maintenance schedule GMC SAVANA 2006 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2006, Model line: SAVANA, Model: GMC SAVANA 2006Pages: 394, PDF Size: 2.56 MB

Page 1 of 394

Seats and Restraint Systems........................... 1-1

Front Seats

............................................... 1-3

Rear Seats

............................................... 1-7

Safety Belts

.............................................1-10

Child Restraints

.......................................1-32

Airbag System

.........................................1-65

Restraint System Check

............................1-81

Features and Controls..................................... 2-1

Keys

........................................................ 2-2

Doors and Locks

....................................... 2-7

Windows

.................................................2-14

Theft-Deterrent Systems

............................2-17

Starting and Operating Your Vehicle

...........2-17

Mirrors

....................................................2-28

Storage Areas

.........................................2-30

Instrument Panel............................................. 3-1

Instrument Panel Overview

.......................... 3-4

Climate Controls

......................................3-17

Warning Lights, Gages, and Indicators

........3-23

Audio System(s)

.......................................3-43

Driving Your Vehicle....................................... 4-1

Your Driving, the Road, and Your Vehicle

..... 4-2

Towing

...................................................4-35Service and Appearance Care.......................... 5-1

Service

..................................................... 5-3

Fuel

......................................................... 5-5

Checking Things Under the Hood

...............5-10

All-Wheel Drive

........................................5-43

Rear Axle

...............................................5-44

Front Axle

...............................................5-44

Noise Control System

...............................5-45

Bulb Replacement

....................................5-46

Windshield Wiper Blade Replacement

.........5-51

Tires

......................................................5-52

Appearance Care

.....................................5-84

Vehicle Identification

.................................5-92

Electrical System

......................................5-93

Capacities and Specifications

.....................5-98

Maintenance Schedule..................................... 6-1

Maintenance Schedule

................................ 6-2

Customer Assistance and Information.............. 7-1

Customer Assistance and Information

........... 7-2

Reporting Safety Defects

...........................7-13

Index................................................................ 1

2006 GMC Savana Owner ManualM

Page 157 of 394

A reading in the low pressure zone may be caused by a

dangerously low oil level or other problem causing

low oil pressure. Check your oil as soon as possible.

{CAUTION:

Do not keep driving if the oil pressure is low. If

you do, your engine can become so hot that it

catches �re. You or others could be burned.

Check your oil as soon as possible and have

your vehicle serviced.

Notice:Lack of proper engine oil maintenance may

damage the engine. The repairs would not be

covered by your warranty. Always follow the

maintenance schedule in this manual for changing

engine oil.

Change Engine Oil Light

This light is displayed

when your vehicle needs

to be serviced.

If your vehicle has a V8 engine and this light is flashing,

it indicates that the oil level is low.

When this light is on steady, your vehicle needs to be

serviced. SeeScheduled Maintenance (Gasoline

Engine) on page 6-4for more information.

Once the engine oil has been changed, the change

engine oil light must be reset. Until it is reset, the light

will stay on for a while each time the engine is

started. For more information on resetting the system,

see “How to Reset the Engine Oil Life System”

underEngine Oil Life System (Gasoline Engine) on

page 5-16.

3-39

Page 247 of 394

Maintenance When Trailer Towing

Your vehicle will need service more often when you’re

pulling a trailer. See the Maintenance Schedule for more

on this. Things that are especially important in trailer

operation are automatic transmission fluid (don’t overfill),

engine oil, axle lubricant, belt, cooling system and

brake system. Each of these is covered in this manual,

and the Index will help you find them quickly. If

you’re trailering, it’s a good idea to review these sections

before you start your trip.

Check periodically to see that all hitch nuts and bolts

are tight.

Trailer Wiring Harness

The optional heavy-duty trailer wiring package includes

a seven-wire harness assembly at the rear of the

vehicle and a four-wire harness assembly under the left

hand side of the instrument panel. The seven-wire

harness assembly is taped together and located in a

frame pocket at the driver side rear left corner of

the frame. The seven-wire harness includes a 30-amp

feed wire. Both harnesses come without connectors and

should be wired by a qualified electrical technician.

