washer fluid GEELY FC 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 16 of 419

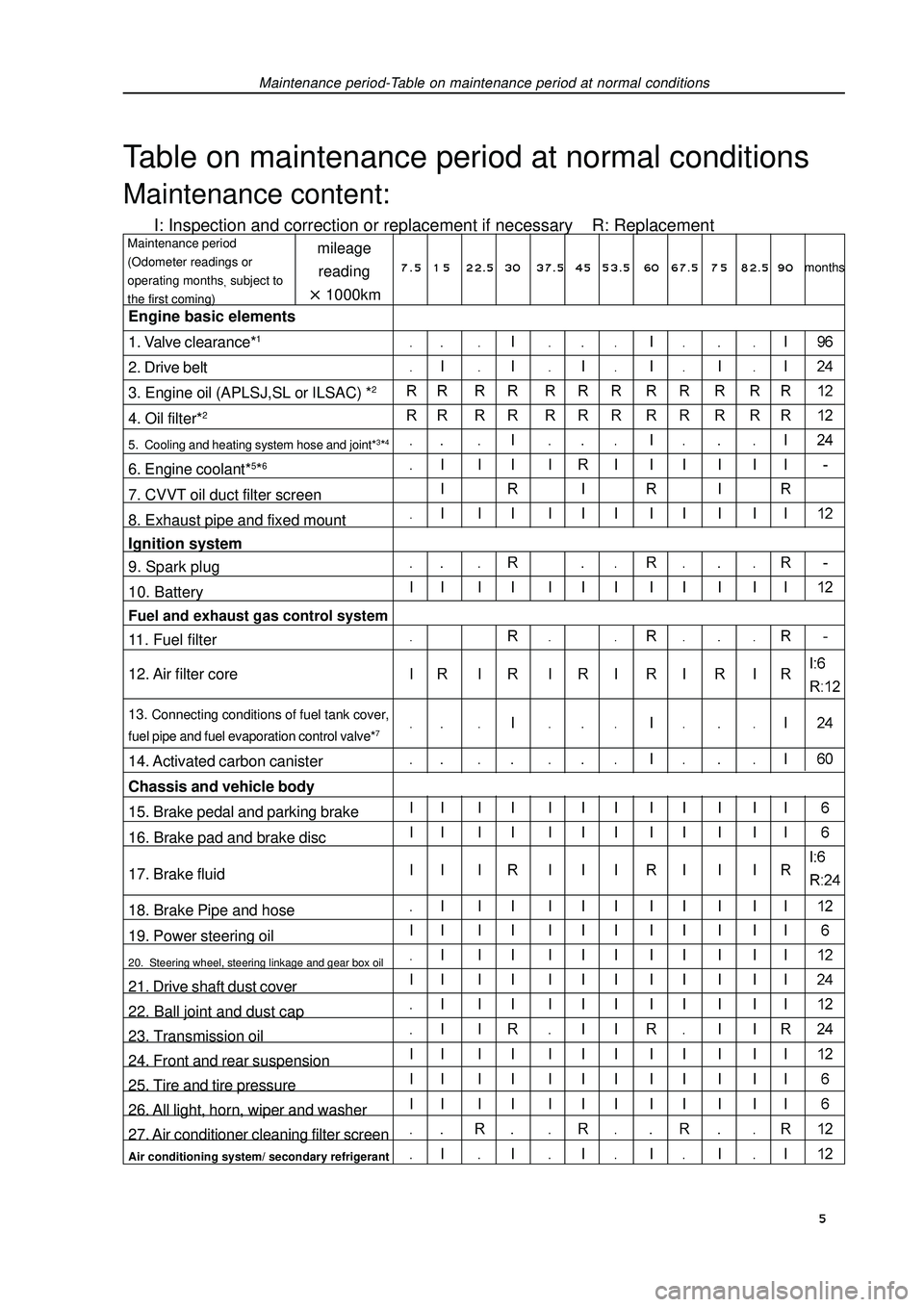

Maintenance period-Table on maintenance period at normal conditionsTable on maintenance period at normal conditionsMaintenance content:I: Inspection and correction or replacement if necessary R: Replacementmileage

reading1000kmMaintenance period

(Odometer readings or

operating monthssubject to

the first coming)Engine basic elements

1. Valve clearance*12. Drive belt

3. Engine oil (APLSJ,SL or ILSAC) *24. Oil filter*25. Cooling and heating system hose and joint*3*46. Engine coolant*5*67. CVVT oil duct filter screen

8. Exhaust pipe and fixed mount

Ignition system

9. Spark plug

10. BatteryFuel and exhaust gas control system11. Fuel filter

12. Air filter core13. Connecting conditions of fuel tank cover,

fuel pipe and fuel evaporation control valve*714. Activated carbon canister

Chassis and vehicle body

15. Brake pedal and parking brake

16. Brake pad and brake disc

17. Brake fluid

18. Brake Pipe and hose

19. Power steering oil20. Steering wheel, steering linkage and gear box oil21. Drive shaft dust cover

22. Ball joint and dust cap

23. Transmission oil

24. Front and rear suspension

25. Tire and tire pressure

26. All light, horn, wiper and washer

27. Air conditioner cleaning filter screenAir conditioning system/ secondary refrigerant7 . 5 1 5 22.5 3037.5 4553.5 60 67.5 7 582.5 90months 5

