system indicator

will flash. If this does not occur, repeat

the procedure from step 2. If after

repeated attempts to enter the reset

mode, the horn does not chirp and the

system indicator does not flash, have

your vehicle checked by an authorized

dealer as soon as possible.

5. Train the system sensors in the tires using the following reset sequence

starting with the left front tire and

following a clockwise order: Left front,

right front, right rear, left rear.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn chirps.

Note: The single horn chirp confirms that

the sensor identification code has been

learned by your vehicle for this position. If a

double horn chirp is heard, the reset

procedure was unsuccessful and must be

repeated.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn chirps.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn chirps. 9. Remove the valve cap from the valve

stem on the left rear tire. Decrease the

air pressure until the horn chirps.

Training is complete when the horn

chirps after the last system sensor (left

rear) has been trained and the system

indicator stops flashing.

10. Switch the ignition off. If two short horn chirps are heard, the reset

procedure was unsuccessful and

must be repeated.

Note: If after repeating the procedure two

short horn chirps are heard again, have your

vehicle checked by an authorized dealer as

soon as possible.

11. Set all four tires to the correct pressure See Maintenance (page

211). or the tire inflation pressure label

(located on the edge of driver door or

the B-Pillar).

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealant may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be

used. The tire pressure monitoring system

sensor and valve stem on the wheel must

be replaced by an authorized dealer after

use of the sealant. If the tire pressure monitor sensor

becomes damaged, it will no longer

function. See

Tire Pressure

Monitoring System (page 266). Note:

The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on this vehicle.

270

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and Tires

Page 274 of 484

If you get a flat tire while driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road.

Have a flat serviced by an authorized

dealer in order to prevent damage to the

system sensors See Tire Pressure

Monitoring System (page 266). Replace

the spare tire with a road tire as soon as

possible. During repairing or replacing of

the flat tire, have the authorized dealer

inspect the system sensor for damage.

Dissimilar Spare Wheel and Tire

Assembly Information WARNING

Failure to follow these guidelines

could result in an increased risk of

loss of vehicle control, injury or death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided

by Ford. If the dissimilar spare tire or wheel

is damaged, it should be replaced rather

than repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and wheels

and can be one of three types:

1.

T-type mini-spare:

This spare tire

begins with the letter T for tire size and

may have Temporary Use Only molded in

the sidewall.

2. Full-size dissimilar spare with label

on wheel:

This spare tire has a label on

the wheel that states: THIS WHEEL AND

TIRE ASSEMBLY FOR TEMPORARY USE

ONLY When driving with one of the dissimilar

spare tires listed above, do not:

•

Exceed

50 mph (80 km/h).

• Load the vehicle beyond maximum

vehicle load rating listed on the Safety

Compliance Label.

• Tow a trailer.

• Use snow chains on the end of the

vehicle with the dissimilar spare tire.

• Use more than one dissimilar spare tire

at a time.

• Use commercial car washing

equipment.

• Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tires

listed above at any one wheel location can

lead to impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

3. Full-size dissimilar spare without

label on wheel

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use commercial car washing

equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

271

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and Tires

Page 275 of 484

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

•

Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

Locking Lug Nuts

You can obtain replacement locking lug

nuts or a locking lug nut key using the

reference number certificate.

Vehicles With a Spare Wheel

Van, Bus or Wagon

The spare wheel is under the rear of your

vehicle.

If the spare wheel is the same type and

size as your vehicle road wheel, you can fit

the spare wheel and continue to drive in

the normal manner.

