ABS GEELY MK 2008 Manual Online

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 373 of 416

Part VII BodyChapter 1 SurveySection 1 Body StructureThe body is made up of main structure, movable plate work, interior/exterior trim parts, and body accessories.I. Main StructureAs shown in Fig.5-1, the main structure is made up of various assemblies and parts including engine compartment

assembly & front wall parts, floor assembly, left/right wall assembly, rear wall assembly, roof assembly and

luggage compartment main cover assembly etc.Fig. 5-1 Main Structure

1 Engine compartment assembly & front wall parts 2. Left/right wall assembly

3. Luggage compartment main cover assembly 4. Rear wall assembly 5. Floor assembly

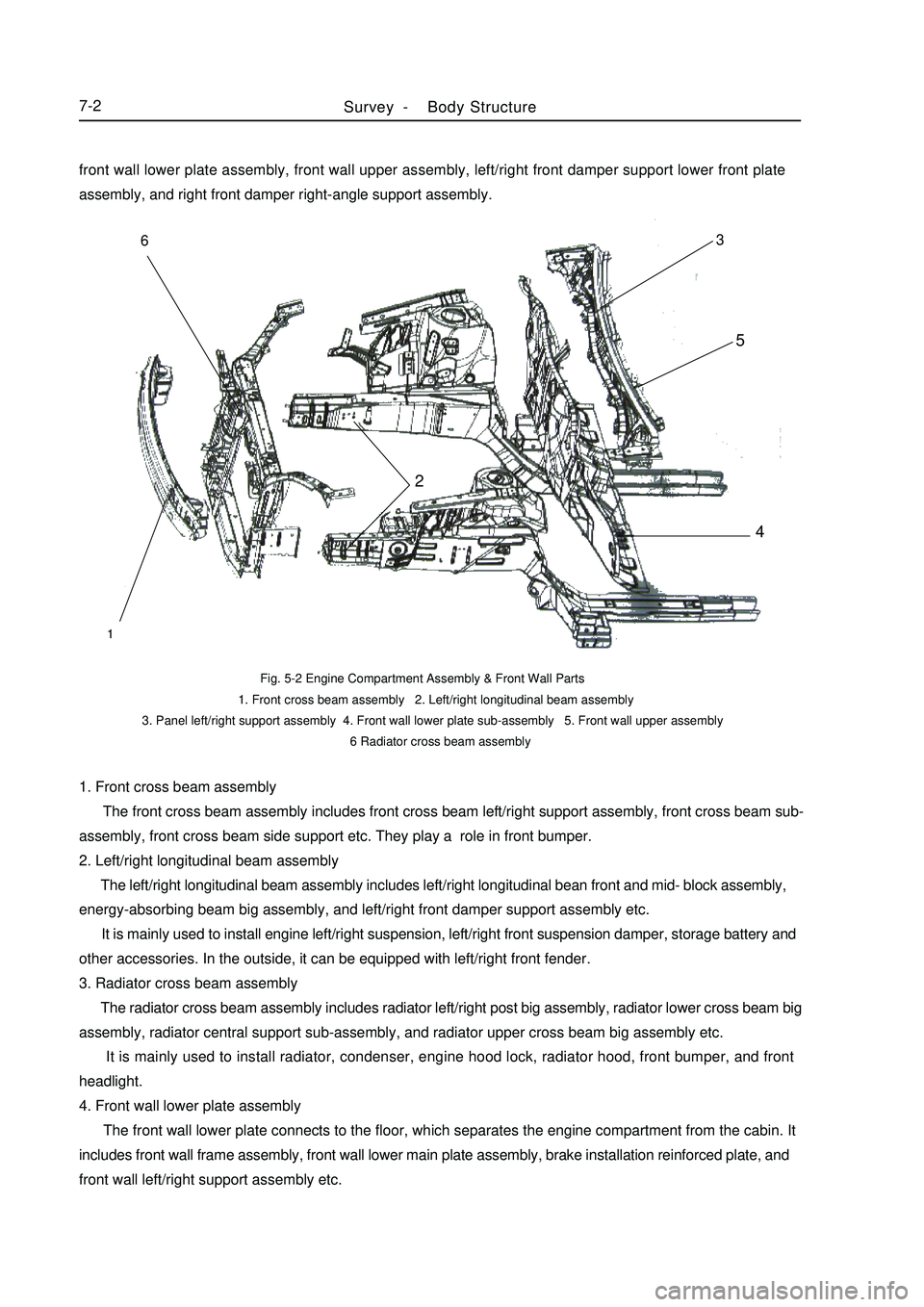

6. Roof assembly 7. Front cross beam assembly(1) Engine Compartment Assembly & Front Wall Parts The main function of the engine compartment assembly and front wall parts is to form an engine compartment

and absorb most energy generated when the vehicle is collided from the front. The compartment provides a hood

for the engine and its accessories, which can prevent the front wheel from throwing mud. In the appearance, it

represents the body's design requirements. As shown in Fig.5-2, the engine compartment assembly and front wall

parts include front cross beam assembly, left/right longitudinal beam assembly, radiator cross beam assembly,Body -Survey7-1

123456

7

Page 374 of 416

1. Front cross beam assembly

The front cross beam assembly includes front cross beam left/right support assembly, front cross beam sub-

assembly, front cross beam side support etc. They play a role in front bumper.

2. Left/right longitudinal beam assembly

The left/right longitudinal beam assembly includes left/right longitudinal bean front and mid- block assembly,

energy-absorbing beam big assembly, and left/right front damper support assembly etc.

It is mainly used to install engine left/right suspension, left/right front suspension damper, storage battery and

other accessories. In the outside, it can be equipped with left/right front fender.

3. Radiator cross beam assembly

The radiator cross beam assembly includes radiator left/right post big assembly, radiator lower cross beam big

assembly, radiator central support sub-assembly, and radiator upper cross beam big assembly etc.

