lock FORD WINDSTAR 2002 2.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: WINDSTAR, Model: FORD WINDSTAR 2002 2.GPages: 296, PDF Size: 2.45 MB

Page 186 of 296

²Do not operate the vehicle with a low power steering pump fluid level

(below the MIN mark on the reservoir).

If the power steering system breaks down (or if the engine is turned

off), you can steer the vehicle manually, but it takes more effort.

If the steering wanders or pulls, the condition could be caused by any of

the following:

²underinflated tire(s) on any wheel(s)

²uneven vehicle loading

²high crown in center of road

²high crosswinds

²wheels out of alignment

²loose or worn suspension components

AUTOMATIC TRANSAXLE OPERATION

Brake-shift interlock

This vehicle is equipped with a brake-shift interlock feature that prevents

the gearshift lever from being moved from P (Park) unless the brake

pedal is depressed.

If the gearshift lever cannot be moved from P (Park) with the brake

pedal depressed, it is possible that a fuse has blown or the vehicle's

brakelamps are not operating properly. Refer toFuses and relaysin the

Roadside emergencieschapter.

Do not drive your vehicle until you verify that the brakelamps

are working.

If your vehicle gets stuck in mud or snow it may be rocked out by

shifting between forward and reverse gears, stopping between shifts, in a

steady pattern. Press lightly on the accelerator in each gear.

Do not rock the vehicle if the engine is not at normal operating

temperature or damage to the transaxle may occur.

Do not rock the vehicle for more than a few minutes or damage

to the transaxle and tires may occur or the engine may overheat.

Driving

186

Page 188 of 296

has been learned. The adaptive learning strategy is maintained by power

from the battery. When the battery is disconnected or a new battery is

installed, the transaxle must relearn its adaptive strategy. Optimal

shifting will resume within a few hundred kilometers (miles) of

operation.

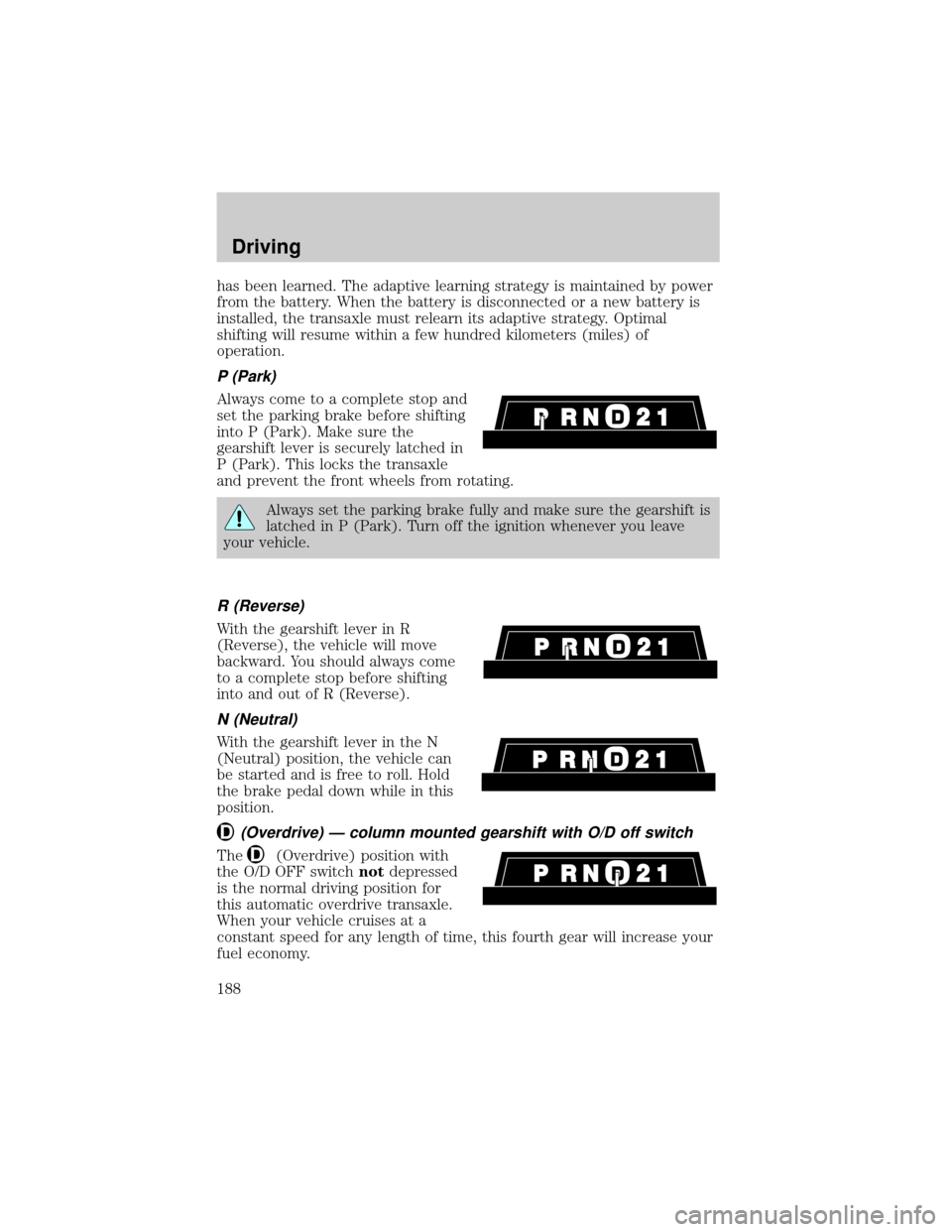

P (Park)

Always come to a complete stop and

set the parking brake before shifting

into P (Park). Make sure the

gearshift lever is securely latched in

P (Park). This locks the transaxle

and prevent the front wheels from rotating.

