horn GEELY MK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 37 of 416

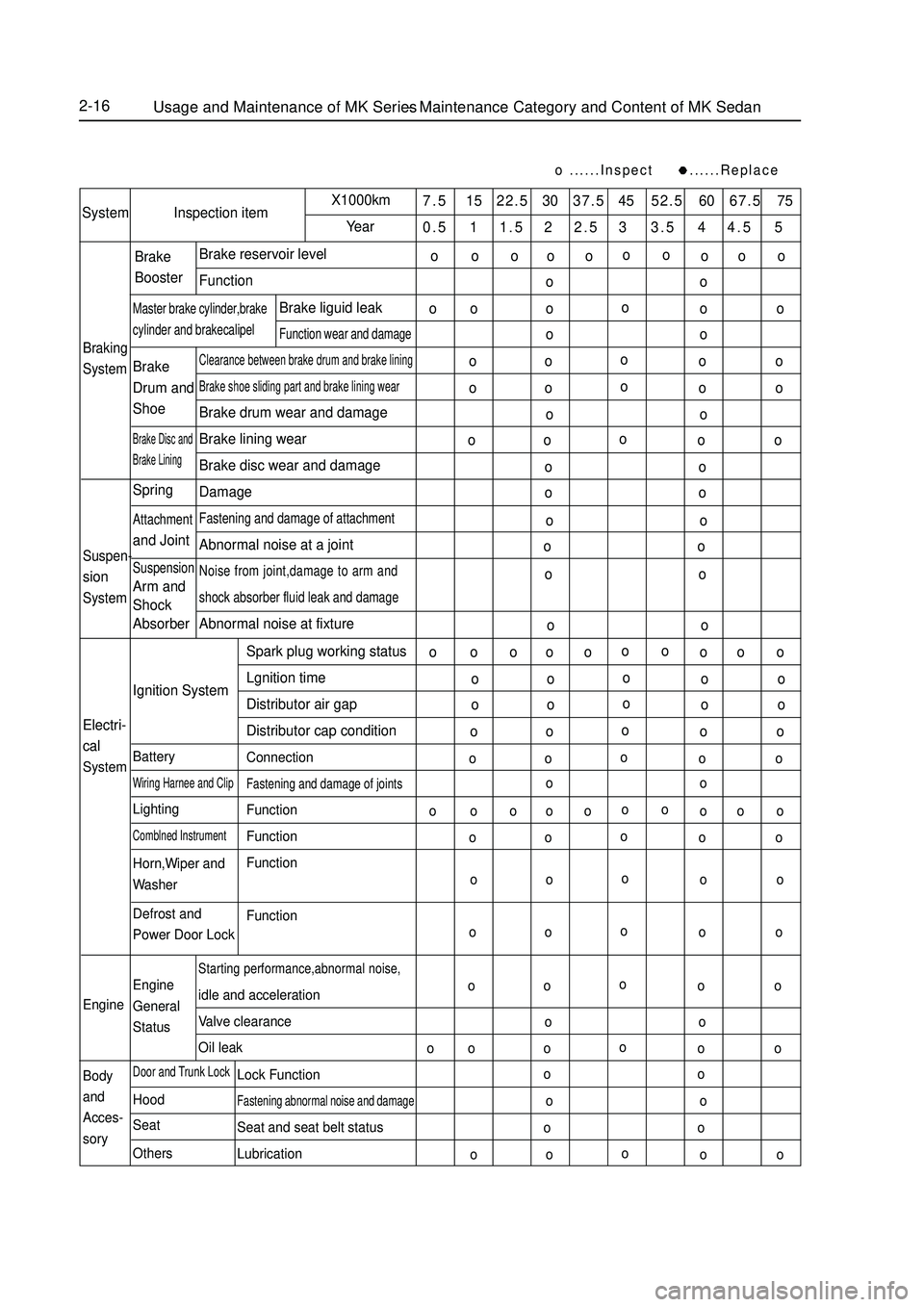

2-16......Inspect ......Replace7.5 15 22.5 30 37.5 45 52.5 60 67.5 75

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5System Inspection itemX1000km

YearBraking

SystemBrake reservoir level

FunctionClearance between brake drum and brake liningBrake shoe sliding part and brake lining wearBrake drum wear and damage