If the spare wheel is not the same type and

size as your vehicle road wheel, it has a

label showing the maximum driving speed

limit. Note:

If your vehicle is fitted with a tire

pressure monitoring system, the warning

indicator will flash if you fit the spare wheel

to your vehicle. To restore the correct

operation of the tire pressure monitoring

system, you must have the repaired road

wheel and tire assembly refitted to your

vehicle. See Tire Pressure Monitoring

System (page 266). To prevent damage

occurring to the tire pressure monitoring

system sensors, make sure you have a

damage tire repaired or replaced by a tire

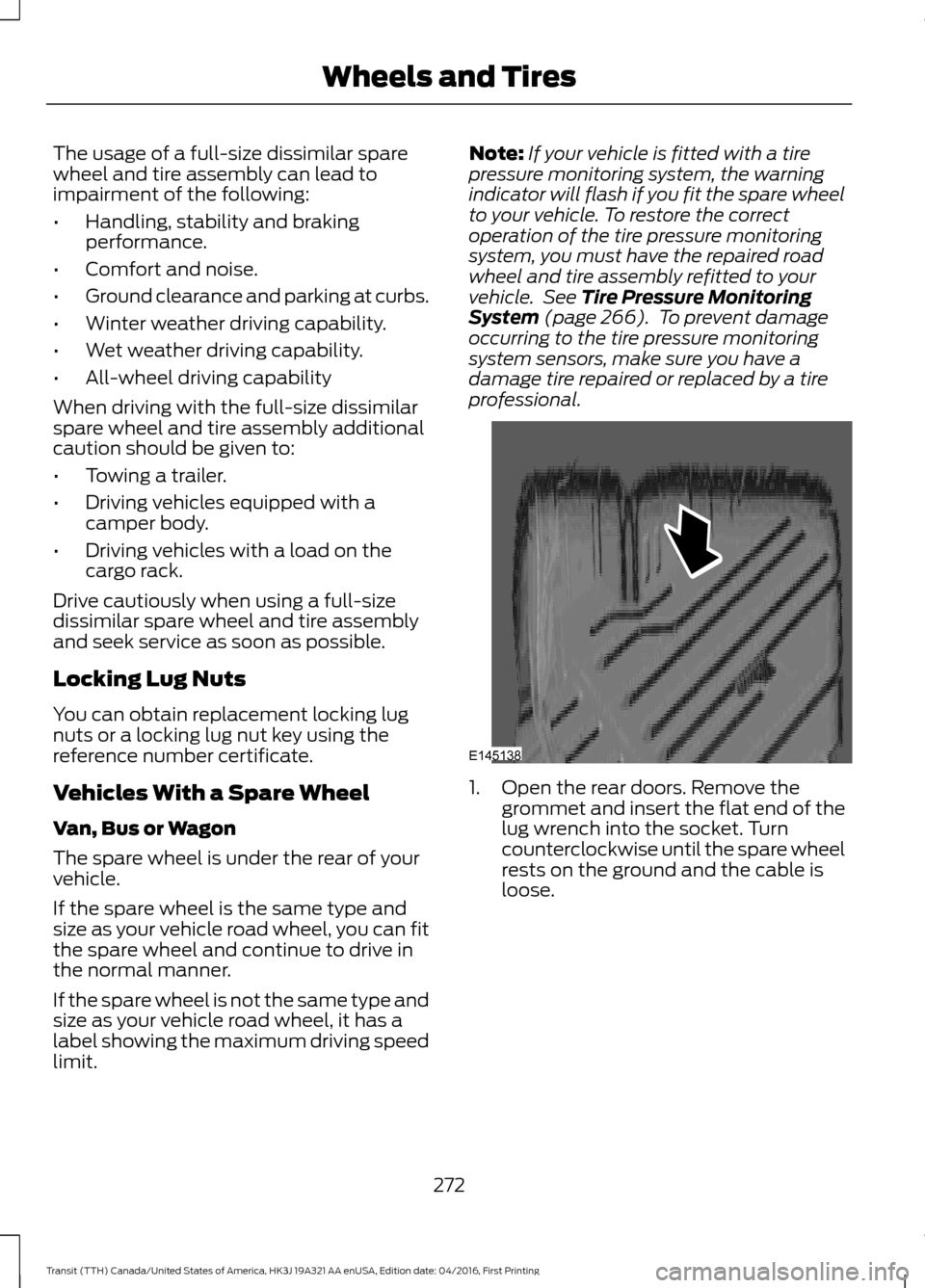

professional. 1. Open the rear doors. Remove the

grommet and insert the flat end of the

lug wrench into the socket. Turn

counterclockwise until the spare wheel

rests on the ground and the cable is

loose.