Always set the parking brake fully and make sure the gearshift is

latched in P (Park). Turn off the ignition whenever you leave

your vehicle.

R (Reverse)

With the gearshift lever in R

(Reverse), the vehicle will move

backward. You should always come

to a complete stop before shifting

into and out of R (Reverse).

N (Neutral)

With the gearshift lever in the N

(Neutral) position, the vehicle can

be started and is free to roll. Hold

the brake pedal down while in this

position.

(Overdrive) Ð column mounted gearshift with O/D off switch

The(Overdrive) position with

the O/D OFF switchnotdepressed

is the normal driving position for

this automatic overdrive transaxle.

When your vehicle cruises at a

constant speed for any length of time, this fourth gear will increase your

fuel economy.

Driving

188

Page 200 of 296

GETTING ROADSIDE ASSISTANCE

To fully assist if you should have a vehicle concern, Ford Motor Company

offers a complimentary roadside assistance program. This program is

separate from the New Vehicle Limited Warranty. The service is available:

²24±hours, seven days a week

²for the Basic warranty period (Canada) or New Vehicle Limited

Warranty period (U.S.) of three years or 60 000 km (36 000 miles),

whichever comes first on Ford and Mercury vehicles, and four years or

80 000 km (50 000 miles) on Lincoln vehicles

Roadside assistance will cover:

²changing a flat tire

²jump-starts

²lock-out assistance

²limited fuel delivery*

²towing of your disabled vehicle to the nearest Ford Motor Company

dealership, or your selling dealer if within 25 kms (15.5 miles) of the

nearest Ford Motor Company dealership (one tow per disablement).

Even non-warranty related tows, like accidents or getting stuck in the

mud or snow, are covered (some exclusions apply, such as impound

towing or repossession).

* Canadian customers refer to yourRoadside Assistance supplement

for exact fuel amounts.

USING ROADSIDE ASSISTANCE

Complete the roadside assistance identification card and place it in your

wallet for quick reference. In the United States, this card is found in the

Owner Guide portfolio in the glove compartment in Ford vehicles and is

mailed to you if you own a Mercury or Lincoln. In Canada, the card is

found in the Roadside Assistance book in the glove compartment.

U.S. Ford or Mercury vehicle customers who require roadside assistance,

call 1±800±241±3673; Lincoln vehicle customers call 1±800±521±4140.

Canadian customers who require roadside assistance, call

1±800±665±2006.

