steering GMC SIERRA 2010 Repair Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA, Model: GMC SIERRA 2010Pages: 630, PDF Size: 4.65 MB

Page 484 of 630

How to Check Power Steering Fluid

To check the power steering fluid:1. Turn the key off and let the engine compartment cool down.

2. Wipe the cap and the top of the reservoir clean.

3. Unscrew the cap and wipe the dipstick with a clean rag.

4. Replace the cap and completely tighten it.

5. Remove the cap again and look at the fluid level on the dipstick.

The level should be at the FULL COLD mark.

If necessary, add only enough fluid to bring the level up

to the mark.

What to Use

To determine what kind of fluid to use, see

Recommended Fluids and Lubricantson page 7‑12.

Always use the proper fluid.

Notice: Use of the incorrect fluid may damage the

vehicle and the damages may not be covered by the

vehicle's warranty. Always use the correct fluid

listed in Recommended Fluids and Lubricants

on

page 7‑12.

Windshield Washer Fluid

What to Use

When windshield washer fluid needs to be added, be

sure to read the manufacturer's instructions before use.

Use a fluid that has sufficient protection against freezing

in an area where the temperature may fall below

freezing.

Adding Washer Fluid

The vehicle has a low washer fluid message in the

DIC that comes on when the washer fluid is low. The

message is displayed for 15 seconds at the start of

each ignition cycle. When the WASHER FLUID LOW

ADD FLUID message displays, you will need to add

washer fluid to the windshield washer fluid reservoir.

Open the cap with the

washer symbol on it.

Add washer fluid until the

tank is full. See Engine

Compartment Overview

on page 6‑16for

reservoir location.

6-38

Page 516 of 630

Tire Terminology and Definitions

Air Pressure:The amount of air inside the tire

pressing outward on each square inch of the tire.

Air pressure is expressed in pounds per square

inch (psi) or kilopascal (kPa).

Accessory Weight

:This means the combined

weight of optional accessories. Some examples of

optional accessories are, automatic transmission,

power steering, power brakes, power windows,

power seats, and air conditioning.

Aspect Ratio

:The relationship of a tire's height

to its width.

Belt

:A rubber coated layer of cords that is

located between the plies and the tread. Cords

may be made from steel or other reinforcing

materials.

Bead

:The tire bead contains steel wires wrapped

by steel cords that hold the tire onto the rim.

Bias Ply Tire

:A pneumatic tire in which the plies

are laid at alternate angles less than 90 degrees

to the centerline of the tread. Cold Tire Pressure

:The amount of air pressure

in a tire, measured in pounds per square inch (psi)

or kilopascals (kPa) before a tire has built up heat

from driving. See Inflation - Tire Pressure

on

page 6‑72

.

Curb Weight

:The weight of a motor vehicle with

standard and optional equipment including the

maximum capacity of fuel, oil, and coolant, but

without passengers and cargo.

DOT Markings

:A code molded into the sidewall

of a tire signifying that the tire is in compliance

with the U.S. Department of Transportation (DOT)

motor vehicle safety standards. The DOT code

includes the Tire Identification Number (TIN), an

alphanumeric designator which can also identify

the tire manufacturer, production plant, brand, and

date of production.

GVWR

:Gross Vehicle Weight Rating. See

Loading the Vehicle

on page 5‑30.

GAWR FRT

:Gross Axle Weight Rating for the

front axle. See Loading the Vehicle

on page 5‑30.

GAWR RR

:Gross Axle Weight Rating for the rear

axle. See Loading the Vehicle

on page 5‑30.

6-70

Page 535 of 630

Tire Chains

{WARNING:

If your vehicle has dual wheels or P265/65R18,

P275/55R20 or LT265/70R17 size tires, do not

use tire chains. They can damage your vehicle

because there is not enough clearance. Tire

chains used on a vehicle without the proper

amount of clearance can cause damage to the

brakes, suspension, or other vehicle parts. The

area damaged by the tire chains could cause you

to lose control of your vehicle and you or others

may be injured in a crash.