272

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and TiresE145138

Page 276 of 484

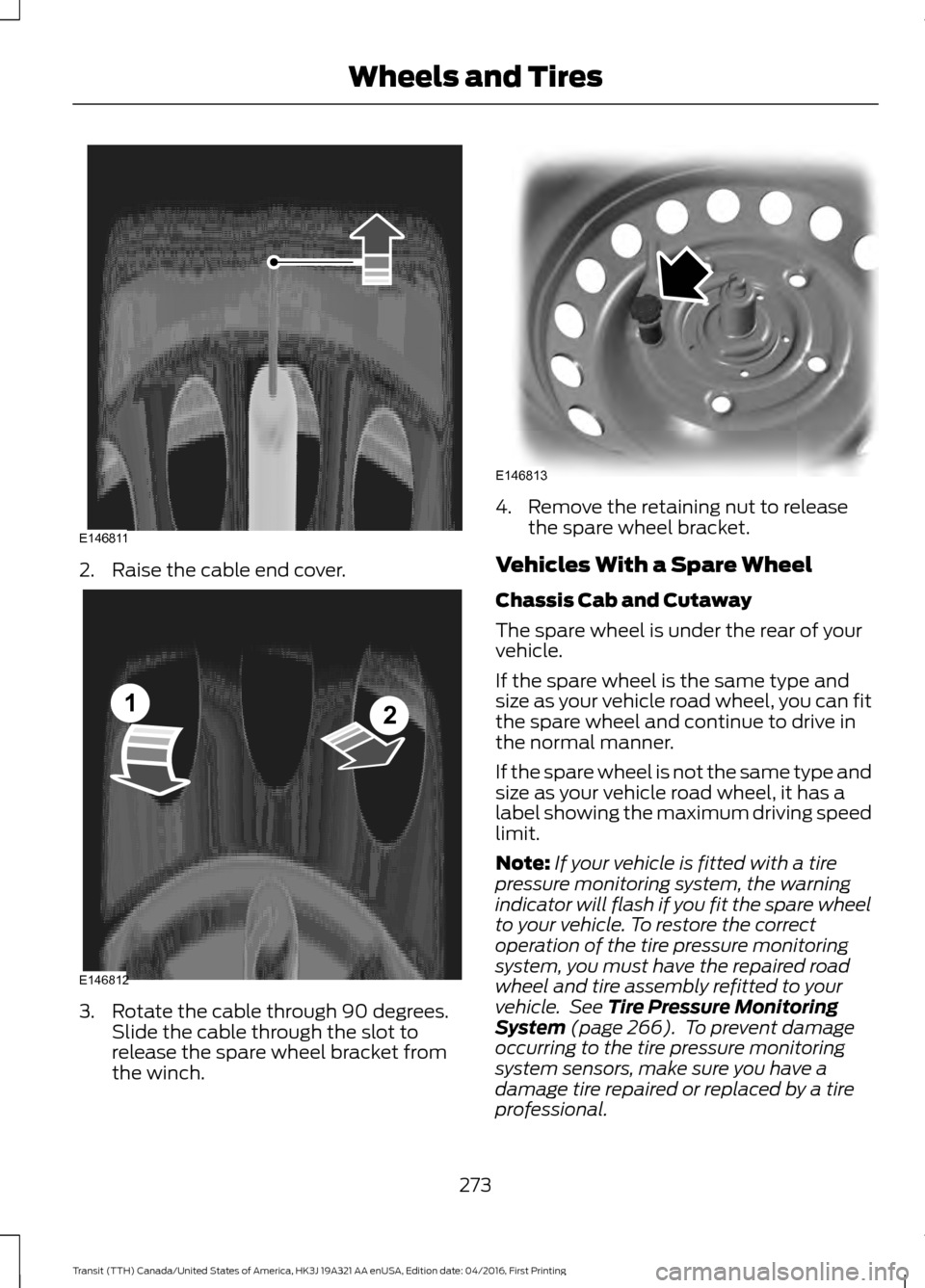

2. Raise the cable end cover.

3. Rotate the cable through 90 degrees.

Slide the cable through the slot to

release the spare wheel bracket from

the winch. 4. Remove the retaining nut to release

the spare wheel bracket.

