brake GMC ACADIA 2007 Repair Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2007, Model line: ACADIA, Model: GMC ACADIA 2007Pages: 554, PDF Size: 2.76 MB

Page 467 of 554

{CAUTION:

Incorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to come loose and even come off.

This could lead to an accident. Be sure to

use the correct wheel nuts. If you have

to replace them, be sure to get new

GM original equipment wheel nuts.

Stop somewhere as soon as you can and

have the nuts tightened with a torque

wrench to the proper torque speci�cation.

SeeCapacities and Specifications on

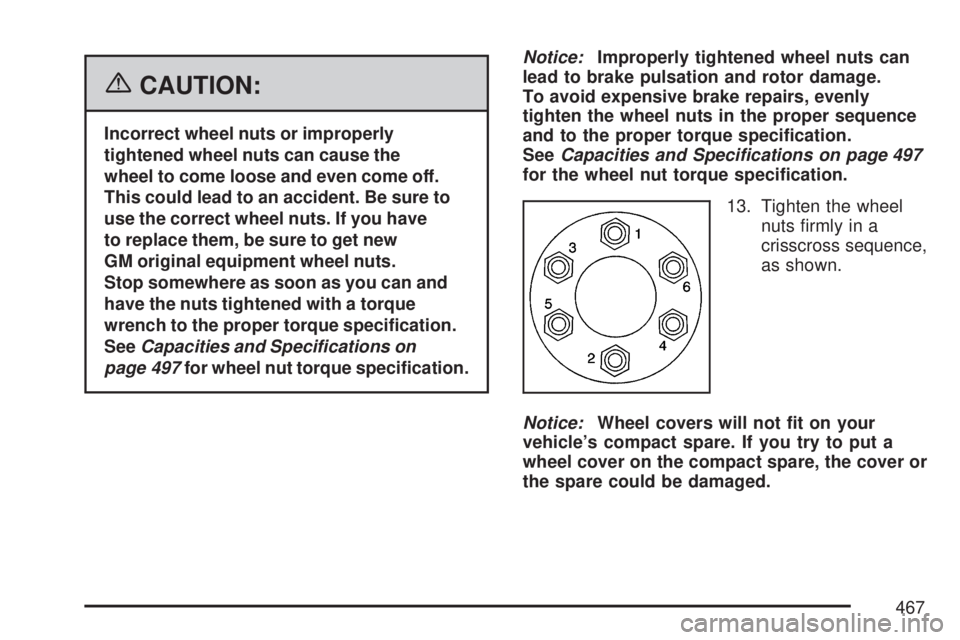

page 497for wheel nut torque speci�cation.Notice:Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage.

To avoid expensive brake repairs, evenly

tighten the wheel nuts in the proper sequence

and to the proper torque speci�cation.

SeeCapacities and Specifications on page 497

for the wheel nut torque speci�cation.

13. Tighten the wheel

nuts �rmly in a

crisscross sequence,

as shown.

Notice:Wheel covers will not �t on your

vehicle’s compact spare. If you try to put a

wheel cover on the compact spare, the cover or

the spare could be damaged.

