GMC YUKON DENALI 2010 Owners Manual

Manufacturer: GMC, Model Year: 2010, Model line: YUKON DENALI, Model: GMC YUKON DENALI 2010Pages: 560, PDF Size: 4.32 MB

Page 441 of 560

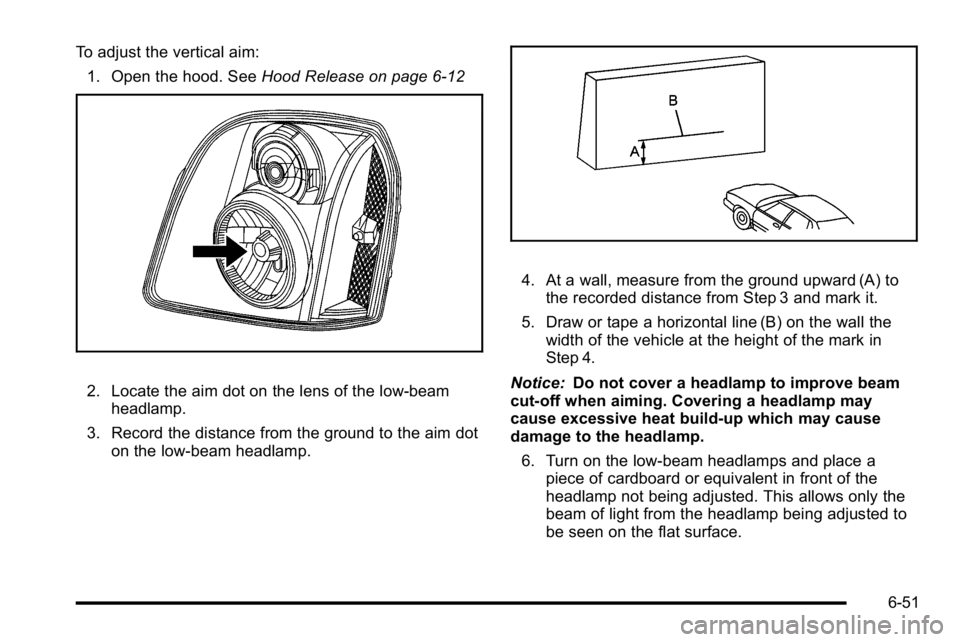

To adjust the vertical aim:1. Open the hood. See Hood Release on page 6‑12

2. Locate the aim dot on the lens of the low‐beam

headlamp.

3. Record the distance from the ground to the aim dot on the low‐beam headlamp.

4. At a wall, measure from the ground upward (A) tothe recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the vehicle at the height of the mark in

Step 4.

Notice: Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a piece of cardboard or equivalent in front of the

headlamp not being adjusted. This allows only the

beam of light from the headlamp being adjusted to

be seen on the flat surface.

