steering oil GEELY MK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 35 of 416

2-14

V. Table 1 List of parts to be replaced regularlyThe intervals in the part list are for cars driven under normal condition. If the car is driven in special circumstances,

the replacement can be advanced from the schedule above.SystemParts need to be replaced regularly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22Brake master cylinder cup valve and dust coverBrake master cylinder cup

Brake hose

Brake caliper valve

Brake booster rubber

Brake booster vacuum hose

Brake fluid

MT Transmission oil

AT Transmission oil

Steering fluid

Air Cleaner

Air c leaner f ilter

Lubricant

Oil filter

Fuel filter

Coolant

All hoses

Canister

Timing beltWedge belt (including the power steering pump,

air conditioner compressor and generator belts)PCV system

Spark plugEvery 2 years (or as required)

Every 2 years (or as required)

Every 2 years (or as required)

Every 4 years (or as required)

Every 2 years (or as required)

Every 4 years (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

To be cleaned every 10,000km and changed

every 30,000km (or as required)

First 2500km or 2 months. Every 7500km or

6 months afterward (or as required)

First 2500km or 2 months. Every 7500km or

6 months afterward (or as required)

Every 5000km (or as required)

Every 40000km (or as required)

Every year (or as required)

Every 2 years (or as required)

Every 60000km (or as required)

Every 120000km (or as required)

Every 50000km (or as required)

Every 20000km or 12 months (or as required)

Every 20000km (or as required)Intervals

DrivelineSteering SystemBraking

SystemEngineA/C System

(API) SG or above(Table 1)Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

Page 36 of 416

2-15

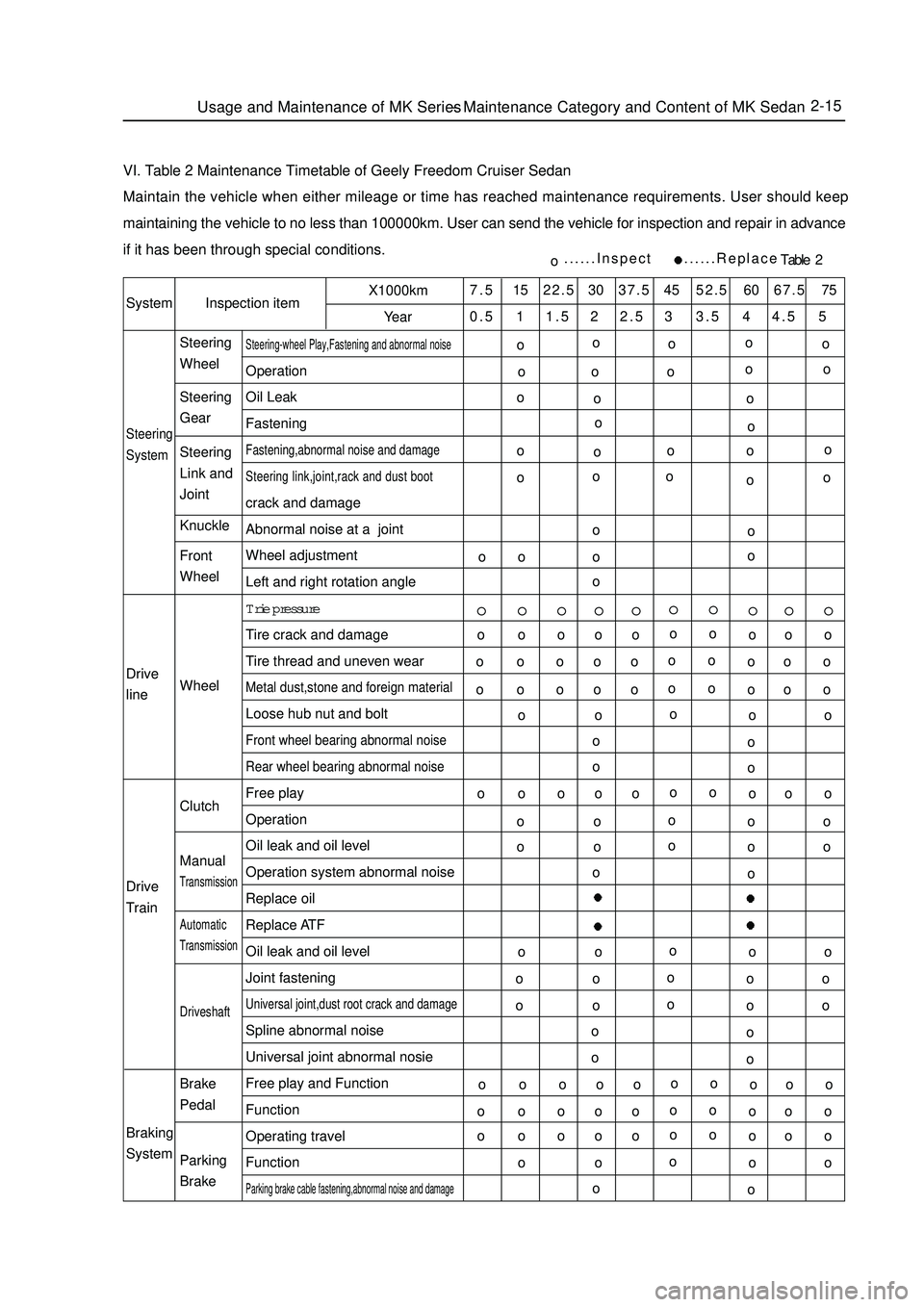

VI. Table 2 Maintenance Timetable of Geely Freedom Cruiser SedanMaintain the vehicle when either mileage or time has reached maintenance requirements. User should keep

