check transmission fluid GMC SIERRA DENALI 2010 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2010Pages: 550, PDF Size: 4.17 MB

Page 338 of 550

Highway Hypnosis

Always be alert and pay attention to your surroundings

while driving. If you become tired or sleepy, find a safe

place to park your vehicle and rest.

Other driving tips include:

.Keep the vehicle well ventilated.

.Keep interior temperature cool.

.Keep your eyes moving—scan the road ahead

and to the sides.

.Check the rearview mirror and vehicle instruments

often.

Hill and Mountain Roads

Driving on steep hills or through mountains is different

than driving on flat or rolling terrain. Tips for driving in

these conditions include:

.Keep the vehicle serviced and in good shape.

.Check all fluid levels and brakes, tires, cooling

system, and transmission.

.Going down steep or long hills, shift to a

lower gear.

{WARNING:

If you do not shift down, the brakes could get so

hot that they would not work well. You would then

have poor braking or even none going down a hill.

You could crash. Shift down to let the engine

assist the brakes on a steep downhill slope.

5-26

Page 371 of 550

{WARNING:

It can be dangerous to get out of the vehicle if the

shift lever is not fully in P (Park) with the parking

brake firmly set. The vehicle can roll.

If the engine has been left running, the vehicle

can move suddenly. You or others could be

injured. To be sure the vehicle will not move, even

when on fairly level ground, always put the shift

lever fully in P (Park) with the parking brake

firmly set.

Leaving After Parking on a Hill

1. Apply and hold the brake pedal.

2. Start the engine

3. Shift into a gear

4. Release the parking brake

5. Let up on the brake pedal.

6. Drive slowly until the trailer is clear of the chocks.

7. Stop and have someone pick up and store thechocks.

Maintenance When Trailer Towing

The vehicle needs service more often when pulling a

trailer. See this manual's Maintenance Schedule or

Index for more information. Things that are especially

important in trailer operation are automatic transmission

fluid, engine oil, axle lubricant, belts, cooling system

and brake system. It is a good idea to inspect these

before and during the trip.

Check periodically to see that all hitch nuts and bolts

are tight.

5-59

Page 375 of 550

Section 6 Service and Appearance Care

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Accessories and Modifications . . . . . . . . . . . . . . . . . . 6-4

California Proposition 65 Warning . . . . . . . . . . . . . . . 6-5

California Perchlorate Materials Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Doing Your Own Service Work . . . . . . . . . . . . . . . . . . 6-5

Adding Equipment to the Outside of the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Gasoline Octane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Gasoline Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

California Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Fuel E85 (85% Ethanol) . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Fuels in Foreign Countries . . . . . . . . . . . . . . . . . . . . . 6-10

Filling the Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Filling a Portable Fuel Container . . . . . . . . . . . . . . . 6-13

Checking Things Under the Hood . . . . . . . . . . . . . . .6-14

Hood Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Engine Compartment Overview . . . . . . . . . . . . . . . . 6-16

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Engine Oil Life System . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Engine Air Cleaner/Filter . . . . . . . . . . . . . . . . . . . . . . . 6-22

Automatic Transmission Fluid . . . . . . . . . . . . . . . . . . 6-24

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28 Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Engine Overheating . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Overheated Engine Protection

Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Engine Fan Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Power Steering Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Windshield Washer Fluid . . . . . . . . . . . . . . . . . . . . . . 6-39

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

All-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

Rear Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-50

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Headlamp Aiming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

Halogen Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

Headlamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

Center High-Mounted Stoplamp (CHMSL) and Cargo Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Taillamps, Turn Signal, Stoplamps and Back-up Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-58

