GMC CANYON 2010 Owner's Manual

Manufacturer: GMC, Model Year: 2010, Model line: CANYON, Model: GMC CANYON 2010Pages: 448, PDF Size: 2.62 MB

Page 321 of 448

{WARNING:

Fans or other moving engine parts can injure you

badly. Keep your hands away from moving parts

once the engine is running.

5. Check that the jumper cables do not have loose

or missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go

to positive (+) or to a remote positive (+) terminal

if the vehicle has one. Negative (−) will go to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−)oryou

will get a short that would damage the battery

and maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

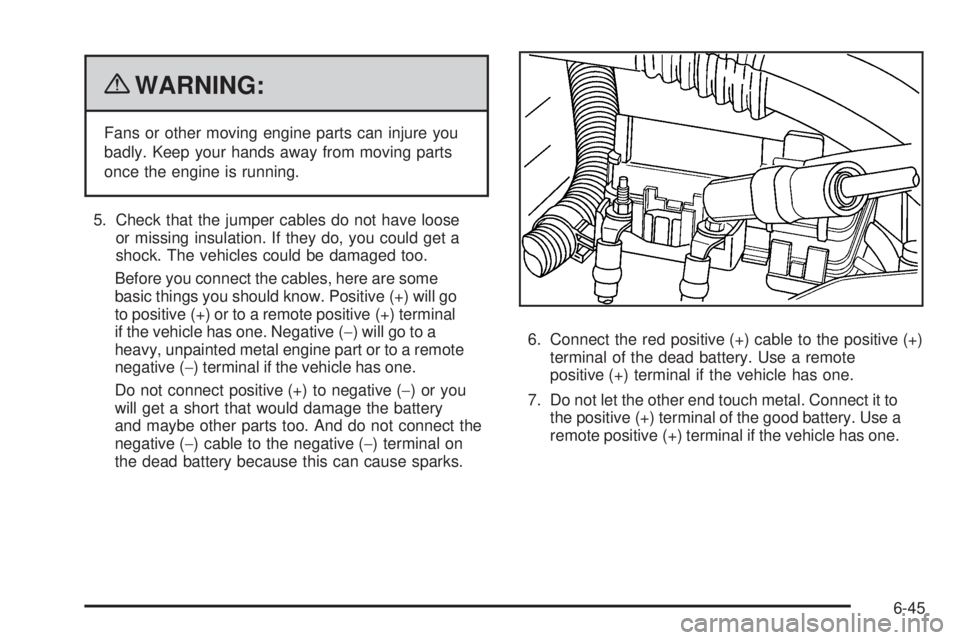

the dead battery because this can cause sparks.6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.

6-45

Page 322 of 448

8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does not go to the dead battery. It goes to a heavy,

unpainted metal engine part, or to a remote

negative (−) terminal on the vehicle with the

dead battery.

9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

Your vehicle has a remote negative (−) terminal

for this purpose.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

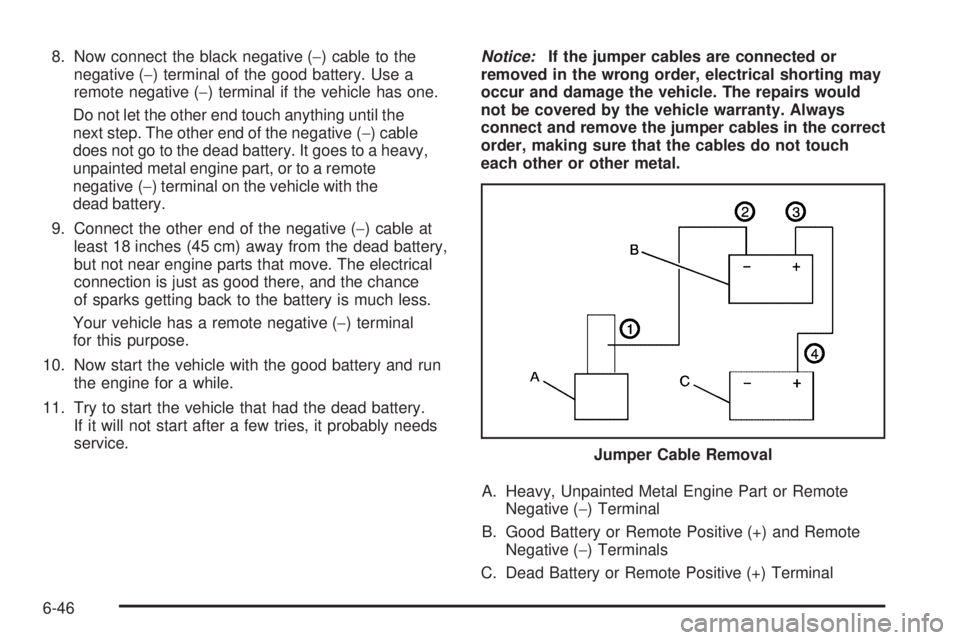

service.Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by the vehicle warranty. Always

connect and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalJumper Cable Removal

