clock GMC ENVOY 2009 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2009, Model line: ENVOY, Model: GMC ENVOY 2009Pages: 474, PDF Size: 2.56 MB

Page 393 of 474

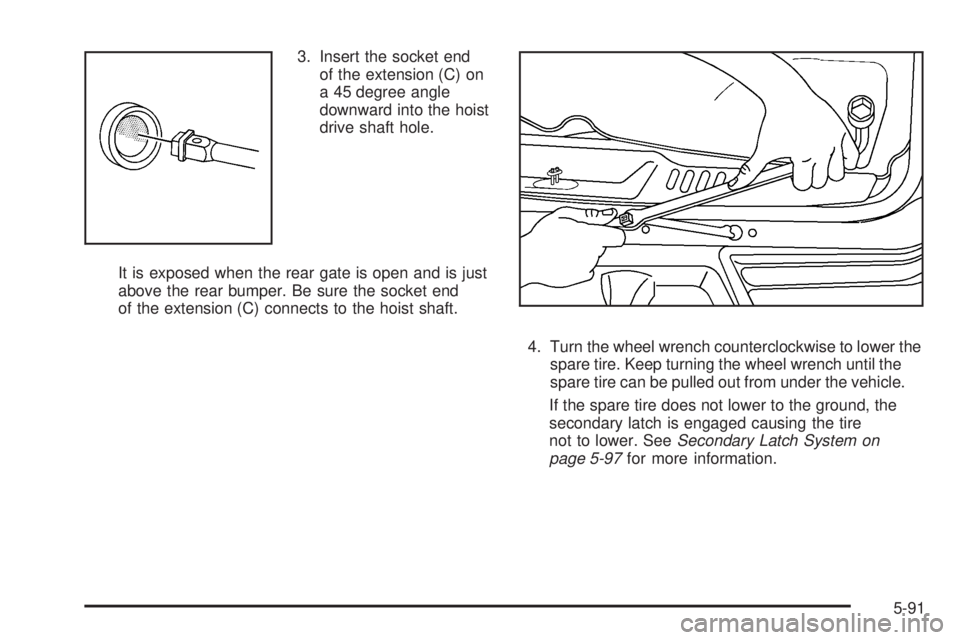

3. Insert the socket end

of the extension (C) on

a 45 degree angle

downward into the hoist

drive shaft hole.

It is exposed when the rear gate is open and is just

above the rear bumper. Be sure the socket end

of the extension (C) connects to the hoist shaft.

4. Turn the wheel wrench counterclockwise to lower the

spare tire. Keep turning the wheel wrench until the

spare tire can be pulled out from under the vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire

not to lower. SeeSecondary Latch System on

page 5-97for more information.

