wheel bolt torque GEELY MK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 120 of 416

Section 3 Front Wheel AlignmentAdjustment:1. Check tire

2. Measure the vehicle height

Vehicle height:Tire sizeFront1 (mm)Rear2 (mm)

175 / 65R14 82H191 265

185 / 60R15 84H192 265Front Suspension System-Front Wheel Alignment4-43 1.front measure point

Measure the distance between the ground and the front underside

suspension mounting bolt center

2.rear measure point

Measure the distance between the ground and the rear axle beam mounting bolt center

Notice:

Before the wheel alignment,adjust the body to the specified height.If the body height is out of spec,adjustment

shall be done by pressing or raising vehicle body.

3. Check the Toe-in

Toe-in:

If the toe-in is out of spec, adjust the ends of rack.

4. Adjust the Toe-in

(1) Remove the clamp of the rack boot

(2) Loose the jam nut of tie rod

(3) Adjust the Toe-in by rotating the same turns of both ends of

rack.

Tips: Adjust the toe-in to the intermediate value of spec.

(4)Make sure the same length for both ends

The length difference of left and right: 1.5mm or smaller

(5)Tighten the jam nut of the tie rod

Torque: 47N.m

(6)Seat the boot and crimp the clamp

Tips: rack boot must not be twistedFront

Rear

Front

Page 122 of 416

(9) Repeat the steps above, replace 1 or 2 bolts

Tips:

Only replace 1 bolt if 2 bolts are needed to be replaced.bolt

Adjustment

value

15'

30'

45'

1°00'Location bolt

AAdjusting bolt

BC

1 point

2 point12121211.

11.

11 .Front Suspension SystemFront Wheel Alignment4-45 Refer to the table below to fix the correct adjustment if the camber is out of spec, then select the bolts for camber

adjustment.

Notice: Tighten the adjustment nuts with washer and new nuts. (4) Mount 2 nuts temporarily.

(5) Adjust the camber angle by pushing or pulling the underside

of shock absorber in the direction of required adjustment.

(6) Tightening the nuts

Torque: 132N.m

(7) Mounting the front wheel

Torque: 103N.m

(8) Check the camber

Tips:

Adjust the camber to the median of spec.

Adjustment value of positioning the bolts: 6' ~ 30'.

(0.1° ~ 0.5°)Adjusting bolt-

Page 125 of 416

Front Suspension System-Front Strut Assembly4-4828. Mount the dust seals of left front suspension bracket

29. Mount the left front suspension bracket sub-assembly

30. Mount the front bracket onto the left front shock absorber nuts

(1) Hold the bracket by two bolts and a screwdriver or analogue.

Mount the new centre nut

Torque: 33N.m

Notice: DonÕt cause damage to the stud of suspension bracket.

(2) The special tool for remove

(3) Apply the multipurpose grease onto the suspension bracket

31. Mount the dust cap of left front suspension bracket

32. Mount the front stud assembly

(1) Mount the #2 suspension bracket

(2) Mount the front stud assembly by three nuts

Torque: 39N.m

(3) Mount the shock absorber onto the knuckle

(4) Film the engine oil onto the thread of two nuts

(5) Mount the two bolts and nuts

Torque: 132N.m

33. Mount the brake hose

Torque: 29N.m

34. Mount the front wheel

Torque: 103N.m

35. Mount the outside cover of vehicle neck

(1) Mount the outside cover of vehicle neck by 8 bolts

Torque: 5N.m

(2) Connect hose and harness (screen wiper)