467

Page 495 of 554

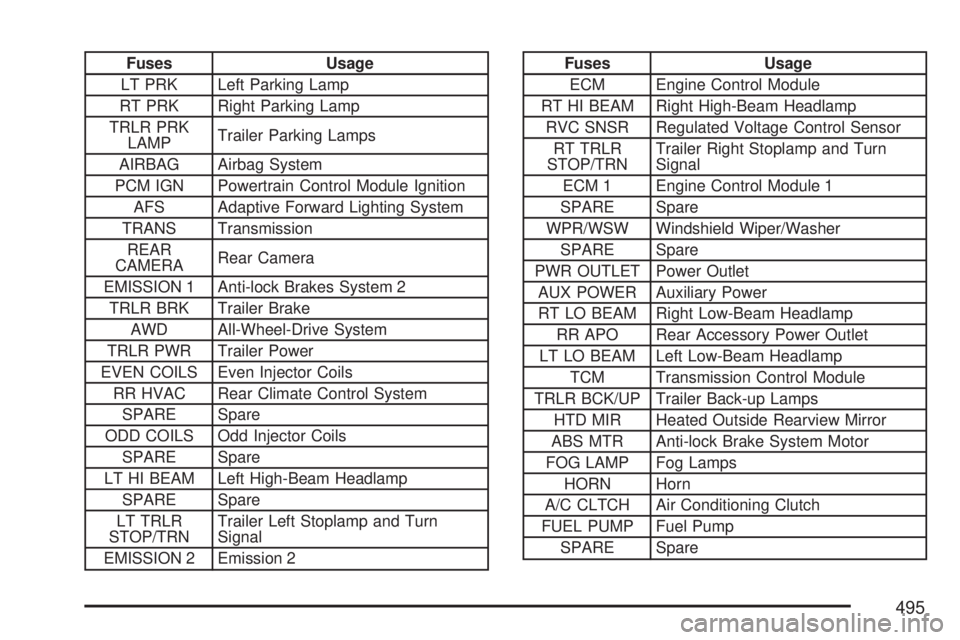

Fuses Usage

LT PRK Left Parking Lamp

RT PRK Right Parking Lamp

TRLR PRK

LAMPTrailer Parking Lamps

AIRBAG Airbag System

PCM IGN Powertrain Control Module Ignition

AFS Adaptive Forward Lighting System

TRANS Transmission

REAR

CAMERARear Camera

EMISSION 1 Anti-lock Brakes System 2

TRLR BRK Trailer Brake

AWD All-Wheel-Drive System

TRLR PWR Trailer Power

EVEN COILS Even Injector Coils

RR HVAC Rear Climate Control System

SPARE Spare

ODD COILS Odd Injector Coils

SPARE Spare

LT HI BEAM Left High-Beam Headlamp

SPARE Spare

LT TRLR

STOP/TRNTrailer Left Stoplamp and Turn

Signal

EMISSION 2 Emission 2Fuses Usage

ECM Engine Control Module

RT HI BEAM Right High-Beam Headlamp

RVC SNSR Regulated Voltage Control Sensor

RT TRLR

STOP/TRNTrailer Right Stoplamp and Turn

Signal

ECM 1 Engine Control Module 1

SPARE Spare

WPR/WSW Windshield Wiper/Washer

SPARE Spare

PWR OUTLET Power Outlet

AUX POWER Auxiliary Power

RT LO BEAM Right Low-Beam Headlamp

RR APO Rear Accessory Power Outlet

LT LO BEAM Left Low-Beam Headlamp