Vehicles With a Spare Wheel

Chassis Cab and Cutaway

The spare wheel is under the rear of your

vehicle.

If the spare wheel is the same type and

size as your vehicle road wheel, you can fit

the spare wheel and continue to drive in

the normal manner.

If the spare wheel is not the same type and

size as your vehicle road wheel, it has a

label showing the maximum driving speed

limit.

Note: If your vehicle is fitted with a tire

pressure monitoring system, the warning

indicator will flash if you fit the spare wheel

to your vehicle. To restore the correct

operation of the tire pressure monitoring

system, you must have the repaired road

wheel and tire assembly refitted to your

vehicle. See Tire Pressure Monitoring

System (page 266). To prevent damage

occurring to the tire pressure monitoring

system sensors, make sure you have a

damage tire repaired or replaced by a tire

professional.

273

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and TiresE146811 E146812

12 E146813

Page 277 of 484

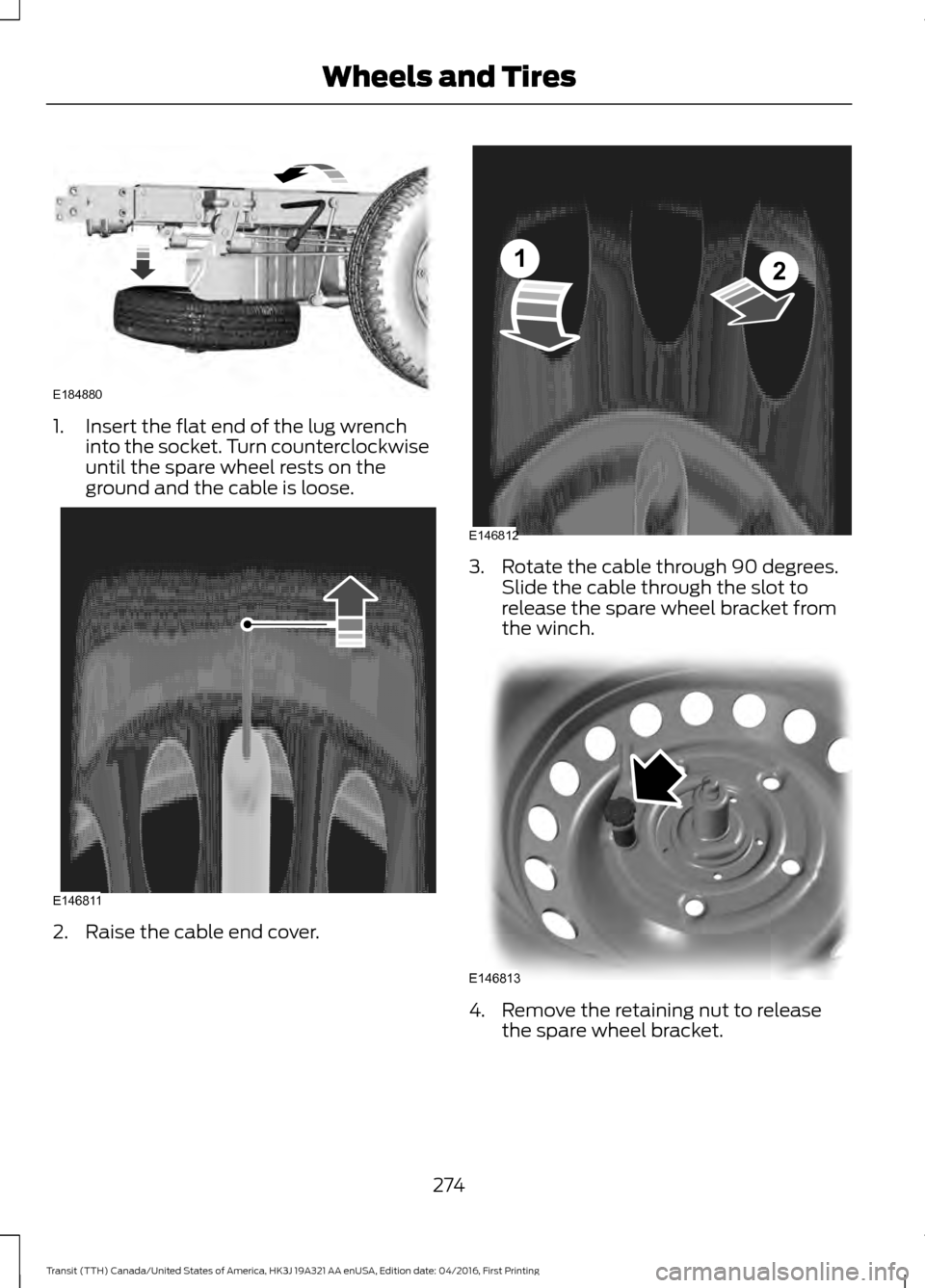

1. Insert the flat end of the lug wrench

into the socket. Turn counterclockwise

until the spare wheel rests on the

ground and the cable is loose. 2. Raise the cable end cover. 3. Rotate the cable through 90 degrees.

Slide the cable through the slot to

release the spare wheel bracket from

the winch. 4. Remove the retaining nut to release

the spare wheel bracket.

274

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and TiresE184880 E146811 E146812

12 E146813

Page 278 of 484

Vehicle Jack

WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent the vehicle from

moving or slipping off the jack. To help prevent the vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P), set the parking brake and block (in

both directions) the wheel that is

diagonally opposite (other side and end of

the vehicle) to the tire being changed. Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured. Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. Disable the power running boards

before jacking, lifting, or placing any

object under the vehicle. Never place

your hand between the power running

board and the vehicle as extended power

running boards will retract when the doors

are closed. Failure to follow these

instructions may result in personal injury. Note:

Passengers should not remain in the

vehicle when the vehicle is being jacked.