The technician can use the following color code chart

when connecting the wiring harness to your trailer

and trailer brake controller.Seven-Wire Harness

•Light Green: Back-up lamps

•Brown: Parking lamps

•Yellow: Left stoplamp and turn signal

•Dark Green: Right stoplamp and turn signal

•Dark Blue: Use for electric trailer brakes

•Orange: Trailer accessory

•White (heavy gage): Ground wire

Four-Wire Harness (Trailer Brake Controller)

•Black: Ground

•Red/White Stripe: Fused Battery

•Dark Blue: Trailer Brake Feed

•Light Blue: Fused Stoplamp/CHMSL

4-51

Page 266 of 394

When to Inspect the Engine Air

Cleaner/Filter

Inspect the air cleaner/filter at the MaintenanceII

intervals and replace it at the first oil change after each

50,000 mile (83 000 km) interval. SeeScheduled

Maintenance (Gasoline Engine) on page 6-4for more

information. If you are driving in dusty/dirty conditions,

inspect the filter at each engine oil change.

How to Inspect the Engine Air

Cleaner/Filter

To inspect the air cleaner/filter, remove the filter from

the vehicle and lightly shake the filter to release

loose dust and dirt. If the filter remains caked with dirt,

a new filter is required.

To inspect or replace the engine air cleaner/filter,

do the following:

1. Unhook the retainer clips and remove the cover.

2. Lift the filter out of the engine air cleaner/filter

housing. Care should be taken to dislodge as

little dirt as possible.

3. Clean the engine air cleaner/filter housing.4. Inspect or replace the engine air cleaner/filter. Make

sure that the filter fits properly into the housing.

5. Reinstall the cover and fasten the retaining clips.

{CAUTION:

Operating the engine with the air cleaner/�lter

off can cause you or others to be burned.

The air cleaner not only cleans the air; it helps

to stop �ames if the engine back�res. If it is

not there and the engine back�res, you could

be burned. Do not drive with it off, and be

careful working on the engine with the air

cleaner/�lter off.

Notice:If the air cleaner/�lter is off, a back�re can

cause a damaging engine �re. And, dirt can

easily get into your engine, which will damage it.

Always have the air cleaner/�lter in place when you

are driving.

5-18

Page 269 of 394

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants (Gasoline Engine) on page 6-13.

Using a funnel, add fluid down the transmission

dipstick tube only after checking the transmission fluid

while it is hot. A cold check is used only as a reference.

If the fluid level is low, add only enough of the proper

fluid to bring the level up to the HOT area for a hot

check. It does not take much fluid, generally less than

one pint (0.5 L). Do not overfill.

Notice:Use of the incorrect automatic transmission

�uid may damage your vehicle, and the damages

may not be covered by your warranty. Always

use the automatic transmission �uid listed in

Recommended Fluids and Lubricants (Gasoline

Engine) on page 6-13.

•After adding fluid, recheck the fluid level as

described under “How to Check Automatic

Transmission Fluid,” earlier in this section.

•When the correct fluid level is obtained, push the

dipstick back in all the way; then flip the handle

down to lock the dipstick in place.

Engine Coolant

The cooling system in your vehicle is filled with

DEX-COOL®engine coolant. This coolant is designed

to remain in your vehicle for five years or 150,000 miles

(240 000 km), whichever occurs first, if you add only

DEX-COOL

®extended life coolant.

The following explains your cooling system and how to

add coolant when it is low. If you have a problem

with engine overheating, seeEngine Overheating on

page 5-24.

A 50/50 mixture of clean, drinkable water and

DEX-COOL

®coolant will:

•Give freezing protection down to−34°F (−37°C).

•Give boiling protection up to 265°F (129°C).

•Protect against rust and corrosion.

•Help keep the proper engine temperature.

•Let the warning lights and gages work as

they should.

Notice:Using coolant other than DEX-COOL

®may

cause premature engine, heater core, radiator

and fuel operated heater (FOH) corrosion. In

addition, the engine coolant may require changing

sooner, at 30,000 miles (50 000 km) or 24 months,

whichever occurs �rst. Any repairs would not

be covered by your warranty. Always use

DEX-COOL

®(silicate-free) coolant in your vehicle.

5-21

Page 283 of 394

Brakes

Brake Fluid

Your brake master cylinder

reservoir is filled with

DOT-3 brake fluid. See

Engine Compartment

Overview on page 5-12for

the location of the

reservoir.

There are only two reasons why the brake fluid level in

the reservoir might go down. The first is that the

brake fluid goes down to an acceptable level during

normal brake lining wear. When new linings are put in,

the fluid level goes back up. The other reason is

that fluid is leaking out of the brake system. If it is, you

should have your brake system fixed, since a leak

means that sooner or later your brakes will not work

well, or will not work at all.So, it is not a good idea to top off your brake fluid.

Adding brake fluid will not correct a leak. If you add fluid

when your linings are worn, then you will have too

much fluid when you get new brake linings. You should

add or remove brake fluid, as necessary, only when

work is done on the brake hydraulic system.

