warning light FORD WINDSTAR 2001 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2001, Model line: WINDSTAR, Model: FORD WINDSTAR 2001 2.GPages: 288, PDF Size: 2.6 MB

Page 140 of 288

Conditions of operation

If... Then...

The driver's safety belt is not

buckled before the ignition switch

is turned to the ON position...The safety belt warning light

illuminates 1-2 minutes and the

warning chime sounds 4-8

seconds.

The driver's safety belt is buckled

while the indicator light is

illuminated and the warning chime

is sounding...The safety belt warning light and

warning chime turn off.

The driver's safety belt is buckled

before the ignition switch is turned

to the ON position...The safety belt warning light and

indicator chime remain off.

Belt minder

The Belt Minder feature is a supplemental warning to the safety belt

warning function. This feature provides additional reminders to the

driver that the driver's safety belt is unbuckled by intermittently

sounding a chime and illuminating the safety belt warning lamp in the

instrument cluster.

If... Then...

The driver's safety belt is not

buckled before the vehicle has

reached at least 5 km/h (3 mph)

and 1-2 minutes have elapsed

since the ignition switch has been

turned to ON...The Belt Minder feature is

activated - the safety belt warning

light illuminates and the warning

chime sounds for 6 seconds every

30 seconds, repeating for

approximately 5 minutes or until

safety belt is buckled.

The driver's safety belt is buckled

while the safety belt indicator light

is illuminated and the safety belt

warning chime is sounding...The Belt Minder feature will not

activate.

The driver's safety belt is buckled

before the ignition switch is turned

to the ON position...The Belt Minder feature will not

activate.

The purpose of the Belt Minder is to remind occasional wearers to wear

safety belts all of the time.

Seating and safety restraints

140

Page 142 of 288

One time disable

Anytime the safety belt is buckled and then unbuckled during an ignition

ON cycle, Belt Minder will be disabled for that ignition cycle only.

Deactivating/activating the belt minder feature

Read steps1-9thoroughly before proceeding with the

deactivation/activation programming procedure.

The Belt Minder feature can be deactivated/activated by performing the

following procedure:

Before following the procedure, make sure that:

²the parking brake is set

²the gearshift is in P (Park) (automatic transmission).

²the ignition switch is in the OFF position

²all vehicle doors are closed

²the driver's safety belt is unbuckled

²the parklamps/headlamps are in OFF position (If vehicle is equipped

with Autolamps, this will not affect the procedure.)

To reduce the risk of injury, do not deactivate/activate the Belt

Minder feature while driving the vehicle.

1. Turn the ignition switch to the RUN (or ON) position. (DO NOT

START THE ENGINE)

2. Wait until the safety belt warning light turns off. (Approximately 1

minute)

²Steps 3±5 must be completed within 60 seconds or the procedure will

have to be repeated.

3. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled. This can be done before or during Belt Minder

warning activation.

4. Turn on the parklamps/headlamps, turn off the parklamps/headlamps.

5. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled.

²After step 5 the safety belt warning light will be turned on for three

seconds.

Seating and safety restraints

142

Page 143 of 288

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

²This will disable Belt Minder if it is currently enabled, or enable Belt

Minder if it is currently disabled.

7. Confirmation of disabling Belt Minder is provided by flashing the

safety belt warning light four times per second for three seconds.

8. Confirmation of enabling Belt Minder is provided by flashing the safety

belt warning light four times per second for three seconds, followed by

three seconds with the safety belt warning light off, then followed by

flashing the safety belt warning light four times per second for three

seconds again.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, wears or cuts, replacing if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), child safety seat tether bracket

assemblies (if equipped), LATCH child seat tether anchors and lower

anchors (if equipped), and attaching hardware, should be inspected after

a collision. Ford recommends that all safety belt assemblies used in

vehicles involved in a collision be replaced. However, if the collision was

minor and a qualified technician finds that the belts do not show damage

and continue to operate properly, they do not need to be replaced,

except as described in theReplacing the front passenger and second

row bench seat belt assemblies after a collisionsection of this chapter.

Safety belt assemblies not in use during a collision should also be

inspected and replaced if either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

Refer toCleaning and maintaining the safety beltsin the

Maintenance and caresection.

Seating and safety restraints

143

Page 147 of 288

Determining if the system is operational

The supplemental restraint system uses a warning indicator in the

instrument cluster or a back-up tone to indicate the condition of the

system. Refer to theRestraints Warning Indicatorsection in the

Instrumentationchapter. Routine maintenance of the air bag is not

required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light (same light

for front and side air bag system)

will either flash or stay lit.