License Plate Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-60

Replacement Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-60

Windshield Wiper Blade Replacement . . . . . . . . . . .6-61

6-1

Page 391 of 550

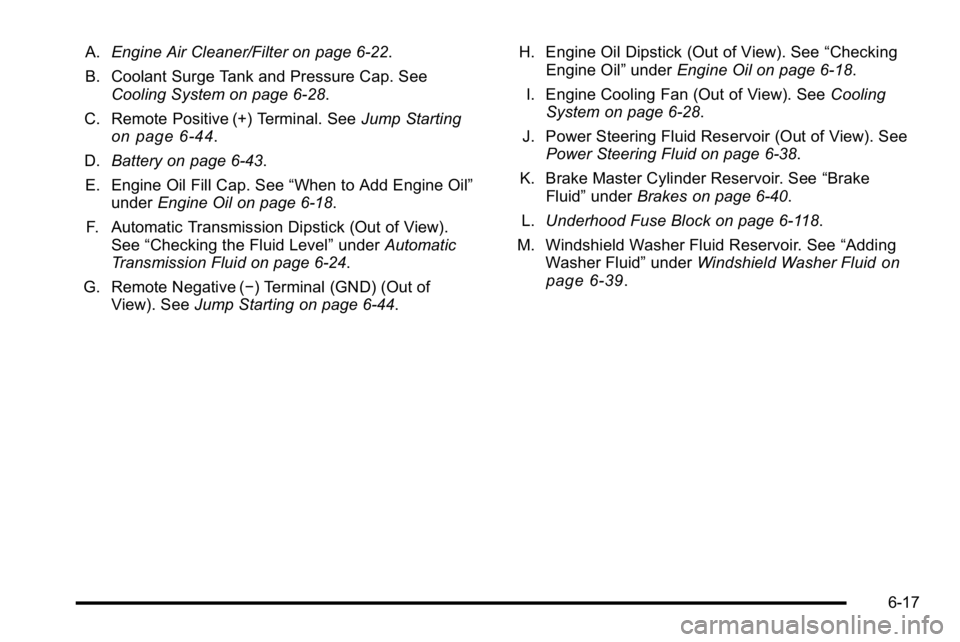

A.Engine Air Cleaner/Filter on page 6‑22.

B. Coolant Surge Tank and Pressure Cap. See Cooling System on page 6‑28.

C. Remote Positive (+) Terminal. See Jump Starting

on page 6‑44.

D. Battery on page 6‑43.

E. Engine Oil Fill Cap. See “When to Add Engine Oil”

under Engine Oil on page 6‑18.

F. Automatic Transmission Dipstick (Out of View). See “Checking the Fluid Level” underAutomatic

Transmission Fluid on page 6‑24.

G. Remote Negative (−) Terminal (GND) (Out of View). See Jump Starting on page 6‑44. H. Engine Oil Dipstick (Out of View). See

“Checking

Engine Oil” underEngine Oil on page 6‑18.

I. Engine Cooling Fan (Out of View). See Cooling

System on page 6‑28.

J. Power Steering Fluid Reservoir (Out of View). See Power Steering Fluid on page 6‑38.

K. Brake Master Cylinder Reservoir. See “Brake

Fluid” under Brakes on page 6‑40.

L. Underhood Fuse Block on page 6‑118.

M. Windshield Washer Fluid Reservoir. See “Adding

Washer Fluid” underWindshield Washer Fluid

on

page 6‑39.

6-17

Page 398 of 550

Automatic Transmission Fluid

When to Check and Change Automatic

Transmission Fluid

It is usually not necessary to check the transmission

fluid level. The only reason for fluid loss is a

transmission leak or overheating the transmission.

If you suspect a small leak, then use the following

checking procedures to check the fluid level. However,

if there is a large leak, then it may be necessary to have

the vehicle towed to a dealer/retailer service department

and have it repaired before driving the vehicle further.

Notice:Use of the incorrect automatic transmission

fluid may damage the vehicle, and the damages may

not be covered by the vehicle's warranty. Always

use the automatic transmission fluid listed in

Recommended Fluids and Lubricants on page 7‑11.