Brake lining wear

Brake disc wear and damage

DamageFastening and damage of attachmentAbnormal noise at a jointNoise from joint,damage to arm and

shock absorber fluid leak and damageAbnormal noise at fixtureBrake

BoosterMaster brake cylinder,brakecylinder and brakecalipelBrake liguid leakFunction wear and damageBrake

Drum and

ShoeBrake Disc and

Brake LiningSuspen-sionSystemSpringAttachmentand JointSuspensionArm and

Shock

Absorber

Electri-

cal

SystemEngine

Body

and

Acces-

soryIgnition System

BatteryWiring Harnee and ClipLightingComblned InstrumentHorn,Wiper and

Washer

Defrost and

Power Door Lock

Engine

General

StatusDoor and Trunk LockHood

Seat

OthersStarting performance,abnormal noise,idle and acceleration

Valve clearance

Oil leakSpark plug working status

Lgnition time

Distributor air gap

Distributor cap condition

ConnectionFastening and damage of jointsFunction

Function

Function

FunctionLock FunctionFastening abnormal noise and damageSeat and seat belt status

LubricationUsage and Maintenance of MK Series - Maintenance Category and Content of MK Sedano

oo

o o o

o

o o ooo o

o o

ooo o

o o

o o

oo o

o o

oo o

o o

oo oo o

o o

o o

o o

o o

o o

o o

oo o o

o o ooo o

o o

oo o

o o

oo o

o o

oo o

o o

oo o

o o

oo o o

o o ooo o

o o

oo o

o o

oo o

o o

oo o

o o

oo o

o o

o o

ooo o

o o

oo oo oo oo o

Page 250 of 416

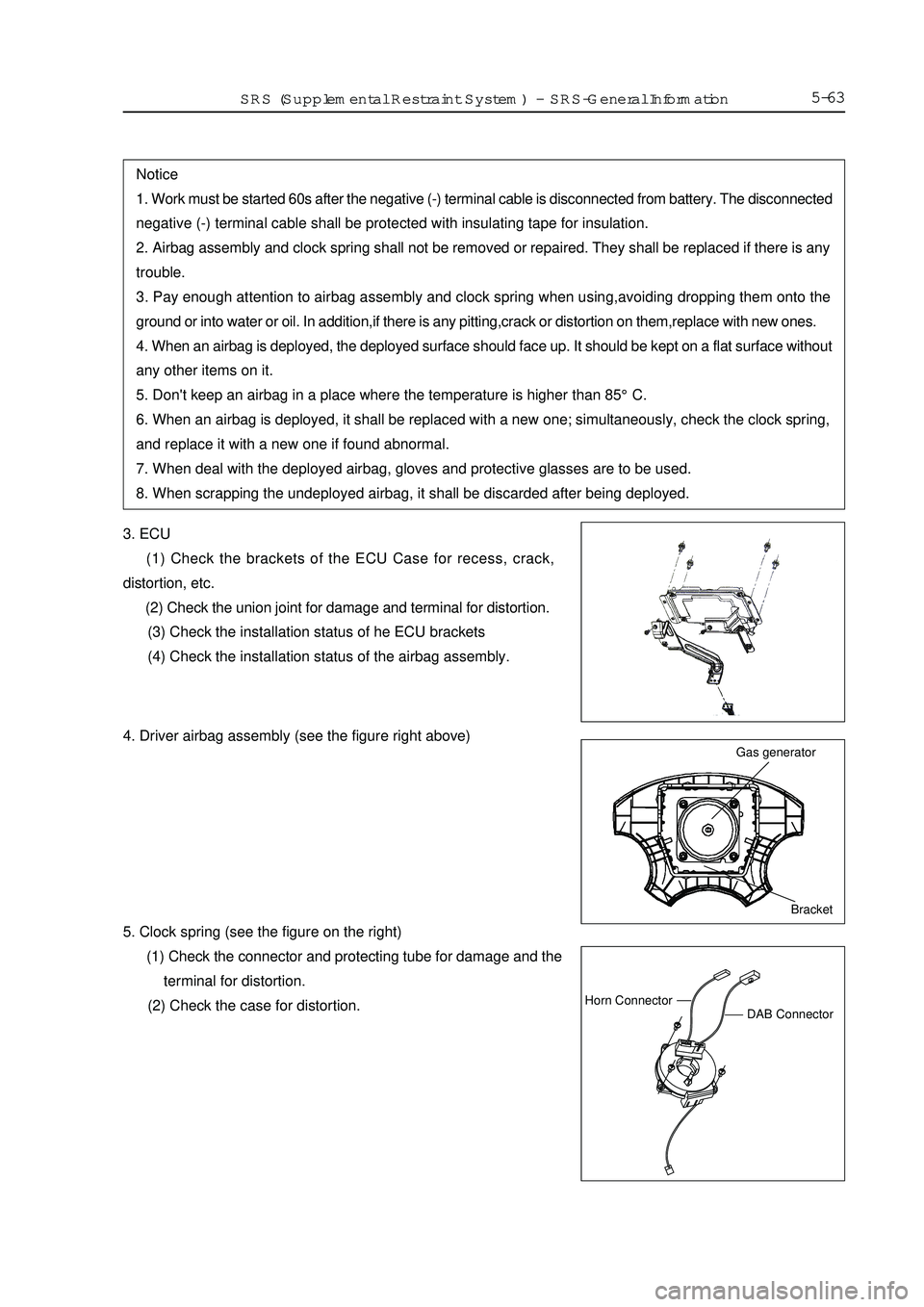

5-633. ECU

(1) Check the brackets of the ECU Case for recess, crack,

distortion, etc.

(2) Check the union joint for damage and terminal for distortion.

(3) Check the installation status of he ECU brackets

(4) Check the installation status of the airbag assembly.Notice

1. Work must be started 60s after the negative (-) terminal cable is disconnected from battery. The disconnected

negative (-) terminal cable shall be protected with insulating tape for insulation.

2. Airbag assembly and clock spring shall not be removed or repaired. They shall be replaced if there is any

trouble.

3. Pay enough attention to airbag assembly and clock spring when using,avoiding dropping them onto the

ground or into water or oil. In addition,if there is any pitting,crack or distortion on them,replace with new ones.

4. When an airbag is deployed, the deployed surface should face up. It should be kept on a flat surface without

any other items on it.

5. Don't keep an airbag in a place where the temperature is higher than 85°C.

6. When an airbag is deployed, it shall be replaced with a new one; simultaneously, check the clock spring,