It is mainly used to install radiator, condenser, engine hood lock, radiator hood, front bumper, and front

headlight.

4. Front wall lower plate assembly

The front wall lower plate connects to the floor, which separates the engine compartment from the cabin. It

includes front wall frame assembly, front wall lower main plate assembly, brake installation reinforced plate, and

front wall left/right support assembly etc.Fig. 5-2 Engine Compartment Assembly & Front Wall Parts

1. Front cross beam assembly 2. Left/right longitudinal beam assembly

3. Panel left/right support assembly 4. Front wall lower plate sub-assembly 5. Front wall upper assembly

6 Radiator cross beam assemblySurvey -Body Structure7-2123456front wall lower plate assembly, front wall upper assembly, left/right front damper support lower front plate

assembly, and right front damper right-angle support assembly.

Page 397 of 416

2. Shock Absorption & Noise Isolation

(1) Body structure (Fig. 5-37)

a. Arrange the reinforced bar reasonably to improve the parts' rigidity, reduce the shock and lower the noise.

b. Apply the sealant in the floor seam to improve the floor sealing and reduce the noise in the cabin.Fig. 5-37 Front Wall Panel

1. Front wall bridge reinforced panel

2. Front wall mid-frame panel

3. Front wall lower main panel

4. Heat-isolated pad

Fig. 5-38 (a) Body floor

1. Front mud guard 2. Rear side wall 3. Rear wheel housing 4.Floor sides (2) Deadening

It is an interactive and systemic work to make the body isolate heat, shock and noise. Besides the measures

carried out to improve the body's stiffness and sealing performance, the following measures shall be taken in the

design and manufacture process.

a. Sound isolation material: add sound isolation pad on the front wall and floor.

b. Sound absorption material: add molded carpet on the front floor and rear floor.

3. Sealing

Special consideration has been given to the sealing of the body both in design process and in manufactureprocess. Sealing plays an important role in many aspects, such as dust resistance, water resistance, corrosionresistance, heat resistance, heat preservation, and noise reduce etc. Especially when the body floor and front wall

stay in a tough external condition, the mud, dust, noises (from the tire and engine) and hot air will invade into the

cabin any time.