maintaining the vehicle to no less than 100000km. User can send the vehicle for inspection and repair in advance

if it has been through special conditions.SystemInspection itemX1000km

Year7.5 15 22.5 30 37.5 45 52.5 60 67.5 75

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5Steering

SystemSteering-wheel Play,Fastening and abnormal noiseOperation

Oil Leak

FasteningFastening,abnormal noise and damage

Steering link,joint,rack and dust bootcrack and damage

Abnormal noise at a joint

Wheel adjustment

Left and right rotation angle

Trie pressure

Tire crack and damage

Tire thread and uneven wearMetal dust,stone and foreign materialLoose hub nut and boltFront wheel bearing abnormal noise

Rear wheel bearing abnormal noiseFree play

Operation

Oil leak and oil level

Operation system abnormal noise

Replace oil

Replace ATF

Oil leak and oil level

Joint fasteningUniversal joint,dust root crack and damageSpline abnormal noise

Universal joint abnormal nosie

Free play and Function

Function

Operating travel

FunctionParking brake cable fastening,abnormal noise and damageo......Inspect ......ReplaceTable 2 Drive

line

Drive

Train

Braking

SystemSteering

Wheel

Steering

Gear

Steering

Link and

Joint

Knuckle

Front

Wheel

Wheel

Clutch

ManualTransmissionAutomaticTransmissionDriveshaftBrake

Pedal

Parking

BrakeUsage and Maintenance of MK Series - Maintenance Category and Content of MK Sedano