5-91

Page 395 of 474

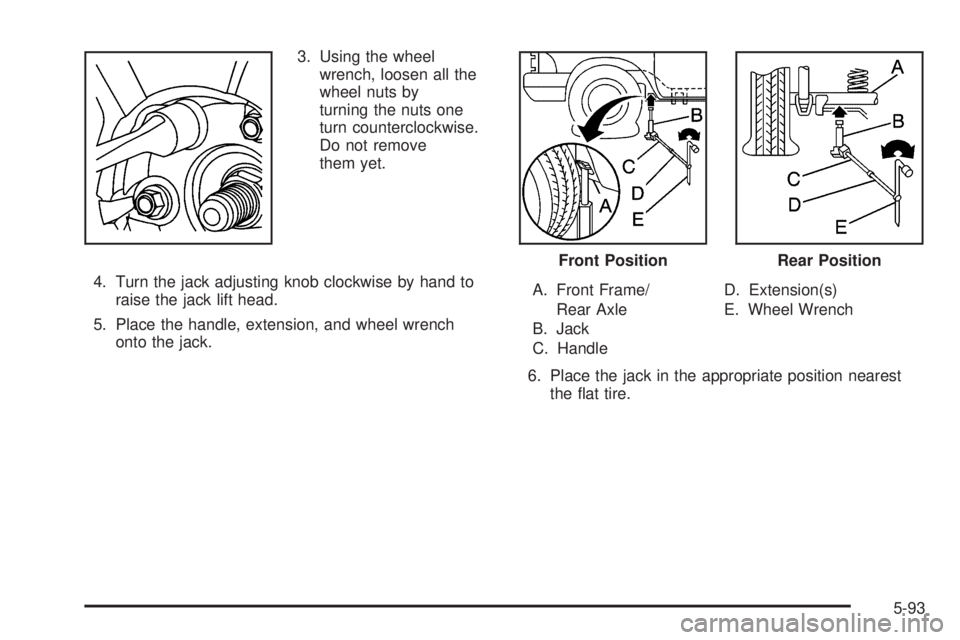

3. Using the wheel

wrench, loosen all the

wheel nuts by

turning the nuts one

turn counterclockwise.

Do not remove

them yet.

4. Turn the jack adjusting knob clockwise by hand to

raise the jack lift head.

5. Place the handle, extension, and wheel wrench

onto the jack.A. Front Frame/

Rear Axle

B. Jack

C. HandleD. Extension(s)

E. Wheel Wrench

6. Place the jack in the appropriate position nearest

the �at tire.

Front PositionRear Position

5-93

Page 396 of 474

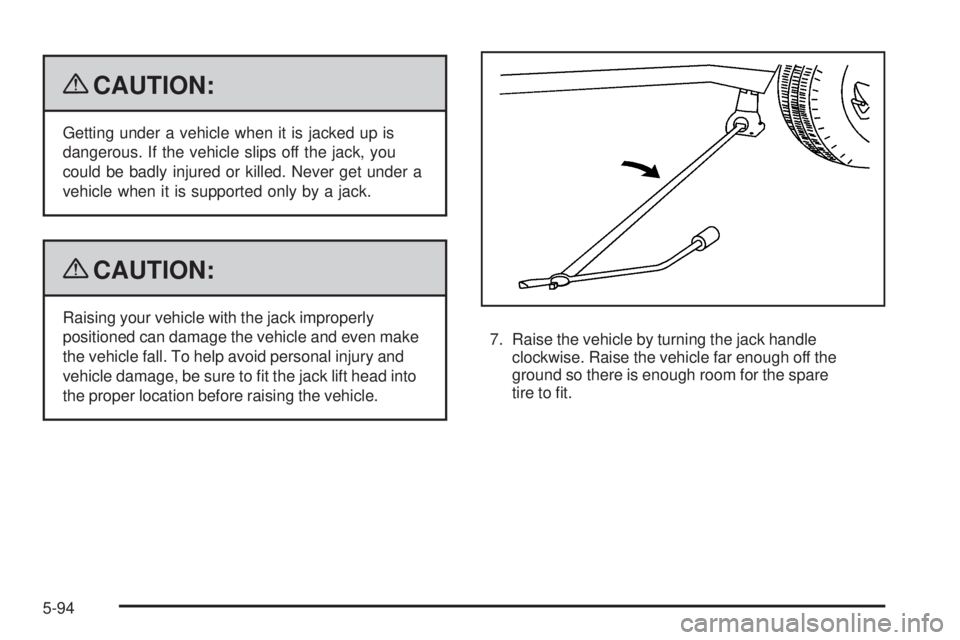

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack, you

could be badly injured or killed. Never get under a

vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even make

the vehicle fall. To help avoid personal injury and

vehicle damage, be sure to �t the jack lift head into

the proper location before raising the vehicle.7. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the

ground so there is enough room for the spare

tire to �t.

