ESP GEELY CK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 381 of 392

3742. Repair Of Outer Plate

1 11 1

1Repair of crackle

The crackle on the metal outer plate can be repaired by CO2 gas Protecting welding. When welded, the

two sides of the metal plate should be aligned, and then spot-weld on the outside of the outer plate. If the

crackle length is less than 50mm, it should be welded from the crackle end, and along the run of the

crackle and the outside edge. If the crackle length is very long, it should be spot-welded in some intervals,

and then weld the crackle in several sections. So, it can prevent the crackle metal from being over-burnt

and warping because of an extremely high temperature.

If the crackle appears on the place that is greatly loaded and it is very convenient to weld, 2-step welding

can be adopted, that is, After spot-welding on the outside, then you can first weld on the inside of the

crackle. After that, a welding seam is then applied on the outside in the same run.

After the welding finishes, put a backing block under the crackle, and then use a hammer to gently knock

on the outside of the crackle to remove the remaining welding stress. Finally, trim the appearance of the

crackle to make it smooth and convenient to apply paint.

2 22 2

2Repair of partial damage of the outer plate

When the outer plate has partial rust or serious damage and even cannot be repaired, it can be mended by

cutting off the damage or pasting a new one on it.

How to cut off the damage:

a. Confirm the area that needs cutting;

b. Cut a paper example;

c. Cut the metal plate according to the paper example;

d. Paste the metal piece cut onto the surface of the area that needs cutting off;

e. Use a draw needle tip to make an outline along the sides of the metal piece. And cut off the

damaged or rusted area along the outline;

f. Use a wooden hammer or a backing block to smooth the cut, and use a file to file the burr, to assure

that the cut is parallel with both sides of the substitute piece and the clearance should be no more

than 1mm;

g. Substitute the damaged area with the piece. Use pliers to hold it and spot-weld the joint in an

interval of 50mm for fixation;

h. Weld in sections. First weld the central part and then the left and right in turn, to avoid deformation;

i. Use a hammer or block to knock on the seam to remove the remaining stress. And use a file or

hand grindstone to grind the seam to make it smooth to the plates around. Finally, paint the substitute

piece.

3 33 3

3Repair of uneven damage of the outer plate caused by crash

When the outer plate is crashed, a concave pit appears on it. The repair should be taken from the point C

(Figure 5-17). Put the block on the top of the protrusion area, use a hammer to knock it and correspondingly

change the position of the block. After the protrusion area is knocked down to the level, most of concave

in B area will spring back. It is already very much like the former outline of the plate. As to some little

remaining depressions, use a block with a same radian with the plate and use a hand to press the block

upwards. Knock the top point of the concave with a hammer (Figure 5-19).

Page 382 of 392

375At the beginning of knocking it, make your force slightly greater. In the finishing period of repair, make

your force softer and try your best to reduce the beating times. Make sure not to knock one point for too

many times to avoid extending on partial area of the metal plate, which may make the repair complex.

As to the concave with a comparatively big radian, a backing plate whose area should be comparatively

big can be put under the center of the concave. Directly push up the depressed plate by a propping-up

tool. Sometimes, the concave place can be heated to dark red to reduce the pushing force. A slight rise is

recommended when pushing up. (Figure 5-20)

Heat-shrinkable method:

After the concave area is pushed up, if the plate is greatly stretched and its area is too big to repair, the

heat-shrinkable method can be adopted.

Use oxygen-acetylene flame to heat to cherry red. The area of heating depends to its extension degree.

The heating area should be bigger (Diameter approx. 20-30mm), when it is seriously extended or the area

is big. If it is slightly extended or the area is small, the heating area should be smaller (Diameter approx.

10-15mm). Quickly knock the heated points with a wooden hammer while they are hot. A backing block

is recommended to push it up. After it cools down, use an iron hammer to gently knock for smoothness.

The shrinkage order is from the highest point gradually to the center and then to the edge. Heat and then

flatten the extended area repeatedly, till the plate is completely flat. If the protrusion is very high, first

compress the whole protrusion to its half. After it cools down, heat the former heating point to remove the

rest half of the protrusion.

When the method is applied, it must be specially noted that you'd better not use the heat-shrinkage

method to avoid side effects. Especially for thin plates, prevent them from being melted through hole..

When the outer plate is lightly crashed and the depressed area belongs to elastic deformation, you may

press its inside to recover to its former shape.

Some depressed area can be repair by prying which is a repair method without disassembling parts. YouIllustration 5-18 Panel Flattening (A)

A Concave Point B Protrusion Point C Knocking PointIllustration 5-19 Panel Flattening (B)

1 Hammer 2 Panel Parts 3 Backing BlockFigure 5-20 Heat and flatten the protrusion

1 heating point

Page 388 of 392

3812 Adopt sound insulating material to reduce the noise in the compartment.

For the heat, vibration and sound insulation of the body, they are a systematic engineering. Besides you

take measures on effectively improving the rigidity of the body and sealing technique, the following

measures can be taken in the body design and manufacturing:

a. Sound insulating material: paste a layer of asphalt board on the floor and FR/RR fenders. Add

insulation pads on the cowl and the floor.

b. Sound absorbing material: adopt formed carpet which is composed of front floor carpet and rear

floor carpet.