TCM Transmission Control Module

TRLR BCK/UP Trailer Back-up Lamps

HTD MIR Heated Outside Rearview Mirror

ABS MTR Anti-lock Brake System Motor

FOG LAMP Fog Lamps

HORN Horn

A/C CLTCH Air Conditioning Clutch

FUEL PUMP Fuel Pump

SPARE Spare

495

Page 496 of 554

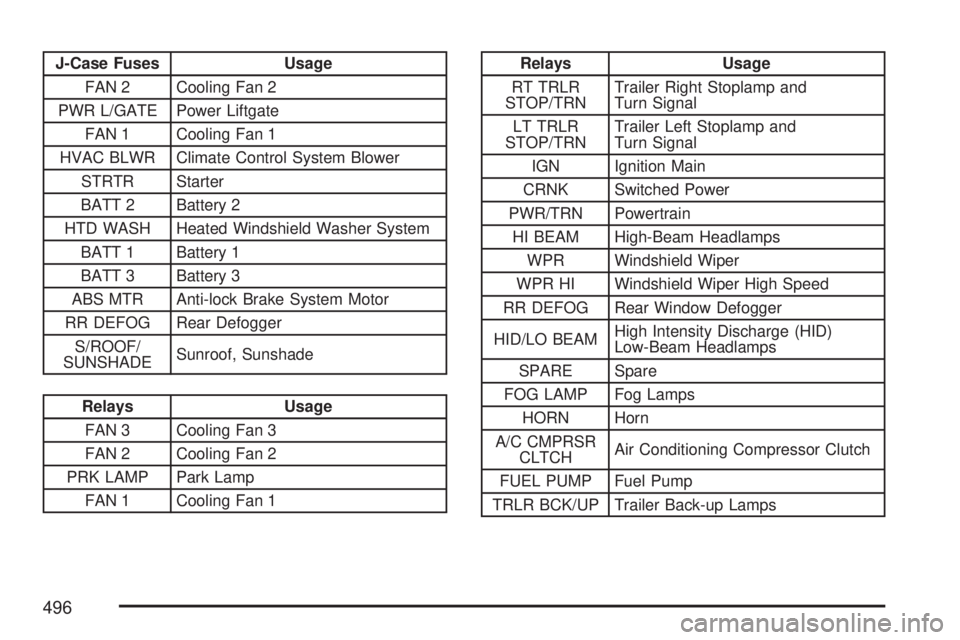

J-Case Fuses Usage

FAN 2 Cooling Fan 2

PWR L/GATE Power Liftgate

FAN 1 Cooling Fan 1

HVAC BLWR Climate Control System Blower

STRTR Starter

BATT 2 Battery 2

HTD WASH Heated Windshield Washer System

BATT 1 Battery 1

BATT 3 Battery 3

ABS MTR Anti-lock Brake System Motor

RR DEFOG Rear Defogger

S/ROOF/

SUNSHADESunroof, Sunshade

Relays Usage

FAN 3 Cooling Fan 3

FAN 2 Cooling Fan 2

PRK LAMP Park Lamp

FAN 1 Cooling Fan 1

Relays Usage

RT TRLR

STOP/TRNTrailer Right Stoplamp and

Turn Signal

LT TRLR

STOP/TRNTrailer Left Stoplamp and

Turn Signal

IGN Ignition Main

CRNK Switched Power

PWR/TRN Powertrain

HI BEAM High-Beam Headlamps

WPR Windshield Wiper

WPR HI Windshield Wiper High Speed

RR DEFOG Rear Window Defogger

HID/LO BEAMHigh Intensity Discharge (HID)