6-46

Page 323 of 448

To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

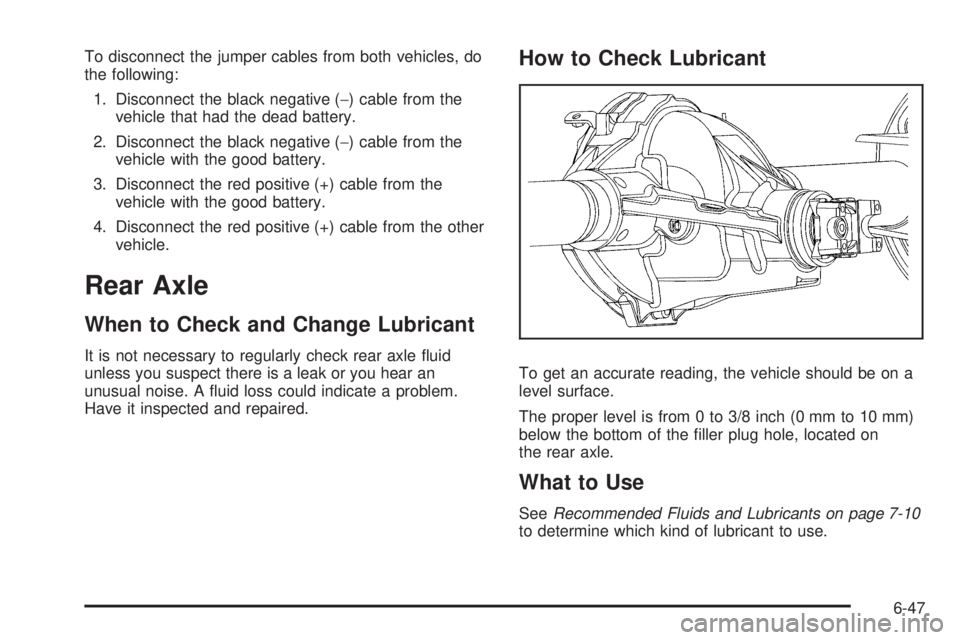

Rear Axle

When to Check and Change Lubricant

It is not necessary to regularly check rear axle fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

The proper level is from 0 to 3/8 inch (0 mm to 10 mm)

below the bottom of the filler plug hole, located on

the rear axle.

What to Use

SeeRecommended Fluids and Lubricants on page 7-10

to determine which kind of lubricant to use.

6-47

Page 324 of 448

Four-Wheel Drive

Lubricant checks in this section apply to this vehicle.

There are two additional systems that need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance on page 7-3.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

A. Drain Plug

B. Filler Plug

If the level is below the bottom of the filler plug hole,

located on the transfer case, you’ll need to add some

lubricant. Remove the plug and add enough lubricant

to raise the level to the bottom of the filler plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants on page 7-10.

