engine GEELY FC 2008 Repair Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 67 of 419

Engine mechanism - CamshaftWarning: if the air pressure in timing advance side oil duct is released earlier than that in

timing delay side oil duct, VVT driver assembly will move suddenly toward

delay side.This will cause the damage of lock pin.

(g) Remove VVT drive fixed bolts.

Notes:

It is strictly forbidden to remove other 4 bolts.

Under the condition of repeating using camshaft

timing sprocket, release lock pin at first, and then

install sprocket.12. Install VVT driver assembly.

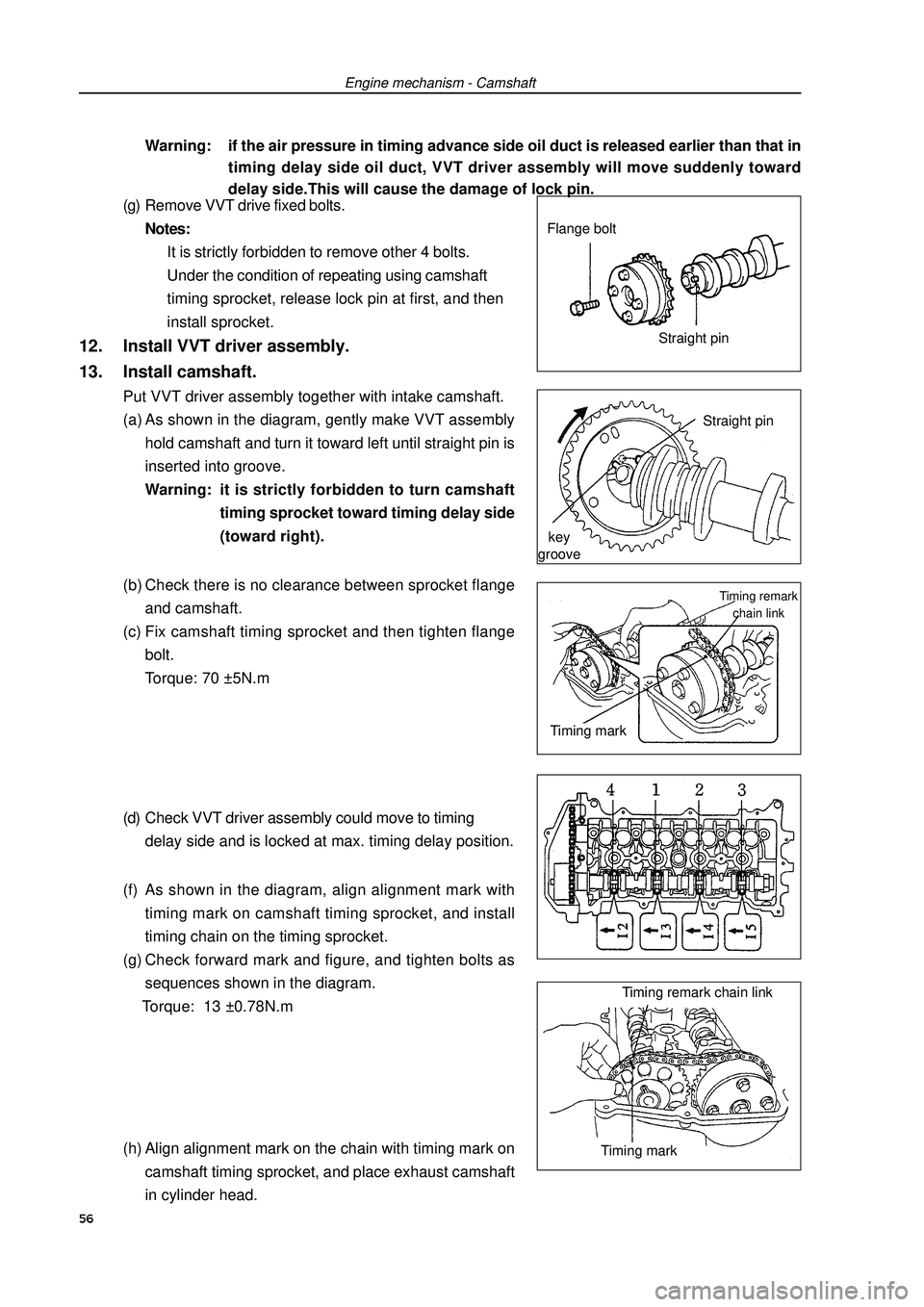

13. Install camshaft.Put VVT driver assembly together with intake camshaft.

(a) As shown in the diagram, gently make VVT assembly

hold camshaft and turn it toward left until straight pin is

inserted into groove.

Warning: it is strictly forbidden to turn camshaft

timing sprocket toward timing delay side

(toward right).

(b) Check there is no clearance between sprocket flange

and camshaft.

(c) Fix camshaft timing sprocket and then tighten flange

bolt.