and replace it with a new one if found abnormal.

7. When deal with the deployed airbag, gloves and protective glasses are to be used.

8. When scrapping the undeployed airbag, it shall be discarded after being deployed.Bracket Gas generatorDAB ConnectorHorn ConnectorSRS (Supplemental Restraint System)-SRS-General Information4. Driver airbag assembly (see the figure right above)

5. Clock spring (see the figure on the right)

(1) Check the connector and protecting tube for damage and the

terminal for distortion.

(2) Check the case for distortion.

Page 253 of 416

(2) Disconnect the connector of the wire harness.

(3) Remove the components of airbag assembly.

(4) Remove steering wheel.

Removal procedures of clock spring:

(1) Remove the driver airbag assembly (disconnect the connector).

(2) Remove steering wheel gently (see the precaution).

(3) Remove the steering column cover and disconnect the connector of wire harness in the lower end.

(4) Remove clock spring.

Installation procedures of the driver airbag assembly

(1) Pre-Check

1- Install steering wheel

2- Connect the wire harness

3- Install driver airbag assembly

4- Screw up the installation screws of the two sides

(2) Connection of the negative (-) terminal of the battery

(3) Check after installation.

Installation procedures of clock spring:

(1) Pre-Check

1- Connection and fixation of the clock spring and combination switch

2- the connector of wire harness in the lower end

3- the steering column cover

4-Thread the line at the upper end of the clock spring through hole on the body part of the steering wheel

5-Install the steering wheel

6-Connect wiring harness

7-Install the airbag assembly components

(2) Connect the negative (-) terminal cable of the battery

(3) Check after installation5-66Key points for installation

(1)Pre-Check

a. The new airbag or clock spring shall be checked before being installed.SRS (Supplemental Restraint System)-SRS-General InformationNotice

Use scanner to do adiagnossis of airbag circnit, not to break down.

Keep the removed driver airbag assembly upside down in a clean and dry place.Notice

Keep the removed clock sprint in a clean and dry place.fig.2Installation nutRemoval of steering wheel (see the figure 2)

(1) Remove the installation screws from the middle and remove

the steering wheel.(Disconnect the horn connector)

Page 256 of 416

5-69Notice

Work must be started 60s after the positive (+) and negative (-) terminal cables are detached from battery.

3) The airbag assembly shall be deployed according to the following procedures.