After the body assembly is welded, sealant will be employed on all joints to prevent the water and steam

penetrating into the metal seam and ensure the quality of subsequent painting.

In addition, a thick layer of impact-proof PVC coat is applied on the base of the body, which has excellentsealing performance. For the sealing to those assemblies, the traditional sealing method is used, such as rubber sealBody Repair -Features and Composition of Automobile Body7-251

123Front4

Page 406 of 416

4. Surface Treatment

Surface treatment shall be strict, careful and all-around. Though this car is not a deluxe sedan, it nearly has no

difference with the deluxe sedan in the surface treatment.

a. Phosphoric acid processing

Phosphoric acid processing is also called pretreatment before painting. After removing the grease on the body

by washing, apply zinc phosphate onto the body, with a thickness under 3

but also can help to increase adhesion in the next coating process.

b. Cathode electrophoresis

In the practical application, the electrophoresis painting shows many advantages, such as high efficiency, good

quality, safety and cost effectiveness. It is accompanied with four electrochemical phenomena including

electroanalysis, electrophoresis, electrodeposition and electroosmosis. The cathode electrophoresis is much better

than the anode electrophoresis both in the features and advantages. Incomparably, the process is strict extremely.

c. Intermediate coat

The intermediate coat is also called intermediate layer, which is located between the primer and the surface

paint. Its function is to improve the evenness of the painted work piece and the primer and provide the surface paint

with a good base to improve the paint's brightness and richness and improve the decoration of the entire coat.

d. Surface paint

The surface paint is the last coat in the multiple coats, which directly affect the vehicle's decoration,

weatherability and appearance etc. Great attention shall be made when selecting the surface paint, including its

adaptability, cost-effectiveness and usability. All performance indexes shall meet the national standard and

industrial standard. The paint shall be even and smooth.

e. Protective coat

For those vehicles parked outside for a long time (more than three months) or used for shipping, water-soluble

protective wax shall be applied on the outside surface of the body. This agent contains ultraviolet absorbent. Before

selling the vehicle, wash it with soap detergent and flush it with clean water, to make the paint brighter.7-34Fig. 5-38 (j) Painting Position of Impact-proof CoatPVC Impact-proof Coat Body Repair -Features and Composition of Automobile Body m. It not only can protect the work piece,

1U

Page 410 of 416

Appendix: Body Key Dimensions1. Engine CompartmentAppendix-Body Key Dimensions7-38

(mm)

Item Description

Diameter of Hole

XY Z

A,a

Front fender installetion hole(Front)

7(M6 nut) -336.18 +/-652.5 580.69

B,b

Front absorber spring support hole(Inside)

10 1.09 +/-519.51 641.4

C,c

Front fender installetion hole(Rear)

7(M6 nut) 62.3 +/-661.71 665.72

D Cowl panel drip charnel fixing hole 7(M6 nut) 66.13 -1.2 648.7

E,e Collision sensor installation hole 9(M8 nut) -445.74 +/-436.17 273.26

F Braking pipe instaltion hole 7(M6 nut) -49 -418.74 309.12

f

ABS actuator installatim hole(front)

9(M8 nut) -48.64 417.53 291

G,g

Radiator upper crossmermber installation hole(front)