Roadside Emergencies

200

Page 206 of 296

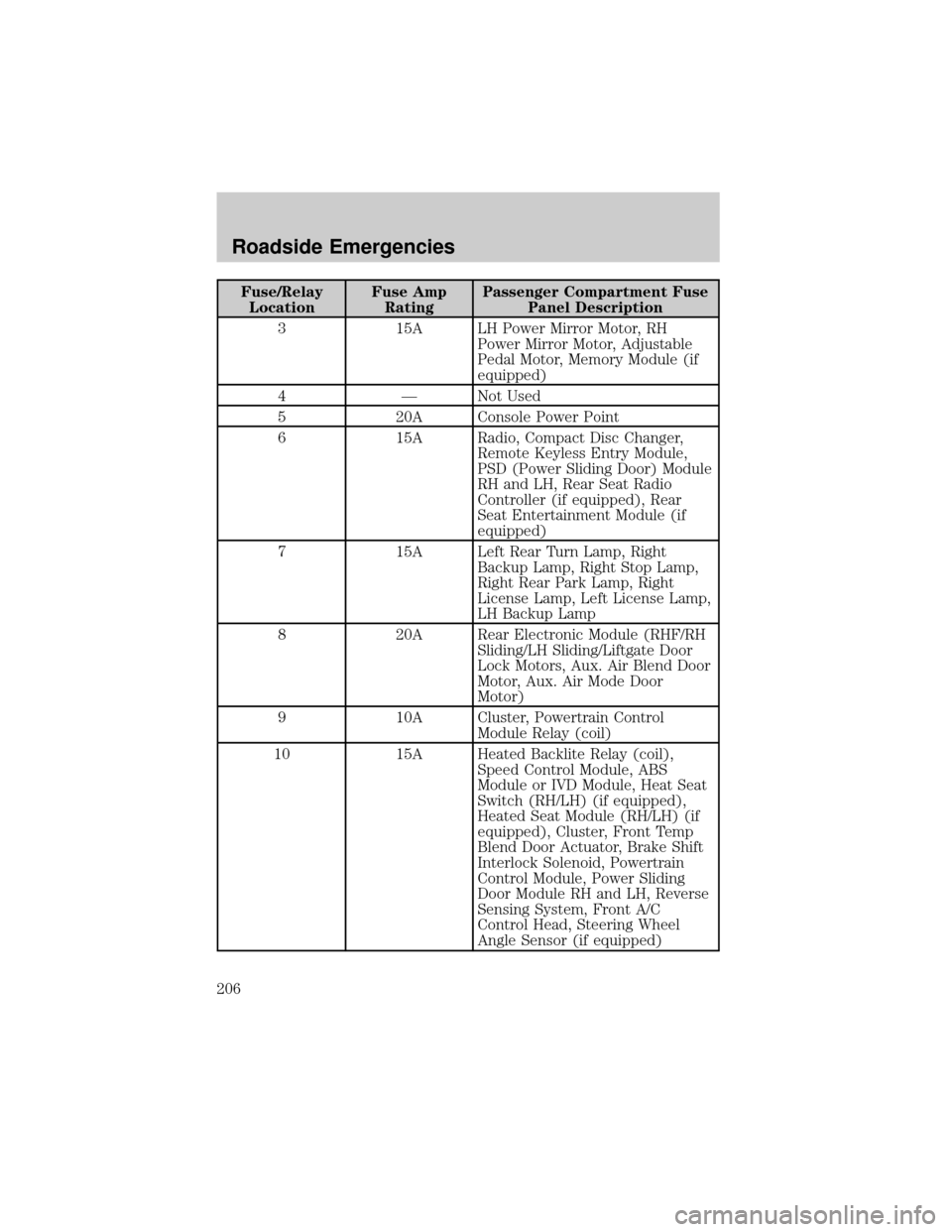

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

3 15A LH Power Mirror Motor, RH

Power Mirror Motor, Adjustable

Pedal Motor, Memory Module (if

equipped)

4 Ð Not Used

5 20A Console Power Point

6 15A Radio, Compact Disc Changer,

Remote Keyless Entry Module,

PSD (Power Sliding Door) Module

RH and LH, Rear Seat Radio

Controller (if equipped), Rear

Seat Entertainment Module (if

equipped)

7 15A Left Rear Turn Lamp, Right

Backup Lamp, Right Stop Lamp,

Right Rear Park Lamp, Right

License Lamp, Left License Lamp,

LH Backup Lamp

8 20A Rear Electronic Module (RHF/RH

Sliding/LH Sliding/Liftgate Door

Lock Motors, Aux. Air Blend Door

Motor, Aux. Air Mode Door

Motor)

9 10A Cluster, Powertrain Control

Module Relay (coil)

10 15A Heated Backlite Relay (coil),

Speed Control Module, ABS

Module or IVD Module, Heat Seat

Switch (RH/LH) (if equipped),

Heated Seat Module (RH/LH) (if

equipped), Cluster, Front Temp

Blend Door Actuator, Brake Shift

Interlock Solenoid, Powertrain

Control Module, Power Sliding

Door Module RH and LH, Reverse

Sensing System, Front A/C

Control Head, Steering Wheel

Angle Sensor (if equipped)