(3) Mount the harness by bolts and two clips

36. Mount the linkage assembly of windshield wiper

37. Mount the ventilation hood of left vehicle neck

38. Mount the ventilation hood of right vehicle neck

39. Mount the engine hood and seals of vehicle neck

40. Mount the left front wiper arm

41. Mount the right front wiper arm

42. Check and adjust the front wheel alignmentMulti-purpose grease

Page 129 of 416

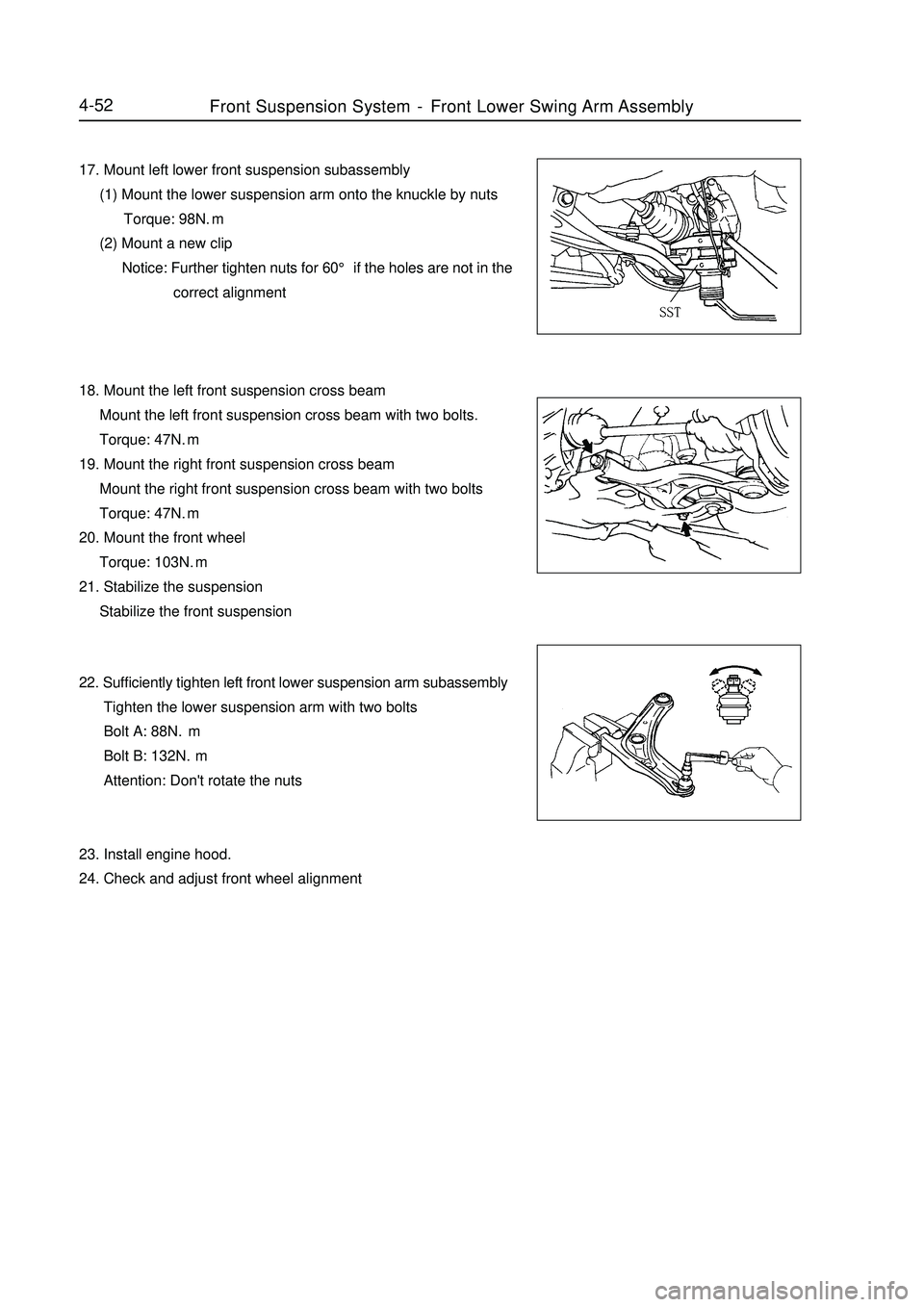

4-5217. Mount left lower front suspension subassembly

(1) Mount the lower suspension arm onto the knuckle by nuts

Torque: 98N.m

(2) Mount a new clip

Notice: Further tighten nuts for 60° if the holes are not in the

correct alignment

18. Mount the left front suspension cross beam

Mount the left front suspension cross beam with two bolts.