Page 26 of 419

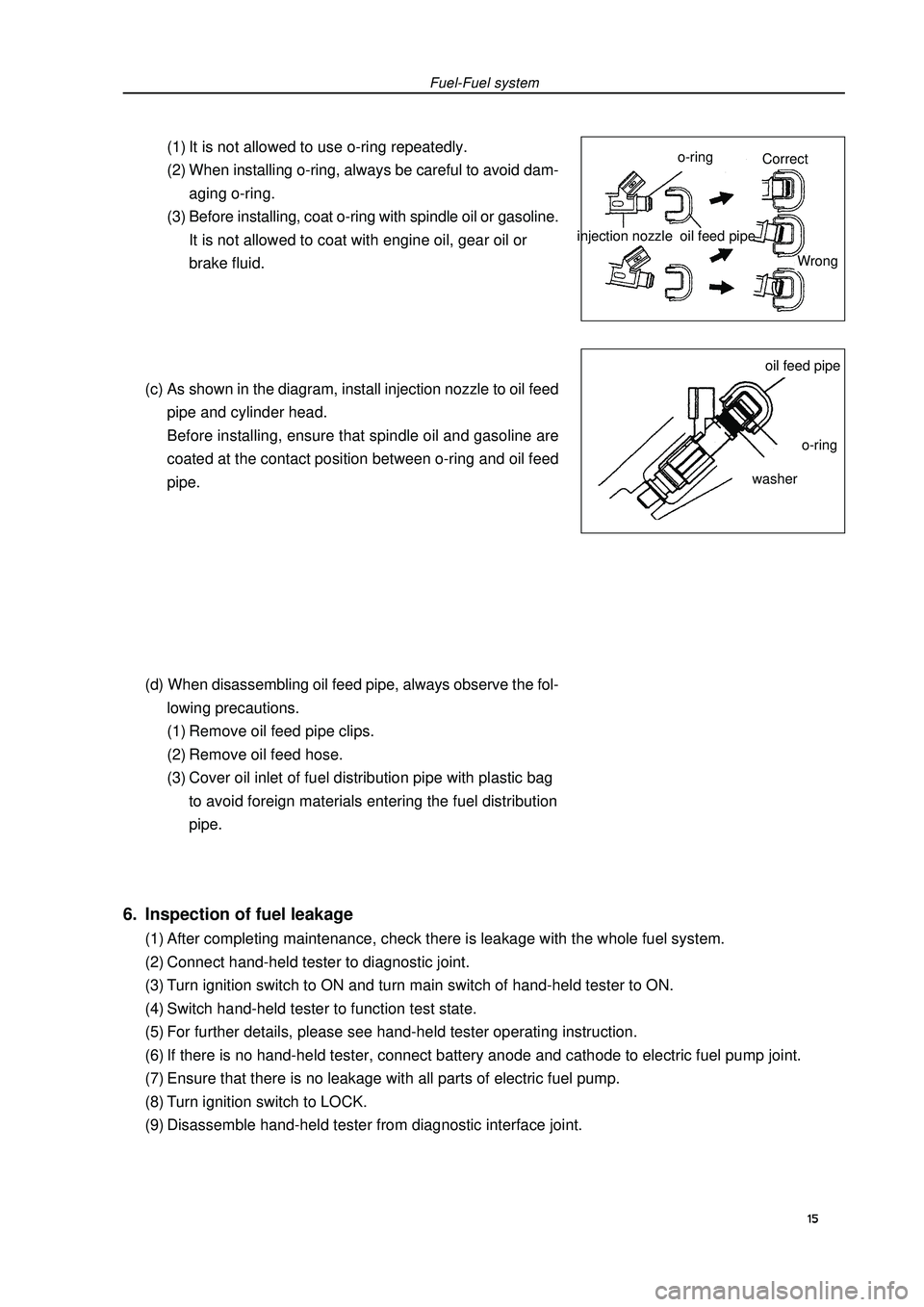

Fuel-Fuel system(1) It is not allowed to use o-ring repeatedly.

(2) When installing o-ring, always be careful to avoid dam-

aging o-ring.

(3) Before installing, coat o-ring with spindle oil or gasoline.

It is not allowed to coat with engine oil, gear oil or

brake fluid.

(c) As shown in the diagram, install injection nozzle to oil feed

pipe and cylinder head.

Before installing, ensure that spindle oil and gasoline are

coated at the contact position between o-ring and oil feed

pipe.

(d) When disassembling oil feed pipe, always observe the fol-

lowing precautions.

(1) Remove oil feed pipe clips.

(2) Remove oil feed hose.

(3) Cover oil inlet of fuel distribution pipe with plastic bag

to avoid foreign materials entering the fuel distribution

pipe.injection nozzle6. Inspection of fuel leakage(1) After completing maintenance, check there is leakage with the whole fuel system.

(2) Connect hand-held tester to diagnostic joint.

(3) Turn ignition switch to ON and turn main switch of hand-held tester to ON.

(4) Switch hand-held tester to function test state.

(5) For further details, please see hand-held tester operating instruction.

(6) If there is no hand-held tester, connect battery anode and cathode to electric fuel pump joint.

(7) Ensure that there is no leakage with all parts of electric fuel pump.

(8) Turn ignition switch to LOCK.

(9) Disassemble hand-held tester from diagnostic interface joint.15o-ringoil feed pipeoil feed pipeo-ringwasherCorrect

Wrong