Section 7 GMC SIERRA 2010 Repair Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA, Model: GMC SIERRA 2010Pages: 630, PDF Size: 4.65 MB

Page 482 of 630

If No Steam Is Coming From The

Engine Compartment

The ENGINE OVERHEATED STOP ENGINE or the

ENGINE OVERHEATED IDLE ENGINE message, along

with a low coolant condition, can indicate a serious

problem.

If you get an engine overheat warning, but see or hear

no steam, the problem may not be too serious.

Sometimes the engine can get a little too hot when you:

.Climb a long hill on a hot day.

.Stop after high-speed driving.

.Idle for long periods in traffic.

.Tow a trailer. SeeTowing a Trailer on page 5‑50.

If you get the ENGINE OVERHEATED STOP ENGINE

or the ENGINE OVERHEATED IDLE ENGINE message

with no sign of steam, try this for a minute or so: 1. Turn the air conditioning off.

2. Turn the heater on to the highest temperature and to the highest fan speed. Open the windows as

necessary.

3. If you are stopped in a traffic jam, apply the brake, shift to N (Neutral); otherwise, shift to the highest

gear while driving —D (Drive) or 3 (Third). If the temperature overheat gage is no longer in the

overheat zone or an overheat warning no longer

displays, the vehicle can be driven. Continue to drive

the vehicle slow for about 10 minutes. Keep a safe

vehicle distance from the car in front of you. If the

warning does not come back on, continue to drive

normally.

If the warning continues, pull over, stop, and park the

vehicle right away.

If there is no sign of steam, idle the engine for

five minutes while parked. If the warning is still

displayed, turn off the engine until it cools down. Also,

see

“Overheated Engine Protection Operating Mode”

later in this section.

Overheated Engine Protection

Operating Mode

If an overheated engine condition exists and the

REDUCED ENGINE POWER message is displayed, an

overheat protection mode which alternates firing groups

of cylinders helps prevent engine damage. In this mode,

you will notice a loss in power and engine performance.

This operating mode allows the vehicle to be driven to a

safe place in an emergency. Driving extended

miles (km) and/or towing a trailer in the overheat

protection mode should be avoided.

6-36

Page 486 of 630

Do not top off the brake fluid. Adding fluid does not

correct a leak. If fluid is added when the linings are

worn, there will be too much fluid when new brake

linings are installed. Add or remove brake fluid, as

necessary, only when work is done on the brake

hydraulic system.

{WARNING:

If too much brake fluid is added, it can spill on the

engine and burn, if the engine is hot enough. You

or others could be burned, and the vehicle could

be damaged. Add brake fluid only when work is

done on the brake hydraulic system. See

“Checking Brake Fluid”in this section.

Refer to the Maintenance Schedule to determine when

to check the brake fluid. See Scheduled Maintenance

on page 7‑3.

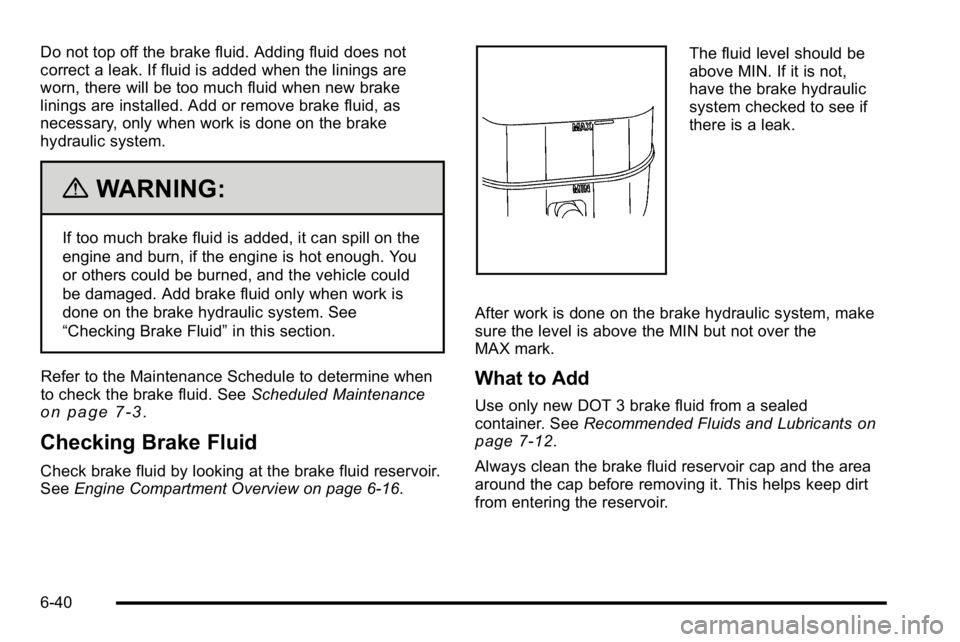

Checking Brake Fluid

Check brake fluid by looking at the brake fluid reservoir.