²The readiness light will not

illuminate immediately after ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and/or light are repaired.

If any of these things happen, even intermittently, have the supplemental

restraint system serviced at your dealership or by a qualified technician

immediately. Unless serviced, the system may not function properly in

the event of a collision.

How does the air bag supplemental restraint system work?

The air bag SRS is designed to

activate when the vehicle sustains

longitudinal deceleration sufficient

to cause the sensors to close an

electrical circuit that initiates air

bag inflation.

The fact that the air bags did not

inflate in a collision does not mean

that something is wrong with the

system. Rather, it means the forces

were not of the type sufficient to

cause activation. Front air bags are designed to inflate in frontal and

near-frontal collisions, not rollover, side-impact, or rear-impacts unless

the collision causes sufficient longitudinal deceleration.

Seating and safety restraints

147

Page 149 of 288

²a readiness light and tone.

²diagnostic module.

²and the electrical wiring which connects the components.

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power and the air bag ignitors.

Side air bag system (if equipped)

Do not place objects or mount equipment on or near the air bag

cover on the side of the seatbacks of the front seats or in front

seat areas that may come into contact with a deploying air bag. Failure

to follow these instructions may increase the risk of personal injury in

the event of a collision.

Do not use accessory seat covers. The use of accessory seat

covers may prevent the deployment of the side air bags and

increase the risk of injury in an accident.

Do not lean your head on the door. The side air bag could injure

you as it deploys from the side of the seatback.

Do not attempt to service, repair, or modify the air bag

Supplemental Restraint System, its fuses or the seat cover on a

seat containing an air bag. See your Ford or Lincoln Mercury dealer.

All occupants of the vehicle including the driver should always

wear their safety belts even when an air bag SRS is provided.