Torque: 70 ±5N.m

(d) Check VVT driver assembly could move to timing

delay side and is locked at max. timing delay position.

(f) As shown in the diagram, align alignment mark with

timing mark on camshaft timing sprocket, and install

timing chain on the timing sprocket.

(g) Check forward mark and figure, and tighten bolts as

sequences shown in the diagram.

Torque: 13 ±0.78N.m

(h) Align alignment mark on the chain with timing mark on

camshaft timing sprocket, and place exhaust camshaft

in cylinder head.Straight pin

key

grooveFlange bolt

Straight pin56Timing remark

chain linkTiming mark

Timing remark chain link

Timing mark

Page 68 of 419

Engine mechanism - Camshaft(i) Temporarily tighten fixed bolts.

(j) Check forward mark and figure, and tighten bolts as

sequences shown in the diagram.

Torque: ±0.78N.m

(k) Install camshaft front bearing cover.

Torque: 23 ±1.38N.m

(l) Fix camshaft with variable wrench and then tighten the

fixed bolts of exhaust camshaft timing sprocket.

Torque: 54 ±10.8N.m

Note: be careful not to damage valve lifter.

(m)Check the alignment marks on timing chain and cam-

shaft timing sprocket, and then align the groove of damp-

ing pulley with the timing mark on timing chain hood as

shown in the diagram.Fixing

Tightening57Mark

Mark

Mark

Timing chain hood

Groove

Page 69 of 419

Engine mechanism - Camshaft(n) Install chain tensioner components.

(1) Check o-ring is clean, and buckle on the hook as

shown in the diagram.

(2) Coat engine oil on the chain tensioner, and then

install it.

Torque: 9 ±1.8N.m

Note:when installing the chain temsioner,

buckle on the hook again if plunger has

ejected.

(3) Turn crankshaft counterclockwise to separate the

hook from lock pin on the plunger.

(4) Turn crankshaft clockwise, and check the sliding

parts are blocked by plunger.

Hint: if the plunger does not eject, press the ten-

sion rail toward chain tensioner with

screwdriver or fingers to separate the hook

from lock pin and make the plunger eject.Pushing into

Turning Plunger

Pushing into58Lifting

Hook Pressing

in

Pin

PinHook Sepa-

rate

Page 70 of 419

Engine mechanism - Camshaft14. Adjust valve clearance.

15. Install cylinder head cover components.(a) Install gasket to cylinder head cover.

(b) Eliminate all old sealant (FIPG) materials.

(c) Coat sealant on position shown in the diagram.

Sealant: silicon rubber flange sealant 1596 (Kesaixin

1596).

Notes:Eliminate all oil on contact surface.After coating sealant, finish installation of cylinder

head cover within 3 minutes.After installing, do not refill engine oil within 2

minutes.

(d) Install cylinder head cover and harness bracket with 9

bolts, 2 oil seal washers and 2 nuts.

Evenly tighten bolts and nuts at several times.

Torque: nut: 29 ±5.8N.m

Bolt: 69 ±13.8N.m16. Install drive belt tensioner device.Torque: nut: 29 ±5.8N.m

Bolt: 69 ±13.8N.m17. Install right engine mounting assembly.Torque: 52N.m18. Check there is oil leakage.

59

Page 71 of 419

Engine mechanism - Crankshaft front oil seal assemblyReplacement1. Remove engine right bottom shield.

2. Remove drive belt.Slowly turn drive belt tensioner clockwise to loosen it. Then

remove drive belt and put back drive belt tensioner slowly and

gently.3. Remove right engine mounting assembly.(a) Remove PS oil pump reservoir and put it aside.

(b) Place wooden block between jack and engine, properly

place the jack, and then remove right engine mounting

assembly.4. remove damping pulley.(a) Remove pulley bolts with special tool.

(b) Remove damping pulley with special tool.Special

tool

Special

tool60Crankshaft front oil seal assembly

Page 72 of 419

Engine mechanism - Crankshaft front oil seal assembly5. Remove crankshaft front oil seal.(a) Cut oil seal lip with blade.

(b) Prize out oil seal with flat screwdriver whose sharp end is

winded with tape.

Note:check crankshaft is damaged after removing oil

seal, and repair with abrasive paper (#400) if it

is damaged.6. Install crankshaft front oil seal.(a) Coat a little MP grease on new oil seal lip.

Note: do not let oil seal lip contact with foreign

matters.

(b) Gently knock new oil seal in with special tool and hammer

until the seal surface is parallel and level with the end sur-

face edge of mounting hole.

Note: wipe off redundant grease on crankshaft.7. Install damping pulley.(a) Align the key groove on the pulley with the key on the

crankshaft, and slide pulley in.

(b) Install pulley bolts with special tool.