SeeEngine Compartment Overview on page 6‑16.

The fluid level should be

above MIN. If it is not,

have the brake hydraulic

system checked to see if

there is a leak.

After work is done on the brake hydraulic system, make

sure the level is above the MIN but not over the

MAX mark.

What to Add

Use only new DOT 3 brake fluid from a sealed

container. See Recommended Fluids and Lubricantson

page 7‑12.

Always clean the brake fluid reservoir cap and the area

around the cap before removing it. This helps keep dirt

from entering the reservoir.

6-40

Page 496 of 630

.For all 6.0L and 6.2L 2500HD Series applications,

the proper level is from 0 to 0.5 inches (0 mm to

13 mm) below the bottom of the filler plug hole,

located on the rear axle. Add only enough fluid to

reach the proper level.

.For all 6.6L DURAMAX DIESEL 2500HD Series

applications and all 3500 Series applications, the

proper level is from 0.6 inches to 0.8 inches

(17 mm to 21 mm) below the bottom of the filler

plug hole, located on the rear axle. Add only

enough fluid to reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeeRecommended Fluids and

Lubricants on page 7‑12.

Four-Wheel Drive

Lubricant checks in this section also apply to these

vehicles.

Transfer Case

When to Check Lubricant

It is not necessary to regularly check transfer case fluid

unless you suspect there is a leak, or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