Use another type of traction device only if its

manufacturer recommends it for use on your

vehicle and tire size combination and road

conditions. Follow that manufacturer's

instructions. To help avoid damage to your

vehicle, drive slowly, readjust, or remove the

device if it is contacting your vehicle, and do not

spin your vehicle's wheels.

If you do find traction devices that will fit, install

them on the rear tires.Notice:

If your vehicle does not have dual

wheels and has a tire size other than P265/65R18,

P275/55R20 or LT265/70R17, use tire chains only

where legal and only when you must. Use chains

that are the proper size for your tires. Install them

on the tires of the rear axle. Do not use chains on

the tires of the front axle. Tighten them as tightly as

possible with the ends securely fastened. Drive

slowly and follow the chain manufacturer's

instructions. If you can hear the chains contacting

your vehicle, stop and retighten them. If the contact

continues, slow down until it stops. Driving too fast

or spinning the wheels with chains on will damage

your vehicle.

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain your vehicle's tires properly.

If air goes out of a tire, it is much more likely to leak out

slowly. But if you should ever have a blowout, here are

a few tips about what to expect and what to do:

If a front tire fails, the flat tire creates a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

6-89

Page 536 of 630

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout remove your foot from

the accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.

{WARNING:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without the

appropriate safety equipment and training. If a

jack is provided with the vehicle, it is designed

only for changing a flat tire. If it is used for

anything else, you or others could be badly

injured or killed if the vehicle slips off the jack. If a

jack is provided with the vehicle, only use it for

changing a flat tire.

If a tire goes flat, the next part shows how to use the

jacking equipment to change a flat tire safely.

Changing a Flat Tire

If a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. See Hazard Warning Flashers

on

page 4‑3.

{WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put an automatic transmission shift lever in P (Park), or shift a manual transmission to

1 (First) or R (Reverse).

(Continued)

6-90

Page 565 of 630

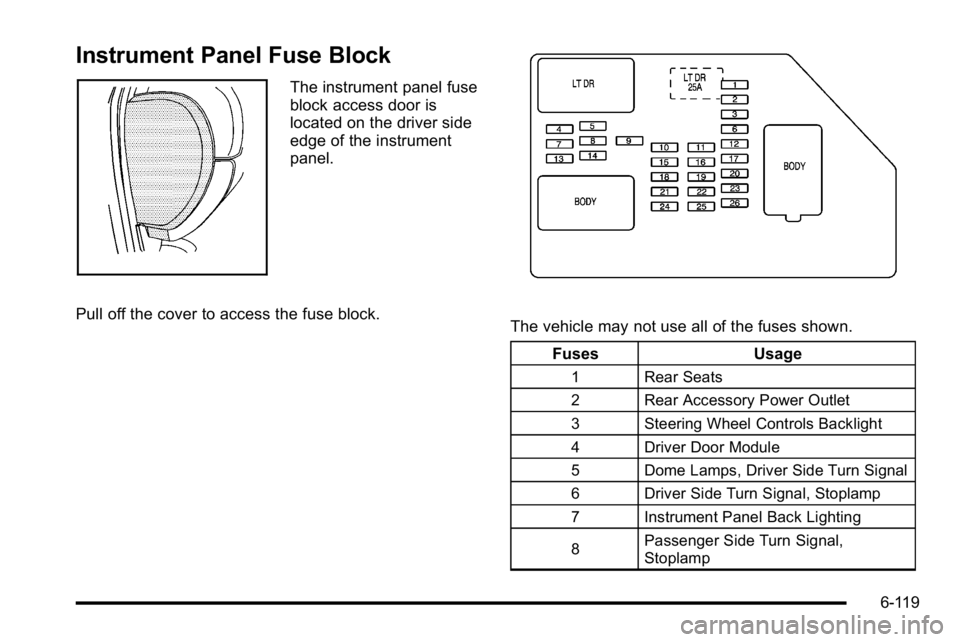

Instrument Panel Fuse Block

The instrument panel fuse

block access door is

located on the driver side

edge of the instrument

panel.