o

oo

o o oo o

o o

oo

o o

oo

ooo

o

o oo

o ooo

o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

o

oo o o o

o o o o

oo o o

o

o

o o o

o

o

o o o

o

o

o o o

o

o

o o o

o

o

o o o

o

oo o

o o

o o

o o

o o

o oo o o

o

o

Page 38 of 416

2-17

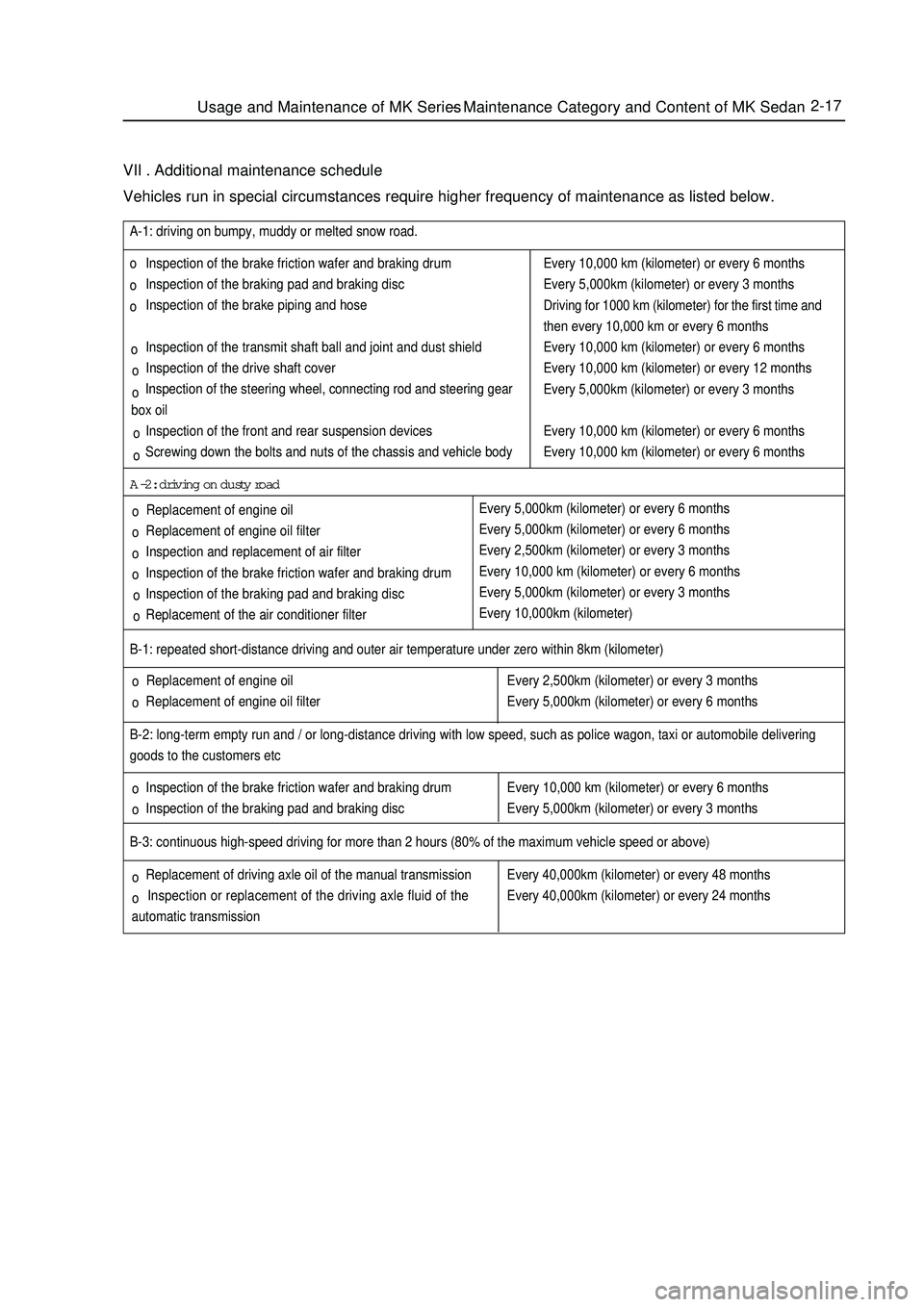

VII . Additional maintenance scheduleVehicles run in special circumstances require higher frequency of maintenance as listed below. Replacement of engine oil

Replacement of engine oil filter B-1: repeated short-distance driving and outer air temperature under zero within 8km (kilometer)

Inspection of the brake friction wafer and braking drum

Inspection of the braking pad and braking disc B-2: long-term empty run and / or long-distance driving with low speed, such as police wagon, taxi or automobile delivering

goods to the customers etcEvery 2,500km (kilometer) or every 3 months

Every 5,000km (kilometer) or every 6 months

Every 10,000 km (kilometer) or every 6 months

Every 5,000km (kilometer) or every 3 monthsB-3: continuous high-speed driving for more than 2 hours (80% of the maximum vehicle speed or above)

Replacement of driving axle oil of the manual transmission

Inspection or replacement of the driving axle fluid of the

automatic transmissionEvery 40,000km (kilometer) or every 48 months

Every 40,000km (kilometer) or every 24 months Inspection of the brake friction wafer and braking drum

Inspection of the braking pad and braking disc

Inspection of the brake piping and hose

Inspection of the transmit shaft ball and joint and dust shield

Inspection of the drive shaft cover

Inspection of the steering wheel, connecting rod and steering gear

box oil

Inspection of the front and rear suspension devices

Screwing down the bolts and nuts of the chassis and vehicle body A-1: driving on bumpy, muddy or melted snow road.

Replacement of engine oil

Replacement of engine oil filter

Inspection and replacement of air filter

Inspection of the brake friction wafer and braking drum

Inspection of the braking pad and braking disc

Replacement of the air conditioner filterA-2: driving on dusty roadEvery 10,000 km (kilometer) or every 6 months

Every 5,000km (kilometer) or every 3 months

Driving for 1000 km (kilometer) for the first time and

then every 10,000 km or every 6 months

Every 10,000 km (kilometer) or every 6 months

Every 10,000 km (kilometer) or every 12 months

Every 5,000km (kilometer) or every 3 months

Every 10,000 km (kilometer) or every 6 months

Every 10,000 km (kilometer) or every 6 months

Every 5,000km (kilometer) or every 6 months

Every 5,000km (kilometer) or every 6 months

Every 2,500km (kilometer) or every 3 months

Every 10,000 km (kilometer) or every 6 months

Every 5,000km (kilometer) or every 3 months

Every 10,000km (kilometer)Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedanoo o