5-94

Page 398 of 474

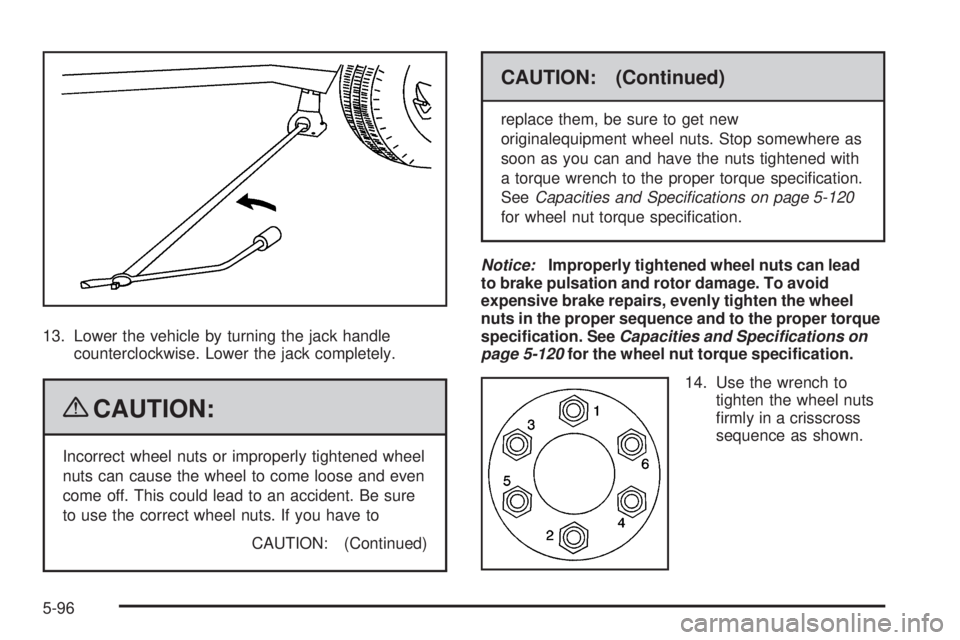

13. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{CAUTION:

Incorrect wheel nuts or improperly tightened wheel

nuts can cause the wheel to come loose and even

come off. This could lead to an accident. Be sure

to use the correct wheel nuts. If you have to

CAUTION: (Continued)

CAUTION: (Continued)

replace them, be sure to get new

originalequipment wheel nuts. Stop somewhere as

soon as you can and have the nuts tightened with

a torque wrench to the proper torque speci�cation.

SeeCapacities and Specifications on page 5-120

for wheel nut torque speci�cation.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

speci�cation. SeeCapacities and Specifications on

page 5-120for the wheel nut torque speci�cation.

14. Use the wrench to

tighten the wheel nuts

�rmly in a crisscross

sequence as shown.