Change the fluid and filter at the intervals listed in the

Maintenance Schedule. See Scheduled Maintenance

on page 7‑3. Be sure to use the transmission fluid

listed in Recommended Fluids and Lubricantson

page 7‑11.

How to Check Automatic Transmission

Fluid

Notice: Too much or too little fluid can damage your

transmission. Too much can mean that some of the

fluid could come out and fall on hot engine parts or

exhaust system parts, starting a fire. Too little fluid

could cause the transmission to overheat. Be sure

to get an accurate reading if you check your

transmission fluid.

Before checking the fluid level, prepare the vehicle as

follows:

1. Start the engine and park the vehicle on a level surface. Keep the engine running.

2. Apply the parking brake and place the shift lever in P (Park).

3. With your foot on the brake pedal, move the shift lever through each gear range, pausing for about

three seconds in each range. Then, move the shift

lever back to P (Park).

6-24

Page 399 of 550

4. Allow the engine to idle (500–800 rpm) for at least

one minute. Slowly release the brake pedal.

5. Keep the engine running and press the Trip/Fuel button or trip odometer reset stem until TRANS

TEMP (Transmission Temperature) displays on the

Driver Information Center (DIC).

6. Using the TRANS TEMP reading, determine and perform the appropriate check procedure. If the

TRANS TEMP reading is not within the required

temperature ranges, allow the vehicle to cool,

or operate the vehicle until the appropriate

transmission fluid temperature is reached.Cold Check Procedure

Use this procedure only as a reference to determine if

the transmission has enough fluid to be operated safely

until a hot check procedure can be made. The hot

check procedure is the most accurate method to check

the fluid level. Perform the hot check procedure at the

first opportunity. Use this cold check procedure to check

fluid level when the transmission temperature is

between 80°F and 90°F (27°C and 32°C).

1. Locate thetransmission dipstick at

the rear of the engine

compartment, on the

passenger side of the

vehicle.

See Engine Compartment Overview

on page 6‑16for more information.

2. Flip the handle up and then pull out the dipstick and wipe it with a clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way, wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

6-25

Page 400 of 550

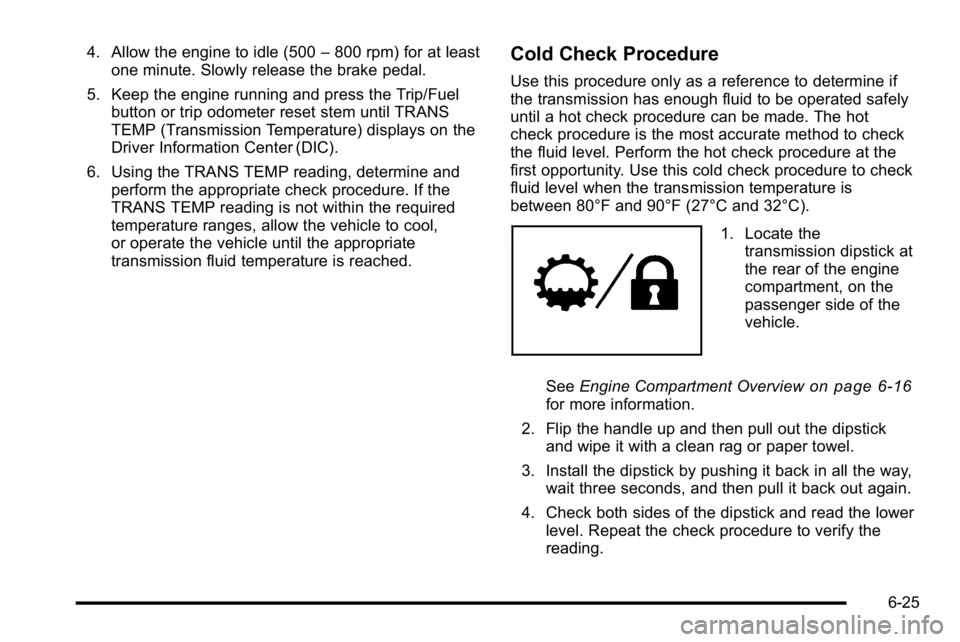

5. If the fluid level is below the COLD check band,add only enough fluid as necessary to bring the

level into the COLD band. It does not take much

fluid, generally less than one pint (0.5L). Do not

overfill.

