fuel filter GEELY MK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 32 of 416

2-11a. Keep air filter clean, Block of air filter affects engine air induction efficiency and increases fuel

consumption. So it must be cleaned and replaced in time.

b. Keep ignition system under good work condition. Bad connection or electricity leak of ignition coil and

power distributor or inappropriate gap or carbon residue of spark plug decreases ignition power supply

and efficiency, which leads to engine fuel consumption increase. So they need regular inspection and

repair to keep their good work condition.

c. Fuel feeding system works well. Often check if fuel feeder pipe leaks, and check if injectors and other

parts perform well on regular basis (electrical injection engines).

d. Keep regular tire pressure. If the tire pressure is not enough, vehicle rolling resistance increases and

engine fuel consumption increases accordingly. So tire pressure must be checked on time (around once

a week).Usage and Maintenance of MK Series - Usage of MK Series

Page 33 of 416

2-12Section 2 Maintenance Category and Content of MK SedanAs the vehicle is being used, its technical performance changes as the mileage accumulates and being affected by

various factors, which results in decrease of power, fuel economy, safety, and increase of emission pollutions,

noise and incidents. So timely maintenance during vehicle usage eliminates potential risks and prevents incidents

from happening, improves vehicle integrity and technical functionality, and prolongs useful life of the vehicle.

According to the vehicle technical requirements and usage history, maintenance of freedom Cruiser sedan can be

classified into several categories.I. first time maintenanceFirst time maintenance is also called breaking-in maintenance. It is performed when the vehicle mileage has

accumulated to 1500~2500km in breaking-in period. First time maintenance must be conducted at the appointed

service shops. It includes:

1. Check if there is any leak in engine, transmission, and differential. Fix if there is any.

2. Replace engine oil filter, engine oil and ATF for A/T.

3. Check the level of engine coolant, braking fluid, windshield washing fluid, power steering fluid and if there

is any leak. Refill if the level is too low and repair if there is any leak.

4. Check if there is any damage in triangle arm and ball joint, connection ball joint, triangle arm flexible hinge,

or the ball joint is loose. If there is, fix or replace it.

5. Check if the drive shaft dust cover is damaged. If there is, replace it.

6. Check if there is any leak in steering mechanism, or front and rear absorber and fix it there is any.

7. Check the tire pressure, front 230kpa, and rear 210kpa.II. Regular maintenanceAfter first time maintenance, the vehicle is in regular usage life. During regular use, the vehicle needs to be

maintained regularly according to the way it is used in.

1.Regular maintenance for vehicles used under extreme bad conditions. Any of the condition below is defined

as extreme bad condition:

(1) Frequent start.

(2) Often drive the vehicle in dusty circumstances.

(3) Drive the vehicle in hot areas (such as in summer in the south).

(4) Often drive in cold areas (often runs short trips, engine temperate cannot reach regular work temperature).

Vehicles ran under extreme bad conditions need to be maintained every 5000km.

2. Regular maintenance for vehicles Vehicles that have not been through extreme bad conditions need to be

maintained every 7500km.

Regular maintenance is required to be performed at Geely service shop, too.

List of parts that need to be replaced regularly is in table 1.

Maintenance timetable is in table2.III. Geely maintenance programGeely recommends following Geely maintenance program.

The intervals of maintenance schedules are determined by mileage meter or time periods. Maintain the vehicle

when either meets the schedule. For details, please refer to the schedule.Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

Page 35 of 416

2-14

V. Table 1 List of parts to be replaced regularlyThe intervals in the part list are for cars driven under normal condition. If the car is driven in special circumstances,

the replacement can be advanced from the schedule above.SystemParts need to be replaced regularly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22Brake master cylinder cup valve and dust coverBrake master cylinder cup

Brake hose

Brake caliper valve

Brake booster rubber

Brake booster vacuum hose

Brake fluid

MT Transmission oil

AT Transmission oil

Steering fluid

Air Cleaner

Air c leaner f ilter

Lubricant

Oil filter

Fuel filter

Coolant

All hoses

Canister

Timing beltWedge belt (including the power steering pump,

air conditioner compressor and generator belts)PCV system

Spark plugEvery 2 years (or as required)