6-48

Page 325 of 448

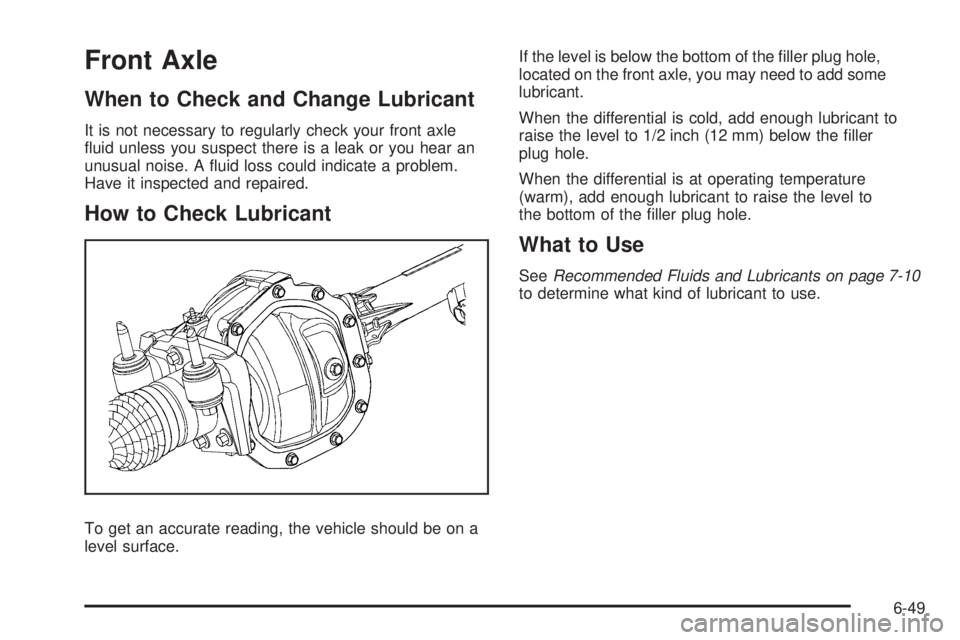

Front Axle

When to Check and Change Lubricant

It is not necessary to regularly check your front axle

fluid unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If the level is below the bottom of the filler plug hole,

located on the front axle, you may need to add some

lubricant.

When the differential is cold, add enough lubricant to

raise the level to 1/2 inch (12 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to

the bottom of the filler plug hole.

What to Use

SeeRecommended Fluids and Lubricants on page 7-10

to determine what kind of lubricant to use.

6-49

Page 326 of 448

Headlamp Aiming

Headlamp aim has been preset at the factory and

should need no further adjustment.

However, if your vehicle is damaged in a crash, the

headlamp aim may be affected. Aim adjustment to the

low-beam headlamps may be necessary if oncoming

drivers flash their high-beam headlamps at you

(for vertical aim).

If the headlamps need to be re-aimed, it is

recommended that you take the vehicle to your

dealer/retailer for service.

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 6-54.

For any bulb changing procedure not listed in this

section, contact your dealer/retailer.

Halogen Bulbs

{WARNING:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and follow

the instructions on the bulb package.

6-50

Page 327 of 448

Headlamps

A. Low-Beam Headlamp/Daytime Running

Lamps (DRL)

B. High-Beam Headlamp

To replace one of these bulbs:

1. Open the hood. SeeHood Release on page 6-11.

2. Reach in and access the bulb sockets from

inside the engine compartment.3. Turn the bulb socket counterclockwise to remove it

from the headlamp assembly and pull it straight out.

4. Unplug the electrical connector from the old bulb by

releasing the clips on the bulb socket.

5. Pull the old bulb straight out.

6. Push the new bulb straight in until it clicks to

secure it.

7. Plug in the electrical connector to the new bulb

socket.

8. Push the bulb socket straight in and turn it clockwise

to secure it in the headlamp assembly.

6-51

Page 328 of 448

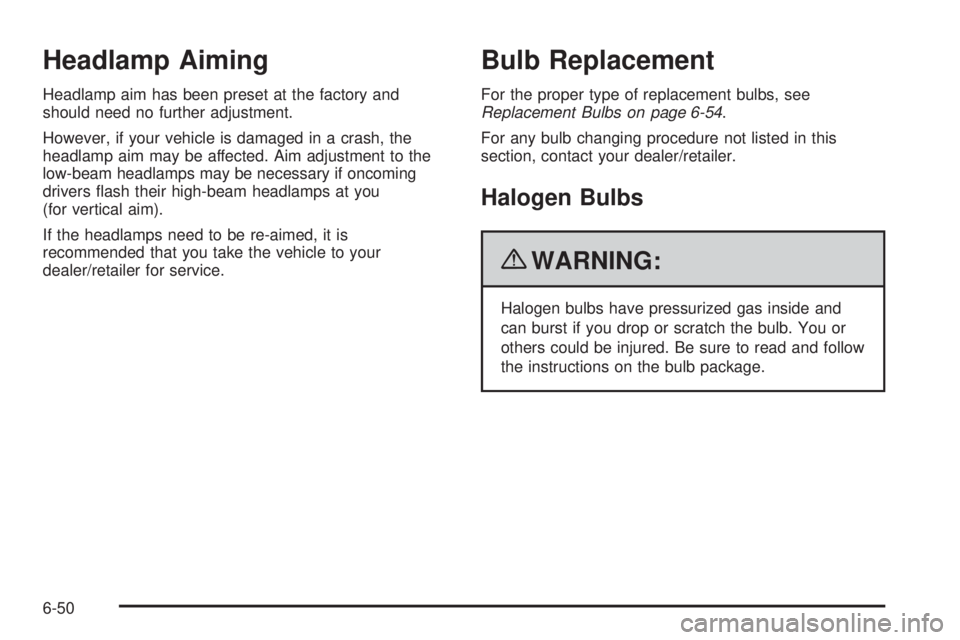

Front Turn Signal, Parking and

Daytime Running Lamps (DRL)

To replace one of these bulbs:

1. Open the hood. SeeHood Release on page 6-11.

2. Reach in to access either one of the bulb sockets in

the engine compartment.