7(M6 nut) -589.94 +/-397 452.84

H,h

Radiator side insulation gasket installation hole

10x8-621.82 +/-403.33 94.99

I Hood lock bracket installation hole 7(M6 nut) -662.61 0 36.34

J,j

FR bumper horizontal installation hole

9(M8 nut) -651.68 -487.41 275.57

K,k

Windscreen fastener installation hole

11.5x8.7-849.35 +/-357.86 111.07

L,l

Radiator uppor crossmenber installation hole

7(M6 nut) -553.26 +/-392.02 502.18

M,m Hood hinge hole(Rear) 9(M8 nut) 149.64 +/-668.27 678.44

N,n Front fender support hole 10 -368.55 +/-704.84 379.94

O,o

Joint between side outerpanel and roof panel

£ 202.21 +/-636.33 736.57

P,p

Joint between side outer panel and dash panel

- 851.59 +/-508.37 1092.37

A-D 771±2.5

4

a-D 771±2.5

B-c 1183±2.5

4

b-C 1183±2.5

B-D 522±2.5

4

b-D 552±2.5

C-M 89±2.5

c-m 89±2.5

D-E 771±2.5

4

D-e 777±2.5

D-L 746±2.5

4

D-l 746±2.5

N-O 1410±2.5

A-c 1376±2.5

4

a-C 1376±2.5

I-j 547±2.5

4

I-J 547±2.5

I-H 410±2.5

4

I-h 410±2.5

O-p 1360±2.5

4

o-P 1360±2.5

A-o 1408±2.5

4

a-O 1408±2.5

I-g 580±2.5

4

i-G 580±2.5

F-b 997±2.5

f-B 1088±2.5

L-c 1231±2.5

4

l-C 1231±2.5

Measuring

point

Value

ToleranceMeasuring

point

Value

ToleranceMeasuring

point

Value

Tolerance

Measuring

point

Value

Tolerance

Page 412 of 416

3. Body Opening Part (Back View)

A-d 1504±2.5

4

a-D 1504±2.5

C-d 1191±2.5

4

c-D 1191±2.5

f-G 1217±2.5

4

F-g 1217±2.5

e-B 1599±2.5

4

E-b 1599±2.5

h-I 1003±2.5

4

H-i 1003±2.5

(mm)