6-51

Page 442 of 560

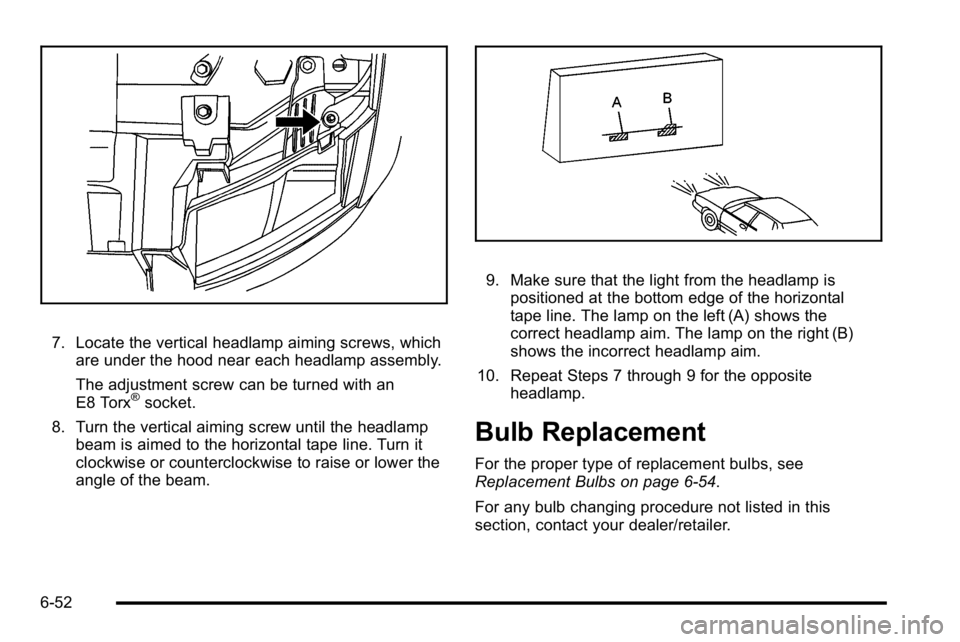

7. Locate the vertical headlamp aiming screws, whichare under the hood near each headlamp assembly.

The adjustment screw can be turned with an

E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal

tape line. The lamp on the left (A) shows the

correct headlamp aim. The lamp on the right (B)

shows the incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 6‑54.

For any bulb changing procedure not listed in this

section, contact your dealer/retailer.

6-52

Page 443 of 560

Halogen Bulbs

{WARNING:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and

follow the instructions on the bulb package.

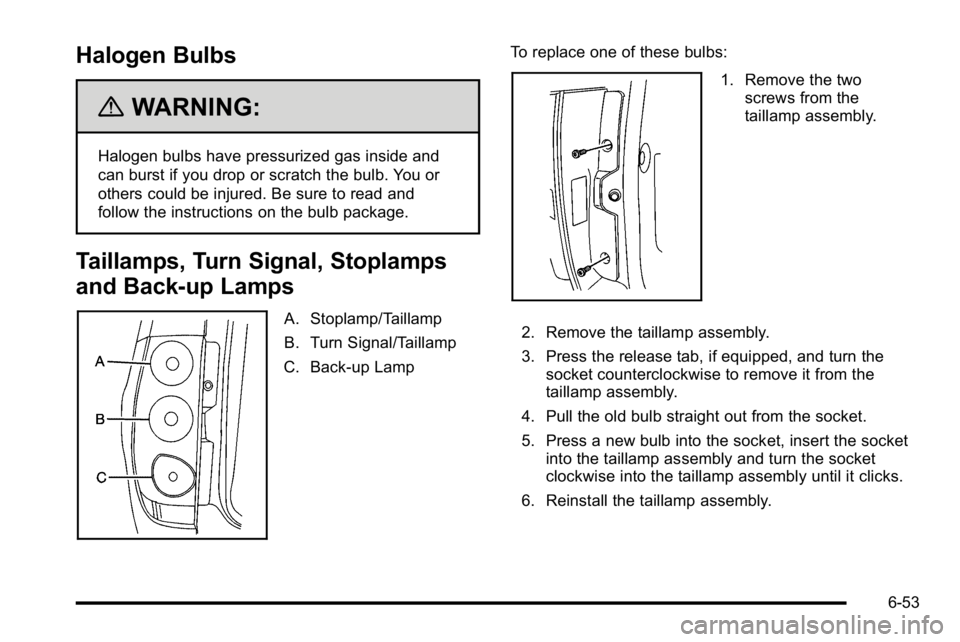

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

A. Stoplamp/Taillamp

B. Turn Signal/Taillamp

C. Back-up Lamp To replace one of these bulbs:

1. Remove the two

screws from the

taillamp assembly.

2. Remove the taillamp assembly.

3. Press the release tab, if equipped, and turn the socket counterclockwise to remove it from the

taillamp assembly.

4. Pull the old bulb straight out from the socket.

5. Press a new bulb into the socket, insert the socket into the taillamp assembly and turn the socket

clockwise into the taillamp assembly until it clicks.