Note: Vehicles with a Temporary Mobility

Kit do not have a vehicle jack or a lug

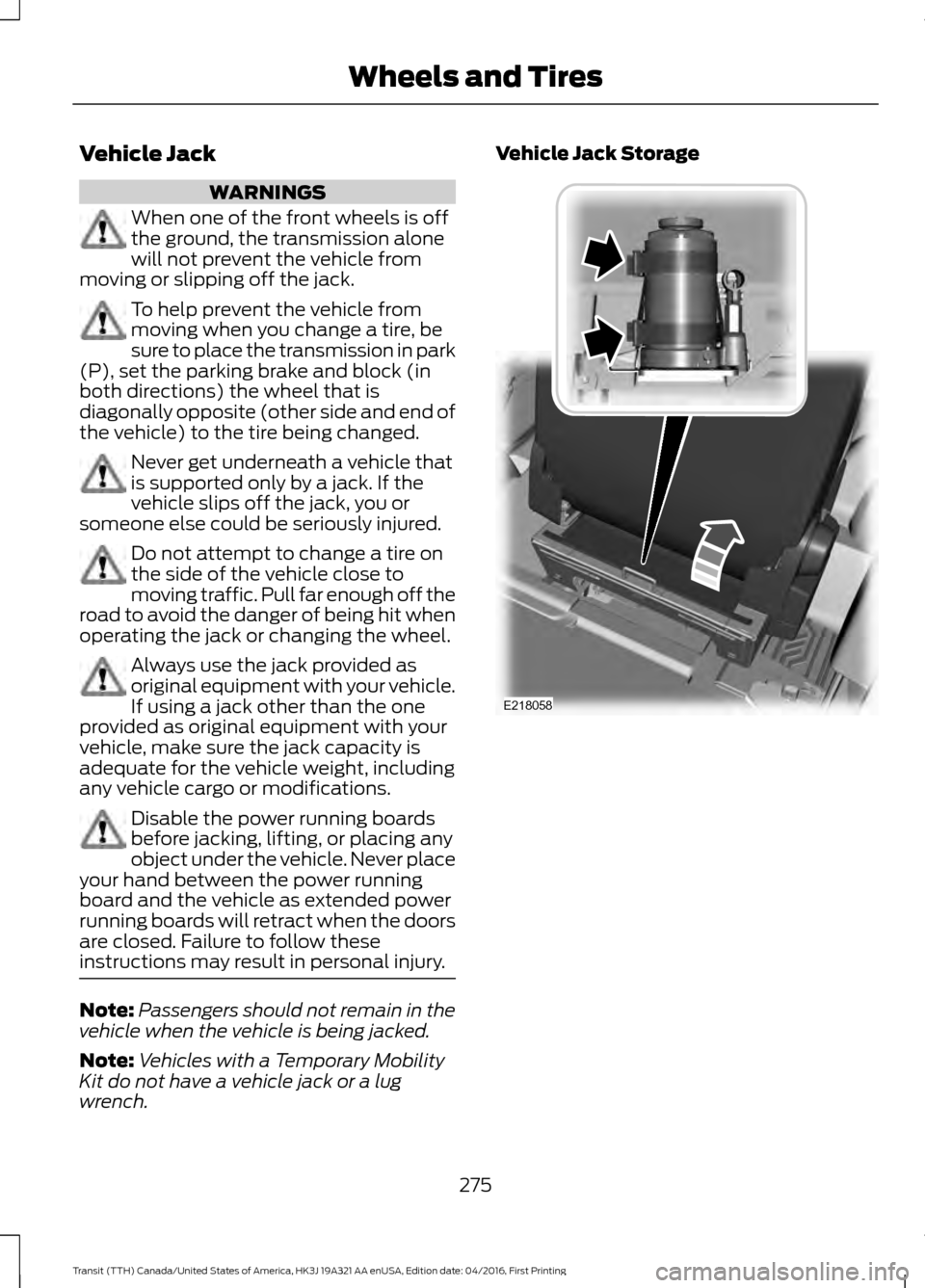

wrench. Vehicle Jack Storage

275

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and TiresE218058

Page 279 of 484

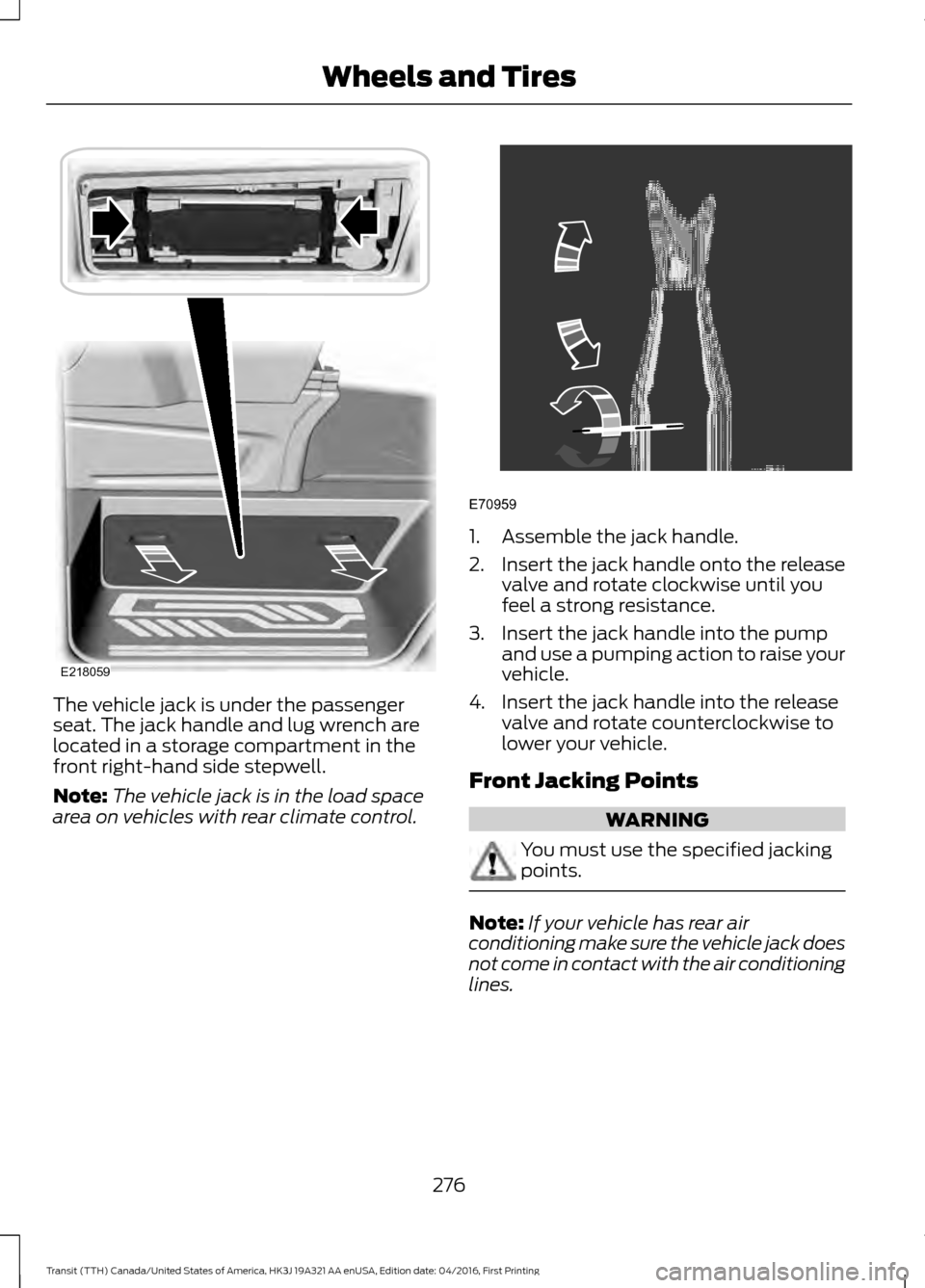

The vehicle jack is under the passenger

seat. The jack handle and lug wrench are

located in a storage compartment in the

front right-hand side stepwell.

Note:

The vehicle jack is in the load space

area on vehicles with rear climate control. 1. Assemble the jack handle.

2.

Insert the jack handle onto the release

valve and rotate clockwise until you

feel a strong resistance.

3. Insert the jack handle into the pump and use a pumping action to raise your

vehicle.

4. Insert the jack handle into the release valve and rotate counterclockwise to

lower your vehicle.

Front Jacking Points WARNING

You must use the specified jacking

points.

Note:

If your vehicle has rear air

conditioning make sure the vehicle jack does

not come in contact with the air conditioning

lines.