Roadside Emergencies

206

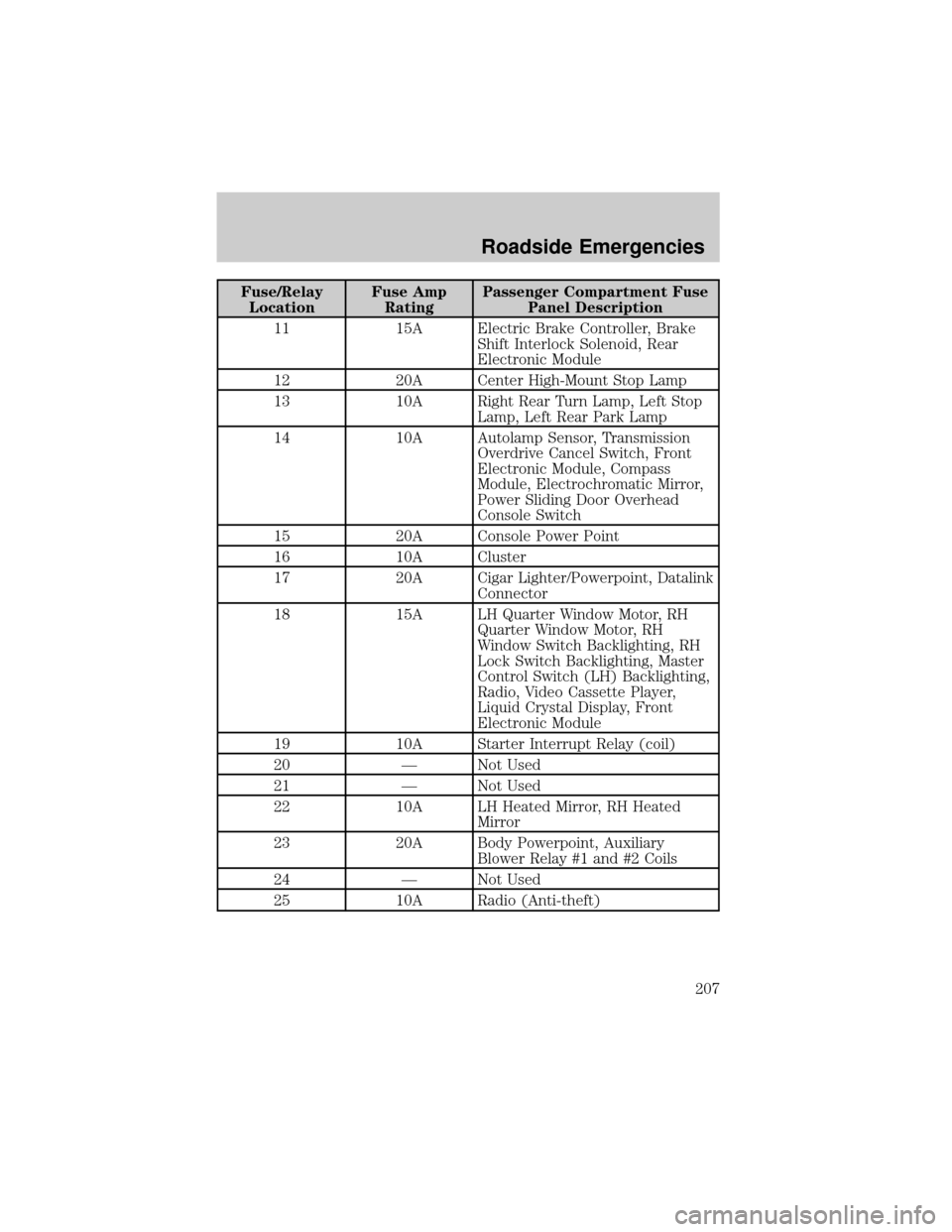

Page 207 of 296

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

11 15A Electric Brake Controller, Brake

Shift Interlock Solenoid, Rear

Electronic Module

12 20A Center High-Mount Stop Lamp

13 10A Right Rear Turn Lamp, Left Stop

Lamp, Left Rear Park Lamp

14 10A Autolamp Sensor, Transmission

Overdrive Cancel Switch, Front

Electronic Module, Compass

Module, Electrochromatic Mirror,

Power Sliding Door Overhead

Console Switch

15 20A Console Power Point

16 10A Cluster

17 20A Cigar Lighter/Powerpoint, Datalink

Connector

18 15A LH Quarter Window Motor, RH

Quarter Window Motor, RH

Window Switch Backlighting, RH

Lock Switch Backlighting, Master

Control Switch (LH) Backlighting,

Radio, Video Cassette Player,

Liquid Crystal Display, Front

Electronic Module

19 10A Starter Interrupt Relay (coil)

20 Ð Not Used

21 Ð Not Used

22 10A LH Heated Mirror, RH Heated

Mirror

23 20A Body Powerpoint, Auxiliary

Blower Relay #1 and #2 Coils

24 Ð Not Used

25 10A Radio (Anti-theft)