Seating and safety restraints

149

Page 150 of 288

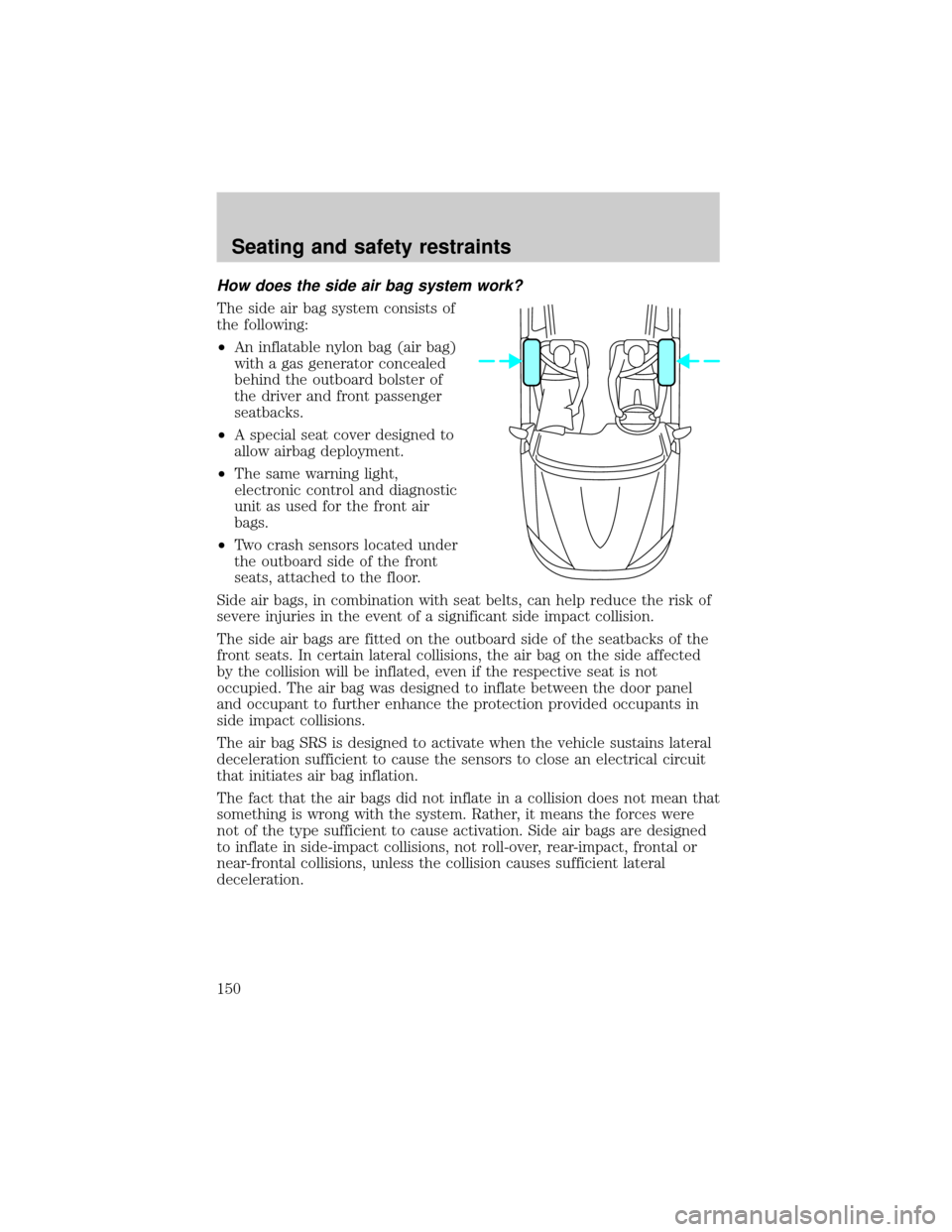

How does the side air bag system work?

The side air bag system consists of

the following:

²An inflatable nylon bag (air bag)

with a gas generator concealed

behind the outboard bolster of

the driver and front passenger

seatbacks.

²A special seat cover designed to

allow airbag deployment.

²The same warning light,

electronic control and diagnostic

unit as used for the front air

bags.

²Two crash sensors located under

the outboard side of the front

seats, attached to the floor.

Side air bags, in combination with seat belts, can help reduce the risk of

severe injuries in the event of a significant side impact collision.

The side air bags are fitted on the outboard side of the seatbacks of the

front seats. In certain lateral collisions, the air bag on the side affected

by the collision will be inflated, even if the respective seat is not

occupied. The air bag was designed to inflate between the door panel

and occupant to further enhance the protection provided occupants in

side impact collisions.

The air bag SRS is designed to activate when the vehicle sustains lateral

deceleration sufficient to cause the sensors to close an electrical circuit

that initiates air bag inflation.

The fact that the air bags did not inflate in a collision does not mean that

something is wrong with the system. Rather, it means the forces were

not of the type sufficient to cause activation. Side air bags are designed

to inflate in side-impact collisions, not roll-over, rear-impact, frontal or

near-frontal collisions, unless the collision causes sufficient lateral

deceleration.

