steering GEELY MK 2008 Repair Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 212 of 416

III. Wiper switch assemblyReplacement

1. Detach steering wheel assembly

(1) Disconnect the main power source of the vehicle.

(2) Remove the passenger SRS module assembly, and cautiously put it in a safe place.

(3) Loosen steering wheel lock-bolts and remove the assembly.

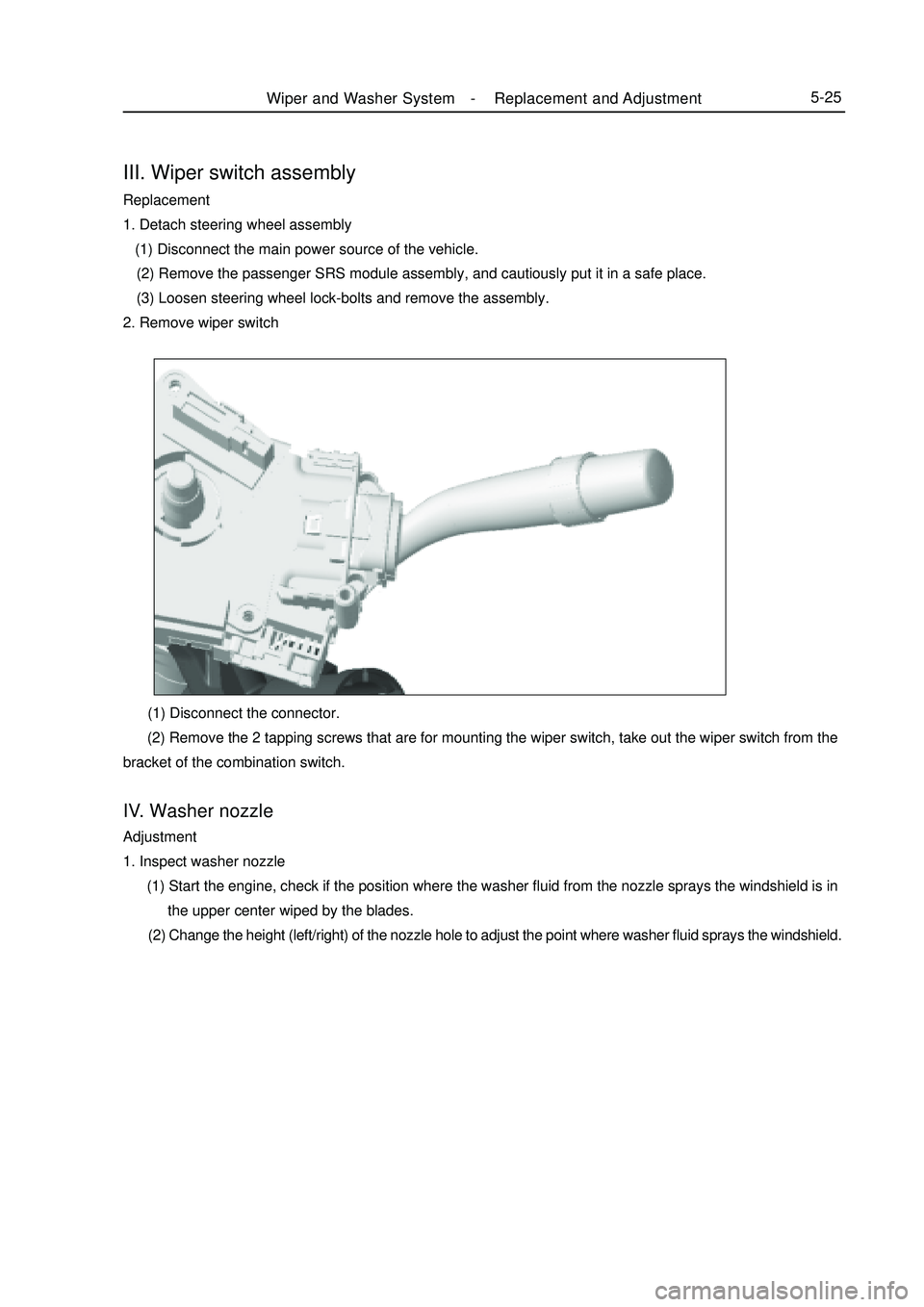

2. Remove wiper switch (1) Disconnect the connector.

(2) Remove the 2 tapping screws that are for mounting the wiper switch, take out the wiper switch from the

bracket of the combination switch.IV. Washer nozzleAdjustment

1. Inspect washer nozzle

(1) Start the engine, check if the position where the washer fluid from the nozzle sprays the windshield is in

the upper center wiped by the blades.