Every 2 years (or as required)

Every 2 years (or as required)

Every 4 years (or as required)

Every 2 years (or as required)

Every 4 years (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

To be cleaned every 10,000km and changed

every 30,000km (or as required)

First 2500km or 2 months. Every 7500km or

6 months afterward (or as required)

First 2500km or 2 months. Every 7500km or

6 months afterward (or as required)

Every 5000km (or as required)

Every 40000km (or as required)

Every year (or as required)

Every 2 years (or as required)

Every 60000km (or as required)

Every 120000km (or as required)

Every 50000km (or as required)

Every 20000km or 12 months (or as required)

Every 20000km (or as required)Intervals

DrivelineSteering SystemBraking

SystemEngineA/C System

(API) SG or above(Table 1)Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

Page 39 of 416

2-18Section 3 Daily Maintenance of MK SedanDaily maintenance means operation of vehicle regular inspection, cleaning, fastening, and refilling according to

vehicle usage and condition on the basis of regular maintenance to make sure the vehicle is at good status. Daily

maintenance can be performed by driver or professional automotive mechanics in daily use of vehicle. But some

of the items must be conducted by professional mechanics at service shops.

1. Maintenance of air cleaner

Air cleaner filters the air that is coming into engine for the first time. Dust and other dirt filtered out gathers in the

induction tube. Air cleaner filters a lot of dust and dirty, so it must be cleaned in time.

2. Maintenance of air filter

Air filter does not only filter the dust and dirt in the air, but also keeps smooth ventilation. Its status has great effects

on the fuel economy and power of the engine, so it must be checked and maintained in time.

Before it is time to replace air filter, maintain it. Remove the filter, knock it with hand or stick to get rid of dust

on the filter and remove dirt inside the filter cover according to the cleanness of the road that the vehicle usually

runs on.

ATTENTION: do not clean the filter with wet cloth. Fasten the filter well when installing it back.

3. Maintenance of battery

Battery is used to start the vehicle and supply power to electrical facilities. Its status directly affects the regular

usage of the vehicle, especially for vehicles equipped with electrical controlled facilities. Keeping the battery in

good technical status and connections is especially important. It is necessary to often perform the following

inspections and maintenance in regular usage:

(1) Clean the outside of battery Inspect if the battery case or cover surface is dirty or has dirt, oil, or other dirty

things regularly. Clean it and keep the surface dry to avoid electrical leak caused by cover deformation.

(2) Check battery connections Bad connection between battery electrode and cable results in low engine start

speed which makes it difficult to start the vehicle or the vehicle cannot be started because of low output voltage

from battery. Loose connection at battery end leads to damage of electrical components and loss of trouble code

and other information stored in RAM of the computer system as a result of low voltage. Therefore, it is necessary

to check if the connection of cables on the battery electrode is good. When it is found loose, it must be fastened.

If there is any rust, the cables must be loosened, washed clean and be connected again.

4. Maintenance of tires and wheels

(1) Keeping tires and wheels under good condition is very important to vehicle fuel consumption and driving

safety. Therefore, inspect and maintain the tires regularly. Every 10000 km, the wheels should be adjusted. Follow

the sequence in picture 3:

Judge if there is any hidden problems in vehicle chassis mechanism by observing wear in different places, andfinding out the hidden problems does not only help you to understand

the technical status of the vehicle, but also benefits driving safety.

a. Serious wear on both edges of tire tread, means tires often

work with low tire pressure.

b. Wear of middle of the tire tread is mainly because the tires

are used with high tire pressure.This kind of wear shortens

the useful life of tires, and may result in sudden flat tire

when the vehicle runs on uneven road surface or meets any

obstacles.Usage and Maintenance of MK Series - Daily Maintenance of MK Sedan

Page 46 of 416

Table 3Section 2 Removal of the Engine Assembly from the Vehicle1. Avoid petrol overflowing (Disconnect from the fuel tank).

2. Remove the front wheel.Figure 1-5Engine AssemblyRemoval of the Engine Assembly from the Vehicle3-5CO

Normal

Low

HighHC

High

High

HighProblems

Bad idle speed

Bad idle speed

(HC reading fluctuates)

Bad idle speed

(Black smoke exhausts)Causes

1. Ignition fault:

Incorrect ignition timing;

Dirt, short circuit, or incorrect spark plug gap.

