height adjustment GMC SIERRA DENALI 2010 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2010Pages: 550, PDF Size: 4.17 MB

Page 13 of 550

Seat Adjustment

Front Seats

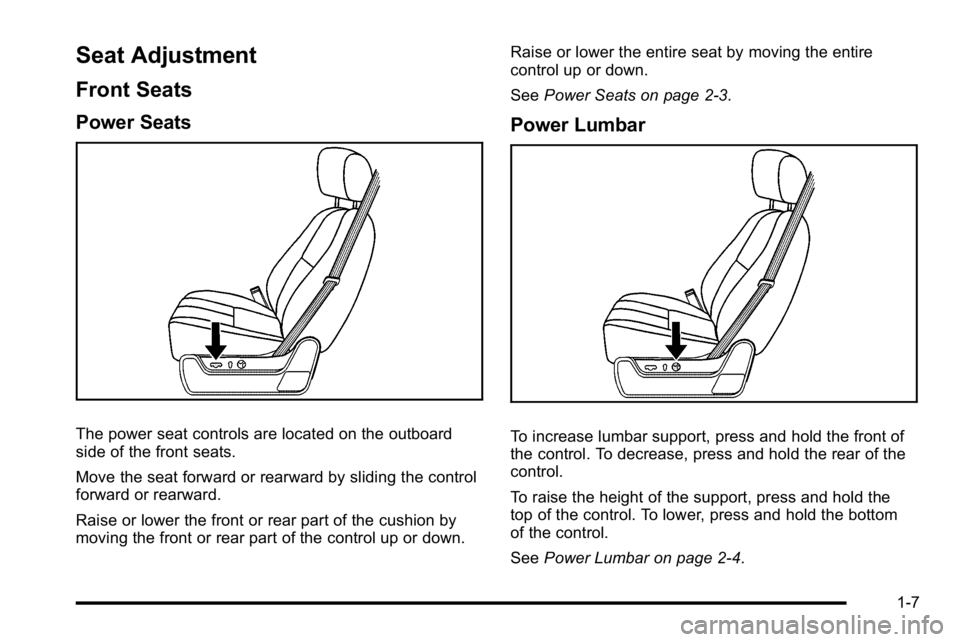

Power Seats

The power seat controls are located on the outboard

side of the front seats.

Move the seat forward or rearward by sliding the control

forward or rearward.

Raise or lower the front or rear part of the cushion by

moving the front or rear part of the control up or down.Raise or lower the entire seat by moving the entire

control up or down.

See

Power Seats on page 2‑3.

Power Lumbar

To increase lumbar support, press and hold the front of

the control. To decrease, press and hold the rear of the

control.

To raise the height of the support, press and hold the

top of the control. To lower, press and hold the bottom

of the control.

SeePower Lumbar on page 2‑4.

1-7

Page 62 of 550

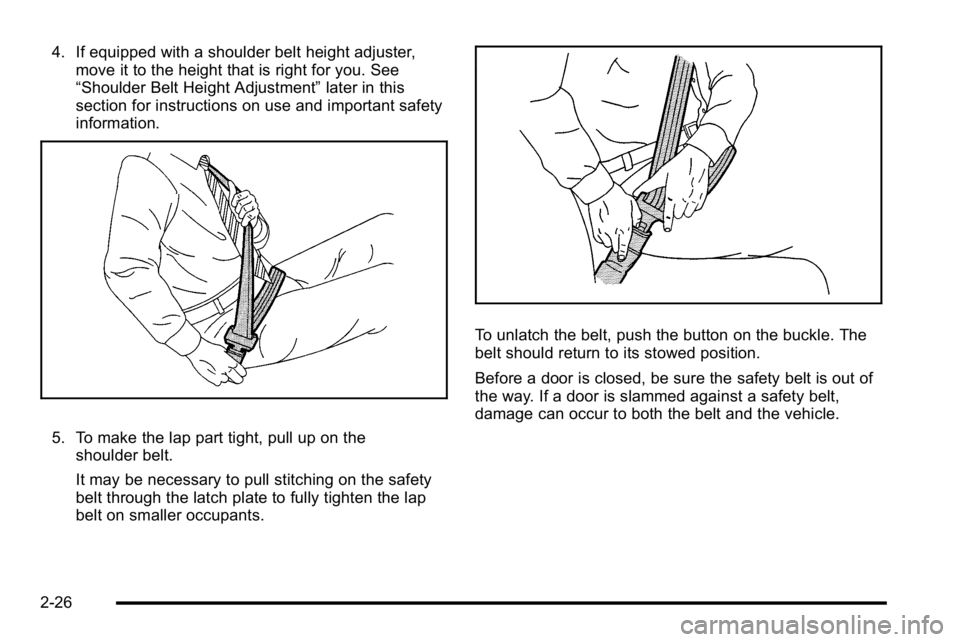

4. If equipped with a shoulder belt height adjuster,move it to the height that is right for you. See

“Shoulder Belt Height Adjustment” later in this

section for instructions on use and important safety

information.

5. To make the lap part tight, pull up on the shoulder belt.

It may be necessary to pull stitching on the safety

belt through the latch plate to fully tighten the lap

belt on smaller occupants.

To unlatch the belt, push the button on the buckle. The

belt should return to its stowed position.

Before a door is closed, be sure the safety belt is out of

the way. If a door is slammed against a safety belt,

damage can occur to both the belt and the vehicle.