Pull off the cover to access the fuse block.

The vehicle may not use all of the fuses shown. Fuses Usage

1 Rear Seats

2 Rear Accessory Power Outlet

3 Steering Wheel Controls Backlight

4 Driver Door Module

5 Dome Lamps, Driver Side Turn Signal

6 Driver Side Turn Signal, Stoplamp

7 Instrument Panel Back Lighting

8 Passenger Side Turn Signal,

Stoplamp

6-119

Page 567 of 630

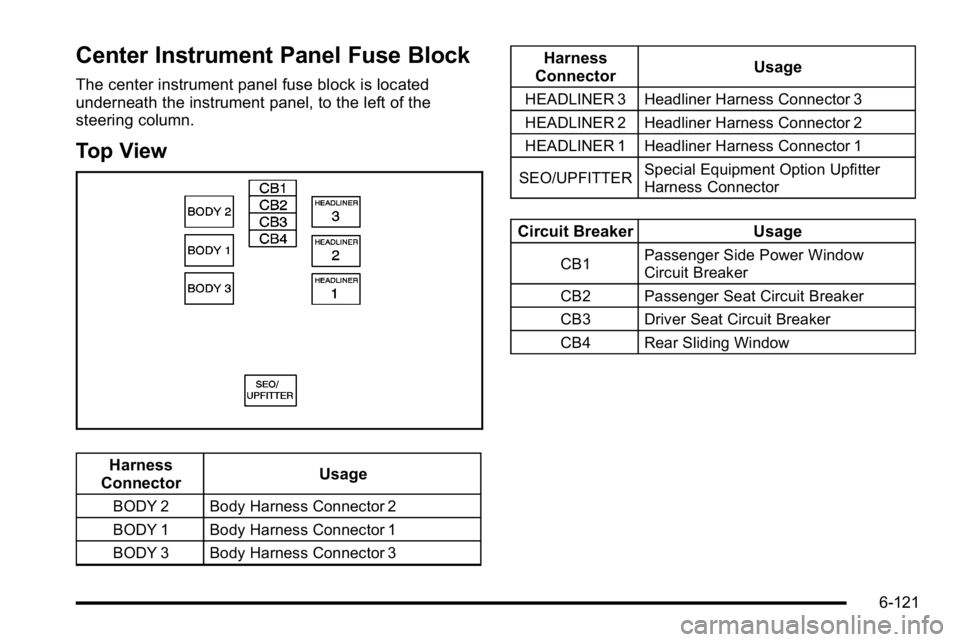

Center Instrument Panel Fuse Block

The center instrument panel fuse block is located

underneath the instrument panel, to the left of the

steering column.

Top View

Harness

Connector Usage

BODY 2 Body Harness Connector 2

BODY 1 Body Harness Connector 1

BODY 3 Body Harness Connector 3

Harness

Connector Usage

HEADLINER 3 Headliner Harness Connector 3

HEADLINER 2 Headliner Harness Connector 2

HEADLINER 1 Headliner Harness Connector 1

SEO/UPFITTER Special Equipment Option Upfitter

Harness Connector

Circuit Breaker

Usage

CB1Passenger Side Power Window

Circuit Breaker

CB2 Passenger Seat Circuit Breaker

CB3 Driver Seat Circuit Breaker

CB4 Rear Sliding Window

6-121

Page 578 of 630

When the Change Engine Oil Soon message

displays, certain services, checks, and inspections are

required. The services described for MaintenanceI

should be performed at every engine oil change.

The services described for Maintenance IIshould be

performed when:

.Maintenance Iwas performed the last time the

engine oil was changed.

.It has been 10 months or more since the Change

Engine Oil Soon message has displayed or since

the last service.

Maintenance I

.Change engine oil and filter. See Engine Oilon

page 6‑18. An Emission Control Service.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑72.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

.Rotate tires. See Tire Inspection and Rotationon

page 6‑80.