2. Incorrect valve gap.

3. Suction and exhaust valve leak.

4. Cylinder leaks.

1. Vacuum leaks.

PCV pipe . manifold;

Idle speed control valve;

Brake booster pipeline.

2. Spark lacks since the mixed gas is too thin.

1. Air filter is blocked.

2. PCV valve is blocked.

3. EFI system fails.

ECU fails.

Pressure regulator of fuel oil is out of order.

Water temperature sensor does not work.

Suction pressure/temperature sensor fails.

Injector fails.

The throttle position sensor fails.3. Discharge the coolant completely.

4. Remove the air filter assembly with hose (see Figure 1-5).

(1) Disconnect the joint of the temperature sensor and the wire

plug.

(2) Disconnect the vent duct from the hose of the air filter.

(3) Release the wire clip bolt on the air filter.

(4) Disconnect the hose of the air filter from the throttle body.

(5) Remove 3 bolts and the air filter assemblies.

5. Remove the battery.

6. Remove the fuel pipe sub-assembly.

7. Disconnect the water pipe; disconnect the water outlet pipe of the

heater from the air conditioner pipe.

8. Release the nut and remove the accelerator control cable. -

Page 49 of 416

Chapter 2 Engine MechanicalSection 1 Engine ComponentsComponent ViewFigure 2-1Engine MechanicalEngine Components3-8Upside of radiator support

Engine cover lock assembly

Starter assembly

Output pipe of oil cooler

Input pipe of oil coolerTransmission control cable assembly Fuel oil sub-assembly Accelerator control cable assemble

Water inlet pipe of heater

Water outlet pipe of heaterTransmission control cable assemblySuitable for 1.5L/1.6L(Tight coupling)Suitable for 1.3L/1.5L(Non-tight coupling) Radiator assemblyAir filter assembly with hose

