engine GMC SAVANA 2008 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2008, Model line: SAVANA, Model: GMC SAVANA 2008Pages: 402, PDF Size: 2.45 MB

Page 276 of 402

Brakes

Brake Fluid

The brake master cylinder

reservoir is filled with

DOT-3 brake fluid. See

Engine Compartment

Overview on page 5-14

for the location of the

reservoir.

There are only two reasons why the brake fluid level in

the reservoir might go down. The first is that the brake

fluid goes down to an acceptable level during normal

brake lining wear. When new linings are put in, the fluid

level goes back up. The other reason is that fluid is

leaking out of the brake hydraulic system. If it is, you

should have the brake hydraulic system fixed, since a

leak means that sooner or later the brakes will not

work well.It is not a good idea to top off the brake fluid. Adding

brake fluid will not correct a leak. If fluid is added when

the linings are worn, there will be too much fluid when

new brake linings are installed. Add or remove brake

fluid, as necessary, only when work is done on the brake

hydraulic system.

{CAUTION:

If you have too much brake �uid, it can spill on

the engine and/or fuel operated heater parts, if

equipped. If your vehicle has a diesel engine

and a fuel operated heater, see “Fuel Operated

Heater (FOH)” in the diesel engine supplement.

The �uid will burn if the engine is hot enough.

You or others could be burned, and your

vehicle could be damaged. Add brake �uid only

when work is done on the brake hydraulic

system. See “Checking Brake Fluid” in this

section.

Refer to the Maintenance Schedule to determine when

to check the brake fluid. SeeScheduled Maintenance

on page 6-4.

5-36

Page 277 of 402

Checking Brake Fluid

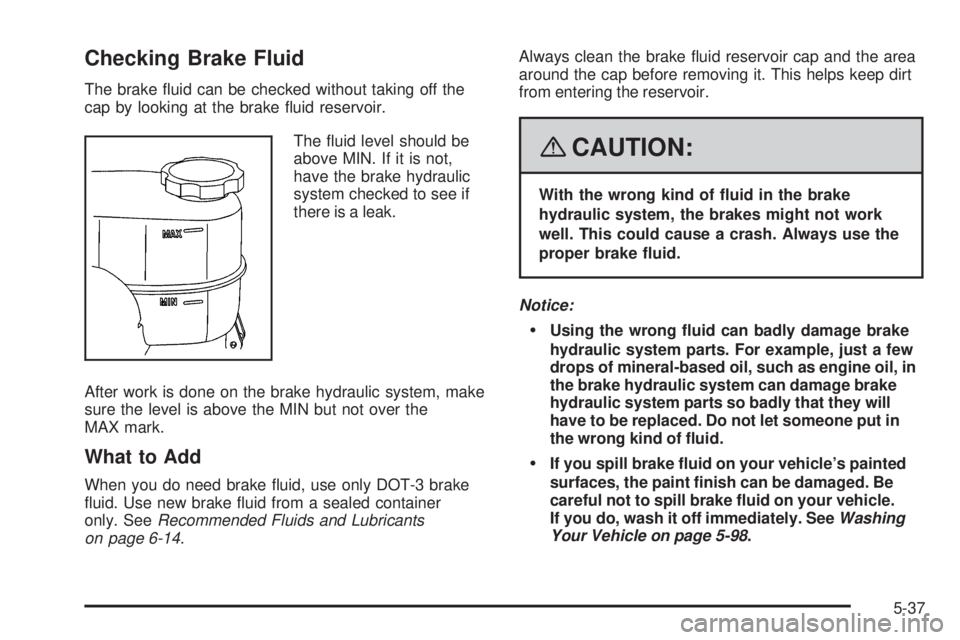

The brake fluid can be checked without taking off the

cap by looking at the brake fluid reservoir.

The fluid level should be

above MIN. If it is not,

have the brake hydraulic

system checked to see if

there is a leak.

After work is done on the brake hydraulic system, make

sure the level is above the MIN but not over the

MAX mark.

What to Add

When you do need brake fluid, use only DOT-3 brake

fluid. Use new brake fluid from a sealed container

only. SeeRecommended Fluids and Lubricants

on page 6-14.Always clean the brake fluid reservoir cap and the area

around the cap before removing it. This helps keep dirt

from entering the reservoir.

{CAUTION:

With the wrong kind of �uid in the brake

hydraulic system, the brakes might not work

well. This could cause a crash. Always use the

proper brake �uid.