Low-Beam Headlamps

SPARE Spare

FOG LAMP Fog Lamps

HORN Horn

A/C CMPRSR

CLTCHAir Conditioning Compressor Clutch

FUEL PUMP Fuel Pump

TRLR BCK/UP Trailer Back-up Lamps

496

Page 503 of 554

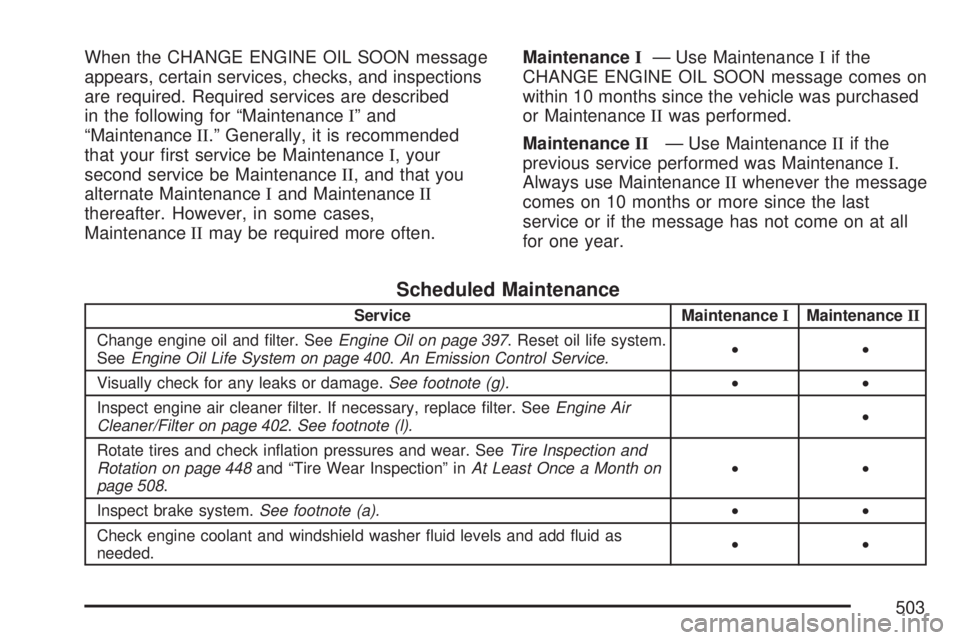

When the CHANGE ENGINE OIL SOON message

appears, certain services, checks, and inspections

are required. Required services are described

in the following for “MaintenanceI” and

“MaintenanceII.” Generally, it is recommended

that your �rst service be MaintenanceI, your

second service be MaintenanceII, and that you

alternate MaintenanceIand MaintenanceII

thereafter. However, in some cases,

MaintenanceIImay be required more often.MaintenanceI— Use MaintenanceIif the

CHANGE ENGINE OIL SOON message comes on

within 10 months since the vehicle was purchased

or MaintenanceIIwas performed.

MaintenanceII— Use MaintenanceIIif the

previous service performed was MaintenanceI.

Always use MaintenanceIIwhenever the message

comes on 10 months or more since the last

service or if the message has not come on at all

for one year.

Scheduled Maintenance

Service MaintenanceIMaintenanceII

Change engine oil and �lter. SeeEngine Oil on page 397. Reset oil life system.

SeeEngine Oil Life System on page 400.An Emission Control Service.••

Visually check for any leaks or damage.See footnote (g).••

Inspect engine air cleaner �lter. If necessary, replace �lter. SeeEngine Air

Cleaner/Filter on page 402.See footnote (l).•

Rotate tires and check in�ation pressures and wear. SeeTire Inspection and

Rotation on page 448and “Tire Wear Inspection” inAt Least Once a Month on

page 508.••

Inspect brake system.See footnote (a).••

Check engine coolant and windshield washer �uid levels and add �uid as

needed.••

503

Page 506 of 554

Maintenance Footnotes

(a)Visually inspect brake lines and hoses for

proper hook-up, binding, leaks, cracks, chafing,

etc. Inspect disc brake pads for wear and rotors for

surface condition. Inspect other brake parts,

including calipers, parking brake, etc. Check

parking brake adjustment.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose, or missing

parts or signs of wear. Inspect power steering lines

and hoses for proper hook-up, binding, leaks,

cracks, chafing, etc.

(c)Visually inspect hoses and have them replaced

if they are cracked, swollen, or deteriorated.

Inspect all pipes, fittings and clamps; replace with

genuine parts as needed. To help ensure

proper operation, a pressure test of the cooling

system and pressure cap and cleaning the outside

of the radiator and air conditioning condenser is

recommended at least once a year.(d)Inspect wiper blades for wear, cracking, or

contamination. Clean the windshield and

wiper blades, if contaminated. Replace wiper

blades that are worn or damaged. See Windshield

Wiper Blade Replacement on page 434and

Windshield, Backglass, and Wiper Blades on

page 484for more information.

(e)Make sure the safety belt reminder light and all

belts, buckles, latch plates, retractors, and

anchorages are working properly. Look for any

other loose or damaged safety belt system parts.

If you see anything that might keep a safety

belt system from doing its job, have it repaired.

Have any torn or frayed safety belts replaced. Also

look for any opened or broken airbag coverings,

and have them repaired or replaced. The airbag

system does not need regular maintenance.

(f)Lubricate all key lock cylinders, hood latch

assemblies, secondary latches, pivots, spring

anchor and release pawl, hood and door hinges,

rear folding seats, and liftgate hinges. More

frequent lubrication may be required when

exposed to a corrosive environment. Applying

silicone grease on weatherstrips with a clean cloth

will make them last longer, seal better, and not

stick or squeak.