Clutch release assembly

Water inlet pipe of radiator

Water outlet pipe of radiator

Battery -

Page 51 of 416

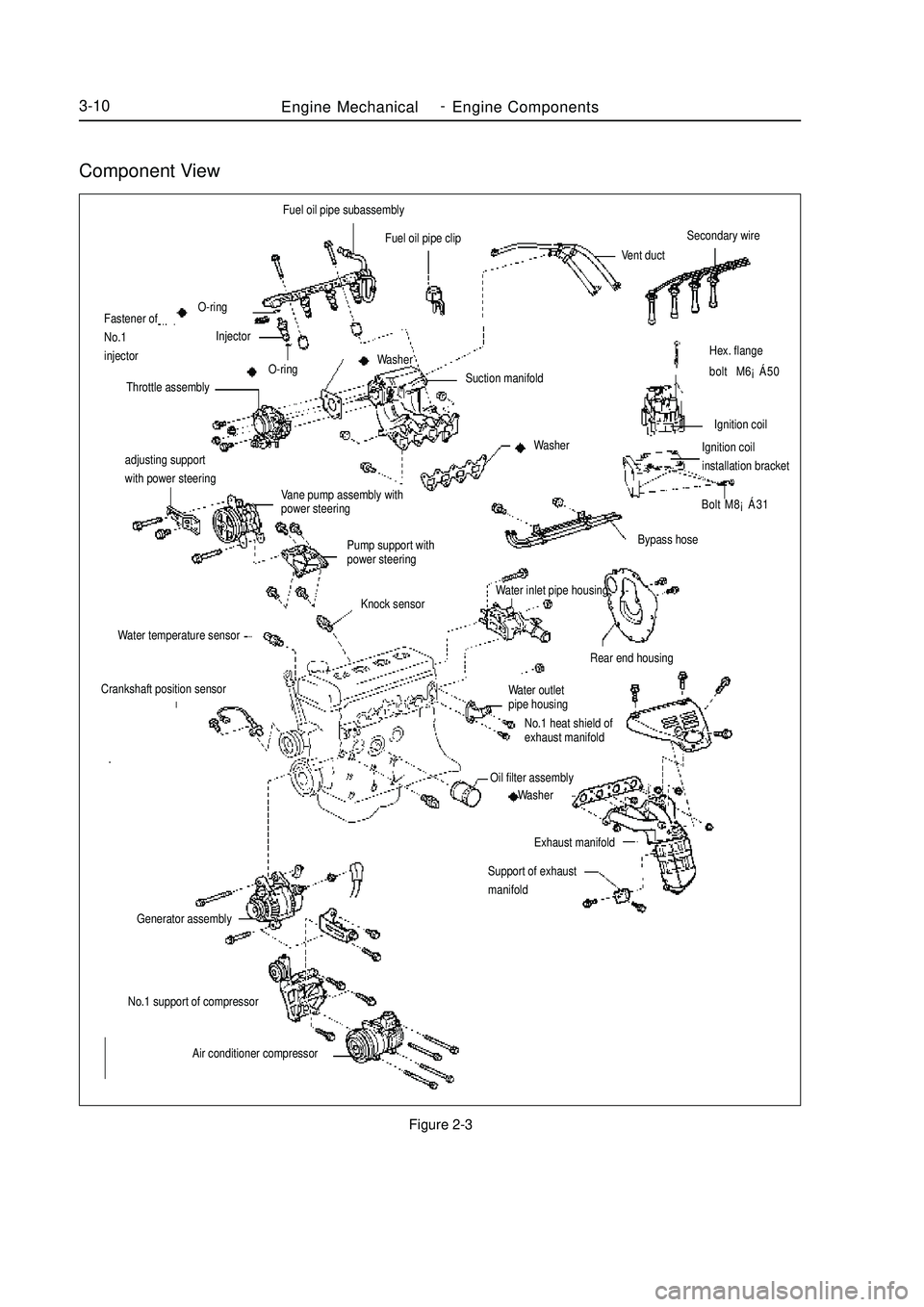

Component ViewFigure 2-3Engine MechanicalEngine Components3-10adjusting support

with power steering

Vane pump assembly with

power steering

Pump support with

power steeringHex. flange

bolt M6¡Á50

Ignition coil

Ignition coilinstallation bracket

Bolt M8¡Á31Fuel oil pipe subassembly

Fuel oil pipe clip

Vent ductSecondary wireBypass hose

Rear end housingWater outlet

pipe housing

No.1 heat shield of

exhaust manifoldOil filter assembly

Washer

Exhaust manifold

Support of exhaust

manifoldO-ring

Fastener of

No.1

injectorInjector

O-ring

Throttle assemblySuction manifold Washer

WasherKnock sensor

Water temperature sensorCrankshaft position sensorGenerator assemblyNo.1 support of compressor