2-26

Page 63 of 550

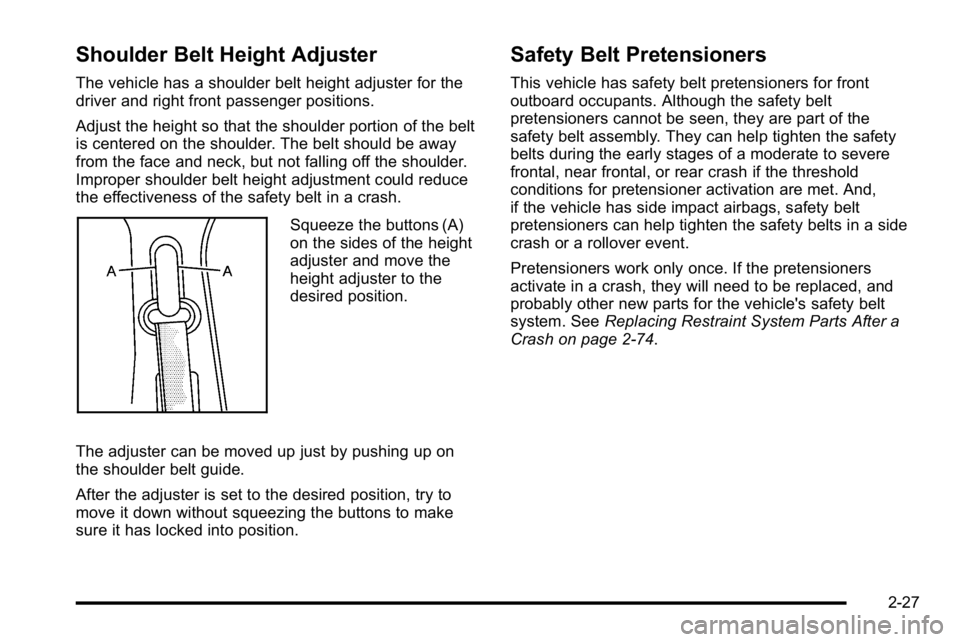

Shoulder Belt Height Adjuster

The vehicle has a shoulder belt height adjuster for the

driver and right front passenger positions.

Adjust the height so that the shoulder portion of the belt

is centered on the shoulder. The belt should be away

from the face and neck, but not falling off the shoulder.

Improper shoulder belt height adjustment could reduce

the effectiveness of the safety belt in a crash.

Squeeze the buttons (A)

on the sides of the height

adjuster and move the

height adjuster to the

desired position.

The adjuster can be moved up just by pushing up on

the shoulder belt guide.

After the adjuster is set to the desired position, try to

move it down without squeezing the buttons to make

sure it has locked into position.

Safety Belt Pretensioners

This vehicle has safety belt pretensioners for front

outboard occupants. Although the safety belt

pretensioners cannot be seen, they are part of the

safety belt assembly. They can help tighten the safety

belts during the early stages of a moderate to severe

frontal, near frontal, or rear crash if the threshold

conditions for pretensioner activation are met. And,

if the vehicle has side impact airbags, safety belt

pretensioners can help tighten the safety belts in a side

crash or a rollover event.

Pretensioners work only once. If the pretensioners

activate in a crash, they will need to be replaced, and

probably other new parts for the vehicle's safety belt

system. See Replacing Restraint System Parts After a

Crash on page 2‑74.

2-27

Page 416 of 550

Brake Wear

This vehicle has front disc brakes and could have rear

drum brakes or rear disc brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads are

worn and new pads are needed. The sound can come

and go or be heard all the time the vehicle is moving,

except when applying the brake pedal firmly.

{WARNING:

The brake wear warning sound means that soon

the brakes will not work well. That could lead to

an accident. When the brake wear warning sound

is heard, have the vehicle serviced.

Notice: Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates can cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

the brakes. Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to torque specifications in

Capacities and Specifications on page 6‑122.

If the vehicle has rear drum brakes, they do not have

wear indicators, but if a rear brake rubbing noise is

heard, have the rear brake linings inspected

immediately. Rear brake drums should be removed and

inspected each time the tires are removed for rotation or

changing. Drum brakes have an inspection hole to

inspect lining wear during scheduled maintenance.

When the front brake pads are replaced, have the rear

brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase in

pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every brake stop, the brakes adjust for wear.

6-42

Page 458 of 550

Wheel Alignment and Tire Balance

The tires and wheels on your vehicle were aligned and

balanced carefully at the factory to give you the longest

tire life and best overall performance. Adjustments to

wheel alignment and tire balancing will not be

necessary on a regular basis. However, if you notice

unusual tire wear or your vehicle pulling to one side or

the other, the alignment might need to be checked.

If you notice your vehicle vibrating when driving on a

smooth road, the tires and wheels might need to be

rebalanced. See your dealer/retailer for proper

diagnosis.

Wheel Replacement

Replace any wheel that is bent, cracked, or badly

rusted or corroded. If wheel nuts keep coming loose,

the wheel, wheel bolts, and wheel nuts should be

replaced. If the wheel leaks air, replace it (except some

aluminum wheels, which can sometimes be repaired).

See your dealer/retailer if any of these conditions exist.

Your dealer/retailer will know the kind of wheel

you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset, and be mounted the

same way as the one it replaces.If you need to replace any of your wheels, wheel bolts,

wheel nuts, or Tire Pressure Monitor System (TPMS)

sensors, replace them only with new GM original

equipment parts. This way, you will be sure to have the

right wheel, wheel bolts, wheel nuts, and TPMS sensors

for your vehicle.

{WARNING:

Using the wrong replacement wheels, wheel bolts,

or wheel nuts on your vehicle can be dangerous.

It could affect the braking and handling of your

vehicle, make your tires lose air and make you

lose control. You could have a collision in which

you or others could be injured. Always use the

correct wheel, wheel bolts, and wheel nuts for

replacement.

Notice: The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance, and tire or tire chain

clearance to the body and chassis.

See Changing a Flat Tire

on page 6‑86for more

information.

6-84