(2) Change the height (left/right) of the nozzle hole to adjust the point where washer fluid sprays the windshield.Wiper and Washer System -Replacement and Adjustment5-25

Page 249 of 416

5-62 (22) There are problems in the configuration of the airbag ECU (DTC 93D6)

When using the scan tool to test the airbag ECU, the DTC is 93D6, indicating that there are problems in the

configuration of the airbag ECU.

Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93D6? Go to step 2 other

2Go to step 3

3 Go to step 4 Go to step 1

4 The fault has been removed, use the scan tool to eliminate the DTC.Check whether the configuration of the airbag ECU is consistent with the

actual on-board configuration?

After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check). (23) The impact signal output interface of the airbag ECU is short to ground or the impact output circuit is

disconnected. (DTC 93D7)

When using the scan tool to test the airbag ECU, the DTC is 93D7, indicating that the impact signal output

interface of the airbag ECU is short to ground or the impact output circuit is disconnected.IV. Diagnosis of collided vehicle No matter airbag is unfolded or folded, inspection and maintenance of collided vehicle should be performed

according to the following sequence.

1. Check ECU diagnosis signal.

(1) Connect scanner diagnosis joint

(2) Use scanner to read out diagnosis result.

2. Repair sequence

(1) when airbag is unfolded.

The following components should be replaced with new parts

a. Airbag assembly on passenger side

b. ECU

c. Airbag assembly on driver side

d. Seat belt with pretensionerNote:

due to impact, when battery power is insufficient, scanner can not communicate with ECU, now check and

service instrument board wire harness or use external power supply.SRS (Supplemental Restraint System)-SRS-General Information (2 ) Check the following components, if there is any abnormity, replace with new parts

a. Clock spring.

b. Steering wheel, steering column, lower steering shaft assembly

(3 ) The installation status of driver airbag assembly in relation to steering wheel

a. Check and see if there is abnormal noise in the steering wheel, the action of the same is good, or the

clearance is normal.

b. Check the connecter of the wire harness for damage and the terminal for distortion.

Page 251 of 416

6. Steering wheel, steering column and steering lower shaft component.

(1) Check the installation status of driver airbag assembly.

(2) Check the steering wheel for any abnormal noise and see if the clearance is normal.

7. Check the wire harness connector (instrument panel wire harness).

Check and see if the wire harness is securely installed, if the joint is damaged and if the terminal is distorted.V. Warning marks When using or maintaining an airbag, the warnings shall be indicated. When maintaining, proceed in

accordance with the description of mark. In addition, if the mark is damaged or stained, it shall be replaced.

(1) Steering wheel, see Fig. 1.

(2) Driver airbag assembly, see Fig. 2.

(3) Clock spring, see Fig. 3.

Fig. 1.Fig. 2.Warning markFig. 3.Warning

mark (4) ECU, see Fig. 4.

(5) Sunshade, see Fig. 5.VI. SRS electronic control unit (ECU)Removal and Installation

1. Operations prior to Removal

(1) Turn the ignition switch OFF.

(2) Remove negative (-) terminal cable of the battery. Put it in a proper position or wrap it up with insulating

tape.Fig. 4.Fig. 5.5-64SunshadeSRS (Supplemental Restraint System)-SRS-General Information

Page 252 of 416

Notice

1. Work must be started 60s after the negative (-) terminal cable is detached from battery. The detached

negative (-) terminal cable shall be protected with insulating tape for insulation.

2. Never attempt to dismantle or repair an ECU. If there is any trouble, replace the ECU with a new one.

3. Prevent the ECU from shock or vibration. If pitting, crack or distortion is found, replace the ECU with a

new one.

4. Every time an airbag is deployed, the ECU shall be replaced with a new one.

5. When disassembling or maintaining the parts around ECU, attention must be given to avoid contacting the

ECU. 2. Removal procedures:

(1) Remove the miscellaneous box in the middle consoce.

(2) Remove the connectors to SRS ECU.

(3) Remove ECU.

3. Installation procedures:

(1) Install ECU.

(2) Install the connectors to SRS ECU.

(3) Install the miscellaneous box in the middle consoce.

(4) Connect negative (-) terminal cable of the battery.

4. Key points for Installation:

(1) Install ECU.Notice

If the ECU cannot be installed correctly, the airbag will not act normally.

5. Check

a. ECU case for pitting, crack and distortion

b. The connector for damage and distortion.Notice

If pitting, crack or distortion is found on an ECU, replace it with a new one.VII. Airbag assembly & clock spring1.Removal and Installation of driver airbag and clock spring

Operations prior to removal

(1)Take out the ignition key after the steering wheel and front

wheel are adjusted to straightforward direction.