506

Page 509 of 554

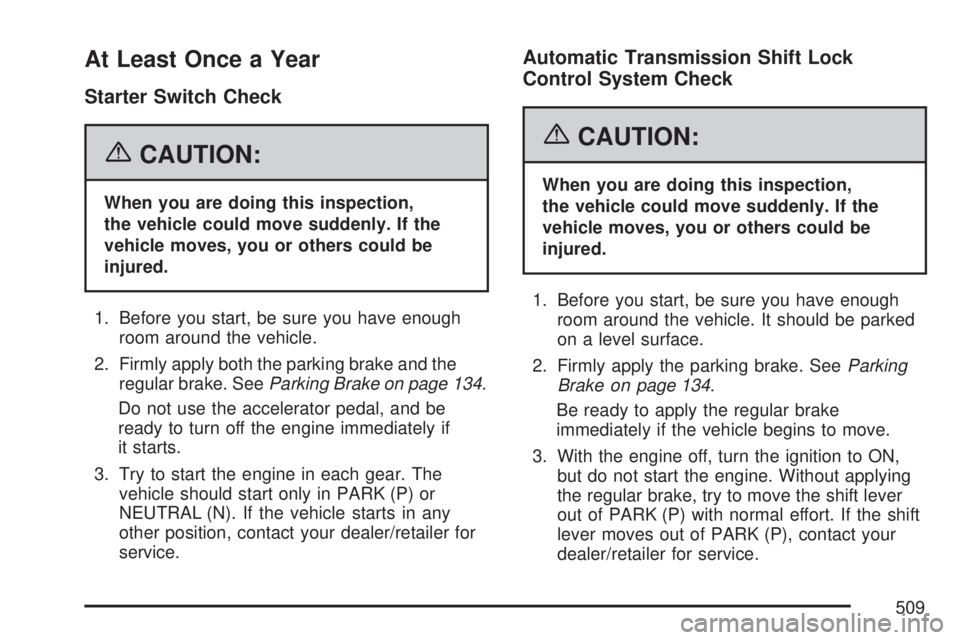

At Least Once a Year

Starter Switch Check

{CAUTION:

When you are doing this inspection,

the vehicle could move suddenly. If the

vehicle moves, you or others could be

injured.

1. Before you start, be sure you have enough

room around the vehicle.

2. Firmly apply both the parking brake and the

regular brake. SeeParking Brake on page 134.

Do not use the accelerator pedal, and be

ready to turn off the engine immediately if

it starts.

3. Try to start the engine in each gear. The

vehicle should start only in PARK (P) or

NEUTRAL (N). If the vehicle starts in any

other position, contact your dealer/retailer for

service.

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this inspection,

the vehicle could move suddenly. If the

vehicle moves, you or others could be

injured.

1. Before you start, be sure you have enough

room around the vehicle. It should be parked

on a level surface.

2. Firmly apply the parking brake. SeeParking

Brake on page 134.

Be ready to apply the regular brake

immediately if the vehicle begins to move.

3. With the engine off, turn the ignition to ON,

but do not start the engine. Without applying

the regular brake, try to move the shift lever

out of PARK (P) with normal effort. If the shift

lever moves out of PARK (P), contact your

dealer/retailer for service.