6. Reinstall the taillamp assembly.

6-53

Page 444 of 560

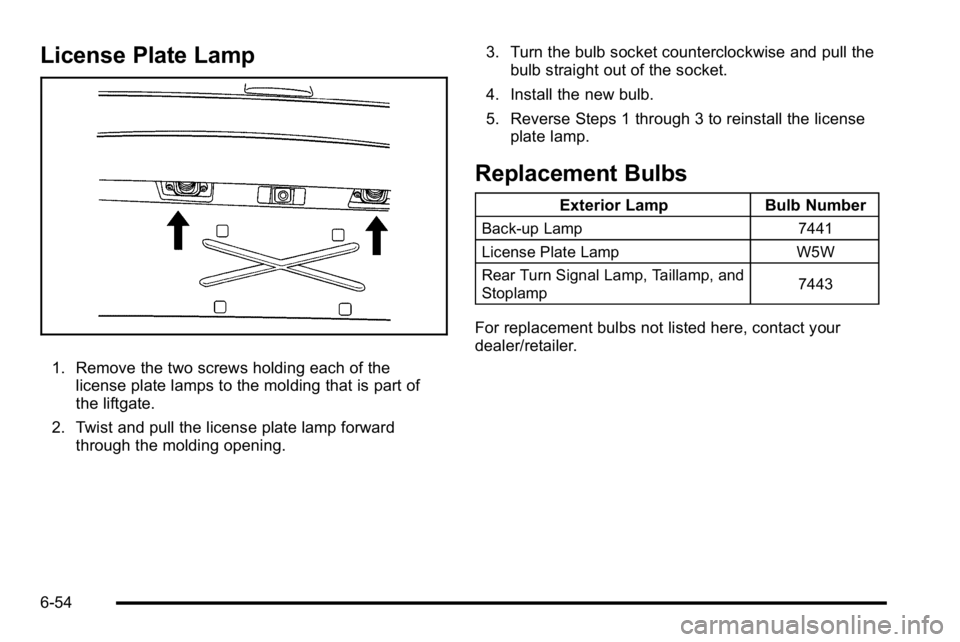

License Plate Lamp

1. Remove the two screws holding each of thelicense plate lamps to the molding that is part of

the liftgate.

2. Twist and pull the license plate lamp forward through the molding opening. 3. Turn the bulb socket counterclockwise and pull the

bulb straight out of the socket.

4. Install the new bulb.

5. Reverse Steps 1 through 3 to reinstall the license plate lamp.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp 7441

License Plate Lamp W5W

Rear Turn Signal Lamp, Taillamp, and

Stoplamp 7443

For replacement bulbs not listed here, contact your

dealer/retailer.

