spare wheel GMC SIERRA DENALI 2010 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2010Pages: 550, PDF Size: 4.17 MB

Page 325 of 550

Before You Go Off-Roading

.Have all necessary maintenance and service

work done.

.Make sure there is enough fuel, that fluid levels are

where they should be, and that the spare tire is

fully inflated.

.Be sure to read all the information about

all-wheel-drive vehicles in this manual.

.Make sure all underbody shields, if the vehicle has

them, are properly attached.

.Know the local laws that apply to off-roading where

you will be driving or check with law enforcement

people in the area.

.Be sure to get the necessary permission if you will

be on private land.

If you think you will need some more ground clearance

at the front of your vehicle, you can remove the front

fascia lower air dam. The air dam is held in place by

two bolts and 10 snaps accessible from underneath the

front fascia. To remove the air dam:

1. Remove the two outboard air dam bolts.

2. With a flat‐blade tool, disengage the snaps.

3. After the bolts are removed and the snaps are disengaged, push forward on the air dam until it

is free.

Notice: Operating your vehicle for extended periods

without the front fascia lower air dam installed can

cause improper air flow to the engine. Always be

sure to replace the front fascia air dam when you

are finished off-road driving.

After off-roading , be sure to reinstall the air dam:

1. Line up the snaps and push the air dam rearward to engage the snaps.

2. Install the two outboard bolts.

5-13

Page 376 of 550

Section 6 Service and Appearance Care

Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-62

Tire Sidewall Labeling . . . . . . . . . . . . . . . . . . . . . . . . . 6-63

Tire Terminology and Definitions . . . . . . . . . . . . . . . 6-68

Inflation - Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . 6-71

High-Speed Operation . . . . . . . . . . . . . . . . . . . . . . . . . 6-72

Tire Pressure Monitor System . . . . . . . . . . . . . . . . . 6-73

Tire Pressure Monitor Operation . . . . . . . . . . . . . . . 6-74

Tire Inspection and Rotation . . . . . . . . . . . . . . . . . . . 6-78

When It Is Time for New Tires . . . . . . . . . . . . . . . . . 6-79

Buying New Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-80

Different Size Tires and Wheels . . . . . . . . . . . . . . . 6-82

Uniform Tire Quality Grading . . . . . . . . . . . . . . . . . . . 6-82

Wheel Alignment and Tire Balance . . . . . . . . . . . . 6-84

Wheel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-84

Tire Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-85

If a Tire Goes Flat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-85

Changing a Flat Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-86

Removing the Spare Tire and Tools . . . . . . . . . . . . 6-88

Removing the Flat Tire and Installing the Spare Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-92

Secondary Latch System . . . . . . . . . . . . . . . . . . . . . . 6-97

Storing a Flat or Spare Tire and Tools . . . . . . . . 6-100

Spare Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-104 Appearance Care

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-105

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-105

Fabric/Carpet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-106

Leather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-107

Instrument Panel, Vinyl, and Other Plastic Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-107

Wood Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-108

Care of Safety Belts . . . . . . . . . . . . . . . . . . . . . . . . . . 6-108

Weatherstrips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-108

Washing Your Vehicle . . . . . . . . . . . . . . . . . . . . . . . . 6-108

Cleaning Exterior Lamps/Lenses . . . . . . . . . . . . . 6-109

Finish Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-109

Windshield and Wiper Blades . . . . . . . . . . . . . . . . . 6-110

Aluminum or Chrome-Plated Wheels and Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-110

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-111

Sheet Metal Damage . . . . . . . . . . . . . . . . . . . . . . . . . 6-111

Finish Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-112

Underbody Maintenance . . . . . . . . . . . . . . . . . . . . . . 6-112

Chemical Paint Spotting . . . . . . . . . . . . . . . . . . . . . . 6-112

6-2

Page 448 of 550

When the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may occur

for a variety of reasons, including the installation of

replacement or alternate tires or wheels on the vehicle

that prevent the TPMS from functioning properly.

Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to

ensure that the replacement or alternate tires and

wheels allow the TPMS to continue to function properly.

SeeTire Pressure Monitor Operation

on page 6‑74for

additional information.

Federal Communications Commission

(FCC) and Industry and Science Canada

See Radio Frequency Statementon page 8‑20for

information regarding Part 15 of the Federal

Communications Commission (FCC) Rules and

RSS-210/211 of Industry and Science Canada.