o o o o

o o

o

o o

o o

o o

o ooo

Page 40 of 416

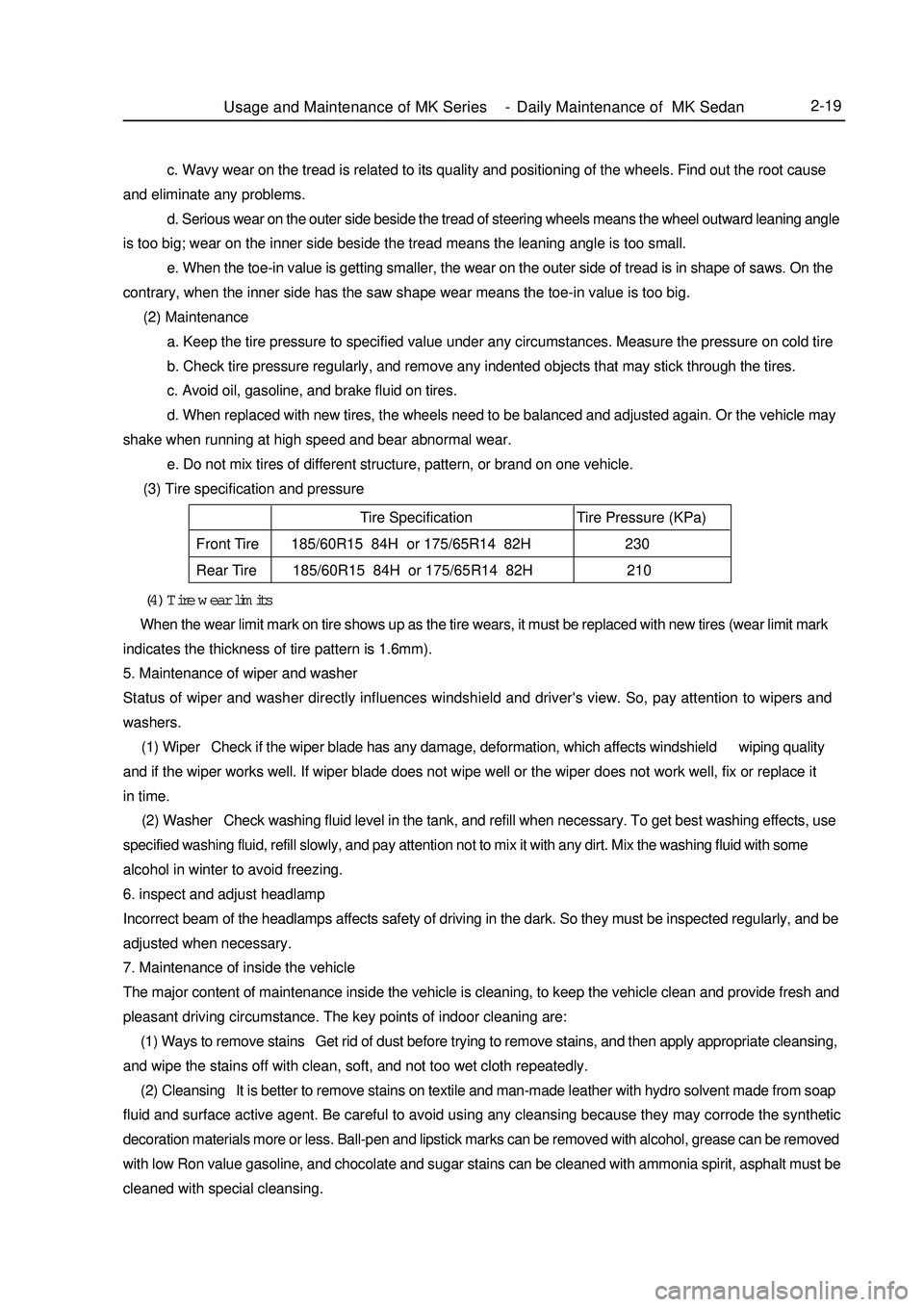

2-19 (4) Tire wear limits When the wear limit mark on tire shows up as the tire wears, it must be replaced with new tires (wear limit mark

indicates the thickness of tire pattern is 1.6mm).

5. Maintenance of wiper and washer

Status of wiper and washer directly influences windshield and driver's view. So, pay attention to wipers and

washers.

(1) Wiper Check if the wiper blade has any damage, deformation, which affects windshield wiping quality

and if the wiper works well. If wiper blade does not wipe well or the wiper does not work well, fix or replace it

in time.

(2) Washer Check washing fluid level in the tank, and refill when necessary. To get best washing effects, use

specified washing fluid, refill slowly, and pay attention not to mix it with any dirt. Mix the washing fluid with some

alcohol in winter to avoid freezing.

6. inspect and adjust headlampIncorrect beam of the headlamps affects safety of driving in the dark. So they must be inspected regularly, and be

adjusted when necessary.

7. Maintenance of inside the vehicle

The major content of maintenance inside the vehicle is cleaning, to keep the vehicle clean and provide fresh and

pleasant driving circumstance. The key points of indoor cleaning are:

(1) Ways to remove stains Get rid of dust before trying to remove stains, and then apply appropriate cleansing,and wipe the stains off with clean, soft, and not too wet cloth repeatedly.

(2) Cleansing It is better to remove stains on textile and man-made leather with hydro solvent made from soap

fluid and surface active agent. Be careful to avoid using any cleansing because they may corrode the synthetic

decoration materials more or less. Ball-pen and lipstick marks can be removed with alcohol, grease can be removed

with low Ron value gasoline, and chocolate and sugar stains can be cleaned with ammonia spirit, asphalt must be

cleaned with special cleansing.Tire Specification Tire Pressure (KPa)

Front Tire 185/60R15 84H or 175/65R14 82H 230

Rear Tire 185/60R15 84H or 175/65R14 82H 210c. Wavy wear on the tread is related to its quality and positioning of the wheels. Find out the root cause

and eliminate any problems.

d. Serious wear on the outer side beside the tread of steering wheels means the wheel outward leaning angle

is too big; wear on the inner side beside the tread means the leaning angle is too small.

e. When the toe-in value is getting smaller, the wear on the outer side of tread is in shape of saws. On the

contrary, when the inner side has the saw shape wear means the toe-in value is too big.

(2) Maintenance

a. Keep the tire pressure to specified value under any circumstances. Measure the pressure on cold tire

b. Check tire pressure regularly, and remove any indented objects that may stick through the tires.

c. Avoid oil, gasoline, and brake fluid on tires.

d. When replaced with new tires, the wheels need to be balanced and adjusted again. Or the vehicle may

shake when running at high speed and bear abnormal wear.

e. Do not mix tires of different structure, pattern, or brand on one vehicle.