Item Description

Diameter of Hole

XYZ

A,a

Back window glass fastener installation hole

11.5¡Á8.52327.46 +/-374.49 1118.41

B,b

Rear absorber spring support hole

18 2506.99 +/-534.81 550.09

C,c Tall lamp installation hole 5 3190.8 +/-679.49 632.24

D,d Rear bumperinstallation bole 15 3202.45 +/-428.13 195.64

E,e B-pillar rear assembly mark - 1493.1 +/-672.96 812.59

F,f

Rear joint between side outer panel and roof panel

- 2310.74 +/-598.88 1106.12

G,g

Joint between side outer panel and luggage compartment

- 2816.19 +/-569.92 831.4

H,h

Joint between side outer panel and tail lmap panel

- 2987.01 +/-569.92 798.34

I,i

Rear joint between side outer panel and rear end panel

- 3327.63 +/-325.23 500.2Appendix-Body Key Dimensions7-40

Measuring

point

Value

Tolerance

Page 413 of 416

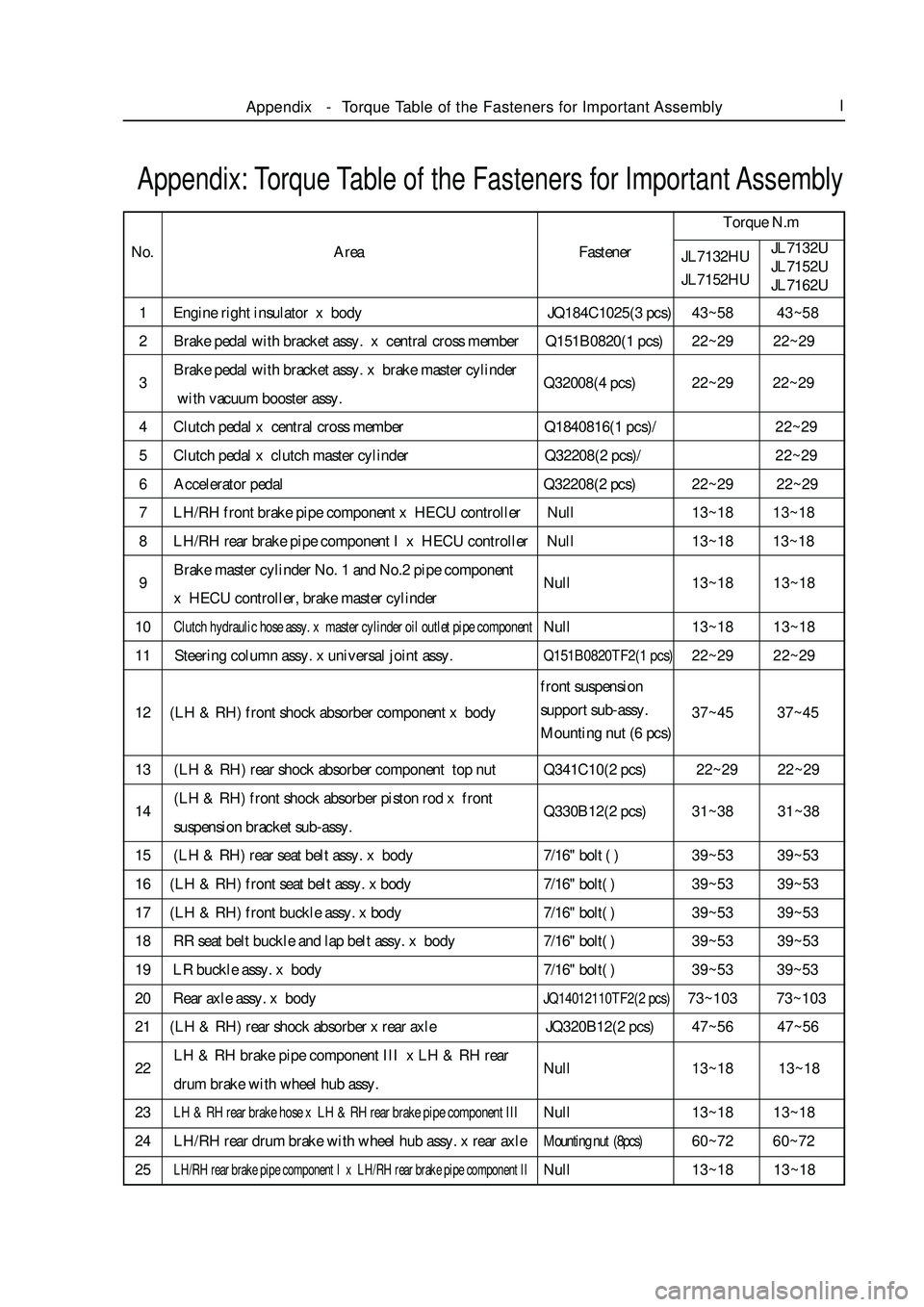

1 Engine right insulator x body JQ184C1025(3 pcs)43~58 43~58

2 Brake pedal with bracket assy. x central cross member Q151B0820(1 pcs)22~29 22~29

3Brake pedal with bracket assy. x brake master cylinder

Q32008(4 pcs)22~29 22~29

with vacuum booster assy.

4 Clutch pedal x central cross member Q1840816(1 pcs)/22~29

5 Clutch pedal x clutch master cylinder Q32208(2 pcs)/22~29

6 Accelerator pedal Q32208(2 pcs)22~29 22~29

7 LH/RH front brake pipe component x HECU controller Null13~18 13~18

8 LH/RH rear brake pipe component I x HECU controller Null13~18 13~18

9Brake master cylinder No. 1 and No.2 pipe component

Null13~18 13~18

x HECU controller, brake master cylinder

10Clutch hydraulic hose assy. x master cylinder oil outlet pipe componentNull13~18 13~18

11 Steering column assy. x universal joint assy.Q151B0820TF2(1 pcs)22~29 22~29

12 (LH & RH) front shock absorber component x body37~45 37~45

13 (LH & RH) rear shock absorber component top nut Q341C10(2 pcs) 22~29 22~29

14(LH & RH) front shock absorber piston rod x front

Q330B12(2 pcs)31~38 31~38

suspension bracket sub-assy.