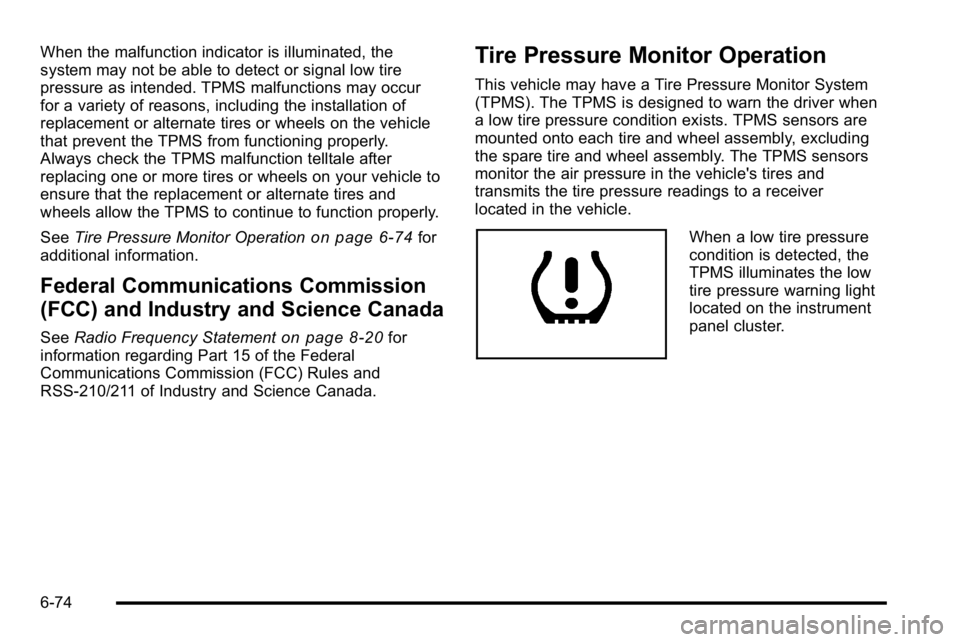

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure Monitor System

(TPMS). The TPMS is designed to warn the driver when

a low tire pressure condition exists. TPMS sensors are

mounted onto each tire and wheel assembly, excluding

the spare tire and wheel assembly. The TPMS sensors

monitor the air pressure in the vehicle's tires and

transmits the tire pressure readings to a receiver

located in the vehicle.

When a low tire pressure

condition is detected, the

TPMS illuminates the low

tire pressure warning light

located on the instrument

panel cluster.

6-74

Page 450 of 550

TPMS Malfunction Light and Message

The TPMS will not function properly if one or more of

the TPMS sensors are missing or inoperable. When the

system detects a malfunction, the low tire warning light

flashes for about one minute and then stays on for the

remainder of the ignition cycle. A DIC warning message

is also displayed. The low tire warning light and DIC

warning message come on at each ignition cycle until

the problem is corrected. Some of the conditions that

can cause the malfunction light and DIC message to

come on are:

.One of the road tires has been replaced with the

spare tire. The spare tire does not have a TPMS

sensor. The TPMS malfunction light and DIC

message should go off once you re‐install the road

tire containing the TPMS sensor.

.The TPMS sensor matching process was started

but not completed or not completed successfully

after rotating the vehicle's tires. The DIC message

and TPMS malfunction light should go off once the

TPMS sensor matching process is performed

successfully. See“TPMS Sensor Matching

Process” later in this section.

.One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

.Replacement tires or wheels do not match your

vehicle's original equipment tires or wheels. Tires

and wheels other than those recommended for

your vehicle could prevent the TPMS from

functioning properly. See Buying New Tires

on

page 6‑80.

.Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signal

a low tire condition. See your dealer/retailer for service

if the TPMS malfunction light and DIC message comes

on and stays on.

6-76

Page 452 of 550

8. Proceed to the driver side rear tire, and repeat theprocedure in Step 5. The horn sounds two times to

indicate the sensor identification code has been

matched to the driver side rear tire, and the TPMS

sensor matching process is no longer active. The

TIRE LEARNING ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.

Tire Inspection and Rotation

We recommend that you regularly inspect your

vehicle's tires, including the spare tire, for signs of

wear or damage. See When It Is Time for New

Tires

on page 6‑79for more information.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). See Scheduled Maintenance

on page 7‑3.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This will

ensure that your vehicle continues to perform

most like it did when the tires were new. Any time you notice unusual wear, rotate your

tires as soon as possible and check wheel

alignment. Also check for damaged tires or

wheels. See

When It Is Time for New Tires

on

page 6‑79

and Wheel Replacementon page 6‑84.