(3) Tire specification and pressureUsage and Maintenance of MK Series - Daily Maintenance of MK Sedan

Page 41 of 416

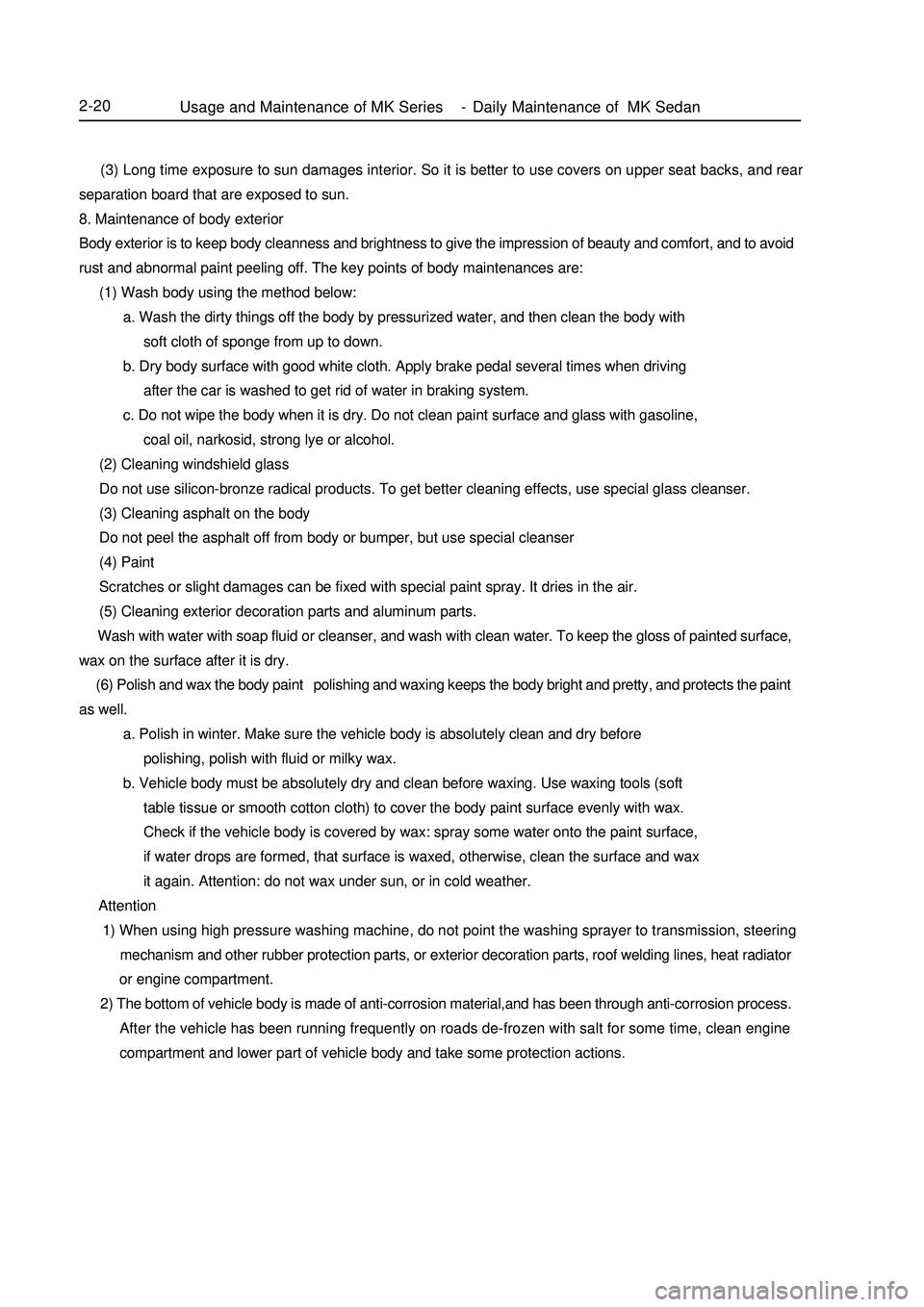

2-20 (3) Long time exposure to sun damages interior. So it is better to use covers on upper seat backs, and rear

separation board that are exposed to sun.

8. Maintenance of body exterior

Body exterior is to keep body cleanness and brightness to give the impression of beauty and comfort, and to avoid

rust and abnormal paint peeling off. The key points of body maintenances are:

(1) Wash body using the method below:

a. Wash the dirty things off the body by pressurized water, and then clean the body with

soft cloth of sponge from up to down.

b. Dry body surface with good white cloth. Apply brake pedal several times when driving

after the car is washed to get rid of water in braking system.

c. Do not wipe the body when it is dry. Do not clean paint surface and glass with gasoline,

coal oil, narkosid, strong lye or alcohol.

(2) Cleaning windshield glass

Do not use silicon-bronze radical products. To get better cleaning effects, use special glass cleanser.

(3) Cleaning asphalt on the body

Do not peel the asphalt off from body or bumper, but use special cleanser

(4) Paint

Scratches or slight damages can be fixed with special paint spray. It dries in the air.