{CAUTION:

If you have too much brake �uid, it can spill on

the engine and/or fuel operated heater parts, if

equipped. If your vehicle has a diesel engine

and a fuel operated heater, see “Fuel Operated

Heater (FOH)” in the diesel engine supplement.

The �uid will burn if the engine is hot enough.

You or others could be burned, and your

vehicle could be damaged. Add brake �uid

only when work is done on the brake hydraulic

system. See “Checking Brake Fluid” in this

section.

Refer to the Maintenance Schedule to determine when

to check your brake fluid. SeeScheduled Maintenance

(Gasoline Engine) on page 6-4.

5-35

Page 291 of 394

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the remote positive (+) terminal cover to its

original position.

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are two additional systems that

need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeeScheduled

Maintenance (Gasoline Engine) on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If the level is below the bottom of the filler plug hole,

you’ll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the filler plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants (Gasoline Engine) on page 6-13.

5-43

Page 292 of 394

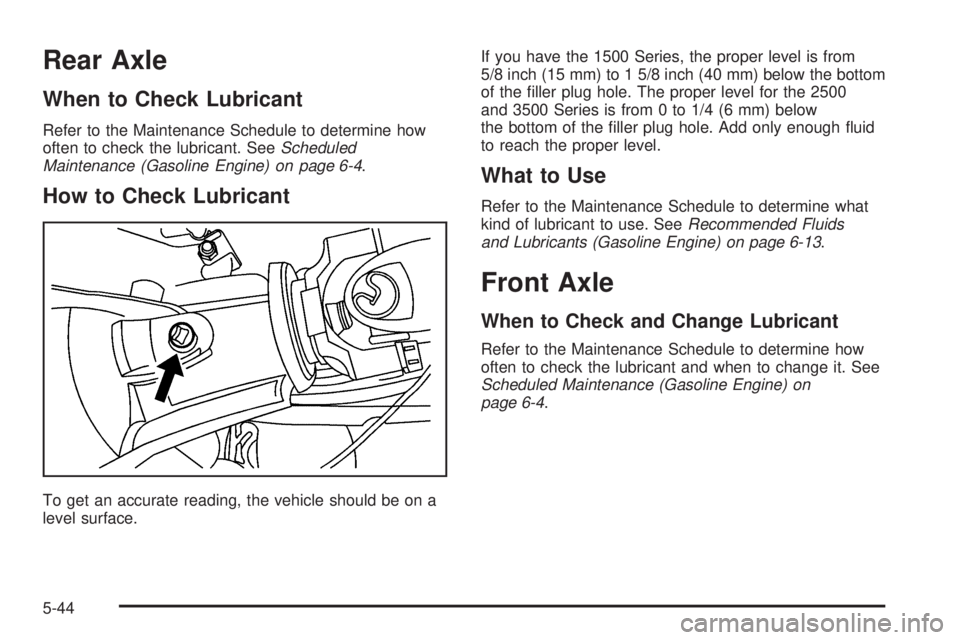

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeeScheduled

Maintenance (Gasoline Engine) on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.If you have the 1500 Series, the proper level is from

5/8 inch (15 mm) to 1 5/8 inch (40 mm) below the bottom

of the filler plug hole. The proper level for the 2500

and 3500 Series is from 0 to 1/4 (6 mm) below

the bottom of the filler plug hole. Add only enough fluid

to reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants (Gasoline Engine) on page 6-13.

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Scheduled Maintenance (Gasoline Engine) on

page 6-4.