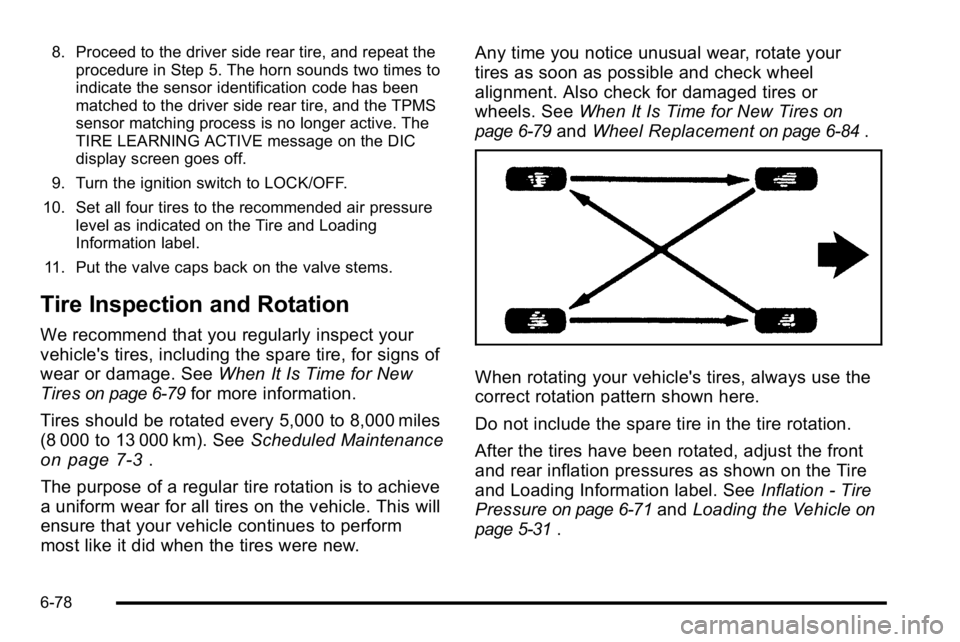

When rotating your vehicle's tires, always use the

correct rotation pattern shown here.

Do not include the spare tire in the tire rotation.

After the tires have been rotated, adjust the front

and rear inflation pressures as shown on the Tire

and Loading Information label. See Inflation - Tire

Pressure

on page 6‑71and Loading the Vehicleon

page 5‑31

.

6-78

Page 453 of 550

Reset the Tire Pressure Monitor System. SeeTire

Pressure Monitor Operation

on page 6‑74.

Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and Specifications

on page 6‑122.

{WARNING:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the

vehicle. In an emergency, you can use a

cloth or a paper towel to do this; but be sure

to use a scraper or wire brush later,

if needed, to get all the rust or dirt off. See

Changing a Flat Tire

on page 6‑86.

Make sure the spare tire is stored securely. Push,

pull, and then try to rotate or turn the tire. If it

moves, tighten the cable. See Storing a Flat or

Spare Tire and Tools

on page 6‑100.

When It Is Time for New Tires

Various factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road conditions,

influence when you need new tires.

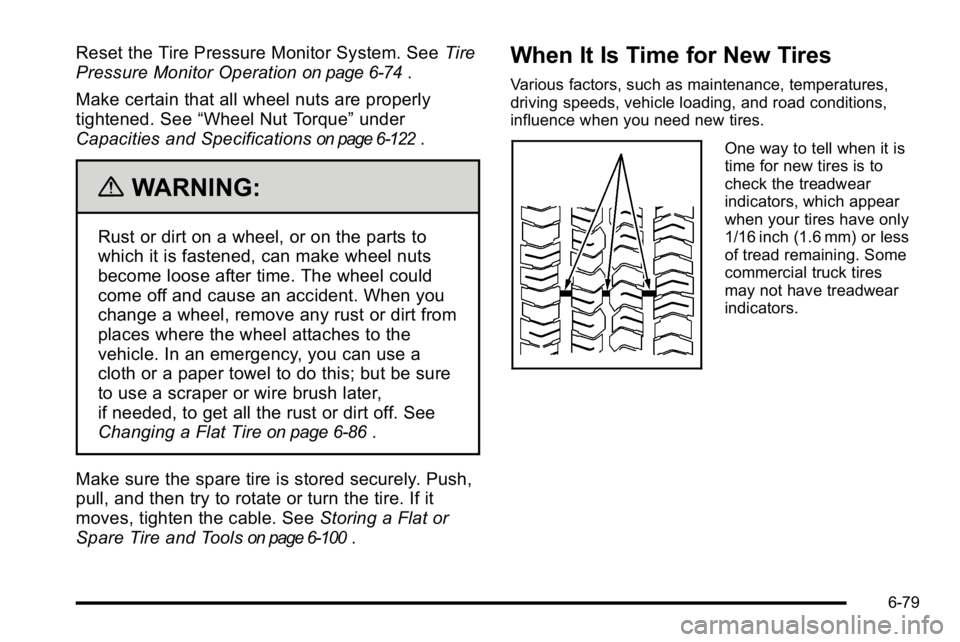

One way to tell when it is

time for new tires is to

check the treadwear

indicators, which appear

when your tires have only

1/16 inch (1.6 mm) or less

of tread remaining. Some

commercial truck tires

may not have treadwear

indicators.