509

Page 510 of 554

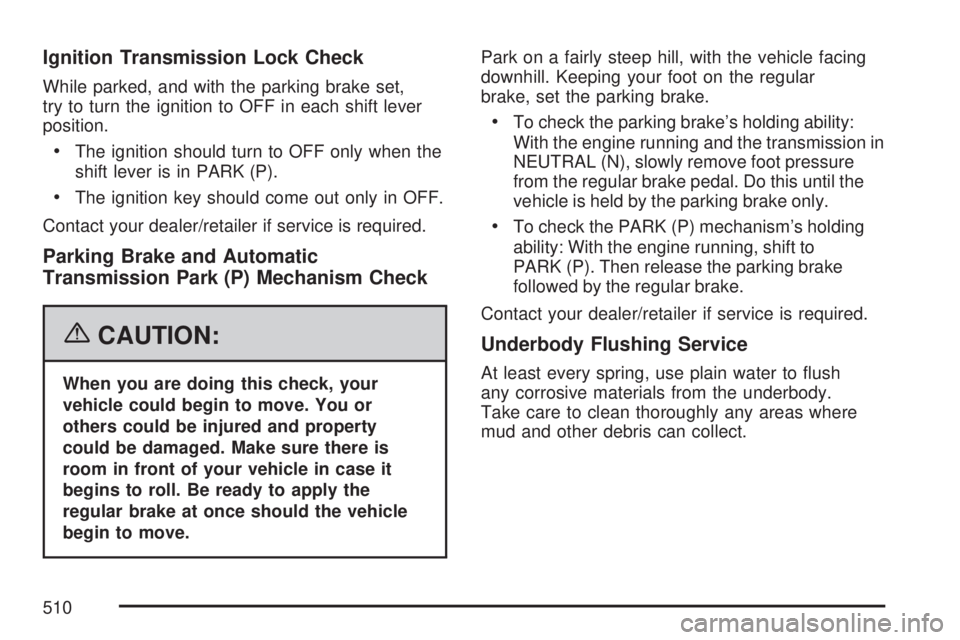

Ignition Transmission Lock Check

While parked, and with the parking brake set,

try to turn the ignition to OFF in each shift lever

position.

The ignition should turn to OFF only when the

shift lever is in PARK (P).

The ignition key should come out only in OFF.

Contact your dealer/retailer if service is required.

Parking Brake and Automatic

Transmission Park (P) Mechanism Check

{CAUTION:

When you are doing this check, your

vehicle could begin to move. You or

others could be injured and property

could be damaged. Make sure there is

room in front of your vehicle in case it

begins to roll. Be ready to apply the

regular brake at once should the vehicle

begin to move.Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular

brake, set the parking brake.

To check the parking brake’s holding ability:

With the engine running and the transmission in

NEUTRAL (N), slowly remove foot pressure

from the regular brake pedal. Do this until the

vehicle is held by the parking brake only.

To check the PARK (P) mechanism’s holding

ability: With the engine running, shift to

PARK (P). Then release the parking brake

followed by the regular brake.

Contact your dealer/retailer if service is required.

Underbody Flushing Service

At least every spring, use plain water to �ush

any corrosive materials from the underbody.

Take care to clean thoroughly any areas where

mud and other debris can collect.

510

Page 511 of 554

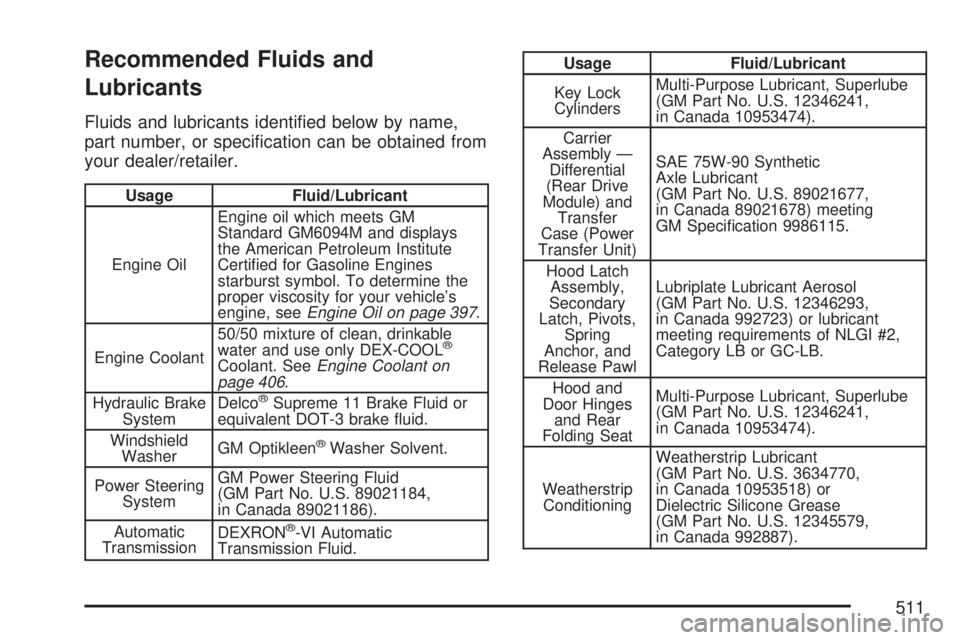

Recommended Fluids and

Lubricants

Fluids and lubricants identi�ed below by name,

part number, or speci�cation can be obtained from

your dealer/retailer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets GM

Standard GM6094M and displays

the American Petroleum Institute

Certi�ed for Gasoline Engines

starburst symbol. To determine the

proper viscosity for your vehicle’s

engine, seeEngine Oil on page 397.