Torque: 47N.m

19. Mount the right front suspension cross beam

Mount the right front suspension cross beam with two bolts

Torque: 47N.m

20. Mount the front wheel

Torque: 103N.m

21. Stabilize the suspension

Stabilize the front suspension

22. Sufficiently tighten left front lower suspension arm subassembly

Tighten the lower suspension arm with two bolts

Bolt A: 88N.m

Bolt B: 132N.m

Attention: Don't rotate the nuts

23. Install engine hood.

24. Check and adjust front wheel alignmentFront Suspension System-Front Lower Swing Arm Assembly

Page 130 of 416

Section 6 Front Stabilizer Bar and Link Rod AssemblyDisassemble1. Remove the front wheel

2. Remove the front stabilizer bar bolts

(1) Remove two nuts, five retainers, four pads and stabilizer bolts when fixing bolts

(2) Take the same steps on other side as above.

3. Remove the front stabilizer bar

Remove four bolts and #1 front stabilizer bar bracket.

4. Mount the front stabilizer bar

Mount the stabilizer bar, two bushings, bracket and four bolts.

Torque: 37N.m

Notice:

Make the groove toward the vehicle rear

Tip:

Keep the bushing outside the paint line

5. Mount the front stabilizer bolts

(1) Mount the front stabilizer bolts, four pads and five retainers

Torque: 18N.m

(2) Take the same operations on other side as above process

6. Mount the front wheel

Torque: 103N.m4-53Installation markFront Suspension System-Front Stabilizer Bar and Link Rod Assembly

Page 136 of 416

Rear Suspension System-LH/RH Rear Suspension Coil Spring4-5918. Mount rear right brake tube

Tips:

Mount the right assembly by using same operations as left.

19. Mount sideslip control sensor wire (with ABS)

(1) Tighten sideslip control sensor wire by bolts

Torque: 8.0 N.m

(2) Mount sideslip control sensor wire

Attention: Mount the right wire by using same operations as left.

20. Mount load-sensing valve bracket (without ABS)

Mount load-sensing valve bracket by two buts

21. Sufficiently tighten the rear axle frame assembly

(1) Stabilize the shock absorber assembly

Use the lifting jack and add 90Kg force on rear luggage

carrier if bolts can not be tightened at this point.

(2) Sufficiently tighten bolts

Torque: 82 N.m

22. Sufficiently tighten the left rear shock absorber assembly

Sufficiently tighten nuts

Torque: 49 N.m

23. Sufficiently tighten the right rear shock absorber assembly

Tips: Mount the right rear shock absorber by using same opera-

tions as left.

24. Release the air in the brake hose

25. Mount the rear wheel

Torque: 103 N.m

26. Check rear the wheel alignment

27. Check the wheel speed sensor signal of ABS( with ABS)

Page 142 of 416

4-6523. Temporarily fasten the rear axle frame assembly

(1) Lift rear axle frame by lifting jack

(2) Mount the rear axle frame by temporarily tightening two bolts

24. Mount rear left helical spring

25. Mount rear right helical spring

Tips:

Mount right parts by using same operations as left

26. Temporarily tighten rear left shock absorber assembly

27. Temporarily tighten rear right shock absorber assembly

Tips:

Mount right parts by using same operations as left

28. Mount rear left hub and bearing assembly

Mount rear brake assembly, rear left hub and bearing assembly by

four bolts

29. Mount rear right hub and bearing assembly

Tips: Mount right parts by using same operations as left

30. Mount rear brake drum subassembly

31. Adjust the gap between brake drum and brake shoe

32. Mount #3 parking brake cable assembly

Tips: Mount right parts by using same operations as left

33. Mount #2 parking brake cable assembly

34. Mount #4 rear brake tube

35. Mount #3 rear brake tube

Tips: Mount right parts by using same operations as left

36. Connect sideslip control sensor wire(with ABS)

37. Connect load-sensing valve braket(without ABS)

38. Sufficiently tighten rear axle frame assembly

39. Sufficiently tighten rear left shock absorber assembly

40. Sufficiently tighten rear right shock absorber assembly

Tips: Mount right parts by using same operations as left

41. Release air from brake tube

42. Mount rear wheel

Torque: 103N.m

43. Check rear wheel alignment

44. Check the speed signal of ABS sensor( with ABS).Rear Suspension System

-Rear Suspension Crossmember

Page 149 of 416

Power Steering System-Steering Drive and Control Mechanism4-7213. Remove the No.2 steering countershaft assembly.

(1) Make a mark on the fit between main shaft and countershaft.

(2) Remove bolt and countershaft.