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system

must be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles

driven in dusty conditions only). See Engine Air

Cleaner/Filter on page 6‑21.

.Brake system inspection (or every 12 months,

whichever occurs first).

.For vehicles with Allison Transmission®only:

At the first engine oil change only, replace external

transmission filter.

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm

ball joints on 2500/3500 series vehicles require

lubrication but should not be lubricated unless their

temperature is−12°C (10°F) or higher, or they

could be damaged. Control arm ball joints on

1500 series vehicles are maintenance‐free.

Vehicles used under severe commercial operating

conditions require lubrication on a regular basis

every 5 000 km/3,000 miles.

7-4

Page 583 of 630

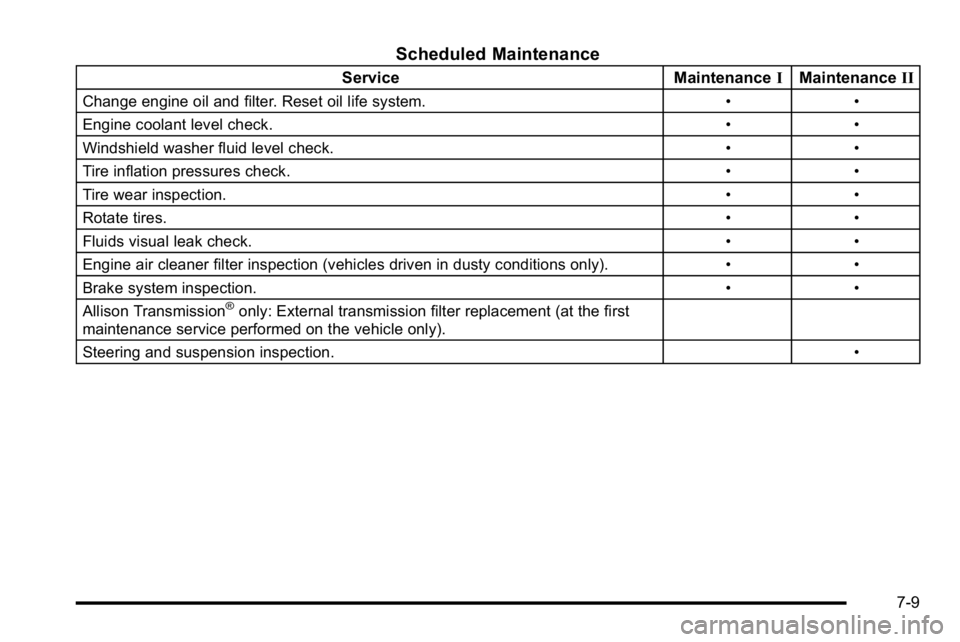

Scheduled Maintenance

ServiceMaintenanceIMaintenance II

Change engine oil and filter. Reset oil life system. ••

Engine coolant level check. ••

Windshield washer fluid level check. ••

Tire inflation pressures check. ••

Tire wear inspection. ••

Rotate tires. ••

Fluids visual leak check. ••

Engine air cleaner filter inspection (vehicles driven in dusty conditions only). ••

Brake system inspection. ••

Allison Transmission

®only: External transmission filter replacement (at the first

maintenance service performed on the vehicle only).

