air suspension GMC ENVOY XUV 2004 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2004, Model line: ENVOY XUV, Model: GMC ENVOY XUV 2004Pages: 460, PDF Size: 2.99 MB

Page 274 of 460

After Off-Road Driving

Remove any brush or debris that has collected on the

underbody, chassis or under the hood. These

accumulations can be a ®re hazard.

After operation in mud or sand, have the brake linings

cleaned and checked. These substances can cause

glazing and uneven braking. Check the body structure,

steering, suspension, wheels, tires and exhaust

system for damage. Also, check the fuel lines and

cooling system for any leakage.

Your vehicle will require more frequent service due to

off-road use. Refer to the Maintenance Schedule

for additional information.

Driving at Night

Night driving is more dangerous than day driving.

One reason is that some drivers are likely to be

impaired Ð by alcohol or drugs, with night vision

problems, or by fatigue.

Here are some tips on night driving.

·Drive defensively.

·Do not drink and drive.

4-28

Page 300 of 460

Using heavier suspension components to get added

durability might not change your vehicle's weight ratings.

Ask your dealer to help you load your vehicle the

right way.

Notice:Overloading your vehicle may cause

damage. Repairs would not be covered by your

warranty. Do not overload your vehicle.

If you put things inside your vehicle-like suitcases, tools,

packages, or anything else-they will go as fast as the

vehicle goes. If you have to stop or turn quickly, or

if there's a crash, they'll keep going.

{CAUTION:

Things you put inside your vehicle can strike

and injure people in a sudden stop or turn, or

in a crash.

·Put things in the cargo area of your

vehicle. Try to spread the weight evenly.

·Never stack heavier things, like suitcases,

inside the vehicle so that some of them

are above the tops of the seats.

·Do not leave an unsecured child restraint

in your vehicle.

·When you carry something inside the

vehicle, secure it whenever you can.

·Do not leave a seat folded down unless

you need to.

There's also important loading information for off-road

driving in this manual.

4-54

Page 301 of 460

Electronically Controlled Air

Suspension System

Your vehicle may be equipped with an electronically

controlled air suspension system that automatically

keeps your vehicle level as you load and unload. The

system includes a compressor, two height sensors

and two air springs supporting the rear axle.

The system also has an internal clock to prevent

overheating. If the system overheats, all leveling function

stops until the system cools down. During this time,

the indicator light on the air in¯ator system will be

¯ashing.

The ignition has to be on for the system to in¯ate, in

order to raise the vehicle to the standard ride height after

loading. The system can lower the vehicle to the

standard ride height after unloading with the ignition on

and also for up to 30 minutes after the ignition has

been turned off.

You may hear the compressor operating when you load

your vehicle, and periodically as the system adjusts

the vehicle to the standard ride height.Load leveling will not function normally with the in¯ator

hose attached to the in¯ator outlet. Remove the

in¯ator hose from the outlet during loading and

unloading.

If the vehicle is parked for an extended period of time,

some bleed down of the suspension is normal. Upon

starting the vehicle, proper height will be achieved.

Overload Protection

The air suspension system is equipped with overload

protection. Overload protection is designed to protect the

air suspension system, and it is an indicator to the

driver that the vehicle is overloaded. When the overload

protection mode is on, it will not allow damage to the

air compressor. However, do not overload the vehicle.

See

Loading Your Vehicle on page 4-49.

If the suspension remains at a low height, the rear axle

load has exceeded GAWR (Gross Axle Weight

Rating). When the overload protection mode is activated,

the compressor operates for about 30 seconds to one

minute without raising the vehicle depending on the

amount of overload. This will continue each time

the ignition is turned on until the rear axle load is

reduced below GAWR.

4-55

Page 380 of 460

Tire Chains

{CAUTION:

Don't use tire chains. There's not enough

clearance. Tire chains used on a vehicle

without the proper amount of clearance can

cause damage to the brakes, suspension or

other vehicle parts. The area damaged by the

tire chains could cause you to lose control of

your vehicle and you or others may be injured

in a crash. Use another type of traction device

only if its manufacturer recommends it for use

on your vehicle and tire size combination and

road conditions. Follow that manufacturer's

instructions. To help avoid damage to your

vehicle, drive slowly, readjust or remove the

device if it's contacting your vehicle, and don't

spin your wheels. If you do ®nd traction

devices that will ®t, install them on the

rear tires.

Accessory In¯ator

Your vehicle may be equipped with an air in¯ator

system. You can in¯ate things like basketballs and

bicycle tires. Also, you can use it to bring your tire

pressure up to the proper pressure. It is not designed to

in¯ate large objects which will require more than ®ve

minutes to in¯ate, such as an air mattress.

