engine coolant GMC SIERRA 2010 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA, Model: GMC SIERRA 2010Pages: 630, PDF Size: 4.65 MB

Page 482 of 630

If No Steam Is Coming From The

Engine Compartment

The ENGINE OVERHEATED STOP ENGINE or the

ENGINE OVERHEATED IDLE ENGINE message, along

with a low coolant condition, can indicate a serious

problem.

If you get an engine overheat warning, but see or hear

no steam, the problem may not be too serious.

Sometimes the engine can get a little too hot when you:

.Climb a long hill on a hot day.

.Stop after high-speed driving.

.Idle for long periods in traffic.

.Tow a trailer. SeeTowing a Trailer on page 5‑50.

If you get the ENGINE OVERHEATED STOP ENGINE

or the ENGINE OVERHEATED IDLE ENGINE message

with no sign of steam, try this for a minute or so: 1. Turn the air conditioning off.

2. Turn the heater on to the highest temperature and to the highest fan speed. Open the windows as

necessary.

3. If you are stopped in a traffic jam, apply the brake, shift to N (Neutral); otherwise, shift to the highest

gear while driving —D (Drive) or 3 (Third). If the temperature overheat gage is no longer in the

overheat zone or an overheat warning no longer

displays, the vehicle can be driven. Continue to drive

the vehicle slow for about 10 minutes. Keep a safe

vehicle distance from the car in front of you. If the

warning does not come back on, continue to drive

normally.

If the warning continues, pull over, stop, and park the

vehicle right away.

If there is no sign of steam, idle the engine for

five minutes while parked. If the warning is still

displayed, turn off the engine until it cools down. Also,

see

“Overheated Engine Protection Operating Mode”

later in this section.

Overheated Engine Protection

Operating Mode

If an overheated engine condition exists and the

REDUCED ENGINE POWER message is displayed, an

overheat protection mode which alternates firing groups

of cylinders helps prevent engine damage. In this mode,

you will notice a loss in power and engine performance.

This operating mode allows the vehicle to be driven to a

safe place in an emergency. Driving extended

miles (km) and/or towing a trailer in the overheat

protection mode should be avoided.

6-36

Page 483 of 630

Notice:After driving in the overheated engine

protection operating mode, to avoid engine damage,

allow the engine to cool before attempting any

repair. The engine oil will be severely degraded.

Repair the cause of coolant loss, change the oil and

reset the oil life system. See Engine Oil

on

page 6‑18.

Engine Fan Noise

If the vehicle has a clutched engine cooling fan, when

the clutch is engaged, the fan spins faster to provide

more air to cool the engine. In most everyday driving

conditions, the fan is spinning slower and the clutch is

not fully engaged. This improves fuel economy and

reduces fan noise. Under heavy vehicle loading, trailer

towing, and/or high outside temperatures, the fan speed

increases as the clutch more fully engages, so you may

hear an increase in fan noise. This is normal and should

not be mistaken as the transmission slipping or making

extra shifts. It is merely the cooling system functioning

properly. The fan will slow down when additional cooling

is not required and the clutch disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch partially

disengages.

If the vehicle has electric cooling fans, you may hear

the fans spinning at low speed during most everyday

driving. The fans may turn off if no cooling is required. Under heavy vehicle loading, trailer towing, and/or high

outside temperatures, or if you are operating the air

conditioning system, the fans may change to high

speed and you may hear an increase in fan noise.

This is normal and indicates that the cooling system is

functioning properly. The fans will change to low speed

when additional cooling is no longer required.

Power Steering Fluid

See

Engine Compartment

Overviewon page 6‑16for reservoir location.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering

fluid unless you suspect there is a leak in the system or

you hear an unusual noise. A fluid loss in this system

could indicate a problem. Have the system inspected

and repaired.

6-37

Page 485 of 630

Notice:

.When using concentrated washer fluid,

follow the manufacturer's instructions for

adding water.