5-96

Page 400 of 474

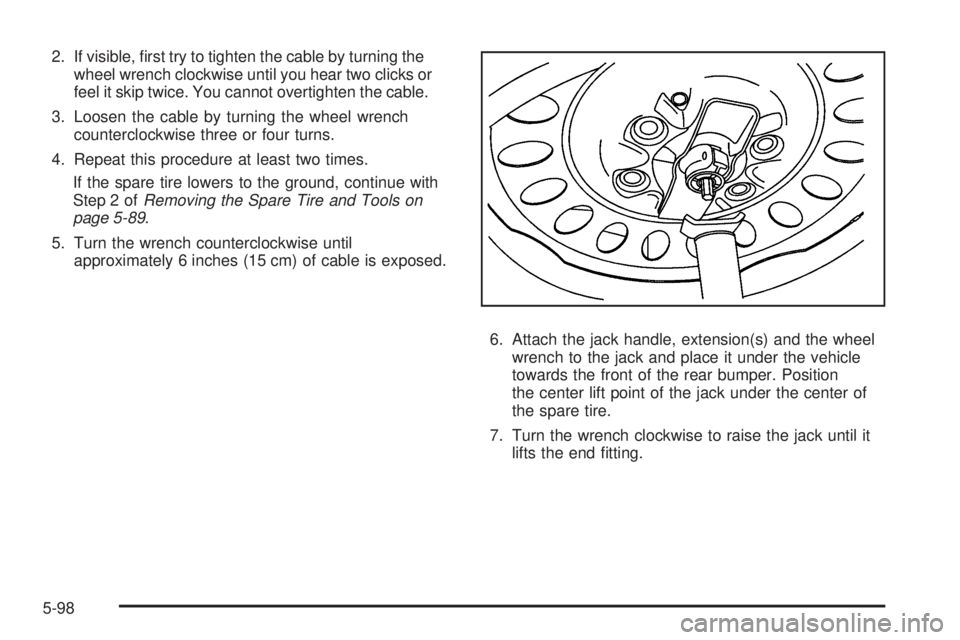

2. If visible, �rst try to tighten the cable by turning the

wheel wrench clockwise until you hear two clicks or

feel it skip twice. You cannot overtighten the cable.

3. Loosen the cable by turning the wheel wrench

counterclockwise three or four turns.

4. Repeat this procedure at least two times.

If the spare tire lowers to the ground, continue with

Step 2 ofRemoving the Spare Tire and Tools on

page 5-89.

5. Turn the wrench counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

6. Attach the jack handle, extension(s) and the wheel

wrench to the jack and place it under the vehicle

towards the front of the rear bumper. Position

the center lift point of the jack under the center of

the spare tire.

7. Turn the wrench clockwise to raise the jack until it

lifts the end �tting.

5-98

Page 401 of 474

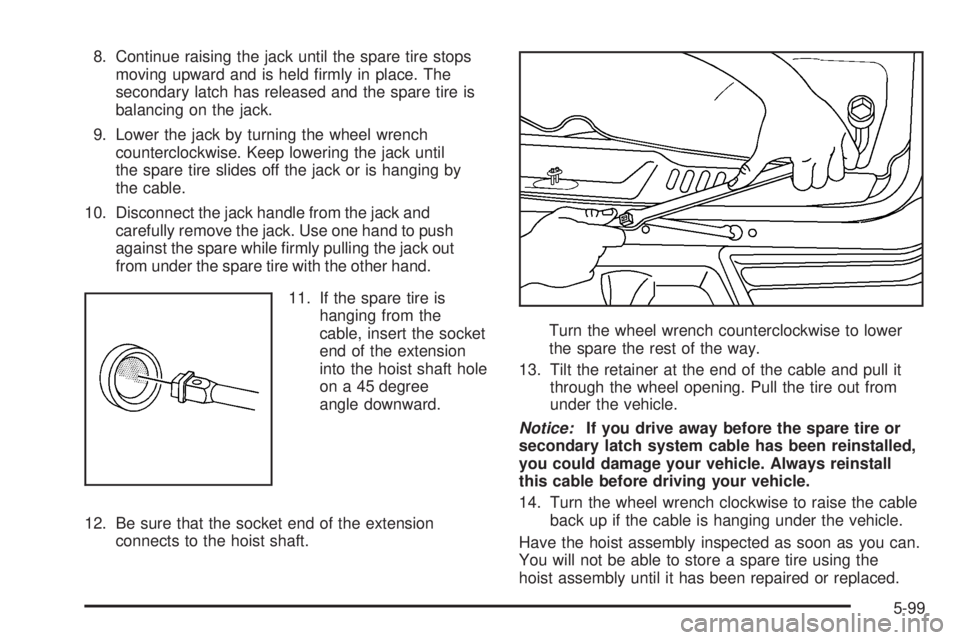

8. Continue raising the jack until the spare tire stops

moving upward and is held �rmly in place. The

secondary latch has released and the spare tire is

balancing on the jack.

9. Lower the jack by turning the wheel wrench

counterclockwise. Keep lowering the jack until

the spare tire slides off the jack or is hanging by

the cable.

10. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while �rmly pulling the jack out

from under the spare tire with the other hand.

11. If the spare tire is

hanging from the

cable, insert the socket

end of the extension

into the hoist shaft hole

on a 45 degree

angle downward.

12. Be sure that the socket end of the extension

connects to the hoist shaft.Turn the wheel wrench counterclockwise to lower

the spare the rest of the way.

13. Tilt the retainer at the end of the cable and pull it

through the wheel opening. Pull the tire out from

under the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

14. Turn the wheel wrench clockwise to raise the cable

back up if the cable is hanging under the vehicle.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare tire using the

hoist assembly until it has been repaired or replaced.

5-99

Page 403 of 474

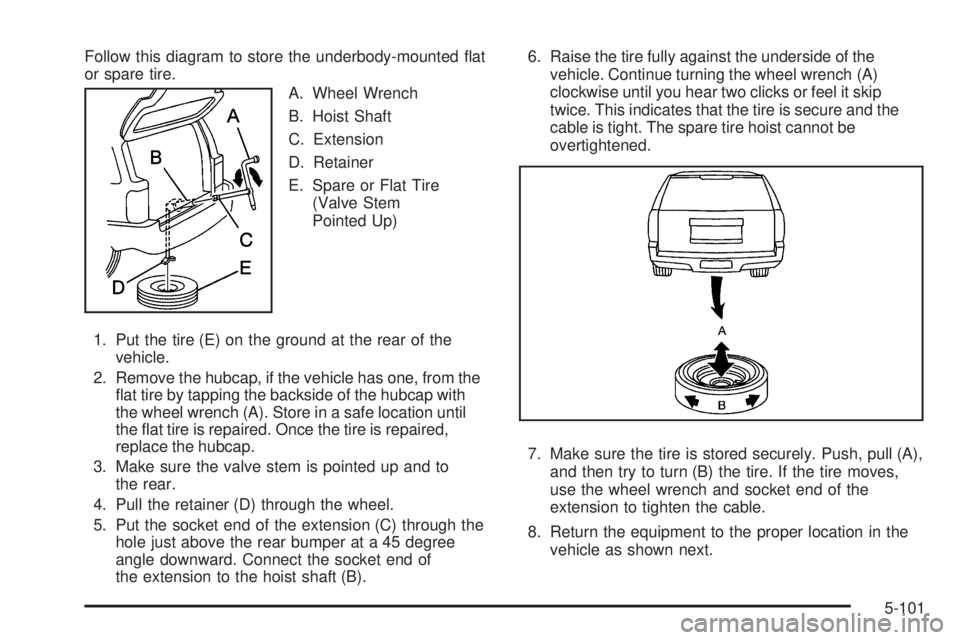

Follow this diagram to store the underbody-mounted �at

or spare tire.

A. Wheel Wrench

B. Hoist Shaft

C. Extension

D. Retainer

E. Spare or Flat Tire

(Valve Stem

Pointed Up)

1. Put the tire (E) on the ground at the rear of the

vehicle.

2. Remove the hubcap, if the vehicle has one, from the

�at tire by tapping the backside of the hubcap with

the wheel wrench (A). Store in a safe location until

the �at tire is repaired. Once the tire is repaired,

replace the hubcap.

3. Make sure the valve stem is pointed up and to

the rear.

4. Pull the retainer (D) through the wheel.

5. Put the socket end of the extension (C) through the

hole just above the rear bumper at a 45 degree

angle downward. Connect the socket end of

the extension to the hoist shaft (B).6. Raise the tire fully against the underside of the

vehicle. Continue turning the wheel wrench (A)

clockwise until you hear two clicks or feel it skip

twice. This indicates that the tire is secure and the

cable is tight. The spare tire hoist cannot be

overtightened.

7. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves,

use the wheel wrench and socket end of the

extension to tighten the cable.

8. Return the equipment to the proper location in the

vehicle as shown next.