Air conditioner compressorWater inlet pipe housing -

Page 56 of 416

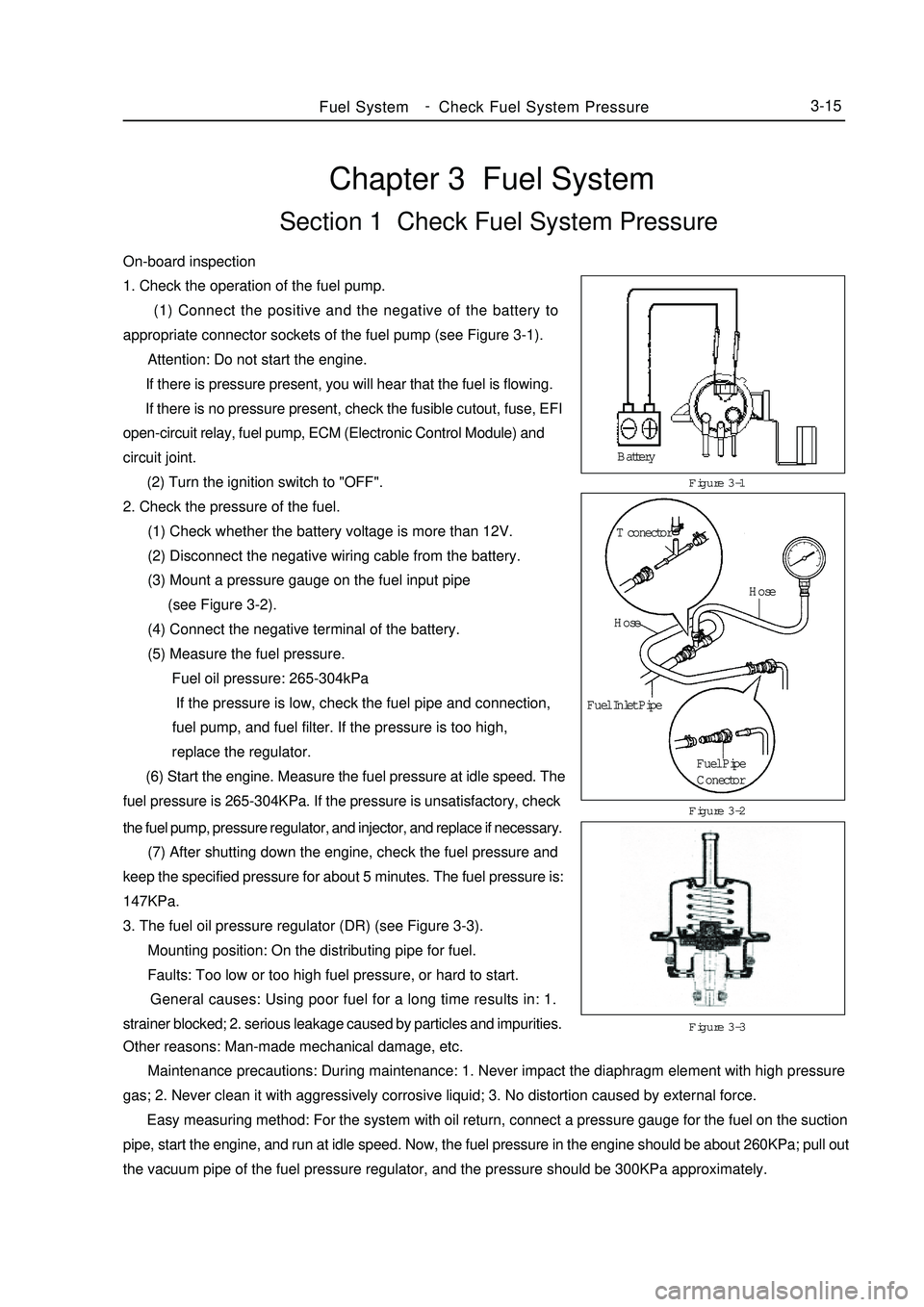

Chapter 3 Fuel SystemSection 1 Check Fuel System PressureOn-board inspection

1. Check the operation of the fuel pump.

(1) Connect the positive and the negative of the battery to

appropriate connector sockets of the fuel pump (see Figure 3-1).

Attention: Do not start the engine.

If there is pressure present, you will hear that the fuel is flowing.

If there is no pressure present, check the fusible cutout, fuse, EFI

open-circuit relay, fuel pump, ECM (Electronic Control Module) and

circuit joint.

(2) Turn the ignition switch to "OFF".

2. Check the pressure of the fuel.

(1) Check whether the battery voltage is more than 12V.

(2) Disconnect the negative wiring cable from the battery.

(3) Mount a pressure gauge on the fuel input pipe

(see Figure 3-2).

(4) Connect the negative terminal of the battery.

(5) Measure the fuel pressure.

Fuel oil pressure: 265-304kPa

If the pressure is low, check the fuel pipe and connection,

fuel pump, and fuel filter. If the pressure is too high,

replace the regulator.

(6) Start the engine. Measure the fuel pressure at idle speed. The

fuel pressure is 265-304KPa. If the pressure is unsatisfactory, checkFigure 3-1

Figure 3-3 Figure 3-2Fuel SystemCheck Fuel System Pressure3-15the fuel pump, pressure regulator, and injector, and replace if necessary.

(7) After shutting down the engine, check the fuel pressure and

keep the specified pressure for about 5 minutes. The fuel pressure is:

147KPa.

3. The fuel oil pressure regulator (DR) (see Figure 3-3).

Mounting position: On the distributing pipe for fuel.

Faults: Too low or too high fuel pressure, or hard to start.