The FR/RR floor carpets are integrated with the floor and sound absorbing pad. It is required that the

floor and the pad will not peeled when torn by outside force.

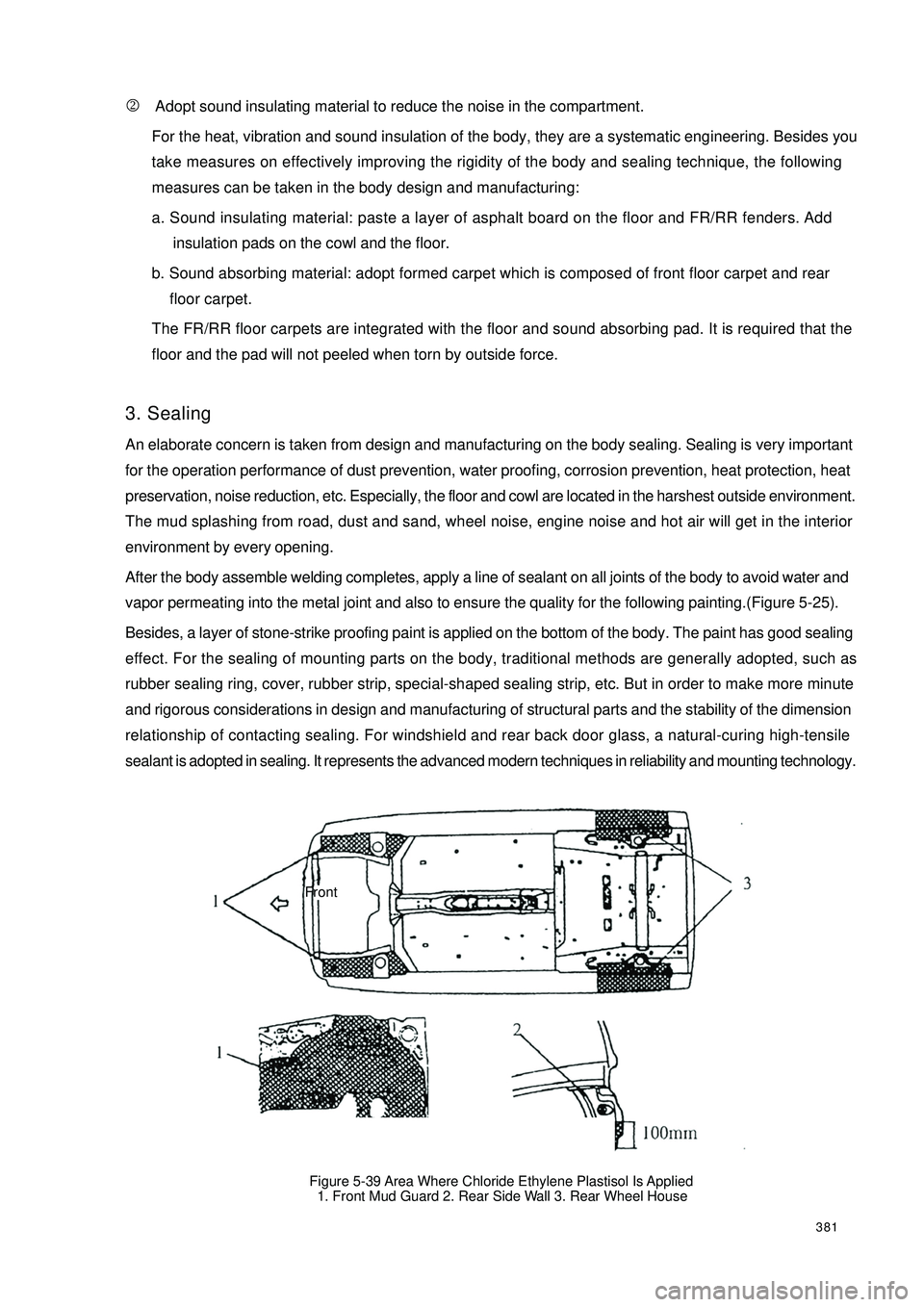

3. Sealing

An elaborate concern is taken from design and manufacturing on the body sealing. Sealing is very important

for the operation performance of dust prevention, water proofing, corrosion prevention, heat protection, heat

preservation, noise reduction, etc. Especially, the floor and cowl are located in the harshest outside environment.

The mud splashing from road, dust and sand, wheel noise, engine noise and hot air will get in the interior

environment by every opening.

After the body assemble welding completes, apply a line of sealant on all joints of the body to avoid water and

vapor permeating into the metal joint and also to ensure the quality for the following painting.(Figure 5-25).

Besides, a layer of stone-strike proofing paint is applied on the bottom of the body. The paint has good sealing

effect. For the sealing of mounting parts on the body, traditional methods are generally adopted, such as

rubber sealing ring, cover, rubber strip, special-shaped sealing strip, etc. But in order to make more minute

and rigorous considerations in design and manufacturing of structural parts and the stability of the dimension

relationship of contacting sealing. For windshield and rear back door glass, a natural-curing high-tensile

sealant is adopted in sealing. It represents the advanced modern techniques in reliability and mounting technology.5-25 1. 2. 3. Figure 5-39 Area Where Chloride Ethylene Plastisol Is Applied

1. Front Mud Guard 2. Rear Side Wall 3. Rear Wheel HouseFront