Roadside Emergencies

207

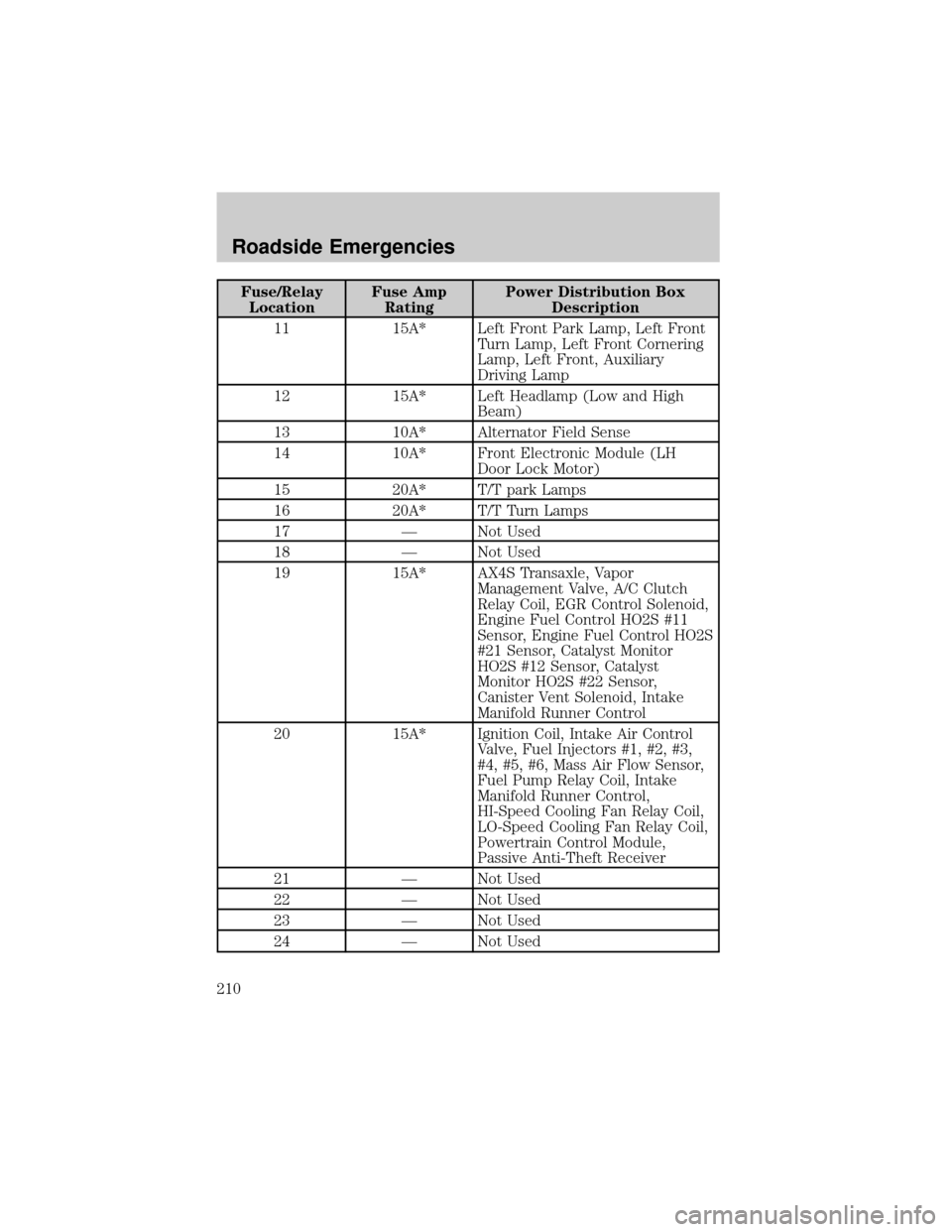

Page 210 of 296

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

11 15A* Left Front Park Lamp, Left Front

Turn Lamp, Left Front Cornering

Lamp, Left Front, Auxiliary

Driving Lamp

12 15A* Left Headlamp (Low and High

Beam)

13 10A* Alternator Field Sense

14 10A* Front Electronic Module (LH

Door Lock Motor)

15 20A* T/T park Lamps

16 20A* T/T Turn Lamps

17 Ð Not Used

18 Ð Not Used

19 15A* AX4S Transaxle, Vapor

Management Valve, A/C Clutch

Relay Coil, EGR Control Solenoid,

Engine Fuel Control HO2S #11

Sensor, Engine Fuel Control HO2S

#21 Sensor, Catalyst Monitor

HO2S #12 Sensor, Catalyst

Monitor HO2S #22 Sensor,

Canister Vent Solenoid, Intake

Manifold Runner Control

20 15A* Ignition Coil, Intake Air Control

Valve, Fuel Injectors #1, #2, #3,

#4, #5, #6, Mass Air Flow Sensor,

Fuel Pump Relay Coil, Intake

Manifold Runner Control,

HI-Speed Cooling Fan Relay Coil,

LO-Speed Cooling Fan Relay Coil,

Powertrain Control Module,

Passive Anti-Theft Receiver

21 Ð Not Used

22 Ð Not Used

23 Ð Not Used

24 Ð Not Used

Roadside Emergencies

210

Page 214 of 296

Removing the jack and tools

1. Locate the access panel on the interior trim. Rotate the two panel

retaining clips and remove the panel.

2. Remove the jack and lug nut wrench by turning the thumbscrew

counterclockwise to remove clamp and relieve tension against the

stowage bracket.