.Do not mix water with ready-to-use washer

fluid. Water can cause the solution to freeze

and damage the washer fluid tank and other

parts of the washer system. Also, water does

not clean as well as washer fluid.

.Fill the washer fluid tank only three-quarters

full when it is very cold. This allows for fluid

expansion if freezing occurs, which could

damage the tank if it is completely full.

.Do not use engine coolant (antifreeze) in the

windshield washer. It can damage the

vehicle's windshield washer system and

paint.

Brakes

Brake Fluid

The brake master cylinder

reservoir is filled with DOT

3 brake fluid. SeeEngine

Compartment Overview

on page 6‑16for the

location of the reservoir.

There are only two reasons why the brake fluid level in

the reservoir might go down:

.The brake fluid level goes down because of

normal brake lining wear. When new linings are

installed, the fluid level goes back up.

.A fluid leak in the brake hydraulic system can also

cause a low fluid level. Have the brake hydraulic

system fixed, since a leak means that sooner or

later the brakes will not work well.

6-39

Page 578 of 630

When the Change Engine Oil Soon message

displays, certain services, checks, and inspections are

required. The services described for MaintenanceI

should be performed at every engine oil change.

The services described for Maintenance IIshould be

performed when:

.Maintenance Iwas performed the last time the

engine oil was changed.

.It has been 10 months or more since the Change

Engine Oil Soon message has displayed or since

the last service.

Maintenance I

.Change engine oil and filter. See Engine Oilon

page 6‑18. An Emission Control Service.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑72.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

.Rotate tires. See Tire Inspection and Rotationon

page 6‑80.

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system

must be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles

driven in dusty conditions only). See Engine Air

Cleaner/Filter on page 6‑21.

.Brake system inspection (or every 12 months,

whichever occurs first).

.For vehicles with Allison Transmission®only:

At the first engine oil change only, replace external

transmission filter.

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm

ball joints on 2500/3500 series vehicles require

lubrication but should not be lubricated unless their

temperature is−12°C (10°F) or higher, or they

could be damaged. Control arm ball joints on

1500 series vehicles are maintenance‐free.

Vehicles used under severe commercial operating

conditions require lubrication on a regular basis

every 5 000 km/3,000 miles.

7-4

Page 579 of 630

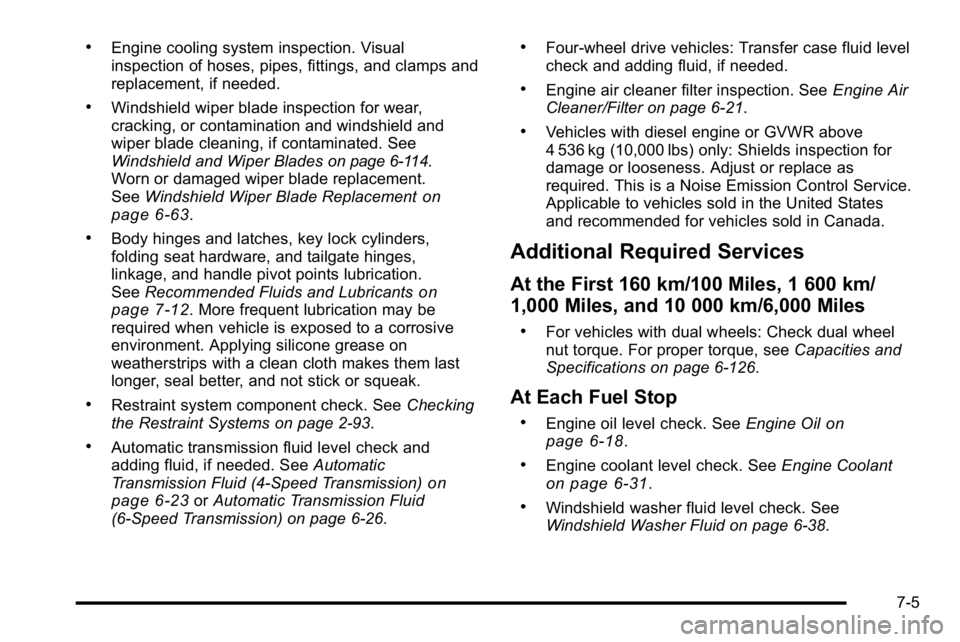

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps and

replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑114.