6. Perform a hot check at the first opportunity after the transmission reaches a normal operating

temperature between 160°F to 200°F

(71°C to 93°C).

7. If the fluid level is in the acceptable range, push the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Hot Check Procedure

Use this procedure to check the transmission fluid level

when the transmission fluid temperature is between

160°F and 200°F (71°C and 93°C).

The hot check is the most accurate method to check the

fluid level. The hot check should be performed at the

first opportunity in order to verify the cold check. The

fluid level rises as fluid temperature increases, so it is

important to ensure the transmission temperature is

within range.

1. Locate thetransmission

dipstick at the

rear of the engine

compartment, on

the passenger side

of the vehicle.

See Engine Compartment Overview

on page 6‑16for more information.

2. Flip the handle up and then pull out the dipstick and wipe it with a clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way, wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

6-26

Page 401 of 550

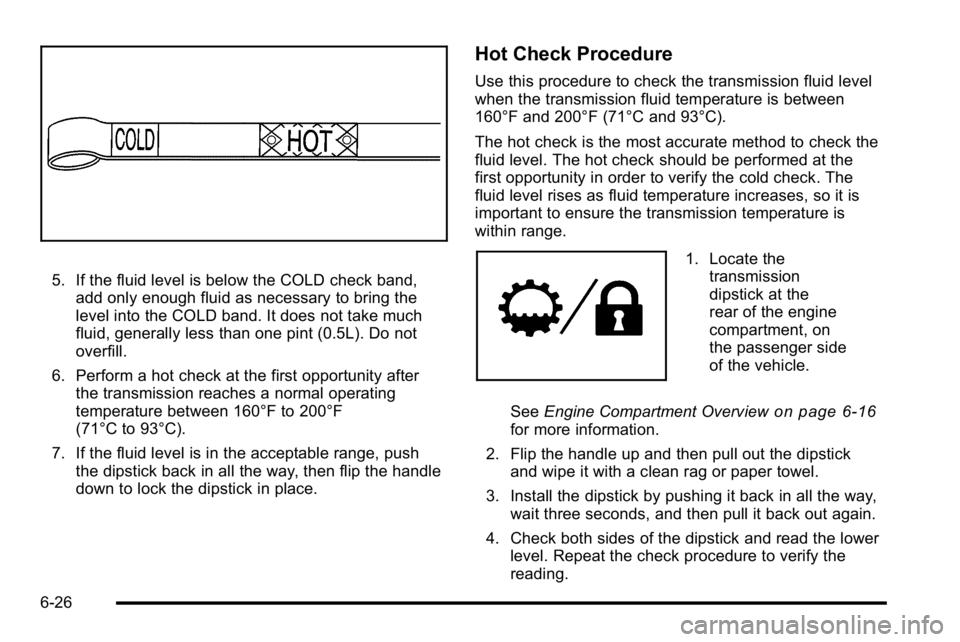

5. Safe operating level is within the HOT cross hatchband on the dipstick. If the fluid level is not within

the HOT band, and the transmission temperature

is between 160°F and 200°F (71°C and 93°C), add

or drain fluid as necessary to bring the level into

the HOT band. If the fluid level is low, add only

enough fluid to bring the level into the HOT band.

It does not take much fluid, generally less than one

pint (0.5L). Do not overfill.

6. If the fluid level is in the acceptable range, push the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Consistency of Readings

Always check the fluid level at least twice using the

procedures described. Consistency (repeatable

readings) is important to maintaining proper fluid level.