15 (LH & RH) rear seat belt assy. x body7/16" bolt ( )39~53 39~53

16 (LH & RH) front seat belt assy. x body7/16" bolt( )39~53 39~53

17 (LH & RH) front buckle assy. x body7/16" bolt( )39~53 39~53

18 RR seat belt buckle and lap belt assy. x body7/16" bolt( )39~53 39~53

19 LR buckle assy. x body7/16" bolt( )39~53 39~53

20 Rear axle assy. x bodyJQ14012110TF2(2 pcs)73~103 73~103

21 (LH & RH) rear shock absorber x rear axle JQ320B12(2 pcs)47~56 47~56

22LH & RH brake pipe component III x LH & RH rear

Null13~18 13~18

drum brake with wheel hub assy.

23LH & RH rear brake hose x LH & RH rear brake pipe component IIINull13~18 13~18

24 LH/RH rear drum brake with wheel hub assy. x rear axleMounting nut (8pcs)60~72 60~72

25LH/RH rear brake pipe component I x LH/RH rear brake pipe component IINull13~18 13~18Appendix: Torque Table of the Fasteners for Important AssemblyTorque N.m

No.

JL7132HU

JL7152HUJL7132U

JL7152U

JL7162UAppendix-Torque Table of the Fasteners for Important AssemblyIArea Fastener

front suspension

support sub-assy.

Mounting nut (6 pcs)

Page 415 of 416

54 Rear insulator x front suspension cross member JQ319C10(2 pcs)43~65 43~65

55 Front stabilizer bar x front suspension cross member Q1400825(4 pcs)22~29 22~29

56Power steering gear with tie rod assy. x front suspension cross memberJQ184B1265(2 pcs)125~152 125~152

57High/low pressure oil pipe assy. x power steering gear with tie rod assy.Null25~32 25~32

58LH & RH lower suspension swing arm x front susJQ1401280TF2(2 pcs)125~152 125~152

pension cross member rear

59LH & RH lower suspension swing arm x front sus

JQ320B12(2pcs)125~152 125~152

pension cross member rear

60LH & RH lower suspension swing arm x front sJQ1401280TF2(2 pcs)83-103 83-103

uspension cross member front

61Front stabilizer bar x LH & RH lower suspension swing arm assy.JQ33808(2 pcs)22~29 22~29

62(LH & RH) front brake hose x (LH & RH) front disk13~18 13~18

brake with steering knuckle assy.

63 Engine rear insulator x rear bracket Q184C10105(1 pcs)61~74 61~74

64High pressure oil pipe assy. x power steering pump with bracket assy.Union bolt51~63 51~63

65(LH & RH) lower swing arm ball joint x (LH & RH) disk

JQ38312(2 pcs)83~103 83~103

brake with steering knuckle assy.

66LH & RH brake with steering knuckle assy. x power

Q383B10(2 pcs)30~40 30~40

steering gear assy. with tie rod assy.

67(LH & RH) front disk brake with steering knuckle assy.

JQ1841450TF2(4 pcs)125~152 125~152

x (LH & RH) front shock absorber

68(LH & RH) front disk brake with steering knuckle assy.

JQ320C14(4 pcs)125~152 125~152

x (LH & RH) front shock absorber

69 LH/RH constant velocity drive shaft assy. Set nut190~230 190~230

70(LH & RH) front brake hose x (LH & RH) front brake pipeNull13~18 13~18

71Front suspension reinforcement member x front

JQ1401020(4 pcs)43~58 43~58

suspension cross member, body

72 Oil tank component x bodyJQ146Db0835A(4 pcs)22~29 22~29

733-way catalytic converter assy. x engine exhaust manifoldJQ189C1058TF2E(4 pcs)40~60 40~60

74 Intermediate muffler x 3-way catalytic converter assy. JQ1461035(2 pcs)40~60 40~60

75 Intermediate muffler x 3-way catalytic converter assy. JQ32010(2 pcs)40~60 40~60

76 Primary muffler x intermediate muffler JQ1461035(2 pcs)40~60 40~60Appendix-

Torque Table of the Fasteners for Important AssemblyIIITorque N.m

No.

JL7132HU

JL7152HUJL7132U

JL7152U

JL7162U Area FastenerAppendix: Torque Table of the Fasteners for Important Assemblybrake hose union

bolt (2 pcs)