The air in¯ator is located in

the rear compartment on

the driver's side of the

vehicle behind an

access cover.

Pull the tab on the cover to access the in¯ator.

The air in¯ator kit may be located in the glove box. The

kit includes a 22 ft (6.7 m) hose with three nozzle

adapters.

5-68

Page 381 of 460

To use the air in¯ator, attach the appropriate nozzle

adapter to the end of the hose if required. Then attach

that end of the hose to the object you wish to in¯ate.

Attach the other end of the hose to the outlet.

Press and release the switch to turn the air in¯ator on.

The indicator light will remain on when the in¯ator is

running.

The system has an internal clock to prevent overheating.

The system will allow about ®ve minutes of running

time, then the compressor will stop. The indicator light

will then begin to ¯ash. When the indicator is off,

the in¯ator can be started again by pressing the switch.

If the compressor is still hot, it may only run for a

short time before shutting off again.

Press and release the switch to turn the in¯ator off.

Place the in¯ator kit tools in the pouch and store

it properly. Remove the in¯ator hose from the outlet

during loading and unloading. Load leveling will

not function with the in¯ator hose attached to the

in¯ator outlet.To reinstall the cover, line up the tabs at the back of the

cover, put it in place and latch the tabs.

A continuous ¯ashing indicator light may also indicate a

malfunction in the air suspension system.

{CAUTION:

In¯ating something too much can make it

explode, and you or others could be injured.

Be sure to read the in¯ator instructions, and

in¯ate any object only to its recommended

pressure.