Steering and suspension inspection. •

7-9

Page 587 of 630

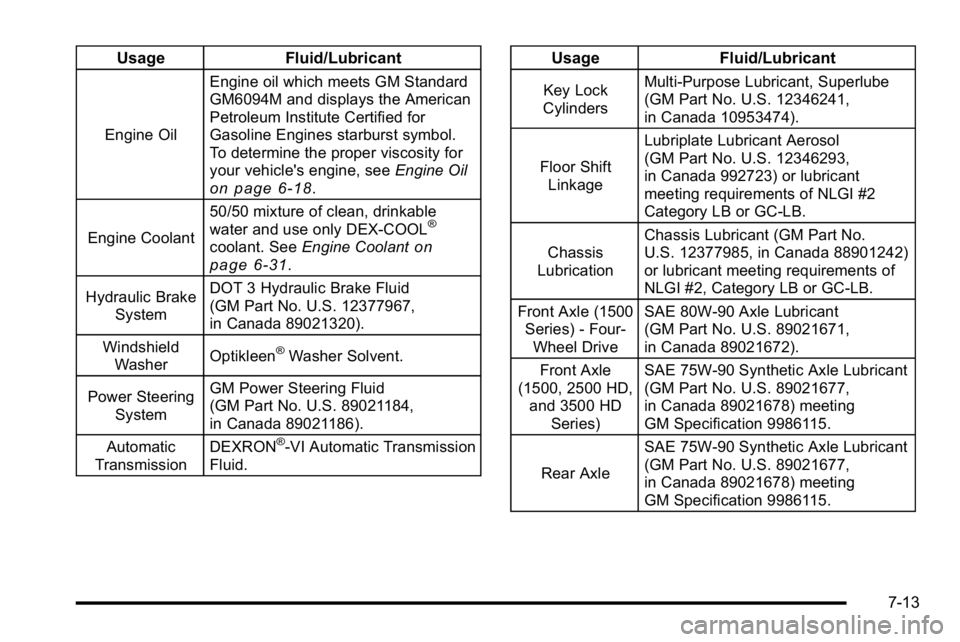

UsageFluid/Lubricant

Engine OilEngine oil which meets GM Standard

GM6094M and displays the American

Petroleum Institute Certified for

Gasoline Engines starburst symbol.

To determine the proper viscosity for

your vehicle's engine, see

Engine Oil

on page 6‑18.

Engine Coolant 50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

coolant. See

Engine Coolanton

page 6‑31.

Hydraulic Brake System DOT 3 Hydraulic Brake Fluid

(GM Part No. U.S. 12377967,

in Canada 89021320).

Windshield Washer Optikleen

®Washer Solvent.

Power Steering System GM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

Transmission DEXRON

®-VI Automatic Transmission

Fluid.

Usage Fluid/Lubricant

Key Lock

Cylinders Multi-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Floor Shift Linkage Lubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2

Category LB or GC-LB.

Chassis

Lubrication Chassis Lubricant (GM Part No.

U.S. 12377985, in Canada 88901242)

or lubricant meeting requirements of

NLGI #2, Category LB or GC-LB.

Front Axle (1500 Series) ‐Four‐

Wheel Drive SAE 80W-90 Axle Lubricant

(GM Part No. U.S. 89021671,

in Canada 89021672).

Front Axle

(1500, 2500 HD, and 3500 HD Series) SAE 75W-90 Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Specification 9986115.

Rear Axle SAE 75W-90 Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Specification 9986115.

7-13

Page 610 of 630

Reporting Safety Defects to the

Canadian Government

If you live in Canada, and you believe that your

vehicle has a safety defect, notify Transport Canada

immediately, in addition to notifying General Motors of

Canada Limited. Call them at 1-800-333-0510 or

write to:Transport Canada

Road Safety Branch

2780 Sheffield Road

Ottawa, Ontario K1B 3V9

Reporting Safety Defects to

General Motors

In addition to notifying NHTSA (or Transport Canada) in

a situation like this, please notify General Motors.

Call 1-800-GMC-8782 (1-800-462-8782), or write:GMC Customer Assistance Center

P.O. Box 33172

Detroit, MI 48232-5172 In Canada, call 1-800-263-3777 (English) or

1-800-263-7854 (French), or write:

General Motors of Canada Limited

Customer Communication Centre, CA1-163-005

1908 Colonel Sam Drive

Oshawa, Ontario L1H 8P7

Service Publications Ordering

Information

Service Manuals

Service Manuals have the diagnosis and repair

information on engines, transmission, axle suspension,

brakes, electrical, steering, body, etc.

Service Bulletins

Service Bulletins give additional technical service

information needed to knowledgeably service General

Motors cars and trucks. Each bulletin contains

instructions to assist in the diagnosis and service of

your vehicle.

8-16