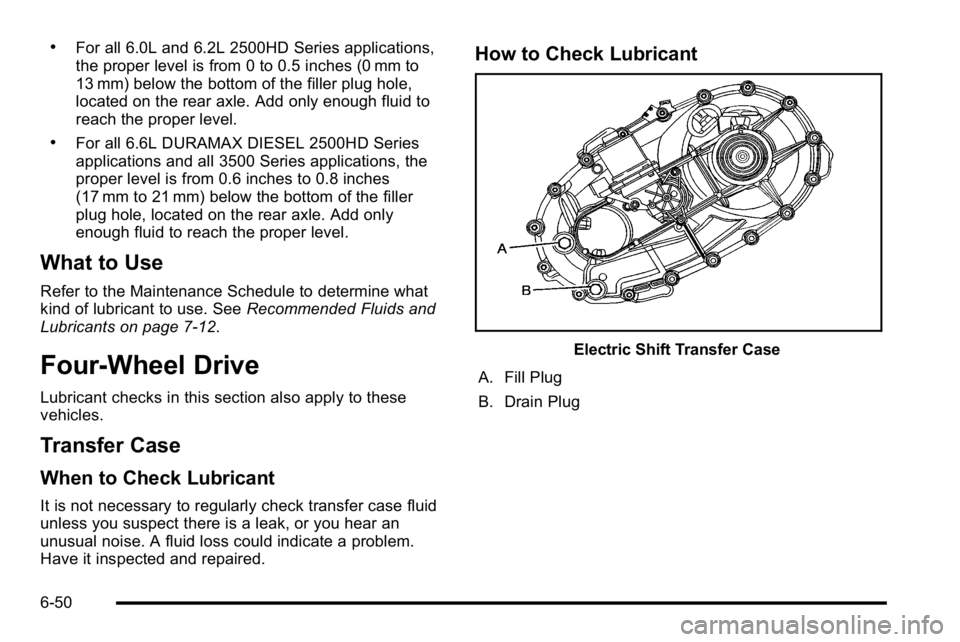

How to Check Lubricant

Electric Shift Transfer Case

A. Fill Plug

B. Drain Plug

6-50

Page 503 of 630

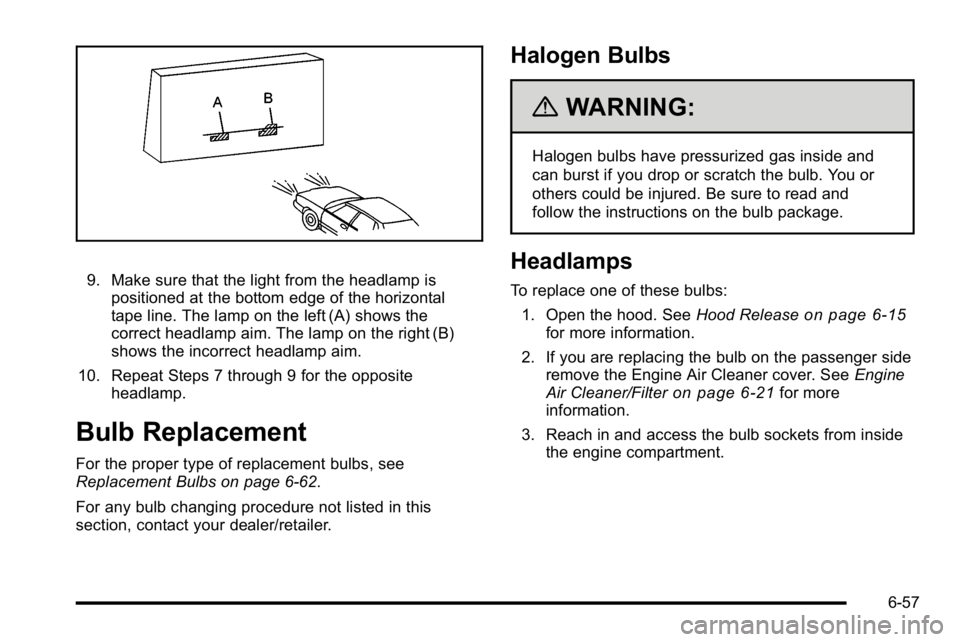

9. Make sure that the light from the headlamp ispositioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows the

correct headlamp aim. The lamp on the right (B)

shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 6‑62.

For any bulb changing procedure not listed in this

section, contact your dealer/retailer.

Halogen Bulbs

{WARNING:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and

follow the instructions on the bulb package.

Headlamps

To replace one of these bulbs:

1. Open the hood. See Hood Release

on page 6‑15for more information.

2. If you are replacing the bulb on the passenger side remove the Engine Air Cleaner cover. See Engine

Air Cleaner/Filter

on page 6‑21for more

information.

3. Reach in and access the bulb sockets from inside the engine compartment.

6-57

Page 511 of 630

Notice:If the vehicle has low‐profile tires, they

are more susceptible to damage from road

hazards or curb impact than standard profile

tires. Tire and/or wheel assembly damage can

occur when coming into contact with road

hazards like, potholes, or sharp edged objects,

or when sliding into a curb. The vehicle

warranty does not cover this type of damage.

Keep tires set to the correct inflation pressure

and, when possible avoid contact with curbs,

potholes, and other road hazards.

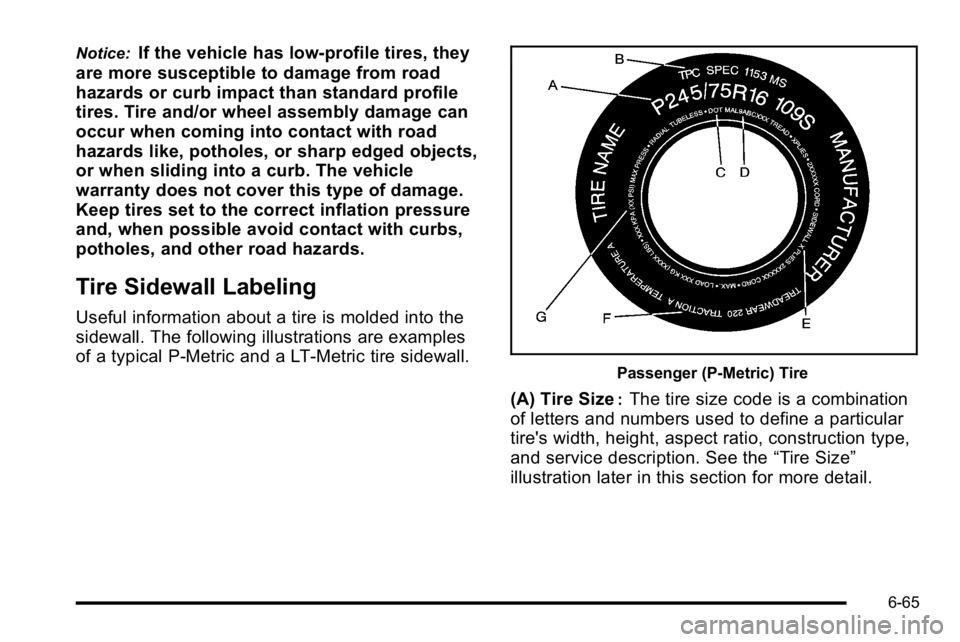

Tire Sidewall Labeling

Useful information about a tire is molded into the

sidewall. The following illustrations are examples

of a typical P‐Metric and a LT‐Metric tire sidewall.