5-69

Page 406 of 460

Fuses Usage

1 Electrically-Controlled Air Suspension

2Passenger's Side High-Beam

Headlamp

3Passenger's Side Low-Beam

HeadlampFuses Usage

4 Back-Up-Trailer Lamps

5 Driver's Side High-Beam Headlamp

6 Driver's Side Low-Beam Headlamp

7 Wash L6 Engine

5-94

Page 409 of 460

Fuses Usage

1Electrically-Controlled Air

Suspension

2Passenger's Side High-Beam

Headlamp

3Passenger's Side Low-Beam

Headlamp

4 Back-Up-Trailer Lamps

5Driver's Side High-Beam

Headlamp

6Driver's Side Low-Beam

Headlamp

7 Wash

8 Automatic Transfer Case

9 Windshield Wipers

10 Powertrain Control Module B

11 Fog Lamps

12 Stop Lamp

13 Cigarette Lighter

14 Ignition Coils

15 Canister Vent

16 TBD-Ignition 1

17 Crank

18 Air Bag

19 Electric Brake

20 Cooling FanFuses Usage

21 Horn

22 Ignition E

23 Electronic Throttle Control

24Instrument Panel Cluster, Driver

Information Center

25Automatic Shift Lock Control

System

26 Engine 1

27 Back-Up

28 Powertrain Control Module 1

30 Air Conditioning

31 Truck Body Controller

32 Trailer

33 Anti-Lock Brakes (ABS)

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger's Side Trailer Turn

51 Driver's Side Trailer Turn

52 Hazard Flashers

53 Oxygen Sensor Bank A

54 Oxygen Sensor Bank B

55 Injector Bank A

56 Injector Bank B

5-97

Page 419 of 460

Scheduled Maintenance

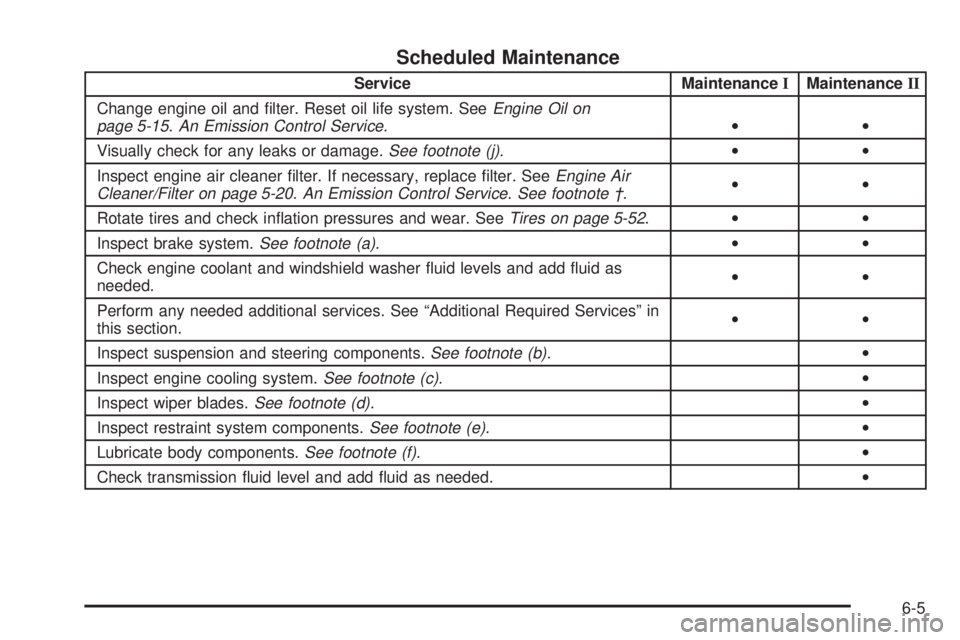

Service MaintenanceIMaintenanceII

Change engine oil and ®lter. Reset oil life system. See

Engine Oil on

page 5-15.An Emission Control Service.··

Visually check for any leaks or damage.

See footnote (j).··

Inspect engine air cleaner ®lter. If necessary, replace ®lter. See

Engine Air

Cleaner/Filter on page 5-20.An Emission Control Service. See footnote ².··

Rotate tires and check in¯ation pressures and wear. See

Tires on page 5-52.··

Inspect brake system.

See footnote (a).··

Check engine coolant and windshield washer ¯uid levels and add ¯uid as

needed.··

Perform any needed additional services. See ªAdditional Required Servicesº in

this section.··

Inspect suspension and steering components.

See footnote (b).·

Inspect engine cooling system.

See footnote (c).·

Inspect wiper blades.

See footnote (d).·

Inspect restraint system components.

See footnote (e).·

Lubricate body components.

See footnote (f).·

Check transmission ¯uid level and add ¯uid as needed.·

6-5

Page 422 of 460

Maintenance Footnotes

²The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle's useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, cha®ng, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose or missing parts or

signs of wear. Inspect power steering lines and

hoses for proper hook-up, binding, leaks, cracks,

cha®ng, etc.

(c)Visually inspect hoses and have them replaced if

they are cracked, swollen or deteriorated. Inspect

all pipes, ®ttings and clamps; replace with genuine GM

parts as needed. To help ensure proper operation, a

pressure test of the cooling system and pressure

cap and cleaning the outside of the radiator and air

conditioning condenser is recommended at least once

a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace blade inserts that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken air bag

coverings, and have them repaired or replaced. (The air

bag system does not need regular maintenance.)

(f)Lubricate all key lock cylinders, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl,

rear compartment hinges, outer liftgate handle pivot

points, rear door detent link, roller mechanism, liftgate

handle pivot points, latch bolt, fuel door hinge, cargo

door hinge, locks and folding seat hardware. More

frequent lubrication may be required when exposed to a

corrosive environment. Applying silicone grease on

weatherstrips with a clean cloth will make them

last longer, seal better and not stick or squeak.

(g)Add ¯uid as needed. A ¯uid loss could indicate a

problem; repair as needed. Check vent hose at transfer

case for kinks and proper installation.

6-8

Page 443 of 460

Reporting Safety Defects to the

Canadian Government

If you live in Canada, and you believe that your vehicle

has a safety defect, you should immediately notify

Transport Canada, in addition to notifying General

Motors of Canada Limited. You may write to:

Transport Canada

330 Sparks Street

Tower C

Ottawa, Ontario K1A 0N5

Reporting Safety Defects to General

Motors

In addition to notifying NHTSA (or Transport Canada) in

a situation like this, we certainly hope you'll notify us.

Please call us at 1-800-GMC-8782 (1-800-462-8782),

or write:

Pontiac-GMC Customer Assistance Center

P.O. Box 33172

Detroit, MI 48232-5172In Canada, please call us at 1-800-263-3777 (English)

or 1-800-263-7854 (French). Or, write:

General Motors of Canada Limited

Customer Communication Centre, 163-005

1908 Colonel Sam Drive

Oshawa, Ontario L1H 8P7

Service Publications Ordering

Information

Service Manuals

Service Manuals have the diagnosis and repair

information on engines, transmission, axle, suspension,

brakes, electrical, steering, body, etc.

RETAIL SELL PRICE: $120.00

Transmission, Transaxle, Transfer

Case Unit Repair Manual

This manual provides information on unit repair service

procedures, adjustments, and speci®cations for GM

transmissions, transaxles, and transfer cases.

RETAIL SELL PRICE: $50.00

7-11