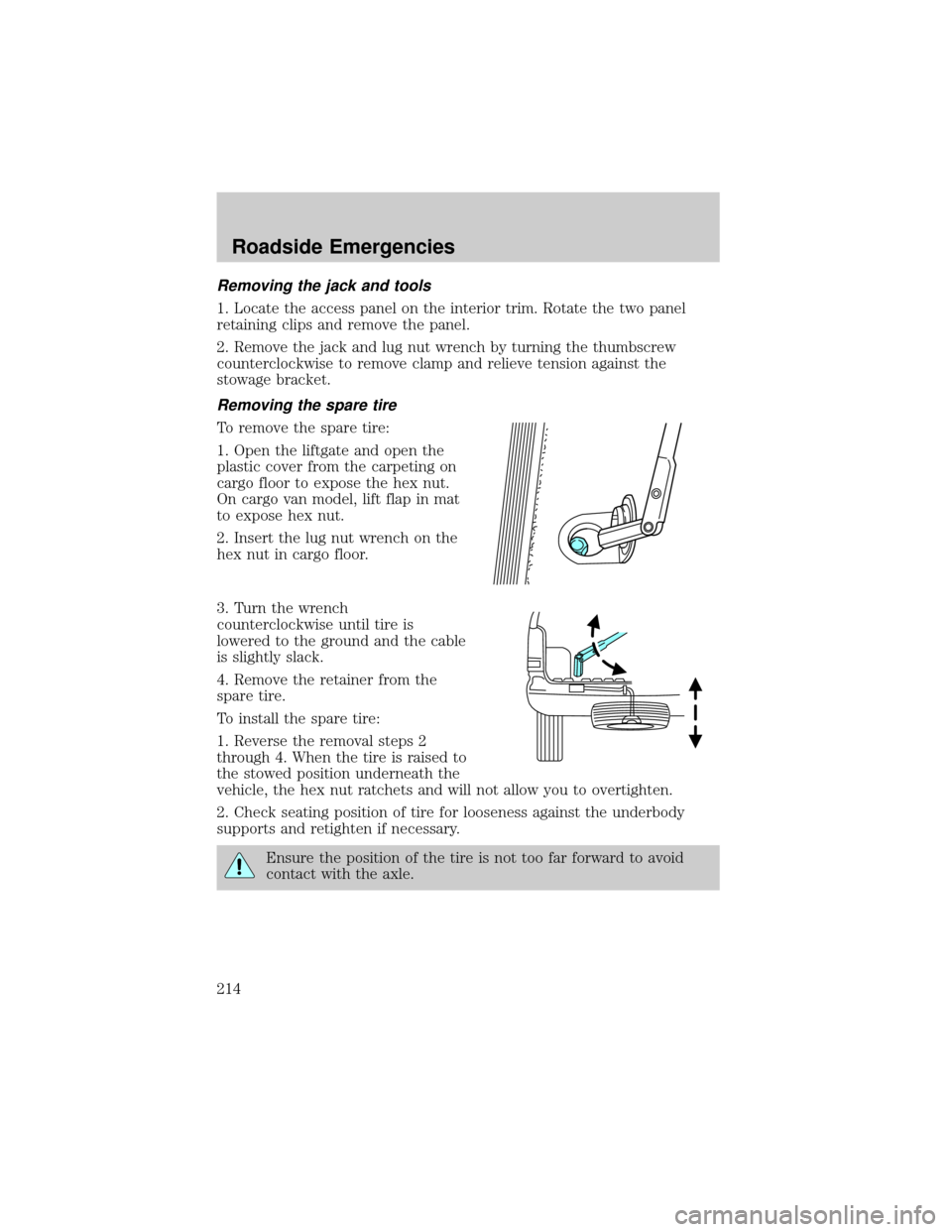

Removing the spare tire

To remove the spare tire:

1. Open the liftgate and open the

plastic cover from the carpeting on

cargo floor to expose the hex nut.

On cargo van model, lift flap in mat

to expose hex nut.

2. Insert the lug nut wrench on the

hex nut in cargo floor.

3. Turn the wrench

counterclockwise until tire is

lowered to the ground and the cable

is slightly slack.

4. Remove the retainer from the

spare tire.

To install the spare tire:

1. Reverse the removal steps 2

through 4. When the tire is raised to

the stowed position underneath the

vehicle, the hex nut ratchets and will not allow you to overtighten.

2. Check seating position of tire for looseness against the underbody

supports and retighten if necessary.

Ensure the position of the tire is not too far forward to avoid

contact with the axle.