If fluid is added, it may take 15 minutes or longer to

obtain an accurate reading because of residual fluid

draining down the dipstick tube. If inconsistent readings

persist, check the transmission breather to be sure it is

clean and not clogged. If readings are still inconsistent,

contact your dealer/retailer.

6-27

Page 496 of 550

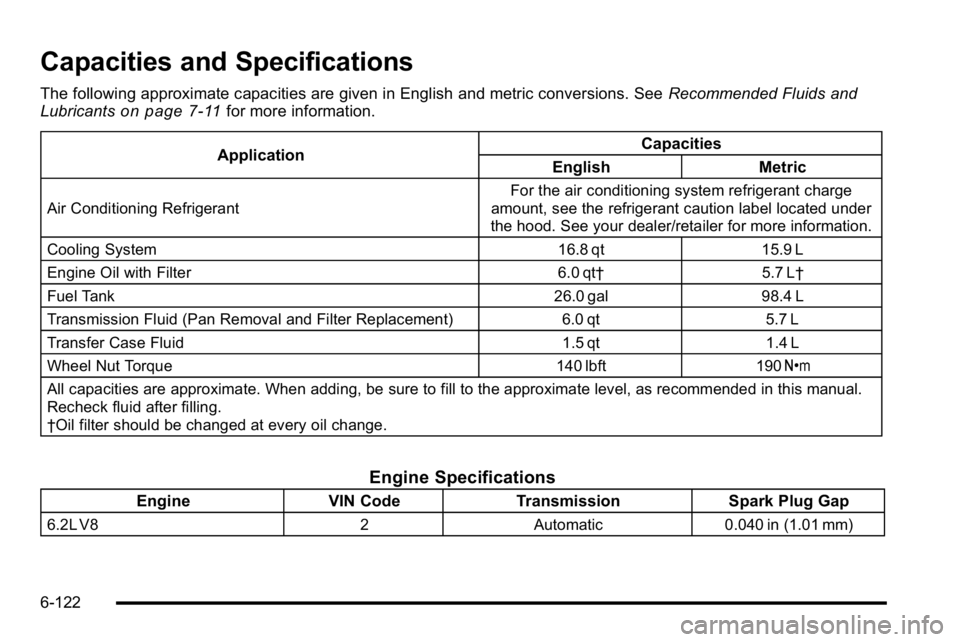

Capacities and Specifications

The following approximate capacities are given in English and metric conversions. SeeRecommended Fluids and

Lubricantson page 7‑11for more information.

Application Capacities

English Metric

Air Conditioning Refrigerant For the air conditioning system refrigerant charge

amount, see the refrigerant caution label located under

the hood. See your dealer/retailer for more information.

Cooling System 16.8 qt15.9 L

Engine Oil with Filter 6.0 qt†5.7 L†

Fuel Tank 26.0 gal98.4 L

Transmission Fluid (Pan Removal and Filter Replacement) 6.0 qt5.7 L

Transfer Case Fluid 1.5 qt1.4 L

Wheel Nut Torque 140 lbft190Y

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this manual.

Recheck fluid after filling.

†Oil filter should be changed at every oil change.

Engine Specifications

Engine VIN CodeTransmission Spark Plug Gap

6.2L V8 2Automatic 0.040 in (1.01 mm)

6-122

Page 500 of 550

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). SeeEngine Air

Cleaner/Filter on page 6‑22.

.Brake system inspection (or every 12 months,

whichever occurs first).

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm ball

joints are maintenance‐free.

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps and

replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑110. Worn

or damaged wiper blade replacement. See

Windshield Wiper Blade Replacement

on

page 6‑61.

.Body hinges and latches, key lock cylinders,

folding seat hardware, and liftgate hinges, linkage,

and handle pivot points lubrication. See

Recommended Fluids and Lubricants

on

page 7‑11. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑73.

.Automatic transmission fluid level check and

adding fluid, if needed. See Automatic

Transmission Fluid on page 6‑24.

.Transfer case fluid level check and adding fluid,

if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑22.

7-4