(2)Remove negative (-) terminal cable from the battery.

Removal procedures of the driver airbag assembly:

(1) Unscrew the screws of the two sides, see fig.15-65SRS (Supplemental Restraint System)-SRS-General Information (2) Check after installation.

a. Turn the ignition switch ON.

b. The warning light goes on within 4s, and then goes out.

(3) If the light doesn't go out, check the trouble and eliminate it.

For other ECU inspections, see Troubleshooting.

fig.1

Page 253 of 416

(2) Disconnect the connector of the wire harness.

(3) Remove the components of airbag assembly.

(4) Remove steering wheel.

Removal procedures of clock spring:

(1) Remove the driver airbag assembly (disconnect the connector).

(2) Remove steering wheel gently (see the precaution).

(3) Remove the steering column cover and disconnect the connector of wire harness in the lower end.

(4) Remove clock spring.

Installation procedures of the driver airbag assembly

(1) Pre-Check

1- Install steering wheel

2- Connect the wire harness

3- Install driver airbag assembly

4- Screw up the installation screws of the two sides

(2) Connection of the negative (-) terminal of the battery

(3) Check after installation.

Installation procedures of clock spring:

(1) Pre-Check

1- Connection and fixation of the clock spring and combination switch

2- the connector of wire harness in the lower end

3- the steering column cover

4-Thread the line at the upper end of the clock spring through hole on the body part of the steering wheel

5-Install the steering wheel

6-Connect wiring harness

7-Install the airbag assembly components

(2) Connect the negative (-) terminal cable of the battery

(3) Check after installation5-66Key points for installation

(1)Pre-Check

a. The new airbag or clock spring shall be checked before being installed.SRS (Supplemental Restraint System)-SRS-General InformationNotice

Use scanner to do adiagnossis of airbag circnit, not to break down.

Keep the removed driver airbag assembly upside down in a clean and dry place.Notice

Keep the removed clock sprint in a clean and dry place.fig.2Installation nutRemoval of steering wheel (see the figure 2)

(1) Remove the installation screws from the middle and remove

the steering wheel.(Disconnect the horn connector)

Page 254 of 416

5-67Notice

When connecting or disconnecting the turn the ignition switch OFF first.

d. Turn the ignition switch ON.

e. Read the diagnostic circuit and see if the other locations than the troubled area of the airbag are normal.

f. Turn the ignition switch OFF.

g. Remove the negative (-) terminal cable from the battery, and protect it with insulating tape for insulation.Notice

Work must be started 60s after the negative (-) terminal cable is disconnected from battery.

(2) Installation of clock spring

Screw up the clock spring clockwise to the end, rotate it counter-

clockwise by 2.5 turns, and align it with the mark (see the figure 3).Notice

If the center of the clock spring cannot be aligned, the steering

wheel will not turn midway, or cause bad performance to the clock

spring circuit, consequently hamper the normal action of the airbag.

(3) Installation of the components of the steering wheel and airbag assembly

a. When the center of the clock spring is aligned, install the components of the steering wheel and airbag

assembly.

b. After being installed, rotate the left and right sides of the steering wheel to position, and make sure there

is no abnormality.

(4) Check after installation

a. Slightly rotate the steering wheel left and right, make sure that there is no abnormality or noise. (Driver

airbag module, clock spring)

b. Turn the ignition switch ON.

c. The warning light goes on within 4s, and then goes out.figure 3SRS (Supplemental Restraint System)-

SRS-General Information b. Connect negative (-) terminal cable of the battery.

c. Connect the diagnostic connector (16 pins).Notice

In case of scrapping an airbag, it shall be noted that the airbag shall be deployed according to the specified

procedures before being scrapped.SRS Air Bag

Warning LightNotice

When installing the components of the steering wheel and

airbag assembly, attention should be given to protect the wire

harness of the clock spring from seizure.

d. The trouble shall be eliminated if the warning light remains on when the ignition switch is turned on or

after it goes out after 4s.

Page 316 of 416

Chapter 10 On-board Vehicle TelephoneI. Key points for use of Geely hands-free car telephone: 1. Microphone of hands-free car telephone is installed on the back of steering wheel upright column, away from

driver to ensure talking effect. During talking, do not open window, otherwise noisy wind might influence talking

effect.

2. Since there are many kinds of mobile phones in Chinese market, in order to ensure talking effect, please

select interface line corresponding to your mobile phone, otherwise talking effect might be influenced. At present,

Nokia, Motorola, Siemens interface lines are available.