6-54

Page 445 of 560

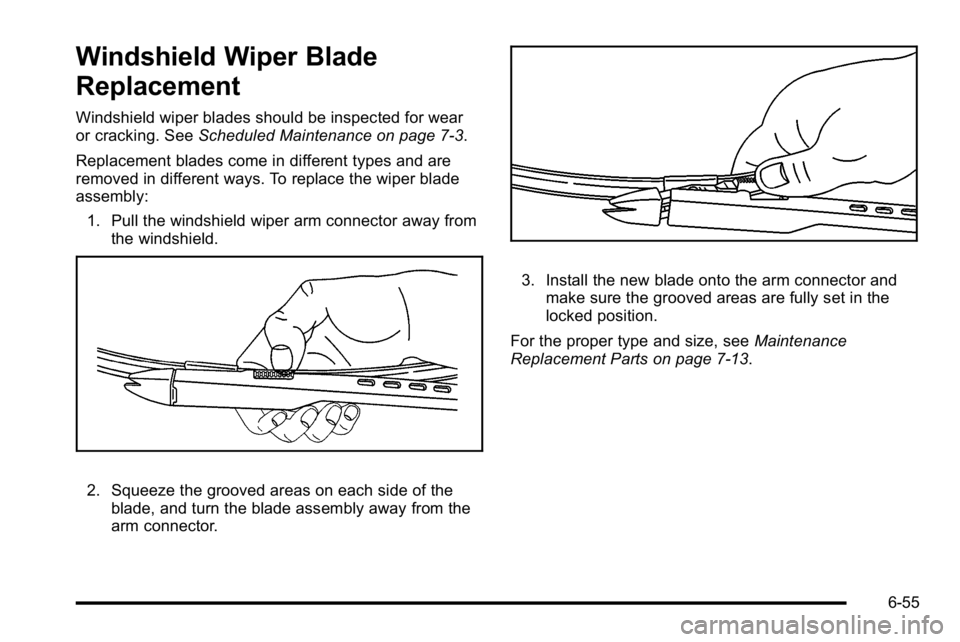

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

or cracking. SeeScheduled Maintenance on page 7‑3.

Replacement blades come in different types and are

removed in different ways. To replace the wiper blade

assembly: 1. Pull the windshield wiper arm connector away from the windshield.

2. Squeeze the grooved areas on each side of the

blade, and turn the blade assembly away from the

arm connector.

3. Install the new blade onto the arm connector andmake sure the grooved areas are fully set in the

locked position.

For the proper type and size, see Maintenance

Replacement Parts on page 7‑13.

6-55

Page 446 of 560

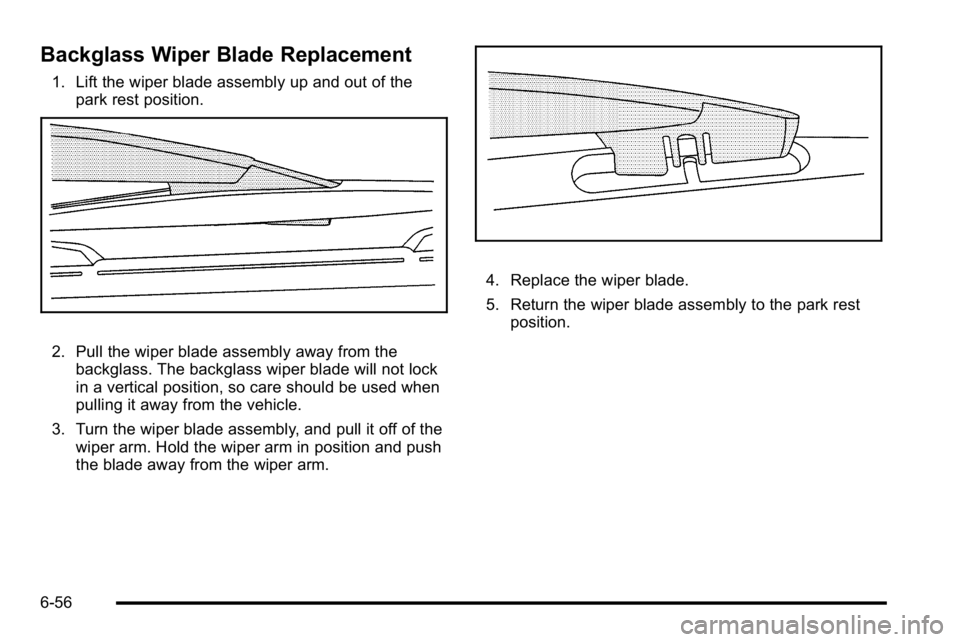

Backglass Wiper Blade Replacement

1. Lift the wiper blade assembly up and out of thepark rest position.

2. Pull the wiper blade assembly away from thebackglass. The backglass wiper blade will not lock

in a vertical position, so care should be used when

pulling it away from the vehicle.

3. Turn the wiper blade assembly, and pull it off of the wiper arm. Hold the wiper arm in position and push

the blade away from the wiper arm.

4. Replace the wiper blade.

5. Return the wiper blade assembly to the park restposition.

6-56

Page 447 of 560

Tires

Your new vehicle comes with high-quality tires

made by a leading tire manufacturer. If you ever

have questions about your tire warranty and

where to obtain service, see your vehicle

Warranty booklet for details. For additional

information refer to the tire manufacturer.