Roadside Emergencies

214

Page 215 of 296

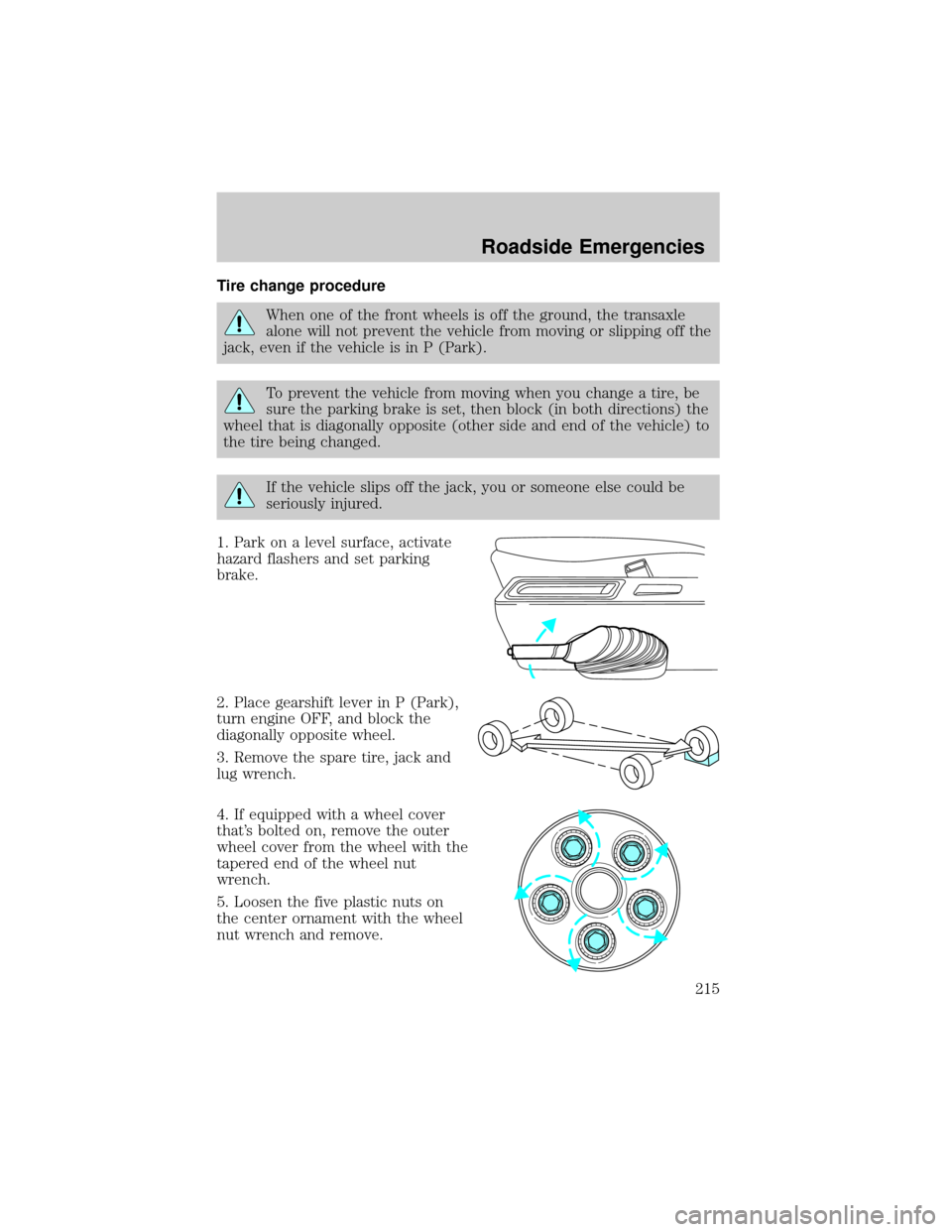

Tire change procedure

When one of the front wheels is off the ground, the transaxle

alone will not prevent the vehicle from moving or slipping off the

jack, even if the vehicle is in P (Park).

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

1. Park on a level surface, activate

hazard flashers and set parking

brake.

2. Place gearshift lever in P (Park),

turn engine OFF, and block the

diagonally opposite wheel.

3. Remove the spare tire, jack and

lug wrench.

4. If equipped with a wheel cover

that's bolted on, remove the outer

wheel cover from the wheel with the

tapered end of the wheel nut

wrench.

5. Loosen the five plastic nuts on

the center ornament with the wheel

nut wrench and remove.

Roadside Emergencies

215

Page 216 of 296

6. Remove the center ornament or wheel cover from the wheel with the

tapered end of the wheel nut wrench. Insert and twist the handle, then

pry against the wheel.

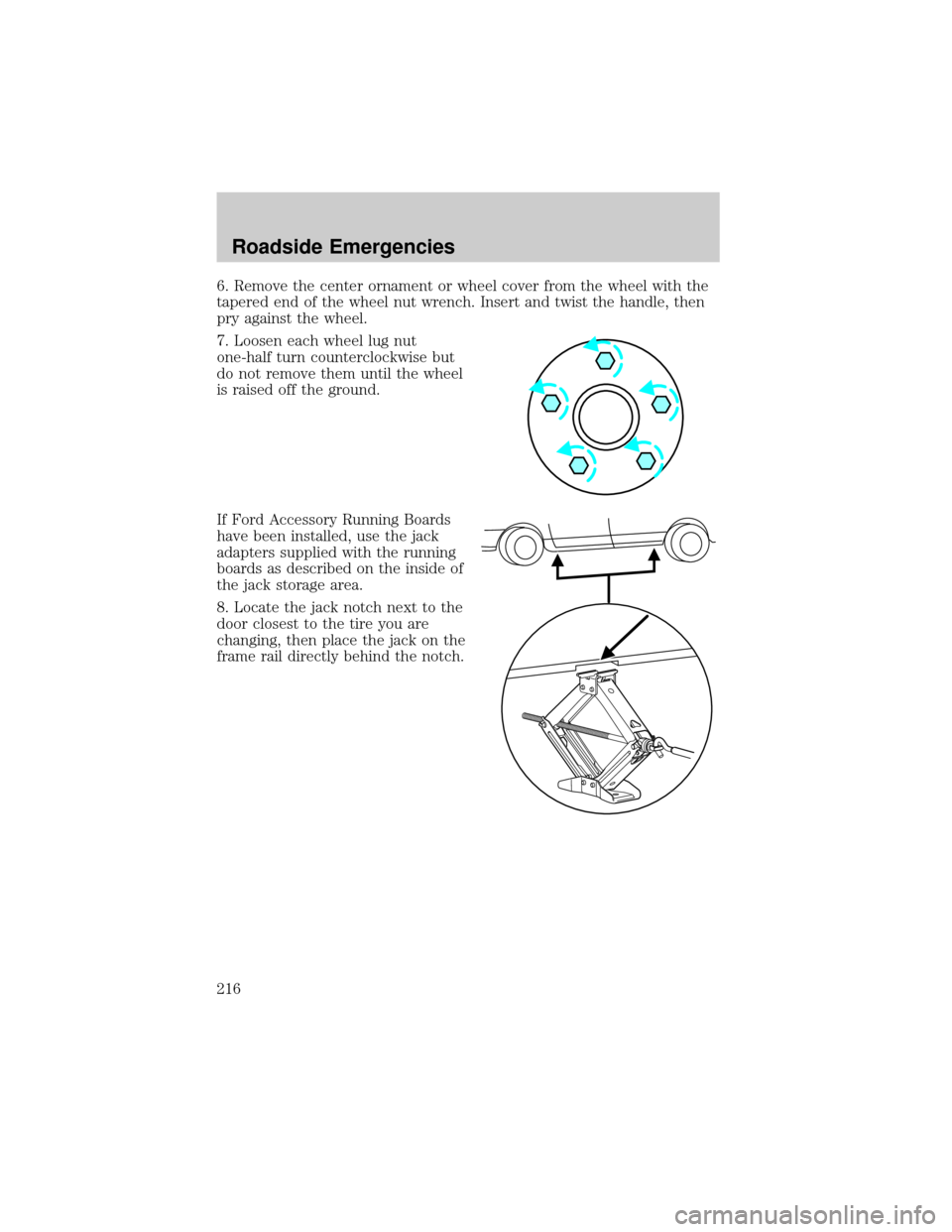

7. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

If Ford Accessory Running Boards

have been installed, use the jack

adapters supplied with the running

boards as described on the inside of

the jack storage area.