5-101

Page 404 of 474

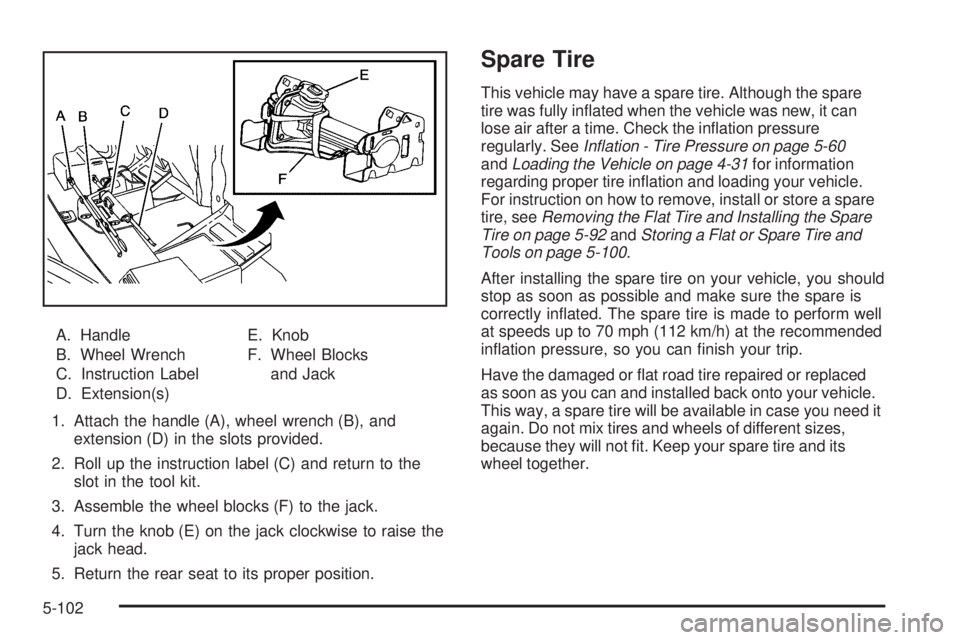

A. Handle

B. Wheel Wrench

C. Instruction Label

D. Extension(s)E. Knob

F. Wheel Blocks

and Jack

1. Attach the handle (A), wheel wrench (B), and

extension (D) in the slots provided.

2. Roll up the instruction label (C) and return to the

slot in the tool kit.

3. Assemble the wheel blocks (F) to the jack.

4. Turn the knob (E) on the jack clockwise to raise the

jack head.

5. Return the rear seat to its proper position.

Spare Tire

This vehicle may have a spare tire. Although the spare

tire was fully in�ated when the vehicle was new, it can

lose air after a time. Check the in�ation pressure

regularly. SeeInflation - Tire Pressure on page 5-60

andLoading the Vehicle on page 4-31for information

regarding proper tire in�ation and loading your vehicle.

For instruction on how to remove, install or store a spare

tire, seeRemoving the Flat Tire and Installing the Spare

Tire on page 5-92andStoring a Flat or Spare Tire and

Tools on page 5-100.

After installing the spare tire on your vehicle, you should

stop as soon as possible and make sure the spare is

correctly in�ated. The spare tire is made to perform well

at speeds up to 70 mph (112 km/h) at the recommended

in�ation pressure, so you can �nish your trip.

Have the damaged or �at road tire repaired or replaced

as soon as you can and installed back onto your vehicle.

This way, a spare tire will be available in case you need it

again. Do not mix tires and wheels of different sizes,

because they will not �t. Keep your spare tire and its

wheel together.

5-102

Page 462 of 474

Audio System (cont.)