{WARNING:

.Poorly maintained and improperly used

tires are dangerous.

.Overloading your tires can cause

overheating as a result of too much

flexing. You could have an air-out and a

serious accident. SeeLoading the Vehicle

on page 5‑31.

(Continued)

WARNING: (Continued)

.Underinflated tires pose the same danger

as overloaded tires. The resulting

accident could cause serious injury.

Check all tires frequently to maintain the

recommended pressure. Tire pressure

should be checked when your tires are

cold. SeeInflation - Tire Pressure

on

page 6‑64

.

.Overinflated tires are more likely to be

cut, punctured, or broken by a sudden

impact —such as when you hit a

pothole. Keep tires at the recommended

pressure.

.Worn, old tires can cause accidents.

If your tread is badly worn, or if your tires

have been damaged, replace them.

See High-Speed Operation

on page 6‑66for

inflation pressure adjustment for high speed

driving.

6-57

Page 448 of 560

20‐Inch Tires

If your vehicle has the optional 20‐inch

P275/55R20 size tires, they are classified as

touring tires and are designed for on road use.

The low‐profile, wide tread design is not

recommended for off‐road driving. SeeOff-Road

Driving

on page 5‑12, for additional information.

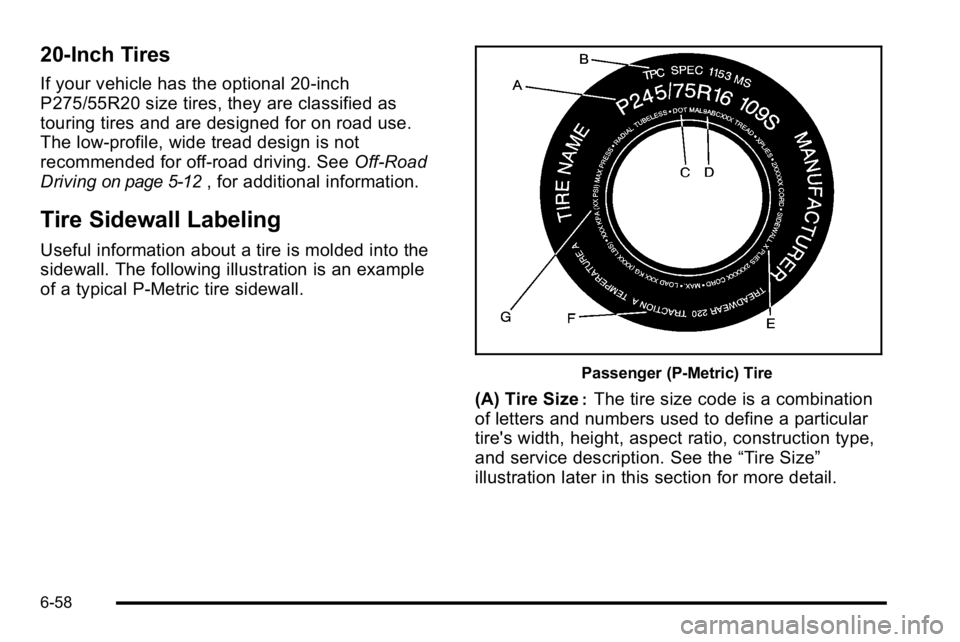

Tire Sidewall Labeling

Useful information about a tire is molded into the

sidewall. The following illustration is an example

of a typical P‐Metric tire sidewall.

Passenger (P‐Metric) Tire

(A) Tire Size:The tire size code is a combination

of letters and numbers used to define a particular

tire's width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail.

6-58

Page 449 of 560

(B) TPC Spec (Tire Performance Criteria

Specification)

:Original equipment tires designed

to GM's specific tire performance criteria have a

TPC specification code molded onto the sidewall.

GM's TPC specifications meet or exceed all

federal safety guidelines.