6-79

Page 455 of 550

{WARNING:

Mixing tires could cause you to lose control while

driving. If you mix tires of different sizes, brands,

or types (radial and bias-belted tires), the vehicle

might not handle properly, and you could have a

crash. Using tires of different sizes, brands,

or types could also cause damage to your vehicle.

Be sure to use the same size, brand, and type

tires on all wheels.

Your vehicle may have a different size spare than

the road tires (those originally installed on your

vehicle). When new, your vehicle included a spare

tire and wheel assembly with a similar overall

diameter as your vehicle's road tires and wheels,

so it is all right to drive on it. Because this spare

was developed for use on your vehicle, it will not

affect vehicle handling.

{WARNING:

If you use bias-ply tires on the vehicle, the

wheel rim flanges could develop cracks after

many miles of driving. A tire and/or wheel

could fail suddenly, causing a crash. Use

only radial-ply tires with the wheels on the

vehicle.

If you must replace your vehicle's tires with those that

do not have a TPC Spec number, make sure they

are the same size, load range, speed rating, and

construction type (radial and bias‐belted tires) as your

vehicle's original tires.

Vehicles that have a tire pressure monitoring system

may give an inaccurate low‐pressure warning if

non‐TPC spec rated tires are installed on your vehicle.

Non‐TPC Spec rated tires may give a low‐pressure

warning that is higher or lower than the proper warning

level you would get with TPC Spec rated tires. SeeTire

Pressure Monitor System on page 6‑73.

Your vehicle's original equipment tires are listed on the

Tire and Loading Information Label. See Loading the

Vehicle

on page 5‑31, for more information about the

Tire and Loading Information Label and its location on

your vehicle.

6-81

Page 456 of 550

Different Size Tires and Wheels

If you add wheels or tires that are a different size than

your original equipment wheels and tires, this could

affect the way your vehicle performs, including its

braking, ride and handling characteristics, stability, and

resistance to rollover. Additionally, if your vehicle has

electronic systems such as anti‐lock brakes, rollover

airbags, traction control, and electronic stability control,

the performance of these systems can be affected.

{WARNING:

If you add different sized wheels, your vehicle

may not provide an acceptable level of

performance and safety if tires not recommended

for those wheels are selected. You may increase

the chance that you will crash and suffer serious

injury. Only use GM specific wheel and tire

systems developed for your vehicle, and have

them properly installed by a GM certified

technician.

See Buying New Tires

on page 6‑80andAccessories

and Modificationson page 6‑4for additional

information.

Uniform Tire Quality Grading

Quality grades can be found where applicable on

the tire sidewall between tread shoulder and

maximum section width. For example:

Treadwear 200 Traction AA

Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration (NHTSA), which

grades tires by treadwear, traction, and

temperature performance. This applies only to

vehicles sold in the United States. The grades are

molded on the sidewalls of most passenger car

tires. The Uniform Tire Quality Grading (UTQG)