Passenger (P‐Metric) Tire

(A) Tire Size:The tire size code is a combination

of letters and numbers used to define a particular

tire's width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail.

6-65

Page 513 of 630

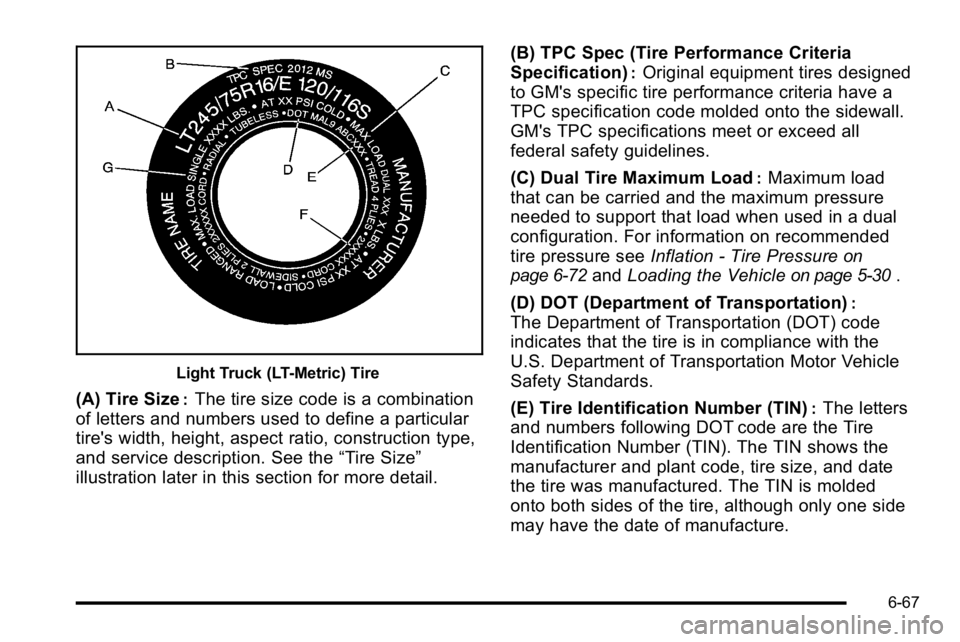

Light Truck (LT-Metric) Tire

(A) Tire Size:The tire size code is a combination

of letters and numbers used to define a particular

tire's width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail. (B) TPC Spec (Tire Performance Criteria

Specification)

:Original equipment tires designed

to GM's specific tire performance criteria have a

TPC specification code molded onto the sidewall.

GM's TPC specifications meet or exceed all

federal safety guidelines.

(C) Dual Tire Maximum Load

:Maximum load

that can be carried and the maximum pressure

needed to support that load when used in a dual

configuration. For information on recommended

tire pressure see Inflation - Tire Pressure

on

page 6‑72

and Loading the Vehicleon page 5‑30.

(D) DOT (Department of Transportation)

:

The Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(E) Tire Identification Number (TIN)

:The letters

and numbers following DOT code are the Tire

Identification Number (TIN). The TIN shows the

manufacturer and plant code, tire size, and date

the tire was manufactured. The TIN is molded

onto both sides of the tire, although only one side

may have the date of manufacture.

6-67

Page 514 of 630

(F) Tire Ply Material:The type of cord and

number of plies in the sidewall and under the

tread.

(G) Single Tire Maximum Load

:Maximum load

that can be carried and the maximum pressure

needed to support that load when used as a

single. For information on recommended tire

pressure see Inflation - Tire Pressure

on page 6‑72

andLoading the Vehicleon page 5‑30.