(C) DOT (Department of Transportation)

:

The Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(D) Tire Identification Number (TIN)

:The letters

and numbers following DOT code are the Tire

Identification Number (TIN). The TIN shows the

manufacturer and plant code, tire size, and date

the tire was manufactured. The TIN is molded

onto both sides of the tire, although only one side

may have the date of manufacture. (E) Tire Ply Material

:The type of cord and

number of plies in the sidewall and under the

tread.

(F) Uniform Tire Quality Grading (UTQG)

:Tire

manufacturers are required to grade tires based

on three performance factors: treadwear, traction,

and temperature resistance. For more information,

see Uniform Tire Quality Grading

on page 6‑76.

(G) Maximum Cold Inflation Load Limit

:

Maximum load that can be carried and the

maximum pressure needed to support that load.

For information on recommended tire pressure

see Inflation - Tire Pressure

on page 6‑64and

Loading the Vehicle

on page 5‑31.

6-59

Page 450 of 560

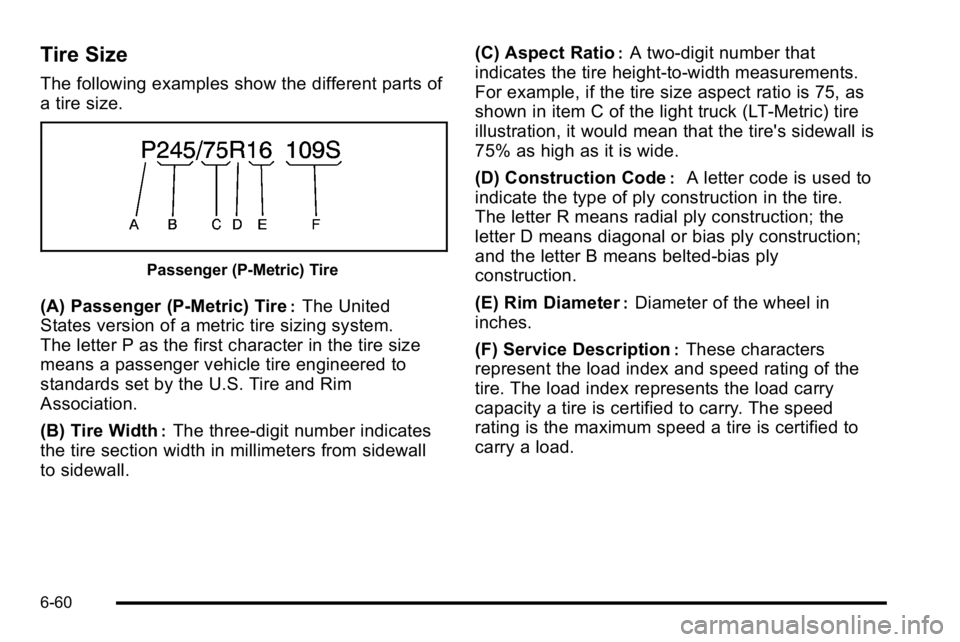

Tire Size

The following examples show the different parts of

a tire size.

Passenger (P‐Metric) Tire

(A) Passenger (P‐Metric) Tire:The United

States version of a metric tire sizing system.

The letter P as the first character in the tire size

means a passenger vehicle tire engineered to

standards set by the U.S. Tire and Rim

Association.

(B) Tire Width

:The three‐digit number indicates

the tire section width in millimeters from sidewall

to sidewall. (C) Aspect Ratio

:A two‐digit number that

indicates the tire height‐to‐width measurements.

For example, if the tire size aspect ratio is 75, as

shown in item C of the light truck (LT‐Metric) tire

illustration, it would mean that the tire's sidewall is

75% as high as it is wide.

(D) Construction Code

:A letter code is used to

indicate the type of ply construction in the tire.

The letter R means radial ply construction; the

letter D means diagonal or bias ply construction;

and the letter B means belted‐bias ply

construction.

(E) Rim Diameter

:Diameter of the wheel in

inches.

(F) Service Description

:These characters

represent the load index and speed rating of the

tire. The load index represents the load carry

capacity a tire is certified to carry. The speed

rating is the maximum speed a tire is certified to

carry a load.

6-60