(5) Cleaning exterior decoration parts and aluminum parts. Wash with water with soap fluid or cleanser, and wash with clean water. To keep the gloss of painted surface,

wax on the surface after it is dry. (6) Polish and wax the body paint polishing and waxing keeps the body bright and pretty, and protects the paint

as well.

a. Polish in winter. Make sure the vehicle body is absolutely clean and dry before

polishing, polish with fluid or milky wax.

b. Vehicle body must be absolutely dry and clean before waxing. Use waxing tools (soft

table tissue or smooth cotton cloth) to cover the body paint surface evenly with wax.

Check if the vehicle body is covered by wax: spray some water onto the paint surface,

if water drops are formed, that surface is waxed, otherwise, clean the surface and wax

it again. Attention: do not wax under sun, or in cold weather.

Attention

1) When using high pressure washing machine, do not point the washing sprayer to transmission, steering

mechanism and other rubber protection parts, or exterior decoration parts, roof welding lines, heat radiator

or engine compartment.

2) The bottom of vehicle body is made of anti-corrosion material,and has been through anti-corrosion process.

After the vehicle has been running frequently on roads de-frozen with salt for some time, clean engine

compartment and lower part of vehicle body and take some protection actions.Usage and Maintenance of MK Series - Daily Maintenance of MK Sedan

Page 47 of 416

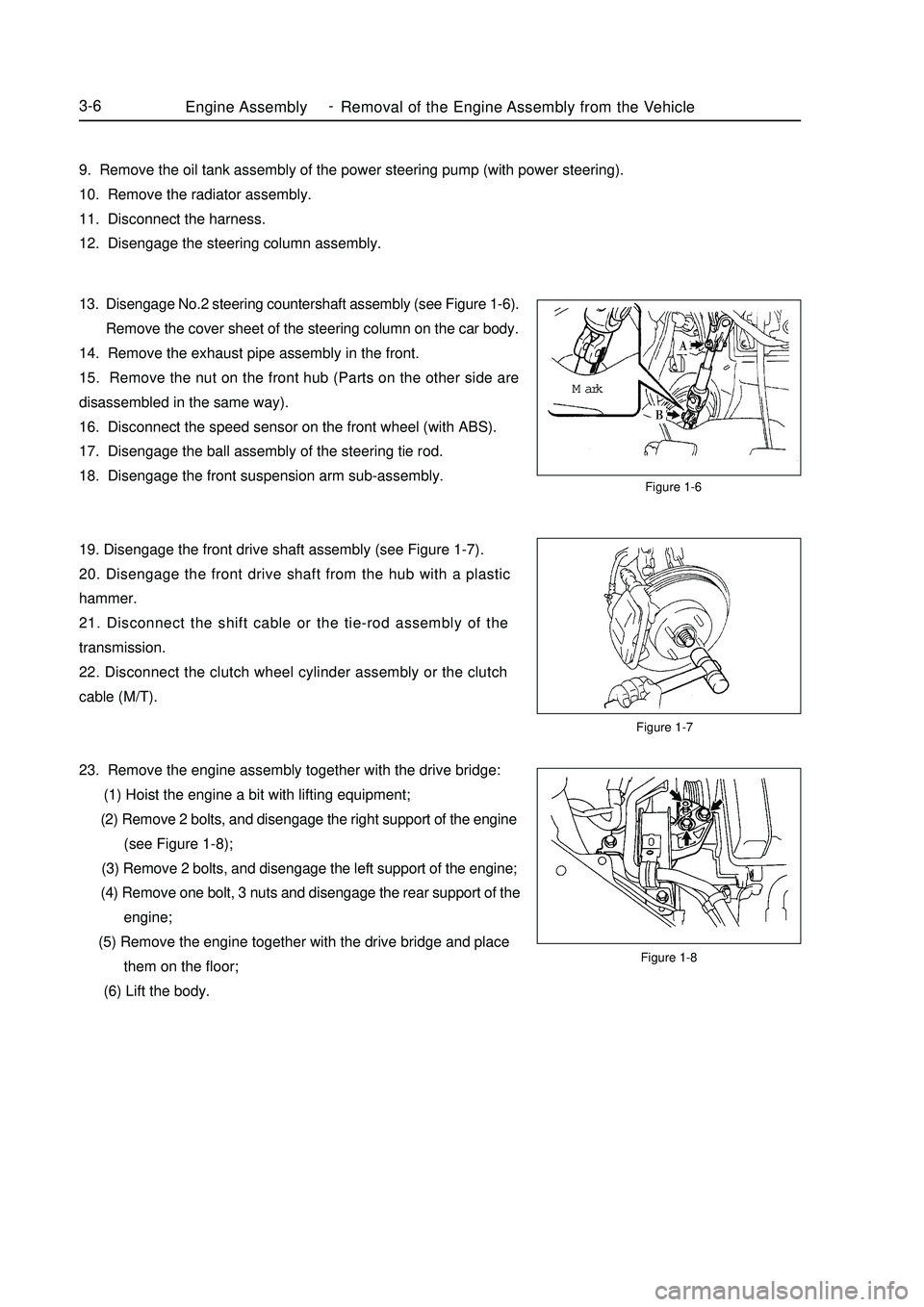

Figure 1-7Figure 1-6

Figure 1-8Engine AssemblyRemoval of the Engine Assembly from the Vehicle3-69. Remove the oil tank assembly of the power steering pump (with power steering).