3. Turn the bulb socket counterclockwise and remove

it from the lamp assembly.

4. Holding the socket, pull the old bulb to release it

from the bulb socket.5. Push the new bulb into the socket until it clicks.

6. Push the bulb socket straight into the lamp

assembly and turn it clockwise to secure.

Center High-Mounted

Stoplamp (CHMSL)

To replace the CHMSL bulb:

1. Remove the two screws and lift off the lamp

assembly from the vehicle.

2. Turn the bulb socket counterclockwise and remove

it from the lamp assembly.

3. Holding the socket, pull the bulb to release it from

the socket.

4. Push the new bulb into the socket until it clicks.

5. Insert the bulb socket into the lamp assembly and

turn it clockwise to secure.

6. Reinstall the lamp assembly and tighten the screws.

6-52

Page 329 of 448

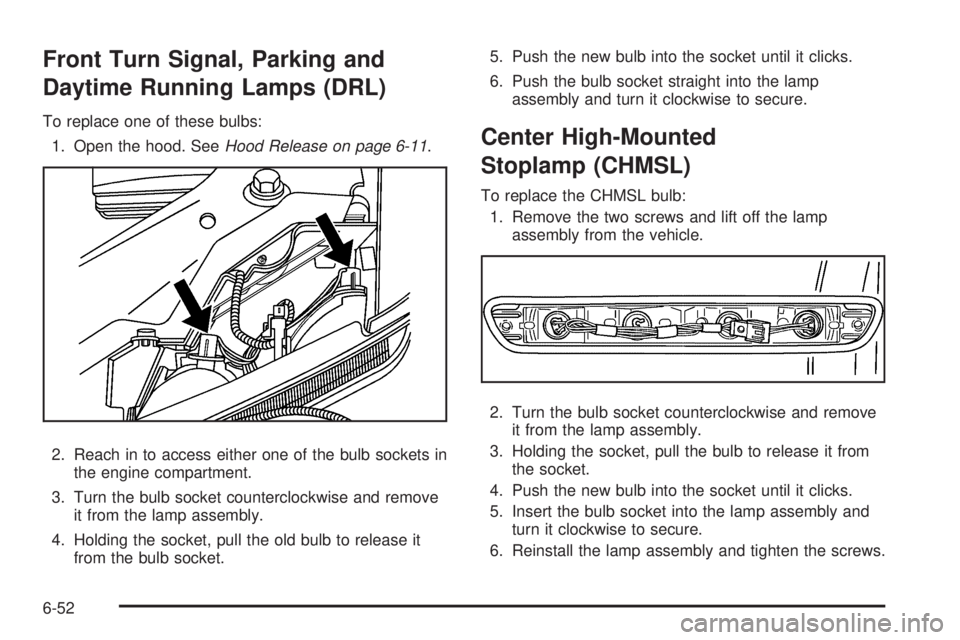

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

A. Stoplamp/Taillamp

B. Turn Signal/Taillamp

C. Back-up LampTo replace one of these bulbs:

1. Open the tailgate. SeeTailgate on page 3-8.

2. Remove the two rear

lamp assembly screws

near the tailgate latch.

3. Pull the lamp assembly away from the vehicle.

4. Turn the bulb socket counterclockwise to remove it

from the taillamp assembly.

5. Holding the socket, pull the old bulb straight out to

release it from the socket.

6. Push the new bulb straight into the socket until it

clicks.

7. Insert the bulb socket into the taillamp assembly

and turn it clockwise to secure.

8. Reinstall the taillamp assembly and tighten the

screws.