14. Remove the ignition switch bracket.

(1) Use the punch pin to make a mark on the 2 conical head bolt.

(2) Drill the 2 conical head bolts with the diameter of 3-4mm drill

bit.

(3) Remove the bolts and bracket for the ignition switch with the

thread die.

15. Remove fixing panel on the steering column.

16.Remove the ignition switch lock core assembly.

(1) Turn the ignition switch to "ACC" position.

(2) press the stop pin and pull the lock core out.

17. After checking or replacing the steering column pipe assembly, install all parts in a reverse order.

Note:

(1) After installing the ignition switch lock core, check the operation of the steering locking function: when

pulling out the key, the steering device is locked; when the key is inserted and turned to ACC position, the

steering device is unlocked.

(2) Tighten the 3 bolts.

(3) Make sure all cables are connected reliably.

(4) After adjusting the combination switch as well as the top shell and bottom shell of the steering pipe shield,

fasten the three screws connecting the combination switch and the steering column assembly.

(5) Tighten the set bolt between the universal joint fork and the steering gear assembly with a torque of

22~39N.m.

(6) Install dust cover and its press plate.

(7) When installing the steering wheel assembly, align the steering wheel assembly and the fit mark of the

steering main shaft assembly. Tighten the special quincunx bolt with a torque of 33~59N.m.

(8) Check the airbag. It is not allowed to use a airbag part removed from another vehicle.

(9) Check the SRS warning lamp.Thread die Installation mark

Page 174 of 416

Brake System -Front Brake Disc4-9719. Check the swing of the brake disc.

(1) Fasten the brake disc temporarily.

Torque: 103N.m

(2) Measure the swing of the brake disc at the 10mm from the disc

edge with a dial test indicator.

Maximum Swing: 0.05 mm

(3) If the swing of the brake disc reaches or exceeds the limit,

check the bearing's axial clearance and the wheel hub's swing.

If the bearing and wheel hub run normally, adjust the swing

of the brake disc, or finish it with onboard finishing machine.

20. Tighten the brake discharge bolt temporarily.

Tighten the brake discharge screw plug on the front brake cylinder temporarily.

21. Install the piston oil seal.

(1) Apply the lithium soap-base glycol lube on the new piston oil seal.

(2) Install the new piston oil seal on the brake cylinder.

22. Install the brake piston.

(1) Apply the lithium soap-base glycol lube on the brake piston.

(2) Install the piston on the front disc brake cylinder.

Note:

Don't tighten the piston into the brake cylinder forcefully.

23. Install the dust shield of the brake wheel cylinder.

(1) Apply the lithium soap-base glycol lube on the dust shield of

the new brake wheel cylinder, and install it on the brake

cylinder.

Tips:

Install the dust shield in the groove of the brake wheel cylinder

and piston reliably.

(2) Install the set ring with screwdriver.

Note:

Be careful not to damage to the dust shield of the brake wheel cylinder.

24. Install the left front disc brake wheel cylinder support.

Fasten the front disc brake wheel cylinder support with two blots.

Torque: 88N.m

25. Install the dust shield of the front disc brake bushing.

Apply the lithium soap-base glycol lube on the surface of the two new dust shields.

Install the two dust shields on the front disc brake cylinder support.

26. Install the sliding pin of the front dist brake cylinder.

Apply the lithium soap-base glycol lube on the surface of the two sliding pin and oil seal.

Install the two sliding pins on the front disc brake cylinder support.