Worn or damaged wiper blade replacement.

See Windshield Wiper Blade Replacement

on

page 6‑63.

.Body hinges and latches, key lock cylinders,

folding seat hardware, and tailgate hinges,

linkage, and handle pivot points lubrication.

See Recommended Fluids and Lubricants

on

page 7‑12. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑93.

.Automatic transmission fluid level check and

adding fluid, if needed. See Automatic

Transmission Fluid (4-Speed Transmission)

on

page 6‑23or Automatic Transmission Fluid

(6-Speed Transmission) on page 6‑26.

.Four‐wheel drive vehicles: Transfer case fluid level

check and adding fluid, if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑21.

.Vehicles with diesel engine or GVWR above

4 536 kg (10,000 lbs) only: Shields inspection for

damage or looseness. Adjust or replace as

required. This is a Noise Emission Control Service.

Applicable to vehicles sold in the United States

and recommended for vehicles sold in Canada.

Additional Required Services

At the First 160 km/100 Miles, 1 600 km/

1,000 Miles, and 10 000 km/6,000 Miles

.For vehicles with dual wheels: Check dual wheel

nut torque. For proper torque, see Capacities and

Specifications on page 6‑126.

At Each Fuel Stop

.Engine oil level check. See Engine Oilon

page 6‑18.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

7-5

Page 582 of 630

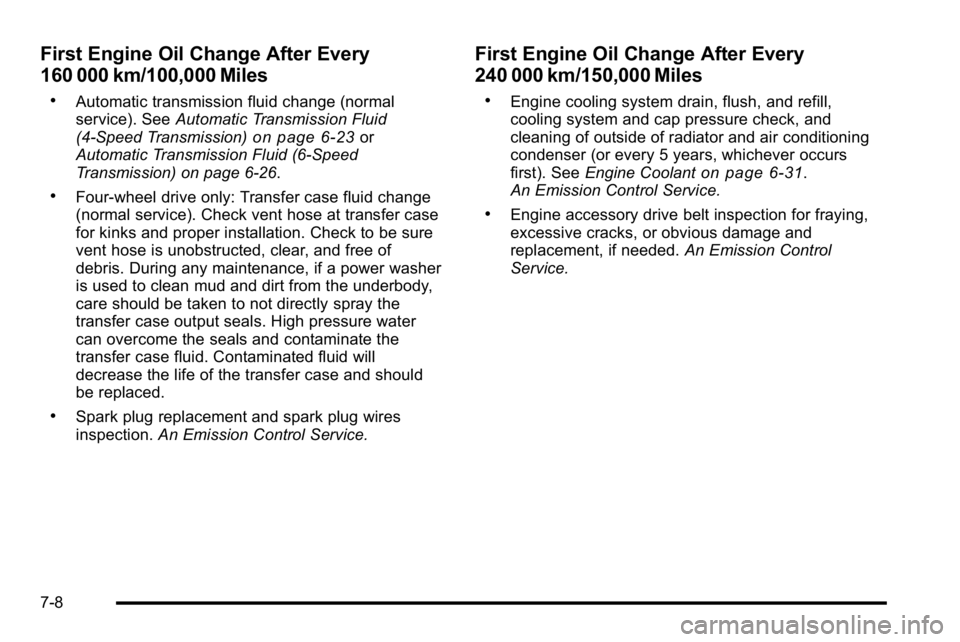

First Engine Oil Change After Every

160 000 km/100,000 Miles

.Automatic transmission fluid change (normal

service). SeeAutomatic Transmission Fluid

(4-Speed Transmission)

on page 6‑23or

Automatic Transmission Fluid (6-Speed

Transmission) on page 6‑26.