(1) Driver airbag assembly

a. Remove the knee bolster.

b. Remove the connector (yellow) that connecting the lower end of the clock spring with the wire harness

of the instrument panel (see the figure below).Notice

Remove the connector of the clock spring from the wire harness of the instrument, the connector will be

short circuited automatically, which can avoid the possible serious accident resulted from the deployment of

the diver airbag assembly due to static electricity.

c. Tie two 6m plus wire harnesses for deployment to the

adaptor wire harness of the airbag, and wrap the connecting points

with insulating tape for insulation.The other ends of the wire harness

for deployment are connected to each other (short circuited). Unex-

pected deployment resulted from static electricity shall be prevented.

d. From the yellow connector of the clock spring, lead the

airbag adapter wire harnesses out of the vehicle by means of the wire

harnesses for deployment (see the figure below).

e. To restrain the noise, close all the windows and doors and

put on the vehicle cover.Notice

The glass will likely break up if there is crack. Vehicle covers shall be put on.

f. Try to disconnect at a location far away from the vehicle the connector of the wire harness for deployment

of the driver airbag assembly, connect them with the two terminals of the battery removed from the

vehicle and deploy the airbag (see the figure below).Notice

Make sure there is no man inside or near the vehicle and then

carry out the operations.

After the driver airbag is deployed, the gas generator is of high

temperature. Keep it for 30 minutes until it gets cool for use.

If the driver airbag assembly cannot be deployed, discuss the

problem with the local Geely service station.Deployed

HarnessCovering the car g. The deployed driver airbag assembly shall be scrapped according to the scrapping procedures.

Deploy outside the vehicleNotice

Keep the airbag over 6m away from a obstacle or person and deploy the airbag in an open flat area.

Deployed the airbag outside the vehicle, avoid to do this job in the strong wind. In case of breeze, fire should

be against the wind.SRS (Supplemental Restraint System)-

SRS-General InformationDAB

Connector Horn

Connector

Page 320 of 416

Centralized Controller System-

Function Inspectior5-133Chapter 12 Centralized Controller SystemSection 1 Function InspectiorI. Glass frame riser: 1. Glass frame riser may be operated to move within 60s after ignition switch is turned on or off; 60s after

ignition switch is turned off, glass frame riser cannot be operated to move;

2. Manual rise: press corresponding glass frame riser switch rise key, corresponding glass frame riser motor

works, glass frame rises, release rise key, it stops.

3. Manual fall: press corresponding glass frame riser switch fall key (hold time 300ms), corresponding glass

frame riser motor works, glass frame falls, release fall key, it stops.

4. Automatic fall: press corresponding glass frame riser switch fall key (hold time < 300 ms), corresponding

glass frame riser motor works, glass frame falls down to end; or fall down until rise key or fall key is pressed again.

Note:

During automatic fall of glass frame, if corresponding glass frame riser switch fall key is pressed down for more

than 300 ms, glass frame riser is changed to manual fall mode; if corresponding glass frame riser switch rise key

is pressed down for more than 300ms, glass frame riser stops work.

5. Remote window closing:

In case of remote protection, if a key is pressed down for more than 1s, perform glass frame riser automatic

rise action, left front, right front, left rear, right rear in turn.II. Central lock: 1. In case protection is deactivated, use a key to open left front door switch or press internal unlock switch to

open four door fasteners; close left front door switch, close four door fasteners.

2. Remote unlock /lock:

(1) Ignition switch opening

a. Press remote control unlock key to open four door fasteners;

b. Press remote lock key to close four door fasteners;

(2) Turn off ignition switch

a. Press remote unlock key to open four front door fasteners, at the same time turn light flashes once.

b. Press remote lock key to close four door fasteners, at the same time turn light flashes twice.

(3) When door is opened, press remote fastener, turn light will flash for three times, at the same time electric

horn beeps for three times.

(4) If the system is triggered in anti-theft condition, when remote unlock system exits protection state,

directional turn signal will flash for four times, at the same time, electric horn beeps for four times.

3. Automatic lock

When vehicle speed exceeds 30km/h, three doors will be closed.

4. Door lock priority

Central door lock should not act simultaneously with glass frame riser; when they conflict with each other,

central door lock acts with priority, while glass frame riser stops; after central door lock action is finished, glass

frame riser continue its work in previous condition.III. Front womdscreem wiper: After spray water signal is finished, the wiper acts twice.