Page 175 of 416

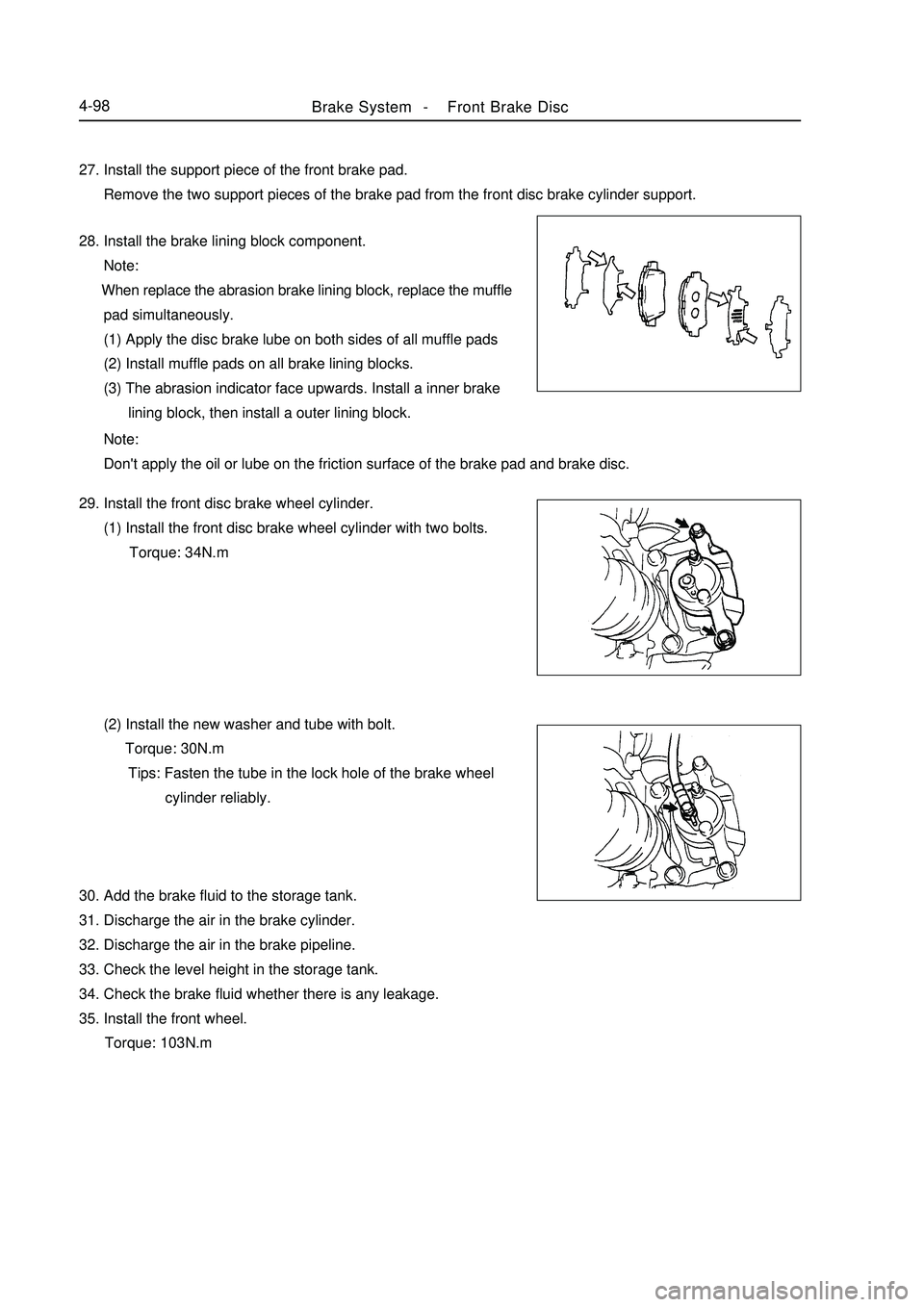

Brake System -Front Brake Disc4-9827. Install the support piece of the front brake pad.

Remove the two support pieces of the brake pad from the front disc brake cylinder support.

28. Install the brake lining block component.

Note:

When replace the abrasion brake lining block, replace the muffle

pad simultaneously.

(1) Apply the disc brake lube on both sides of all muffle pads

(2) Install muffle pads on all brake lining blocks.

(3) The abrasion indicator face upwards. Install a inner brake

lining block, then install a outer lining block.

Note:

Don't apply the oil or lube on the friction surface of the brake pad and brake disc.

29. Install the front disc brake wheel cylinder.

(1) Install the front disc brake wheel cylinder with two bolts.

Torque: 34N.m

(2) Install the new washer and tube with bolt.

Torque: 30N.m

Tips: Fasten the tube in the lock hole of the brake wheel

cylinder reliably.

30. Add the brake fluid to the storage tank.

31. Discharge the air in the brake cylinder.

32. Discharge the air in the brake pipeline.

33. Check the level height in the storage tank.

34. Check the brake fluid whether there is any leakage.

35. Install the front wheel.

Torque: 103N.m