.Four‐wheel drive only: Transfer case fluid change

(normal service). Check vent hose at transfer case

for kinks and proper installation. Check to be sure

vent hose is unobstructed, clear, and free of

debris. During any maintenance, if a power washer

is used to clean mud and dirt from the underbody,

care should be taken to not directly spray the

transfer case output seals. High pressure water

can overcome the seals and contaminate the

transfer case fluid. Contaminated fluid will

decrease the life of the transfer case and should

be replaced.

.Spark plug replacement and spark plug wires

inspection. An Emission Control Service.

First Engine Oil Change After Every

240 000 km/150,000 Miles

.Engine cooling system drain, flush, and refill,

cooling system and cap pressure check, and

cleaning of outside of radiator and air conditioning

condenser (or every 5 years, whichever occurs

first). SeeEngine Coolant

on page 6‑31.

An Emission Control Service.

.Engine accessory drive belt inspection for fraying,

excessive cracks, or obvious damage and

replacement, if needed. An Emission Control

Service.

7-8

Page 583 of 630

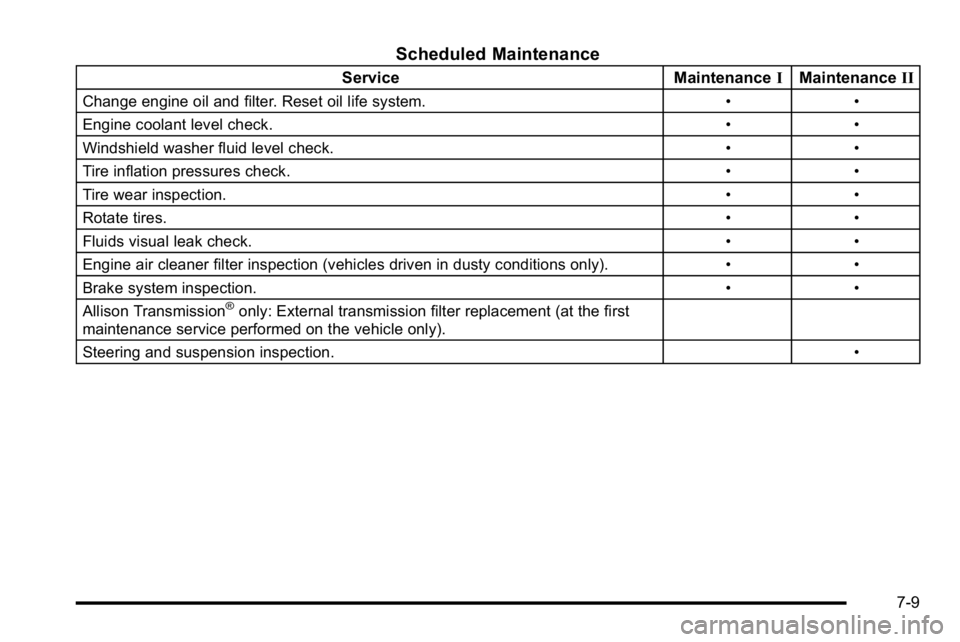

Scheduled Maintenance

ServiceMaintenanceIMaintenance II

Change engine oil and filter. Reset oil life system. ••

Engine coolant level check. ••

Windshield washer fluid level check. ••

Tire inflation pressures check. ••

Tire wear inspection. ••

Rotate tires. ••

Fluids visual leak check. ••

Engine air cleaner filter inspection (vehicles driven in dusty conditions only). ••

Brake system inspection. ••

Allison Transmission

®only: External transmission filter replacement (at the first

maintenance service performed on the vehicle only).