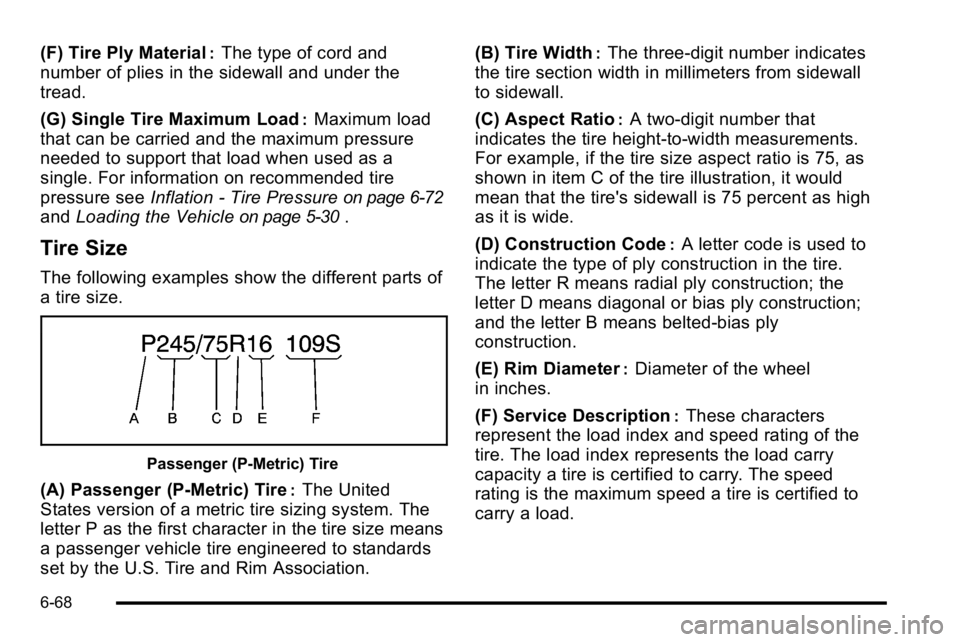

Tire Size

The following examples show the different parts of

a tire size.

Passenger (P‐Metric) Tire

(A) Passenger (P‐Metric) Tire:The United

States version of a metric tire sizing system. The

letter P as the first character in the tire size means

a passenger vehicle tire engineered to standards

set by the U.S. Tire and Rim Association. (B) Tire Width

:The three‐digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

(C) Aspect Ratio

:A two‐digit number that

indicates the tire height‐to‐width measurements.

For example, if the tire size aspect ratio is 75, as

shown in item C of the tire illustration, it would

mean that the tire's sidewall is 75 percent as high

as it is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire.

The letter R means radial ply construction; the

letter D means diagonal or bias ply construction;

and the letter B means belted‐bias ply

construction.

(E) Rim Diameter

:Diameter of the wheel

in inches.

(F) Service Description

:These characters

represent the load index and speed rating of the

tire. The load index represents the load carry

capacity a tire is certified to carry. The speed

rating is the maximum speed a tire is certified to

carry a load.

6-68

Page 515 of 630

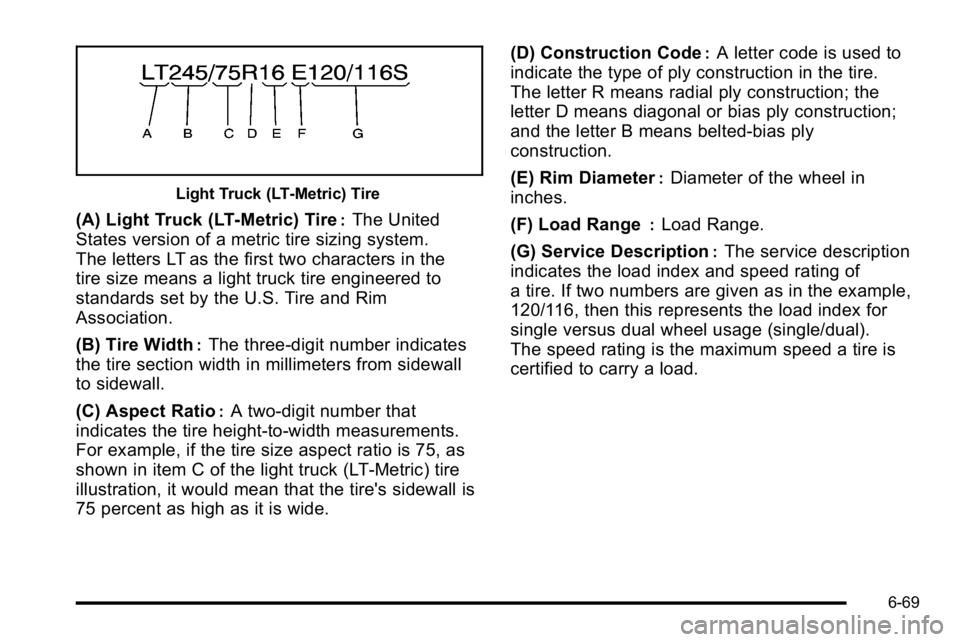

Light Truck (LT‐Metric) Tire

(A) Light Truck (LT‐Metric) Tire:The United

States version of a metric tire sizing system.