10. Remove the radiator assembly.

11. Disconnect the harness.

12. Disengage the steering column assembly.

13. Disengage No.2 steering countershaft assembly (see Figure 1-6).

Remove the cover sheet of the steering column on the car body.

14. Remove the exhaust pipe assembly in the front.

15. Remove the nut on the front hub (Parts on the other side are

disassembled in the same way).

16. Disconnect the speed sensor on the front wheel (with ABS).

17. Disengage the ball assembly of the steering tie rod.

18. Disengage the front suspension arm sub-assembly.

19. Disengage the front drive shaft assembly (see Figure 1-7).

20. Disengage the front drive shaft from the hub with a plastic

hammer.

21. Disconnect the shift cable or the tie-rod assembly of the

transmission.

22. Disconnect the clutch wheel cylinder assembly or the clutch

cable (M/T).

23. Remove the engine assembly together with the drive bridge:

(1) Hoist the engine a bit with lifting equipment;

(2) Remove 2 bolts, and disengage the right support of the engine

(see Figure 1-8);

(3) Remove 2 bolts, and disengage the left support of the engine;

(4) Remove one bolt, 3 nuts and disengage the rear support of the

engine;

(5) Remove the engine together with the drive bridge and place

them on the floor;

(6) Lift the body.Mark -

Page 51 of 416

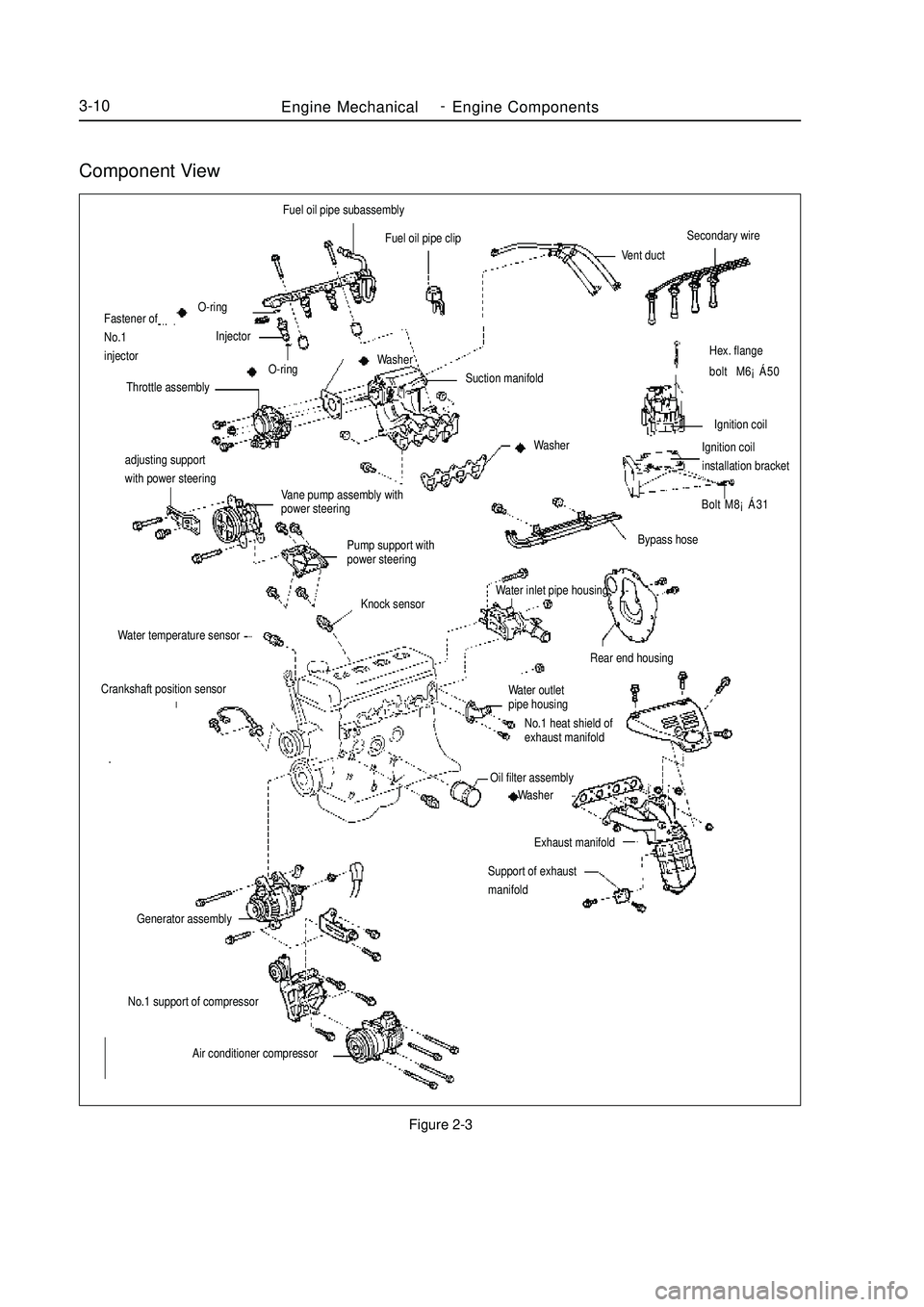

Component ViewFigure 2-3Engine MechanicalEngine Components3-10adjusting support

with power steering

Vane pump assembly with

power steering

Pump support with

power steeringHex. flange

bolt M6¡Á50

Ignition coil

Ignition coilinstallation bracket

Bolt M8¡Á31Fuel oil pipe subassembly

Fuel oil pipe clip

Vent ductSecondary wireBypass hose

Rear end housingWater outlet

pipe housing

No.1 heat shield of

exhaust manifoldOil filter assembly

Washer

Exhaust manifold

Support of exhaust

manifoldO-ring

Fastener of

No.1

injectorInjector

O-ring

Throttle assemblySuction manifold Washer

WasherKnock sensor

Water temperature sensorCrankshaft position sensorGenerator assemblyNo.1 support of compressor

Air conditioner compressorWater inlet pipe housing -

Page 94 of 416

Chapter 4 Propeller Shaft/DriveshaftSection 1 Propeller Shaft, Driveshaft and TransaxleI. Symptom Table The table below can help find the causes of the problem. The numbers indicate the priority of the causes of the

problem. Replace the parts if necessary.

Inspection Area

1. Wheel

2. Front wheel alignment

3. Rear wheel alignment

4. Front wheel hub bearing (worn)

5. Rear wheel hub bearing (worn)

6. Front shock absorber with coil spring

7. Steering linkage (loose or damaged)

8. Stabilizer bar

1. Wheel balance

2. Wheel hub bearing (worn)

3. Front shock absorber with coil spring

1. Outer joint (worn)

2. Inner joint (worn) Symptom

Deviation

Front wheel vibration

Noise (drive shaft)ReferenceII. On-board Inspection1. Check front wheel hub bearing