5-44

Page 293 of 394

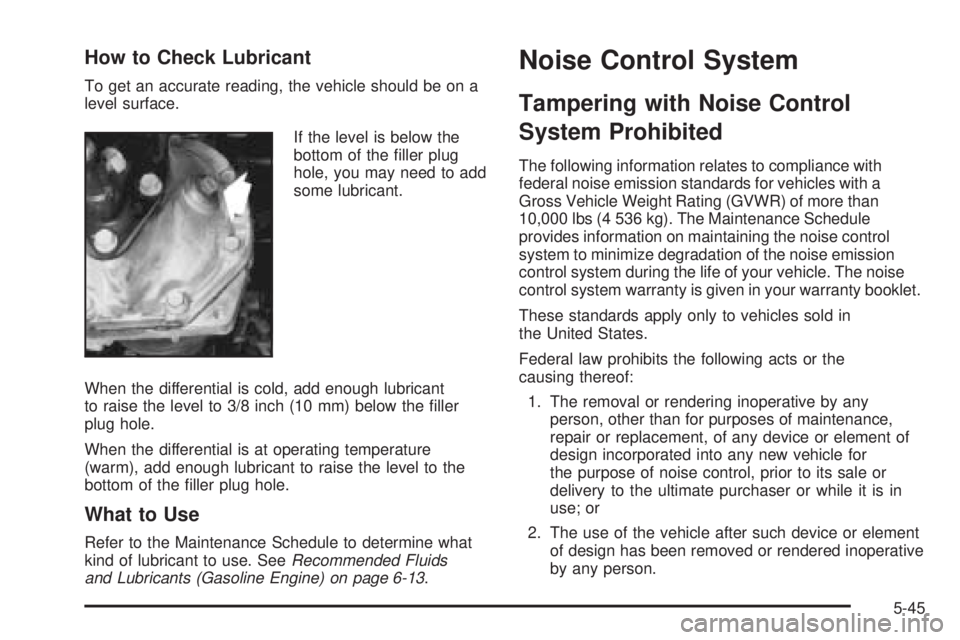

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the

bottom of the filler plug

hole, you may need to add

some lubricant.

When the differential is cold, add enough lubricant

to raise the level to 3/8 inch (10 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids

and Lubricants (Gasoline Engine) on page 6-13.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with a

Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty booklet.

These standards apply only to vehicles sold in

the United States.

Federal law prohibits the following acts or the

causing thereof:

1. The removal or rendering inoperative by any

person, other than for purposes of maintenance,

repair or replacement, of any device or element of

design incorporated into any new vehicle for

the purpose of noise control, prior to its sale or

delivery to the ultimate purchaser or while it is in

use; or

2. The use of the vehicle after such device or element

of design has been removed or rendered inoperative

by any person.

5-45

Page 299 of 394

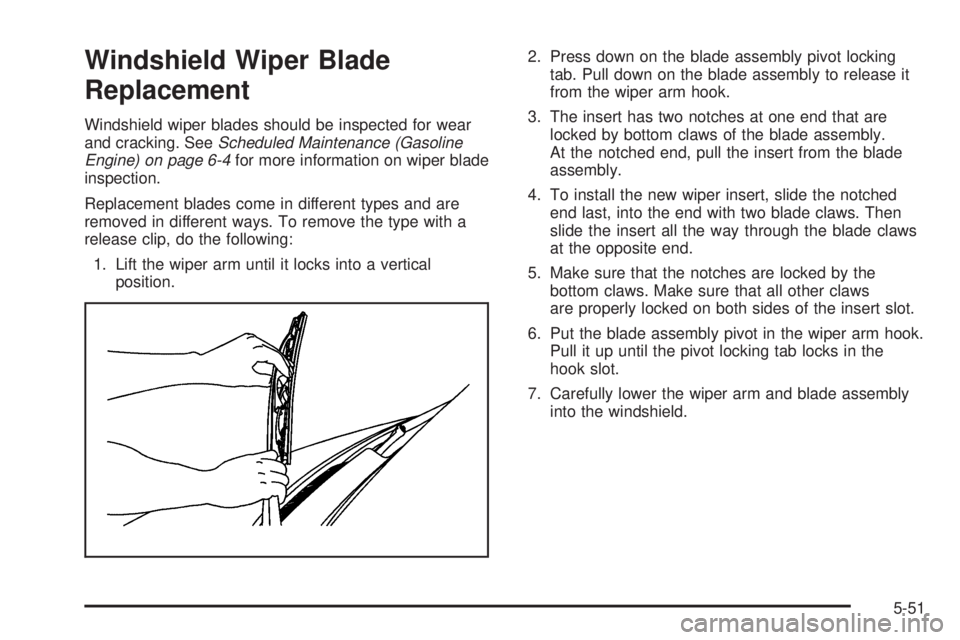

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

and cracking. SeeScheduled Maintenance (Gasoline

Engine) on page 6-4for more information on wiper blade

inspection.

Replacement blades come in different types and are

removed in different ways. To remove the type with a

release clip, do the following:

1. Lift the wiper arm until it locks into a vertical

position.2. Press down on the blade assembly pivot locking

tab. Pull down on the blade assembly to release it

from the wiper arm hook.

3. The insert has two notches at one end that are

locked by bottom claws of the blade assembly.

At the notched end, pull the insert from the blade

assembly.

4. To install the new wiper insert, slide the notched

end last, into the end with two blade claws. Then

slide the insert all the way through the blade claws

at the opposite end.

5. Make sure that the notches are locked by the

bottom claws. Make sure that all other claws

are properly locked on both sides of the insert slot.

6. Put the blade assembly pivot in the wiper arm hook.

Pull it up until the pivot locking tab locks in the

hook slot.

7. Carefully lower the wiper arm and blade assembly

into the windshield.

5-51