Seating and safety restraints

150

Page 167 of 288

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

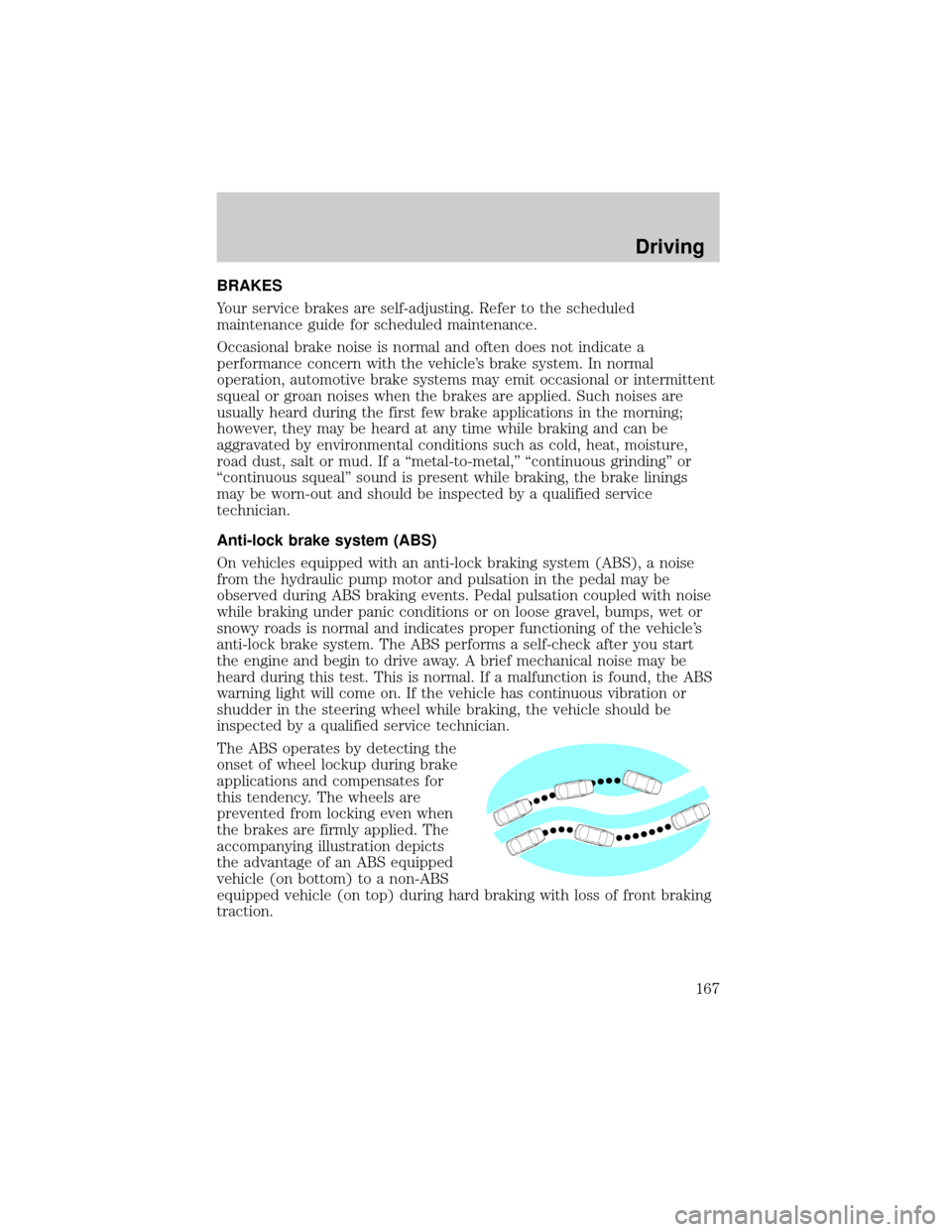

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

167

Page 168 of 288

ABS warning lampABS

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the ON position. If the light does not

illuminate momentarily at start up or remains on the ABS needs to be

serviced.

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately.)