6-53

Page 330 of 448

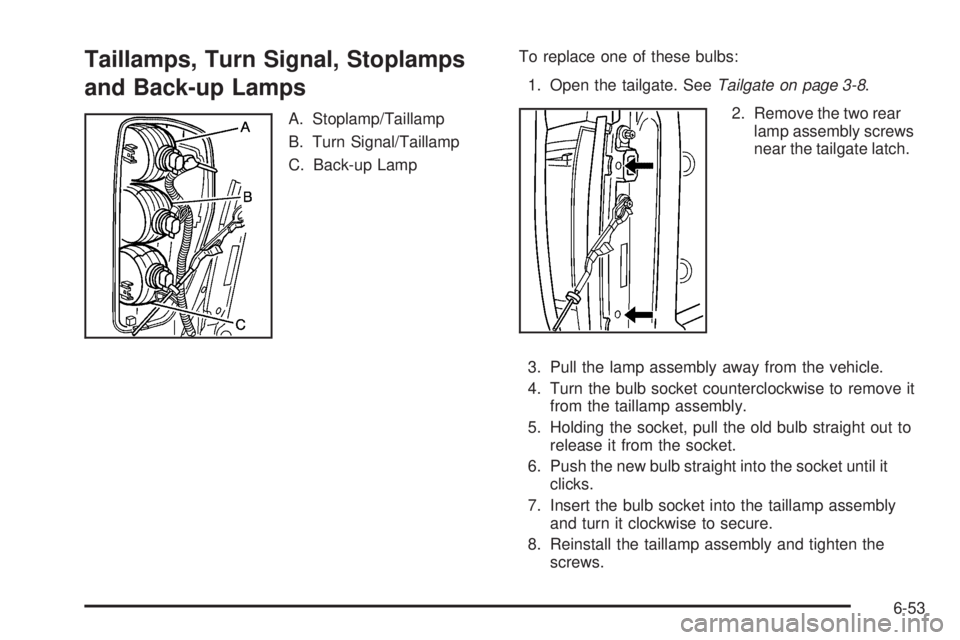

License Plate Lamp

To replace one of these bulbs:

1. Reach under the rear bumper for the bulb socket.

2. Turn the bulb socket counterclockwise and pull

the bulb socket out of the connector.

3. Pull the old bulb straight out from the bulb socket.

4. Push the new bulb straight in until it clicks to

secure it.

5. Reach under the rear bumper to reinstall the bulb

socket into the connector.

6. Turn the bulb socket clockwise to secure it to the

connector.

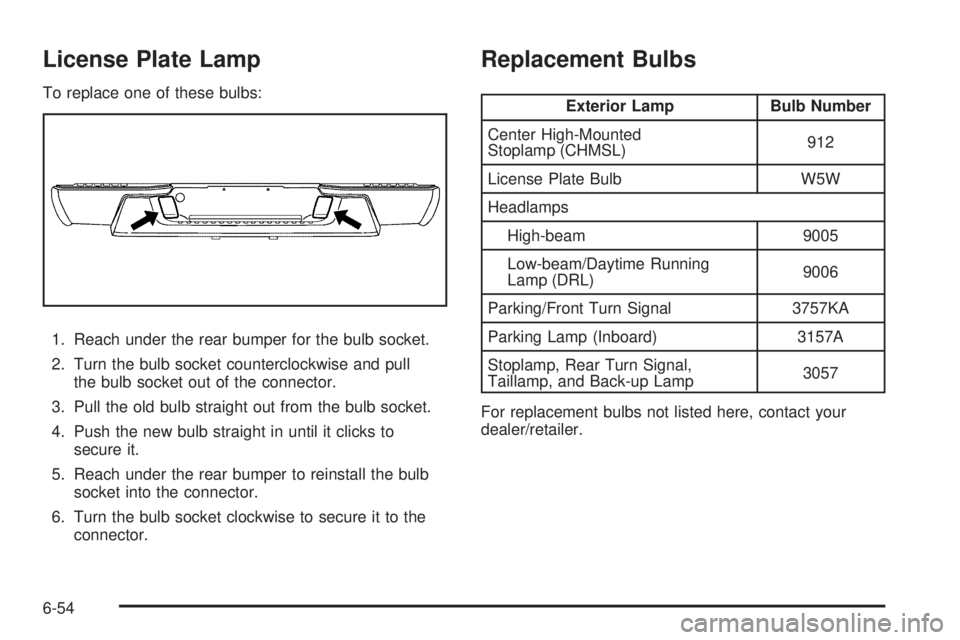

Replacement Bulbs

Exterior Lamp Bulb Number

Center High-Mounted

Stoplamp (CHMSL)912

License Plate Bulb W5W

Headlamps

High-beam 9005

Low-beam/Daytime Running

Lamp (DRL)9006

Parking/Front Turn Signal 3757KA

Parking Lamp (Inboard) 3157A

Stoplamp, Rear Turn Signal,

Taillamp, and Back-up Lamp3057

For replacement bulbs not listed here, contact your

dealer/retailer.

6-54