General causes: Using poor fuel for a long time results in: 1.

strainer blocked; 2. serious leakage caused by particles and impurities.

Other reasons: Man-made mechanical damage, etc.

Maintenance precautions: During maintenance: 1. Never impact the diaphragm element with high pressure

gas; 2. Never clean it with aggressively corrosive liquid; 3. No distortion caused by external force.

Easy measuring method: For the system with oil return, connect a pressure gauge for the fuel on the suction

pipe, start the engine, and run at idle speed. Now, the fuel pressure in the engine should be about 260KPa; pull out

the vacuum pipe of the fuel pressure regulator, and the pressure should be 300KPa approximately.Battery

T conector

Hose

Hose

Fuel Inlet Pipe

Fuel Pipe

Conector -

Page 58 of 416

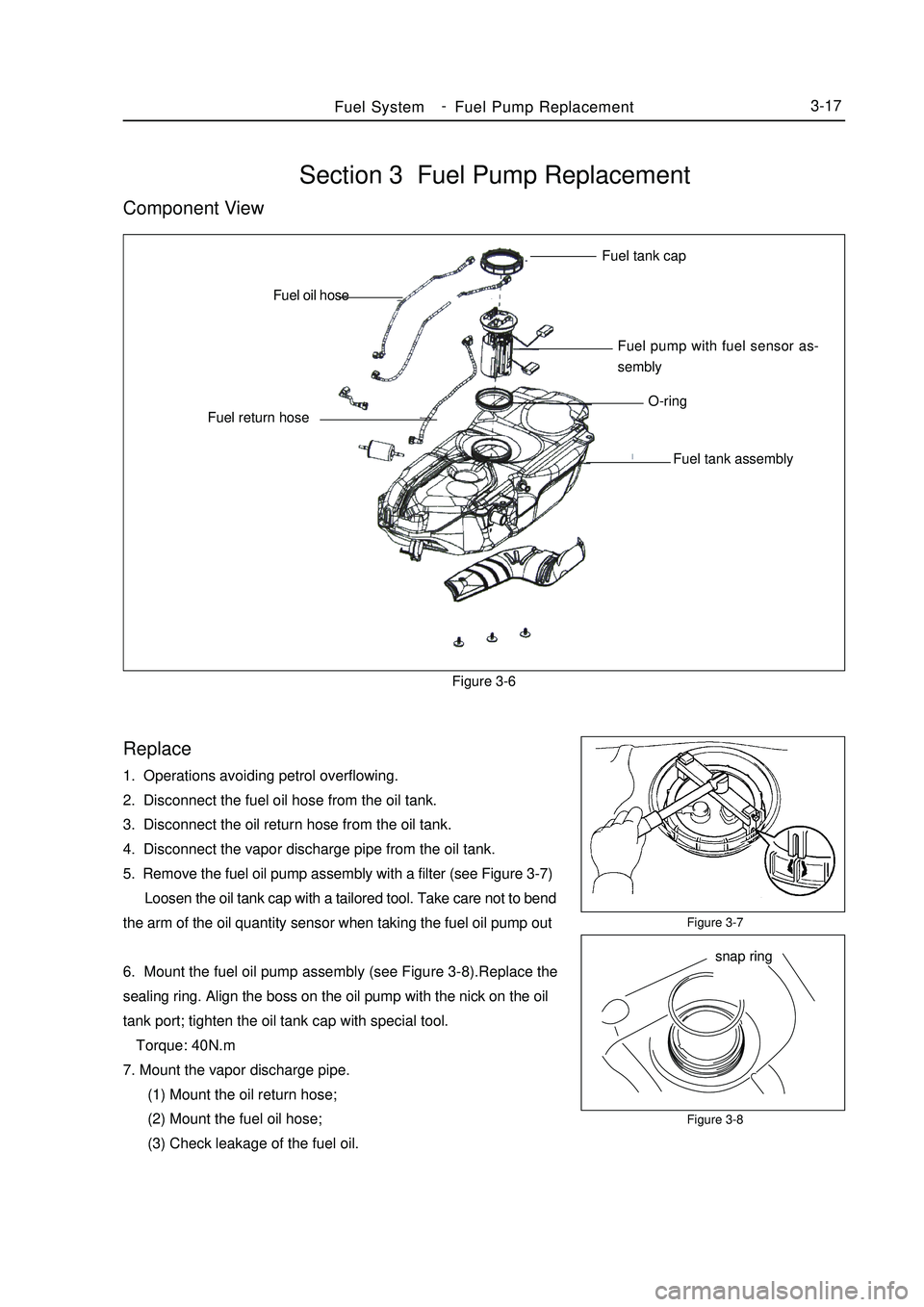

Section 3 Fuel Pump ReplacementComponent ViewFigure 3-6Replace1. Operations avoiding petrol overflowing.

2. Disconnect the fuel oil hose from the oil tank.

3. Disconnect the oil return hose from the oil tank.

4. Disconnect the vapor discharge pipe from the oil tank.

5. Remove the fuel oil pump assembly with a filter (see Figure 3-7)

Loosen the oil tank cap with a tailored tool. Take care not to bend

the arm of the oil quantity sensor when taking the fuel oil pump out

6. Mount the fuel oil pump assembly (see Figure 3-8).Replace the

sealing ring. Align the boss on the oil pump with the nick on the oil

tank port; tighten the oil tank cap with special tool.

Torque: 40N.m

7. Mount the vapor discharge pipe.

(1) Mount the oil return hose;

(2) Mount the fuel oil hose;

(3) Check leakage of the fuel oil.Figure 3-7

Figure 3-8Fuel SystemFuel Pump Replacement3-17Fuel tank cap

Fuel pump with fuel sensor as-

sembly

O-ring

Fuel tank assembly Fuel return hoseFuel oil hose

snap ring -

Page 312 of 416

Symptom

Poor idle speed, malfunction etc

Symptom

Fail to start5-125 Repair precautions:

1. according to engine requirement, electric fuel pumps with different flows are available, they have the same

appearance, mountable fuel pump may not be exactly suitable, during repair, part number of fuel pump used must

be consistent with original one, wrong replacement is not permitted;

2. in order to prevent fuel pump from damaging, please do not run it in dry state for a long time;

3. in case fuel pump needs to be replaced, please pay attention to clean fuel tank and pipeline and replace fuel