3. To use, insert one end of mobile phone interface line into 8 core RJ 45 stand on automobile panel, connect

the other end to earphone output port of the mobile phone. When mobile phone is not connected, automobile sound

works normally, when mobile phone receive a call, CD becomes quiet automatically, at the same time, loudspeaker

in the vehicle is switched to hands-free telephone output. This hands-free car telephone is provided with response

button at the top of microphone, however, new style of mobile phone does not support manual response function

for the time being, while supports automatic response function, namely it receive the call automatically after

ringing for three times.

4. After talking is finished, automobile sound will return to original state automatically.

5. During daily use, note that contact insertion and withdraw force of mobile phone interface line should not

be too large, so as to avoid damage.

6. Hands-free car telephone has no volume switch, volume of loudspeaker voice may be adjusted by regulating

the volume of handset earphone.II. Circuit diagram5-129On Board Vehicle Telephone-On-board Vehicle TelephonePlease Refer to "MK WIRING DIAGRAM"

Page 341 of 416

III. Removal and installation of instrument panel1. Disconnect the negative terminal of storage battery

2. Remove the instrument panel trim panel sub-assembly

a. Loosen 7 clips;

b. Disconnect the connector and unfasten the trim panel.

3. Remove the instrument cluster trim panel sub-assembly

a. Unfix the clamp;

b. Loosen 10 clips and unfasten the trim panel.Steering column upper cover

Steering column lower cover

Auxiliary fasia

console bodyCupholder Instrument cluster trim panel Glove compartment assy Instrument panel

lower housing assyInterior & Exterior Trim and Accessory -Dashboard, Middle Console and Instrument Panel6-12Left Combination switchRight

Combination

switch

7 clips

10 Clips

Page 343 of 416

6-14 e. Pull the instrument panel sub-assembly backward and then take it out.

10. Remove the instrument panel lower housing assembly

Loosen 6 clasps and then pull the lower housing assembly out.

11. Remove the radio set assembly with bracket

a. Unfix 4 screws;

b. Disconnect the connector and then unfasten the radio set

assembly with bracket.

12. Remove the horn button assembly

13. Remove the steering wheel assembly

14. Remove the steering column upper cover assembly

15. Remove the steering column lower cover assembly

16. Remove the cupholder

17. Remove the auxiliary fasia console assembly

a. Unfix 3 screws;

b. Unfix 3 clips by use of a clip remover and then unfasten the

auxiliary fasia console assembly.6 clasps

2 clamps

2 clipsInterior & Exterior Trim and Accessory -Dashboard, Middle Console and Instrument Panel