system does not apply to deep tread, winter-type

snow tires, space-saver, or temporary use spare

tires, tires with nominal rim diameters of

10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

6-82

Page 462 of 550

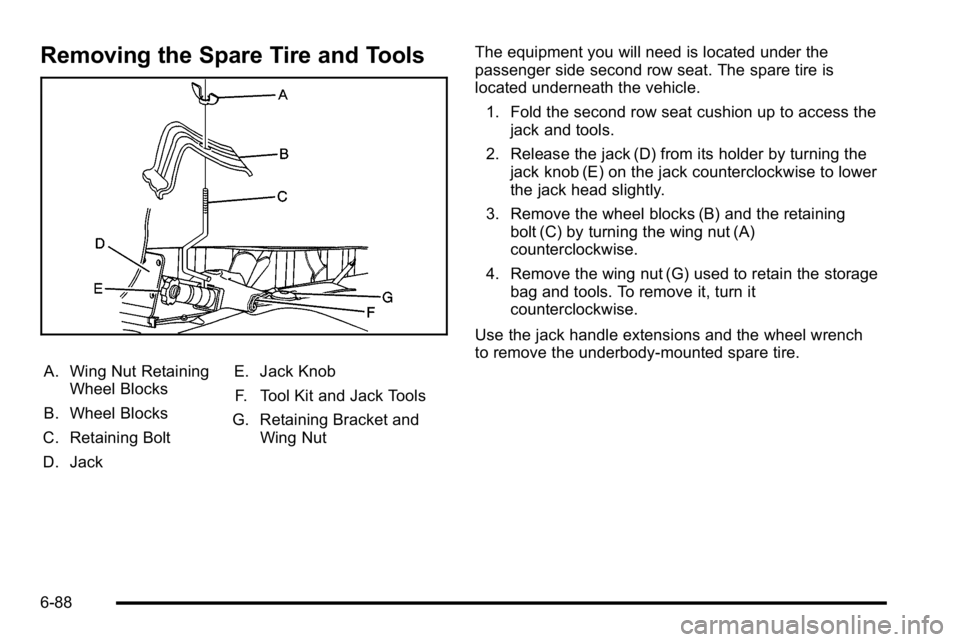

Removing the Spare Tire and Tools

A. Wing Nut RetainingWheel Blocks

B. Wheel Blocks

C. Retaining Bolt

D. Jack E. Jack Knob

F. Tool Kit and Jack Tools

G. Retaining Bracket and Wing Nut The equipment you will need is located under the

passenger side second row seat. The spare tire is

located underneath the vehicle.

1. Fold the second row seat cushion up to access the jack and tools.

2. Release the jack (D) from its holder by turning the jack knob (E) on the jack counterclockwise to lower

the jack head slightly.

3. Remove the wheel blocks (B) and the retaining bolt (C) by turning the wing nut (A)

counterclockwise.

4. Remove the wing nut (G) used to retain the storage bag and tools. To remove it, turn it

counterclockwise.

Use the jack handle extensions and the wheel wrench

to remove the underbody-mounted spare tire.

6-88

Page 463 of 550

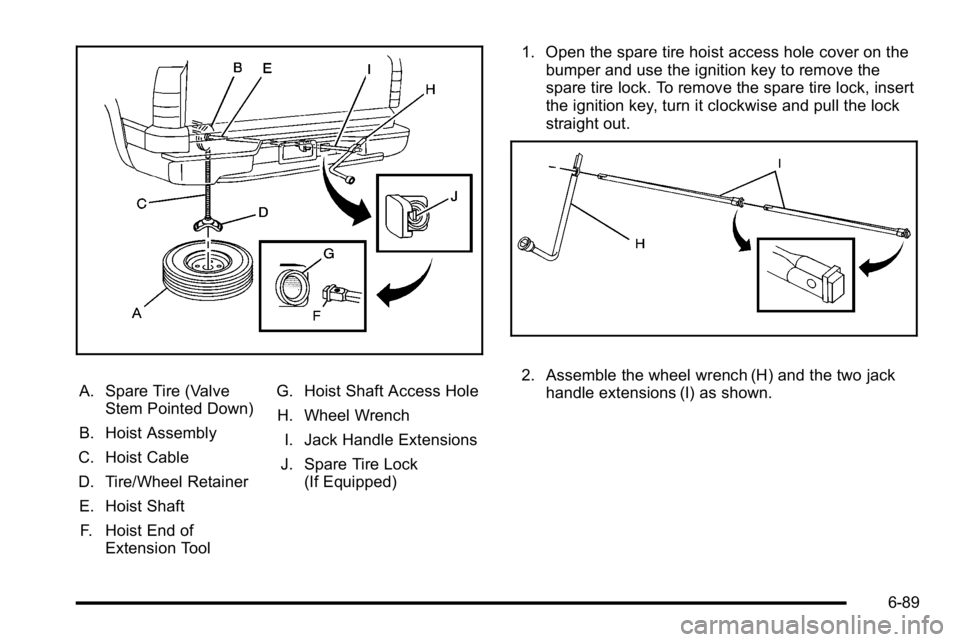

A. Spare Tire (ValveStem Pointed Down)

B. Hoist Assembly

C. Hoist Cable

D. Tire/Wheel Retainer E. Hoist Shaft F. Hoist End of Extension Tool G. Hoist Shaft Access Hole

H. Wheel Wrench I. Jack Handle Extensions

J. Spare Tire Lock (If Equipped) 1. Open the spare tire hoist access hole cover on the

bumper and use the ignition key to remove the

spare tire lock. To remove the spare tire lock, insert

the ignition key, turn it clockwise and pull the lock

straight out.2. Assemble the wheel wrench (H) and the two jack

handle extensions (I) as shown.

6-89