filter.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with fuel pump pins

respectively, measure internal resistance, it should not be zero or infinite (namely not in short circuit, open circuit

condition).

(Connect joint) connect fuel pressure gauge on sucker, start up engine, run the engine at idle speed, now fuel

pressure of engine should be about 260kPa; unplug fuel pressure regulator vacuum tube, now fuel pressure should

be about 300KPa.

11. Canister control valve

(1) Canister in fuel evaporation control system adsorbs oil vapor from oil tank until saturated. Electronic

control unit controls opening of canister control valve, fresh air and saturated fuel vapor in canister form

regeneration stream, which is led into engine intake pipe again. Electronic control unit changes duty ratio of pulsing

signal to canister control valve solenoid according to different operating conditions of engine, thus controls flow

of regeneration stream. In addition, this flow is also influenced by pressure difference at both ends.

Possible cause

Entering of foreign matter into valve inside results in

corrosion or poor leak tightness etc

Repair precautions:

1. To install, airflow direction must meet the specification;

2. when black granules inside valve body result in malfunction of control valve, and control valve needs to be

replaced, please check the condition of canister;

3. avoid water, oil etc liquids from entering valve as far as possible during repair;

4. in order to avoid transfer of solid-borne noise, it is recommended to install canister control valve suspending

on the hose or use soft rubber to fix.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with canister control valve pins

respectively, rated resistance at 20°C is 22 - 30 ohm.

12. Ignition coil

(1) When earthing channel of primary winding is connected, this primary winding is charged. Once ECU cut

off primary winding circuit, charging stops, high voltage is induced in secondary winding at the same time, so spark

plug discharges. Ignition coil ZSK 22 (both ends of 2 secondary windings are connected with a spark plug

respectively, so these two spark plugs ignite simultaneously.

Possible cause

Too heavy current leads to burnout, damaged by external force Repair precautions: it is prohibited to use "short circuit ignition testing method" to test ignition function, soEngine EFI System-

Engine EFI System