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

Coolant. SeeEngine Coolant on

page 406.

Hydraulic Brake

SystemDelco

®Supreme 11 Brake Fluid or

equivalent DOT-3 brake �uid.

Windshield

WasherGM Optikleen

®Washer Solvent.

Power Steering

SystemGM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

TransmissionDEXRON

®-VI Automatic

Transmission Fluid.

Usage Fluid/Lubricant

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Carrier

Assembly —

Differential

(Rear Drive

Module) and

Transfer

Case (Power

Transfer Unit)SAE 75W-90 Synthetic

Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Speci�cation 9986115.

Hood Latch

Assembly,

Secondary

Latch, Pivots,

Spring

Anchor, and

Release PawlLubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood and

Door Hinges

and Rear

Folding SeatMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Weatherstrip

ConditioningWeatherstrip Lubricant

(GM Part No. U.S. 3634770,

in Canada 10953518) or

Dielectric Silicone Grease

(GM Part No. U.S. 12345579,

in Canada 992887).

511

Page 535 of 554

Service Publications Ordering

Information

Service Manuals

Service Manuals have the diagnosis and repair

information on engines, transmission, axle

suspension, brakes, electrical, steering, body, etc.

Transmission, Transaxle, Transfer

Case Unit Repair Manual

This manual provides information on unit repair

service procedures, adjustments, and

speci�cations for GM transmissions, transaxles,

and transfer cases.

Service Bulletins

Service Bulletins give technical service information

needed to knowledgeably service General

Motors cars and trucks. Each bulletin contains

instructions to assist in the diagnosis and service

of your vehicle.In Canada, the service bulletin reference number

can be obtained by contacting your General

Motors dealer or by calling 1-800-GM-DRIVE

(1-800-463-7483). This reference number is

needed to order the service bulletin from

Helm, Inc.

RETAIL SELL PRICE: $6.00 US + Processing Fee

Owner Information

Owner publications are written speci�cally for

owners and intended to provide basic operational

information about the vehicle. The owner

manual includes the Maintenance Schedule for

all models.

In-Portfolio: Includes a Portfolio, Owner Manual,

and Warranty Booklet.

RETAIL SELL PRICE: $35.00 US

+ Processing Fee

Without Portfolio: Owner Manual only.

RETAIL SELL PRICE: $25.00 US

+ Processing Fee

535

Page 537 of 554

Event Data Recorders

Some information about your vehicle’s

performance and how it is driven may be recorded

on various modules if a crash occurs. Some

people refer to these modules asevent data

recorders (EDRs). These modules may record

several seconds of pre-crash and crash data, such

as data related toengine speed, brake

application, throttle position, vehicle speed,

yaw rate, steering wheel angle, lateral

acceleration, safety belt usage, airbag

readiness, airbag performanceandthe severity

of the collision.Unlike the �ight data recorders

on airplanes, these modules do not record sounds

or conversations.To retrieve this data, special equipment and

access to the vehicle or the module that stores

the data are required. Certain data may also

be sent to or retrieved by OnStar®(see below).

GM will not access this information or share it with

others except: with the consent of the vehicle

owner or, if the vehicle is leased, with the consent

of the lessee; in response to an official request

of police or similar government office; as part

of GM’s defense of litigation through the discovery

process; or, as required by law. Data that GM

collects or receives may also be used for

GM research needs or may be made available to

others for research purposes, where a need is

shown and the data is not tied to a speci�c vehicle

or vehicle owner.

Others may be able to retrieve this data if they

have access to the vehicle and have the special

equipment necessary to download the data.

537