Notice:

Using the wrong �uid can badly damage brake

hydraulic system parts. For example, just a few

drops of mineral-based oil, such as engine oil, in

the brake hydraulic system can damage brake

hydraulic system parts so badly that they will

have to be replaced. Do not let someone put in

the wrong kind of �uid.

If you spill brake �uid on your vehicle’s painted

surfaces, the paint �nish can be damaged. Be

careful not to spill brake �uid on your vehicle.

If you do, wash it off immediately. SeeWashing

Your Vehicle on page 5-98.

5-37

Page 279 of 402

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together if

the vehicle is to have really good braking. Your vehicle

was designed and tested with top-quality brake parts.

When you replace parts of the braking system — for

example, when the brake linings wear down and you

need new ones put in — be sure you get new approved

replacement parts. If you do not, the brakes might not

work properly. For example, if someone puts in brake

linings that are wrong for your vehicle, the balance

between the front and rear brakes can change — for the

worse. The braking performance you have come to

expect can change in many other ways if someone puts

in the wrong replacement brake parts.

Battery

Your vehicle has a maintenance free battery. When it is

time for a new battery, see your dealer/retailer for one

that has the replacement number shown on the original

battery’s label. SeeEngine Compartment Overview on

page 5-14for battery location.

Warning:Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

Vehicle Storage

{CAUTION:

Batteries have acid that can burn you and gas

that can explode. You can be badly hurt if you

are not careful. SeeJump Starting on page 5-40

for tips on working around a battery without

getting hurt.

Infrequent Usage: If you drive your vehicle infrequently,

remove the black, negative (−) cable from the battery.

This will help keep the battery from running down.

Extended Storage: For extended storage of your vehicle,

remove the black, negative (−) cable from the battery or

use a battery trickle charger. This will help maintain the

charge of the battery over an extended period of time.

5-39

Page 281 of 402

4. Open the hoods and locate the positive (+) and

negative (−) terminal locations of the other vehicle.

Your vehicle has a remote positive (+) jump starting

terminal and a remote negative (−) jump starting

terminal. You should always use these remote

terminals instead of the terminals on the battery.

The remote positive (+) terminal is located behind

a red plastic cover near the engine accessory

drive bracket on the driver’s side of the engine

compartment, below the alternator. To uncover

the remote positive (+) terminal, open the red

plastic cover.

The remote negative (−) terminal is located on the

engine drive bracket on all V8 engines and is

marked GND (Ground).

On V6 engines the remote negative (−) terminal is

located on a tab attached to the engine accessory

drive bracket and is marked GND (Ground).

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

�ashlight if you need more light.

CAUTION: (Continued)

CAUTION: (Continued)

Be sure the battery has enough water. You do

not need to add water to the battery installed

in your new vehicle. But if a battery has �ller

caps, be sure the right amount of �uid is there.

If it is low, add water to take care of that �rst.

If you do not, explosive gas could be present.

Battery �uid contains acid that can burn you.

Do not get it on you. If you accidentally get it

in your eyes or on your skin, �ush the place

with water and get medical help immediately.

{CAUTION:

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

parts once the engine is running.