Steering and suspension inspection. •

7-9

Page 587 of 630

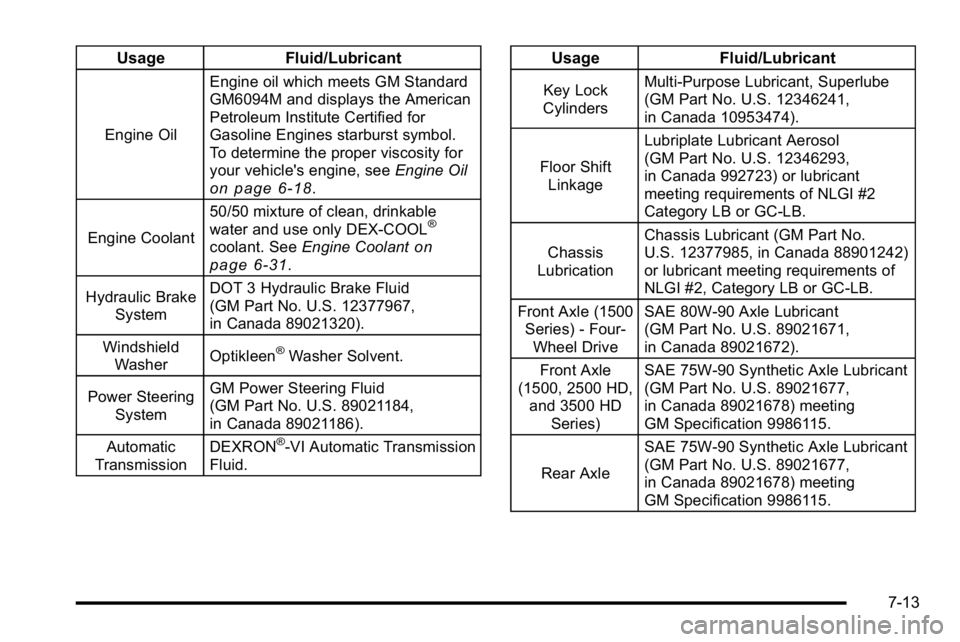

UsageFluid/Lubricant

Engine OilEngine oil which meets GM Standard

GM6094M and displays the American

Petroleum Institute Certified for

Gasoline Engines starburst symbol.

To determine the proper viscosity for

your vehicle's engine, see

Engine Oil

on page 6‑18.

Engine Coolant 50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

coolant. See

Engine Coolanton

page 6‑31.

Hydraulic Brake System DOT 3 Hydraulic Brake Fluid

(GM Part No. U.S. 12377967,

in Canada 89021320).

Windshield Washer Optikleen

®Washer Solvent.

Power Steering System GM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

Transmission DEXRON

®-VI Automatic Transmission

Fluid.

Usage Fluid/Lubricant

Key Lock

Cylinders Multi-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Floor Shift Linkage Lubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2

Category LB or GC-LB.

Chassis

Lubrication Chassis Lubricant (GM Part No.

U.S. 12377985, in Canada 88901242)

or lubricant meeting requirements of

NLGI #2, Category LB or GC-LB.

Front Axle (1500 Series) ‐Four‐

Wheel Drive SAE 80W-90 Axle Lubricant

(GM Part No. U.S. 89021671,

in Canada 89021672).

Front Axle

(1500, 2500 HD, and 3500 HD Series) SAE 75W-90 Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Specification 9986115.

Rear Axle SAE 75W-90 Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Specification 9986115.