Setting the Clock.........................................3-63

Theft-Deterrent Feature...............................3-110

XM™ Satellite Radio Antenna System...........3-112

Audio System(s).............................................3-64

Automatic Headlamp System............................3-14

Automatic Transmission

Fluid..........................................................5-21

Operation...................................................2-25

B

Battery..........................................................5-38

Electric Power Management..........................3-17

Run-Down Protection...................................3-18

Bluetooth

®.....................................................3-86

Brake

Emergencies................................................ 4-6

Brake Fluid....................................................5-35

Brakes..........................................................5-35

System Warning Light..................................3-35

Braking........................................................... 4-4

Braking in Emergencies..................................... 4-6

Break-In, New Vehicle.....................................2-20

Bulb Replacement...........................................5-46

Back-Up Lamps...........................................5-48

Front Turn Signal, Sidemarker and

Parking Lamps.........................................5-47

Halogen Bulbs............................................5-46Bulb Replacement (cont.)

Headlamp Aiming........................................5-45

Headlamps.................................................5-46

License Plate Lamps....................................5-49

Replacement Bulbs......................................5-49

Taillamps, Turn Signal, and Stoplamps............5-47

Buying New Tires...........................................5-70

C

Calibration.....................................................2-40

California Fuel.................................................. 5-6

California Perchlorate Materials Requirements....... 5-4

California Proposition 65 Warning....................... 5-4

Canadian Owners................................................ ii

Capacities and Speci�cations..........................5-120

Carbon Monoxide...........................2-12, 2-37, 4-28

Care of

Safety Belts..............................................5-106

Cargo Cover..................................................2-54

Cargo Tie Downs............................................2-55

CD, MP3 .......................................................3-80

Center Console Storage Area...........................2-52

Chains, Tire...................................................5-76

Charging System Light....................................3-33

Check

Engine Lamp..............................................3-38

Gages Warning Light...................................3-45

Check Gas Cap Light......................................3-47

2

Page 463 of 474

Checking Things Under the Hood......................5-10

Chemical Paint Spotting.................................5-110

Child Restraints

Child Restraint Systems...............................1-39

Infants and Young Children...........................1-35

Lower Anchors and Tethers for Children..........1-43

Older Children.............................................1-32

Securing a Child Restraint in a

Rear Outside Seat Position........................1-49

Securing a Child Restraint in the

Center Rear Seat Position.........................1-51

Securing a Child Restraint in the

Right Front Seat Position..........................1-52

Where to Put the Restraint...........................1-42

Chime Level Adjustment.................................3-112

Cigarette Lighter.............................................3-19

Cleaning

Aluminum Wheels......................................5-109

Exterior Lamps/Lenses................................5-107

Fabric/Carpet............................................5-104

Finish Care...............................................5-108

Instrument Panel, Vinyl, and Other

Plastic Surfaces.....................................5-106

Interior.....................................................5-103

Leather....................................................5-105

Tires........................................................5-109

Underbody Maintenance.............................5-110

Washing Your Vehicle.................................5-107

Weatherstrips............................................5-106

Windshield, Backglass, and Wiper Blades......5-108Climate Control System

Dual ..........................................................3-19

Dual Automatic............................................3-22

Outlet Adjustment........................................3-26

Rear ..........................................................3-26

Clock, Setting.................................................3-63

Collision Damage Repair..................................7-11

Compass.......................................................2-40

Compressor Kit

Storing.......................................................

5-87

Compressor Kit, Tire Sealant............................5-77

Content Theft-Deterrent....................................2-16

Control of a Vehicle.......................................... 4-3

Convenience Net............................................2-54

Coolant

Engine.......................................................5-25

Engine Temperature Gage............................3-37

Cooling System..............................................5-24

Cruise Control................................................3-10

Cruise Control Light........................................3-43

Customer Assistance Information

Courtesy Transportation................................7-10

Customer Assistance for Text

Telephone (TTY) Users............................... 7-6

Customer Assistance Offices........................... 7-6

Customer Satisfaction Procedure..................... 7-2

GM Mobility Reimbursement Program............... 7-7

Reporting Safety Defects to General Motors.......7-15

3