5-41

Page 282 of 402

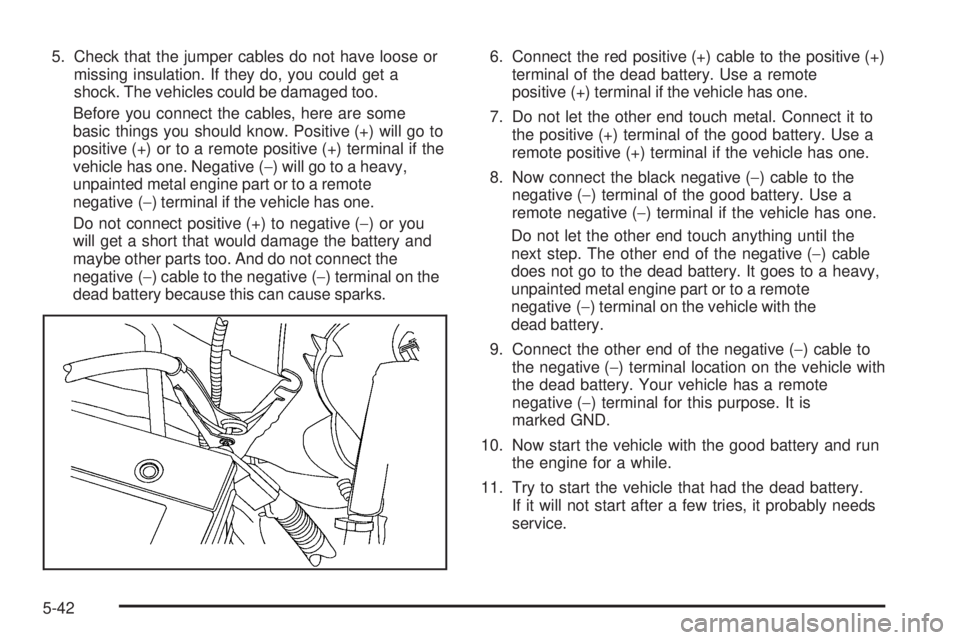

5. Check that the jumper cables do not have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if the

vehicle has one. Negative (−) will go to a heavy,

unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−)oryou

will get a short that would damage the battery and

maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on the

dead battery because this can cause sparks.6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.

8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does not go to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative (−) terminal on the vehicle with the

dead battery.

9. Connect the other end of the negative (−) cable to

the negative (−) terminal location on the vehicle with

the dead battery. Your vehicle has a remote

negative (−) terminal for this purpose. It is

marked GND.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

service.

5-42

Page 283 of 402

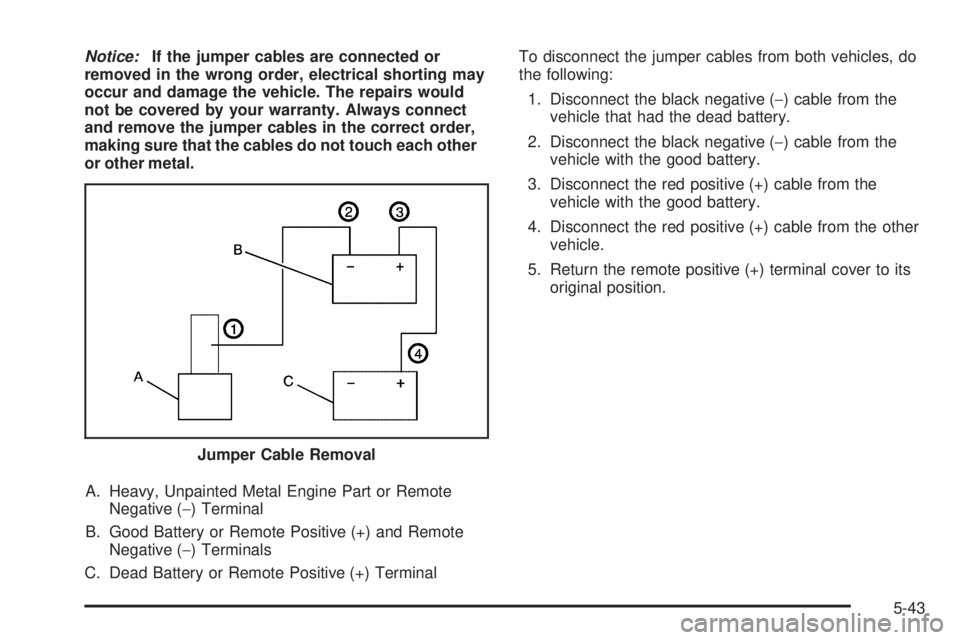

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by your warranty. Always connect

and remove the jumper cables in the correct order,

making sure that the cables do not touch each other

or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the remote positive (+) terminal cover to its

original position.

Jumper Cable Removal

5-43

Page 287 of 402

Among those acts presumed to constitute tampering are

the acts listed below.

Insulation:

•

Removal of the noise shields or any underhood

insulation.

Engine:

•

Removal or rendering engine speed governor, if the

vehicle has one, inoperative so as to allow engine

speed to exceed manufacturer specifications.

Fan and Drive:

•

Removal of fan clutch, if the vehicle has one, or

rendering clutch inoperative.

•Removal of the fan shroud, if the vehicle has one.

Air Intake:

•

Removal of the air cleaner silencer.

•Modification of the air cleaner.

Exhaust:

•

Removal of the muffler and/or resonator.

•Removal of the exhaust pipes and exhaust pipe

clamps.

Fuel Operated Heater (FOH) — Diesel

Engine:

•

Removal of the muffler.

5-47

Page 296 of 402

(G) Single Tire Maximum Load:Maximum load

that can be carried and the maximum pressure

needed to support that load when used as a

single. For information on recommended tire

pressure seeInflation - Tire Pressure on page 5-60

andLoading Your Vehicle on page 4-20.