(1) Remove front wheel.

(2) Remove front brake caliper assembly.

(3) Remove front brake disc.

(4) Check the bearing backlash.

Set a dial indicator near the front wheel hub center to check

the backlash.

Maximum: 0.05mm

If the backlash exceeds the maximum value, replace the front

wheel hub bearing.

(5) Check the front wheel hub deviation

Using a dial indicator, check the deviation of the surface of the

wheel hub outside the hub bolt.

Maximum: 0.07mm

If the backlash exceeds the maximum value, replace the front

wheel hub subassembly.Propeller Shaft/DriveshaftPropeller Shaft, Driveshaft and Transaxle4-17 -

Page 98 of 416

Overhaul1. Drain manual transmission oil (M/T transmission)

Torque: 39N.m

2. Drain automatic transmission oil (A/T transmission)

Torque: 25N.m

3. Remove front wheel

4. Remove engine bottom left shield (M/T transaxle)

5. Remove engine bottom right shield (M/T transaxle)

6. Remove engine bottom shield assembly (A/T transaxle)

7. Remove front wheel hub left bolt

(1) Using a hammer and a drive shaft nut chisel, unstake the

staked part of the left wheel hub nut.

(2) While applying the brake pedal, remove the left wheel hub

nut.

Notice: the staked part of the nut should be fully unstaked,

otherwise it may damage the thread of the drive shaft.

8. Remove left front vehicle speed sensor (with ABS)

(1) Remove the bolt and clip, remove vehicle speed sensor and

brake hose from left front shock absorber assembly.

(2) Remove the bolt, separate the left front vehicle speed sensor

from steering knuckle.

9. Remove front stabilizer bar

(1) Use a 10mm wrench to hold the bolt, remove the nut

(2) Remove two collars, No.1 and No.2 gaskets, remove front

stabilizer barPropeller Shaft/DriveshaftFront Driveshaft4-21 -

Page 99 of 416

10. Separate left lower swing arm assembly

(1) Remove cotter pin and nut

(2) On steering knuckle, remove the left lower swing arm

assembly with ball joint puller.

11. Separate steering gear with tie rod assembly

(1) Remove cotter pin and nut

(2) On steering knuckle, remove the steering gear with tie rod

assembly with ball joint puller.Propeller Shaft/DriveshaftFront Driveshaft4-2212. Separate LF steering knuckle assembly

Using a plastic hamper, separate left front drive shaft assembly from left front steering knuckle assembly

Notice:

Do not damage the boot.

With ABS:

Be careful not to damage the vehicle speed sensor rotor.

13. Remove left constant velocity drive shaft assembly

Using a differential side gear shaft remover, remove the left

constant velocity drive shaft assembly.

Notice:

Do not damage the boot and oil seal.

Be careful not to drop the drive shaft assembly.

14. Remove right constant velocity drive shaft assembly

Using a brass bar and a hammer, remove the right constant

velocity drive shaft assembly.

Notice:

Do not damage the boot and oil seal.

Be careful not to drop the drive shaft assembly. -