Page 413 of 416

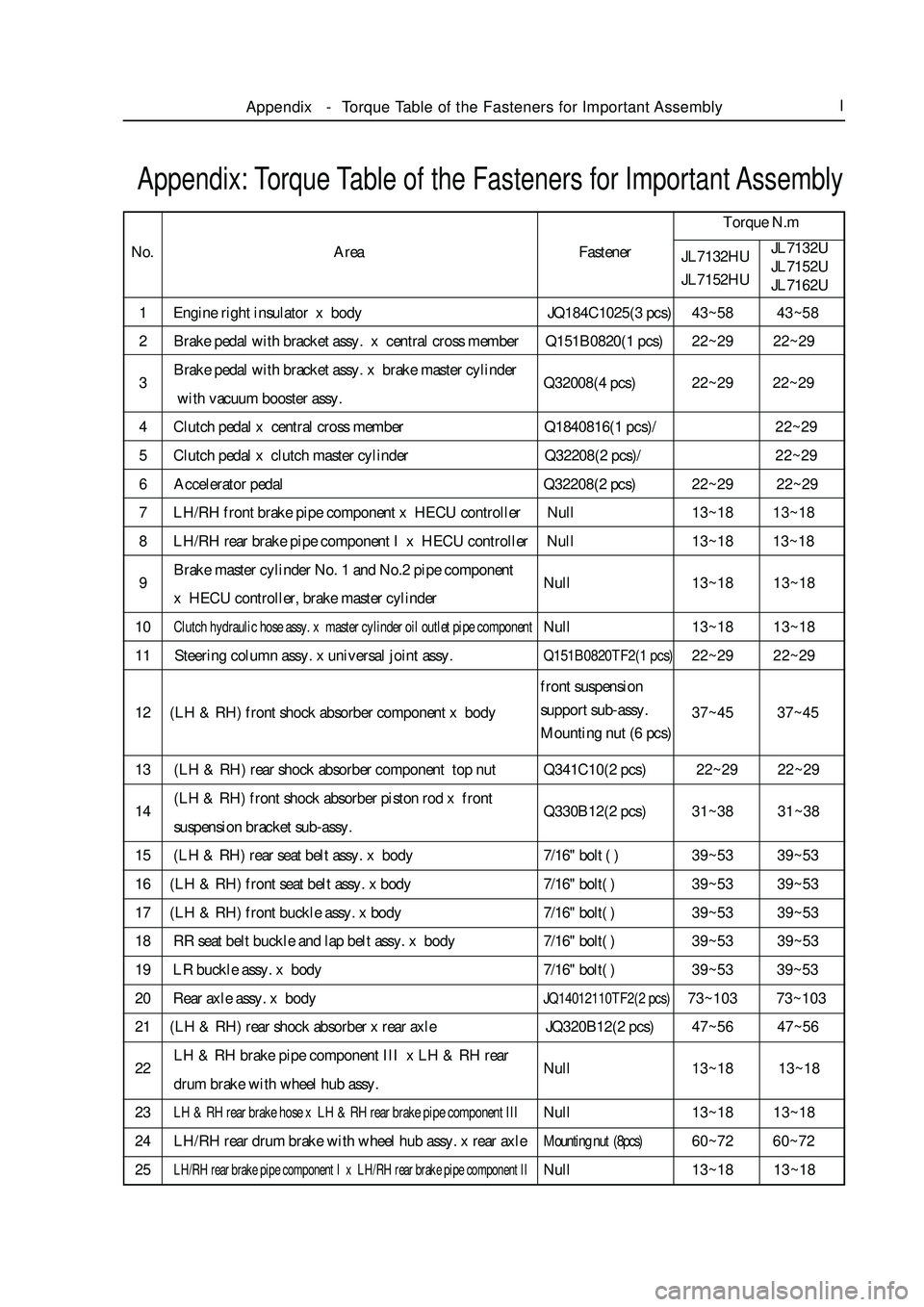

1 Engine right insulator x body JQ184C1025(3 pcs)43~58 43~58

2 Brake pedal with bracket assy. x central cross member Q151B0820(1 pcs)22~29 22~29

3Brake pedal with bracket assy. x brake master cylinder

Q32008(4 pcs)22~29 22~29

with vacuum booster assy.

4 Clutch pedal x central cross member Q1840816(1 pcs)/22~29

5 Clutch pedal x clutch master cylinder Q32208(2 pcs)/22~29

6 Accelerator pedal Q32208(2 pcs)22~29 22~29

7 LH/RH front brake pipe component x HECU controller Null13~18 13~18

8 LH/RH rear brake pipe component I x HECU controller Null13~18 13~18

9Brake master cylinder No. 1 and No.2 pipe component

Null13~18 13~18

x HECU controller, brake master cylinder

10Clutch hydraulic hose assy. x master cylinder oil outlet pipe componentNull13~18 13~18

11 Steering column assy. x universal joint assy.Q151B0820TF2(1 pcs)22~29 22~29

12 (LH & RH) front shock absorber component x body37~45 37~45

13 (LH & RH) rear shock absorber component top nut Q341C10(2 pcs) 22~29 22~29

14(LH & RH) front shock absorber piston rod x front

Q330B12(2 pcs)31~38 31~38

suspension bracket sub-assy.

15 (LH & RH) rear seat belt assy. x body7/16" bolt ( )39~53 39~53

16 (LH & RH) front seat belt assy. x body7/16" bolt( )39~53 39~53

17 (LH & RH) front buckle assy. x body7/16" bolt( )39~53 39~53

18 RR seat belt buckle and lap belt assy. x body7/16" bolt( )39~53 39~53

19 LR buckle assy. x body7/16" bolt( )39~53 39~53

20 Rear axle assy. x bodyJQ14012110TF2(2 pcs)73~103 73~103

21 (LH & RH) rear shock absorber x rear axle JQ320B12(2 pcs)47~56 47~56

22LH & RH brake pipe component III x LH & RH rear

Null13~18 13~18

drum brake with wheel hub assy.

23LH & RH rear brake hose x LH & RH rear brake pipe component IIINull13~18 13~18

24 LH/RH rear drum brake with wheel hub assy. x rear axleMounting nut (8pcs)60~72 60~72

25LH/RH rear brake pipe component I x LH/RH rear brake pipe component IINull13~18 13~18Appendix: Torque Table of the Fasteners for Important AssemblyTorque N.m

No.

JL7132HU

JL7152HUJL7132U

JL7152U

JL7162UAppendix-Torque Table of the Fasteners for Important AssemblyIArea Fastener

front suspension

support sub-assy.

Mounting nut (6 pcs)