Page 321 of 416

IV. Post-defrost: 1. When engine speed exceeds 700rpm (ignition switch is turned on), defrost work is permitted.

2. Turn on defrost switch, perform defrost work for 12 minutes, if defrost switch is pressed down again during

defrost work, defrost work will stop.

3. During defrost, turn off ignition switch, cancel this defrost.V. Light control: 1. Headlight:

(1) After press remote lock key to close four doors, if remote lock key is pressed down again twice in

succession within in 2s, dipped headlight will extend lighting for 1 minute; if remote unlock key is

pressed down within 60s, dipped headlight control output will be turned off.

(2) During output of 60s low level, if ignition switch is turned on, low level output will stop.

2. Ceiling lamp:

(1) When any of the doors is opened, ceiling lamp illuminates; if door is not closed, ceiling lamp will be

turned off after 10 minutes of delay.

(2) For closing of all doors, ceiling lamp will go out after time delay of 30s;

(3) In case all doors are closed,and ceiling lamp illuminates,ignition switch is turned on,ceiling lamp goes

out.

(4) For remote unlock, ceiling lamp illuminates; in case all doors are closed and ceiling lamp illuminates,

remote lock ceiling lamp goes out.VI. Remote anti-theft 1. Protected state: press lock key on remote controller, while closing four doors, anti-theft indicator lamp will

flashes slowly, indicating that the system enters protected state, when the system is triggered, turn light of the

vehicle will flash, warning horn gives out alarm.

2. Cancel protection: press unlock key on remote controller, while opening left front door, anti-theft indicator

lamp flashes rapidly, if at least one of ignition switch, door is opened within 30 s, anti-theft indicator lamp will

go out; otherwise it will enter secondary anti-theft state.

3. Two stage type protection cancellation: while the system is in triggered state, press any key on the remote

controller, alarm sound will stop, however, the system is still in protected state, and car door is still locked; if the

system continues to receive invasion signal, alarm will ring again after brief stop. To cancel protection completely,

cancel alarm for the first time, then press unlock key once immediately;

4. Secondary anti-theft: after protection is cancelled, if any of ignition switch, door is not opened within 30s,

the system will restore alert status automatically, and lock the car door.

Distribution of centralized controller connector terminals:

Connector on wiring harness, as shown in the figure below (view from outgoing terminal):Centralized Controller System-

Function Inspectior5-134Centralized

controller

Page 323 of 416

Terminal No.

B1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25G

G

RY

Br

GB

GW

BLW

Br

RB

RB

YB

YB

RBL

RBL

GBL

R

RW

RW

BR

WR

BL

W

WB

BLB

R

BLB

WB

BLY

WY

RBHazard lamp power supply

Hazard lamp power supply

Dome lamp

Wiper motor (INT)

GND

GND

Right turn light and its indicator lamp

Left turn light and its indicator lamp

IG2

Wiper switch 3#Head light relay 85 #Head light relay 85 #Rear air window defrost and indicator lamp

Rear air window defrost and indicator lamp

Rear air window defrost power supply

Rear air window defrost power supply

GND

Horn relay 85 #Electric glass frame power supply

GND

GND

Fastener power supply

Right front, right rear, left rear fastener

Right front, right rear, left rear fastener

Left actuator

Front left glass regulator

Front left glass regulator

GND

Front right glass regulator

Front right glass regulator

Glass power supply

Rear left glass regulator

Rear left glass regulator

GND

Rear Right glass regulator

Rear Right glass regulator

Left actuatorConductor color Terminal definitionCReplacement ( 1 ) Remove dashboard subassembly (refer to trim)

( 2 ) Remove two bolts5-136Centralized Controller System-

Function Inspectior

Page 343 of 416

6-14 e. Pull the instrument panel sub-assembly backward and then take it out.

10. Remove the instrument panel lower housing assembly

Loosen 6 clasps and then pull the lower housing assembly out.

11. Remove the radio set assembly with bracket

a. Unfix 4 screws;

b. Disconnect the connector and then unfasten the radio set

assembly with bracket.

12. Remove the horn button assembly

13. Remove the steering wheel assembly

14. Remove the steering column upper cover assembly

15. Remove the steering column lower cover assembly

16. Remove the cupholder

17. Remove the auxiliary fasia console assembly

a. Unfix 3 screws;

b. Unfix 3 clips by use of a clip remover and then unfasten the

auxiliary fasia console assembly.6 clasps

2 clamps

2 clipsInterior & Exterior Trim and Accessory -Dashboard, Middle Console and Instrument Panel