276

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and TiresE218059 E70959

Page 280 of 484

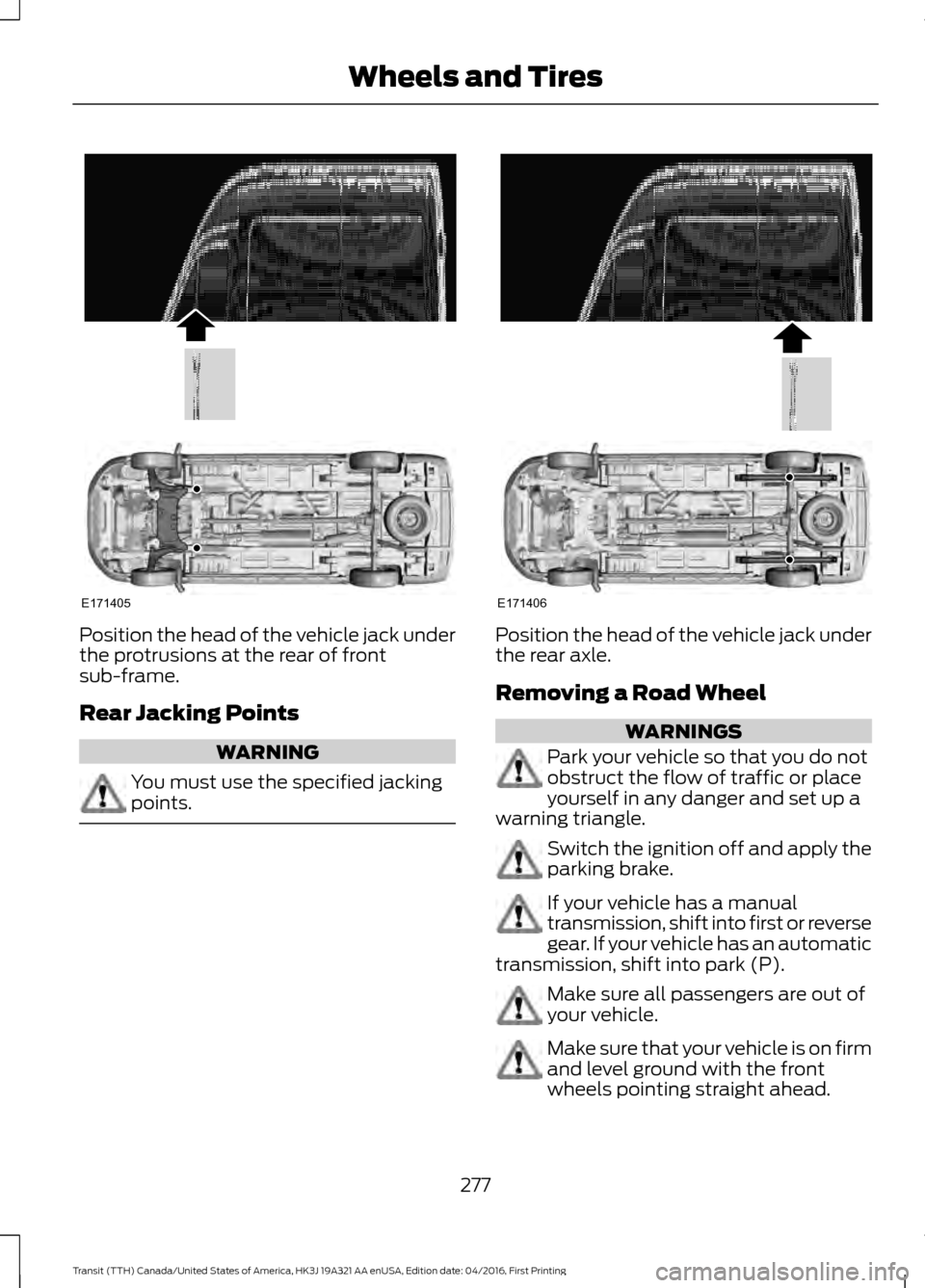

Position the head of the vehicle jack under

the protrusions at the rear of front

sub-frame.

Rear Jacking Points

WARNING

You must use the specified jacking

points. Position the head of the vehicle jack under

the rear axle.

Removing a Road Wheel

WARNINGS

Park your vehicle so that you do not

obstruct the flow of traffic or place

yourself in any danger and set up a

warning triangle. Switch the ignition off and apply the

parking brake.

If your vehicle has a manual

transmission, shift into first or reverse

gear. If your vehicle has an automatic

transmission, shift into park (P). Make sure all passengers are out of

your vehicle.

Make sure that your vehicle is on firm

and level ground with the front

wheels pointing straight ahead.

277

Transit (TTH) Canada/United States of America, HK3J 19A321 AA enUSA, Edition date: 04/2016, First Printing Wheels and TiresE171405 E171406