7-13

Page 618 of 630

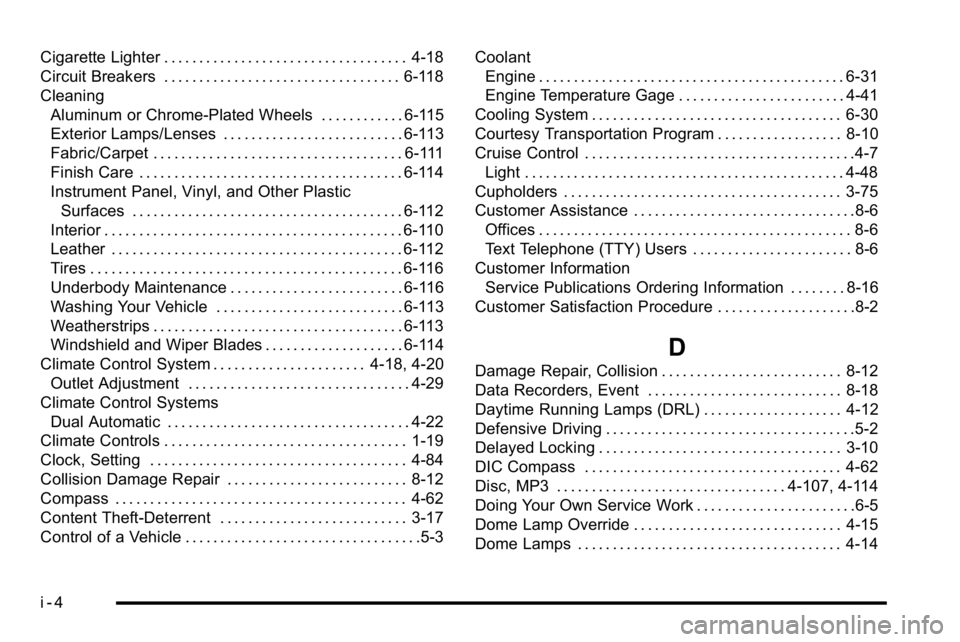

Cigarette Lighter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-118

CleaningAluminum or Chrome-Plated Wheels . . . . . . . . . . . . 6-115

Exterior Lamps/Lenses . . . . . . . . . . . . . . . . . . . . . . . . . . 6-113

Fabric/Carpet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-111

Finish Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-114

Instrument Panel, Vinyl, and Other PlasticSurfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-112

Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-110

Leather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-112

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-116

Underbody Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 6-116

Washing Your Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-113

Weatherstrips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-113

Windshield and Wiper Blades . . . . . . . . . . . . . . . . . . . . 6-114

Climate Control System . . . . . . . . . . . . . . . . . . . . . . 4-18, 4-20 Outlet Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Climate Control Systems Dual Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Climate Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Clock, Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

Collision Damage Repair . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Content Theft-Deterrent . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Control of a Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3 Coolant

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Engine Temperature Gage . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Courtesy Transportation Program . . . . . . . . . . . . . . . . . . 8-10

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7 Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Cupholders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

Customer Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6 Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Text Telephone (TTY) Users . . . . . . . . . . . . . . . . . . . . . . . 8-6

Customer Information Service Publications Ordering Information . . . . . . . . 8-16

Customer Satisfaction Procedure . . . . . . . . . . . . . . . . . . . .8-2

D

Damage Repair, Collision . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Data Recorders, Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Daytime Running Lamps (DRL) . . . . . . . . . . . . . . . . . . . . 4-12

Defensive Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Delayed Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

DIC Compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Disc, MP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-107, 4-114

Doing Your Own Service Work . . . . . . . . . . . . . . . . . . . . . . .6-5

Dome Lamp Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Dome Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

i - 4

Page 620 of 630

Engine (cont.)Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Coolant Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Coolant Temperature Gage . . . . . . . . . . . . . . . . . . . . . . . 4-41

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Drive Belt Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

Fan Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Fast Idle System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Overheated Protection Operating Mode . . . . . . . . . . 6-36

Overheating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Engine Oil

Life System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Entry Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Event Data Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Exit Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Extender, Safety Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Exterior Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10F

Fast Idle System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Filter Engine Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Finish Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-116

Fixed Mast Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-149

Flash-to-Pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Flashers, Hazard Warning . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Flat Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-89

Flat Tire, Changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-90

Flat Tire, Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-106

Fluid Automatic Transmission . . . . . . . . . . . . . . . . . . . . 6-23, 6-26

Power Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Windshield Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Fog Lamps

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Four-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36, 6-50

Four-Wheel-Drive Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

i - 6