Torque: m8. Install right engine mounting assembly.Torque: 9. Check there is oil leakage.Cut

position

Prizing out

Special

tool61Special

tool

Page 73 of 419

Engine mechanism - Crankshaft rear oil seal assemblyReplacement1. Remove transmission assembly.

2. Remove clutch assembly and flywheel components.Fix crankshaft with special tool, remove clutch assembly at

first, and then remove flywheel components.3. Remove crankshaft rear oil seal.(a) Cut oil seal mouth with blade.

(b) Prize out oil seal with flathead screwdriver whose sharp

end is winded with tape.

Note: check crankshaft is damaged after removing oil

seal, and repair with abrasive paper (#400) if it is

damaged.4. Install crankshaft rear oil seal [4G18-1002130].(a) Coat a little MP grease on new oil seal lip.

Note: do not let oil seal lip contact with foreign

matters.

(b) Gently knock new oil seal in with special tool and hammer

until the seal surface is parallel and level with the end sur-

face edge of mounting hole.

Note: wipe off redundant grease on crankshaft.5. Install flywheel components and clutch assembly.(a) Fix crankshaft with special tool.

(b) Clean bolts and bolt holes.

(c) Coat bolts with adhesive.

Adhesive: thread locking adhesive 1234 (Kesaixin 1234)

(d) Install flywheel components.

As sequences shown in the diagram, tighten bolts at sev-

eral times.

Torque: (e) Install clutch assembly.6. Install transmission assembly.Special

tool

Cut

positionSpecial

tool62Crankshaft rear oil seal assembly

Page 74 of 419

Engine mechanism - Cylinder cover gasket componentsReplacement1. Take measures to prevent gasoline leaking.

2. Remove timing chain assembly.

3. Remove camshaft.As sequences shown in the diagram, evenly loosen at

several times, and remove 19 bearing cover bolts, and then

remove 9 bearing covers of intake camshaft and exhaust

camshaft.4. Remove cylinder head assembly.(a) Remove warm air water outlet pipe from cylinder head.

(b) As shown in the diagram, evenly loosen 10 cylinder head

bolts with 10mm dual hexagonal sleeves at several times,

and then remove 10 cylinder head bolts and plain washer.

Notes:Be careful not to let washer fall into cylinder head. Incorrect disassembling sequence will cause cylin-

der head warp or chap.5. Remove cylinder head gasket components

[4G18-1003160].

6. Install cylinder head gasket components.Put new cylinder head gasket on the cylinder body.

Notes:Pay attention to installation direction.Gently put down cylinder head to avoid damaging

cylinder head gasket.7. Install cylinder head assembly.Hint: Lock up cylinder head bolts as 2 steps.

(a) Coat a thin layer of engine oil at bolt thread and the bottom

of bolt head.

(b) As shown in the diagram, evenly tighten 10 cylinder head

bolts and plain washer with 10mm dual hexagonal sleeves

at several times.

Torque: 63Cylinder cover gasket components

Page 75 of 419

Engine mechanism - Cylinder cover gasket components(c) Tighten each cylinder head bolt in turn again.

Torque: m

(d) Install heating air water outlet pipe components.

Torque: 8. Install camshaft.(a) Coat engine oil on camshaft journal.

(b) Put 2 camshafts on cylinder head and with cylinder 1 cam-

shaft end toward the direction shown in the diagram.

(c) Check forward remarks and figures of all bearing cover, and

tighten the bolts as sequences shown in the diagram.

Torque:

Camshaft front bearing cover: Camshaft bearing cover: 9. Check idle speed and ignition timing.

10. Check compression pressure.

11. Check CO/HC.64

Page 77 of 419

Cooling - Cooling syste2. Check engine coolant level in reservoir.Engine coolant level should be between “Low” and “Full” mark line.

Hint: if the level is too low, check there is leakage and refill coolant to “Full” mark line.3. Check engine coolant quality.(a) Remove radiator cap.

Warning: when the temperature of engine and radiator is high, do not remove radiator cap to

avoid being scalded, because coolant and steam will spurt under high pressure.

(b) Check there is too much rust deposit around radiator cap or at outlet and check there is flake; there

should not be oil in the coolant.

Hint: if coolant is too dirty, it is required to replace coolant.

(c) Install back radiator cap.Inspection1. Temperature regulatorHint: the figure on temperature regulator is the

opening temperature of valve.CoolingCooling systemOn-vehicle inspection1. Check there is leakage with cooling system.Warning: when the temperature of engine and radiator is

high, do not remove radiator cap to avoid be-

ing scalded, because coolant and steam will

spurt under high pressure.

(a) Refill coolant to radiator, and install radiator cap tester.

(b) Preheat engine.

(c) Pump tester to make pressure go up to 118KPa, and check

the pressure falls.

Hint: if the pressure falls, check there is leakage with

hose, radiator or water pump, and check heater,

cylinder body and cylinder head if no external leak-

age is found.66