The letters LT as the first two characters in the

tire size means a light truck tire engineered to

standards set by the U.S. Tire and Rim

Association.

(B) Tire Width

:The three‐digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

(C) Aspect Ratio

:A two‐digit number that

indicates the tire height‐to‐width measurements.

For example, if the tire size aspect ratio is 75, as

shown in item C of the light truck (LT‐Metric) tire

illustration, it would mean that the tire's sidewall is

75 percent as high as it is wide. (D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire.

The letter R means radial ply construction; the

letter D means diagonal or bias ply construction;

and the letter B means belted‐bias ply

construction.

(E) Rim Diameter

:Diameter of the wheel in

inches.

(F) Load Range

:Load Range.

(G) Service Description

:The service description

indicates the load index and speed rating of

a tire. If two numbers are given as in the example,

120/116, then this represents the load index for

single versus dual wheel usage (single/dual).

The speed rating is the maximum speed a tire is

certified to carry a load.

6-69

Page 523 of 630

The low tire pressure warning light may come on in cool

weather when the vehicle is first started, and then turn

off as you start to drive. This could be an early indicator

that the air pressure in the tire(s) are getting low and

need to be inflated to the proper pressure.

A Tire and Loading Information label, attached to your

vehicle, shows the size of your vehicle's original

equipment tires and the correct inflation pressure for

your vehicle's tires when they are cold. SeeLoading the

Vehicle

on page 5‑30, for an example of the Tire and

Loading Information label and its location on your

vehicle. Also see Inflation - Tire Pressure on page 6‑72.

Your vehicle's TPMS can warn you about a low tire

pressure condition but it does not replace normal tire

maintenance. See Tire Inspection and Rotation

on

page 6‑80and Tires on page 6‑64.

Notice: Liquid tire sealants could damage the Tire

Pressure Monitor System (TPMS) sensors. Sensor

damage caused by using a tire sealant is not

covered by your warranty. Do not use liquid tire

sealants.

TPMS Malfunction Light and Message

The TPMS will not function properly if one or more of

the TPMS sensors are missing or inoperable. When the

system detects a malfunction, the low tire warning light

flashes for about one minute and then stays on for the

remainder of the ignition cycle. A DIC warning message

is also displayed. The low tire warning light and DIC

warning message come on at each ignition cycle until

the problem is corrected. Some of the conditions that

can cause the malfunction light and DIC message to

come on are:

.One of the road tires has been replaced with the

spare tire. The spare tire does not have a TPMS

sensor. The TPMS malfunction light and DIC

message should go off once you re‐install the road

tire containing the TPMS sensor.

.The TPMS sensor matching process was started

but not completed or not completed successfully

after rotating the vehicle's tires. The DIC message

and TPMS malfunction light should go off once the

TPMS sensor matching process is performed

successfully. See “TPMS Sensor Matching

Process” later in this section.

6-77

Page 531 of 630

Different Size Tires and Wheels

If you add wheels or tires that are a different size than

your original equipment wheels and tires, this could

affect the way your vehicle performs, including its

braking, ride and handling characteristics, stability, and

resistance to rollover. Additionally, if your vehicle has

electronic systems such as anti‐lock brakes, rollover

airbags, traction control, and electronic stability control,

the performance of these systems can be affected.

{WARNING:

If you add different sized wheels, your vehicle

may not provide an acceptable level of

performance and safety if tires not recommended

for those wheels are selected. You may increase

the chance that you will crash and suffer serious

injury. Only use GM specific wheel and tire

systems developed for your vehicle, and have

them properly installed by a GM certified

technician.

See Buying New Tires

on page 6‑83andAccessories

and Modificationson page 6‑4for additional

information.

Uniform Tire Quality Grading

Quality grades can be found where applicable on

the tire sidewall between tread shoulder and

maximum section width. For example:

Treadwear 200 Traction AA

Temperature A

The following information relates to the system

developed by the United States National

Highway Traffic Safety Administration (NHTSA),

which grades tires by treadwear, traction, and

temperature performance. This applies only to

vehicles sold in the United States. The grades are

molded on the sidewalls of most passenger car

tires. The Uniform Tire Quality Grading (UTQG)

system does not apply to deep tread, winter-type

snow tires, space-saver, or temporary use

spare tires, tires with nominal rim diameters of

10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

6-85