Using ABS

²In an emergency or when maximum efficiency from the four wheel

ABS is required, apply continuous force on the brake. The four wheel

ABS will be activated immediately, thus allowing you to retain full

steering control of your vehicle and, providing there is sufficient

space, will enable you to avoid obstacles and bring the vehicle to a

controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

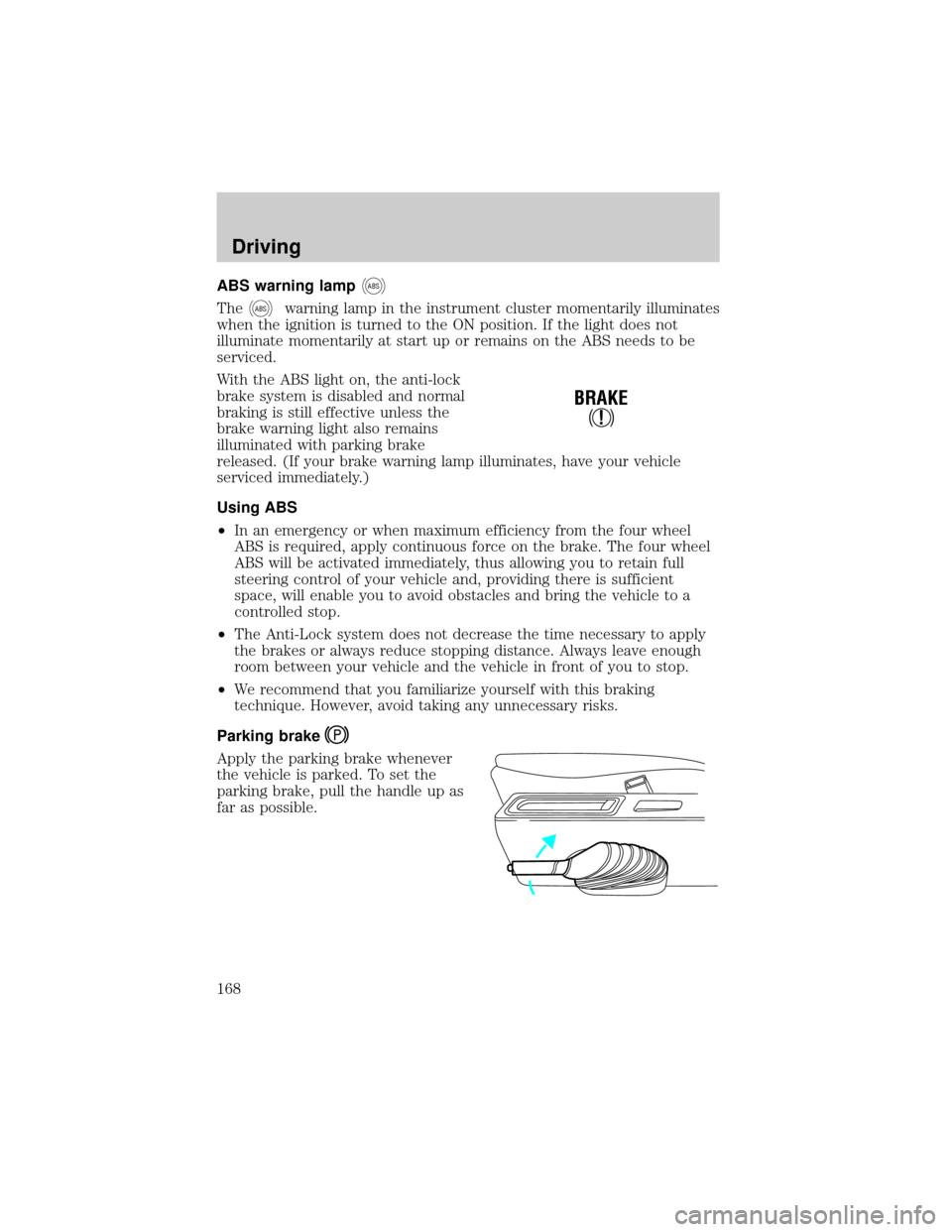

Parking brake

Apply the parking brake whenever

the vehicle is parked. To set the

parking brake, pull the handle up as

far as possible.

!

BRAKE

Driving

168

Page 172 of 288

The AdvanceTracyon/off control

button allows the driver to control

the availability of the Traction

Controlyand AdvanceTracy

system. This is independent of the

ABS function, which canNOTbe

switched off by the driver.

The AdvanceTracysystem status is

indicated by a ªTRAC ACTIVEº

indicator light in the instrument

cluster that will illuminate when the system is active. If a failure is

detected, the ªTRAC OFFº indicator light will stay ON, vehicles with a

message center (if equipped) will also display the warning ªCHECK

ADVANCETRACº, have the system serviced immediately.

The AdvanceTracysystem continually monitors and checks all sensors

used in improving the stability of the vehicle. Some drivers may notice a

slight movement of the brake pedal when the system checks itself.

During AdvanceTracyoperation you may experience the following:

²A rumble or clicking sound much like ABS or Traction Controly

²A slight deceleration or a reduction in the acceleration of the vehicle

²The ªTRAC ACTIVEº indicator light will illuminate

²If your foot is on the brake pedal, you will feel a vibration in the pedal

much like ABS. As with any vehicle equipped with four-wheel ABS, do

not pump the brakes, but instead, press firmly on the pedal.

²If your foot is not on the brake, the brake pedal will move to apply

higher brake forces. You may also hear a whoosh of air from under the

instrument panel during this kind of braking.

All these conditions are normal during AdvanceTracyoperation.

Aggressive driving in any road conditions can cause you to lose

control of your vehicle increasing the risk of severe personal

injury or property damage. The occurrence of an AdvanceTracyevent

is an indication that at least some of the tires have exceeded their

ability to grip the road and that you may lose control of the vehicle. If

you experience a severe road event, SLOW DOWN.

Driving

172

Page 174 of 288

If the gearshift lever cannot be moved from P (Park) with the brake

pedal depressed, it is possible that a fuse has blown or the vehicle's

brakelamps are not operating properly. Refer toFuses and relaysin the

Roadside emergencieschapter.

Do not drive your vehicle until you verify that the brakelamps

are working.

If your vehicle gets stuck in mud or snow it may be rocked out by

shifting between forward and reverse gears, stopping between shifts, in a

steady pattern. Press lightly on the accelerator in each gear.

Do not rock the vehicle if the engine is not at normal operating

temperature or damage to the transaxle may occur.

Do not rock the vehicle for more than a few minutes or damage

to the transaxle and tires may occur or the engine may overheat.

Always set the parking brake fully and make sure the gearshift is

latched in P (Park). Turn off the ignition whenever you leave

your vehicle.

If the parking brake is fully released, but the brake warning lamp

remains illuminated, the brakes may not be working properly.

See your dealer or a qualified service technician.

Driving with an automatic overdrive transaxle with column

gearshift and O/D off switch

Your automatic transaxle electronically controls the shift feel by using an

adaptive learning strategy. This feature is designed to optimize shift

smoothness. It is normal for your transaxle to shift firmly during the first

few hundred kilometers (miles) of operation until the adaptive strategy

has been learned. The adaptive learning strategy is maintained by power

from the battery. When the battery is disconnected or a new battery is

installed, the transaxle must relearn its adaptive strategy. Optimal

shifting will resume within a few hundred kilometers (miles) of

operation.

Driving

174