8. Locate the jack notch next to the

door closest to the tire you are

changing, then place the jack on the

frame rail directly behind the notch.

Roadside Emergencies

216

Page 217 of 296

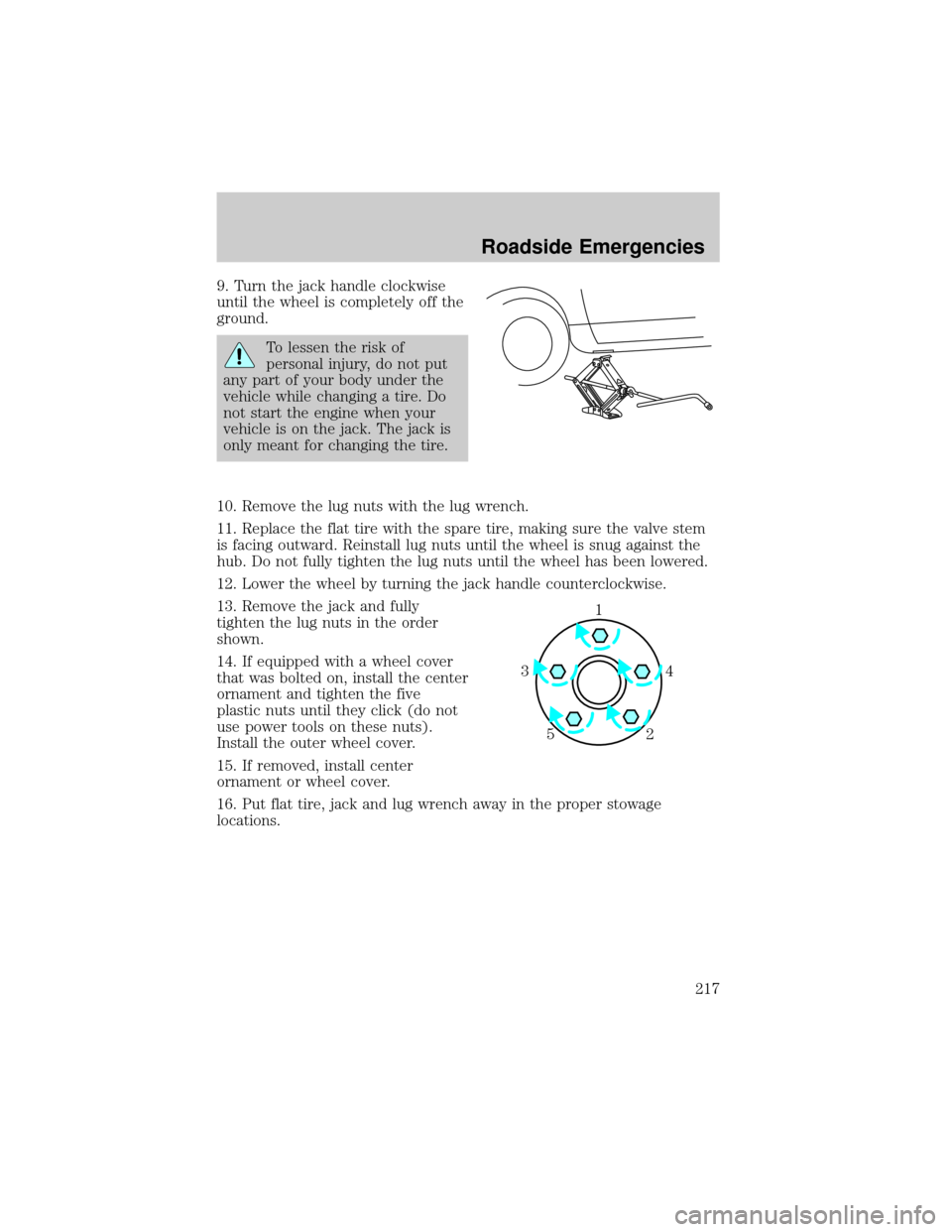

9. Turn the jack handle clockwise

until the wheel is completely off the

ground.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

10. Remove the lug nuts with the lug wrench.

11. Replace the flat tire with the spare tire, making sure the valve stem

is facing outward. Reinstall lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

12. Lower the wheel by turning the jack handle counterclockwise.

13. Remove the jack and fully

tighten the lug nuts in the order

shown.

14. If equipped with a wheel cover

that was bolted on, install the center

ornament and tighten the five

plastic nuts until they click (do not

use power tools on these nuts).

Install the outer wheel cover.

15. If removed, install center

ornament or wheel cover.

16. Put flat tire, jack and lug wrench away in the proper stowage

locations.

1

4 3

2 5

Roadside Emergencies

217