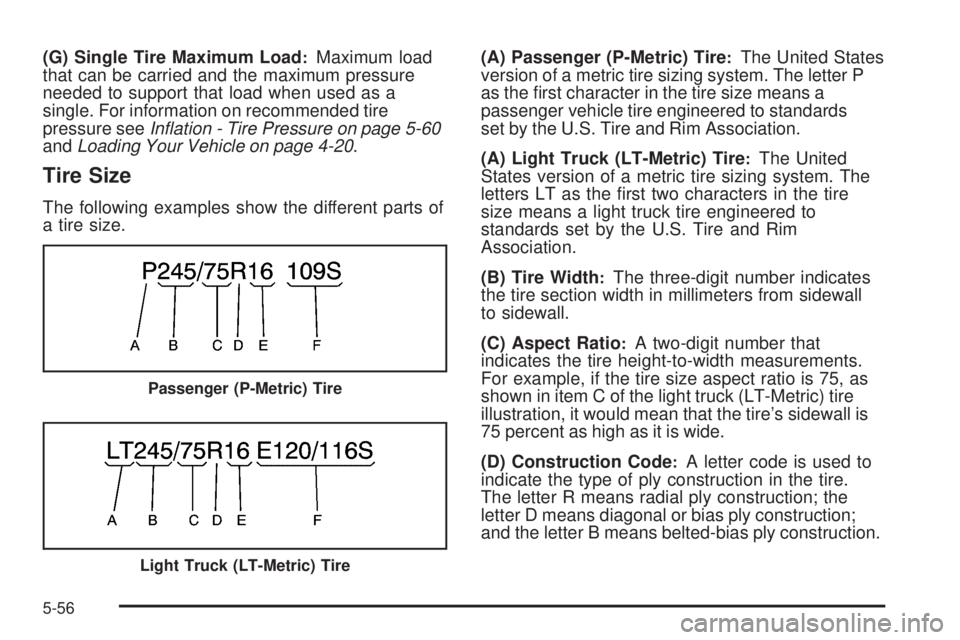

Tire Size

The following examples show the different parts of

a tire size.(A) Passenger (P-Metric) Tire

:The United States

version of a metric tire sizing system. The letter P

as the first character in the tire size means a

passenger vehicle tire engineered to standards

set by the U.S. Tire and Rim Association.

(A) Light Truck (LT-Metric) Tire

:The United

States version of a metric tire sizing system. The

letters LT as the first two characters in the tire

size means a light truck tire engineered to

standards set by the U.S. Tire and Rim

Association.

(B) Tire Width

:The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

(C) Aspect Ratio

:A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is 75, as

shown in item C of the light truck (LT-Metric) tire

illustration, it would mean that the tire’s sidewall is

75 percent as high as it is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire.

The letter R means radial ply construction; the

letter D means diagonal or bias ply construction;

and the letter B means belted-bias ply construction.

Passenger (P-Metric) Tire

Light Truck (LT-Metric) Tire

5-56

Page 306 of 402

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you rotate your vehicle’s tires or replace one or

more of the TPMS sensors, the identification codes will

need to be matched to the new tire/wheel position. The

sensors are matched to the tire/wheel positions in the

following order: driver side front tire, passenger side front

tire, passenger side rear tire, and driver side rear tire

using a TPMS diagnostic tool. See your dealer/retailer

for service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the tire’s

air pressure. If increasing the tire’s air pressure, do not

exceed the maximum inflation pressure indicated on the

tire’s sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gage, or a key.You have two minutes to match the first tire/wheel

position, and five minutes overall to match all

four tire/wheel positions. If it takes longer than

two minutes, to match the first tire and wheel, or more

than five minutes to match all four tire and wheel

positions the matching process stops and you need to

start over.

The TPMS sensor matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the

engine off.

3. Press the Remote Keyless Entry (RKE) transmitter’s

LOCK and UNLOCK buttons at the same time for

approximately five seconds. The horn sounds twice

to signal the receiver is in relearn mode and

TIRE LEARNING ACTIVE message displays on the

DIC screen.

5-66

Page 318 of 402

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your vehicle’s

hazard warning flashers. SeeHazard Warning Flashers

on page 3-6for more information.

{CAUTION:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you

or other people. You and they could be badly

injured or even killed. Find a level place to

change your tire. To help prevent the vehicle

from moving:

1. Set the parking brake �rmly.

2. Put the shift lever in PARK (P).

CAUTION: (Continued)

CAUTION: (Continued)

3. Turn off the engine and do not restart

while the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

To be even more certain the vehicle will not

move, you should put blocks at the front and

rear of the tire farthest away from the one

being changed. That would be the tire, on the

other side, at the opposite end of the vehicle.

When your vehicle has a flat tire, use the following

example as a guide to assist you in the placement of

wheel blocks.

5-78