dashboard GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 164 of 281

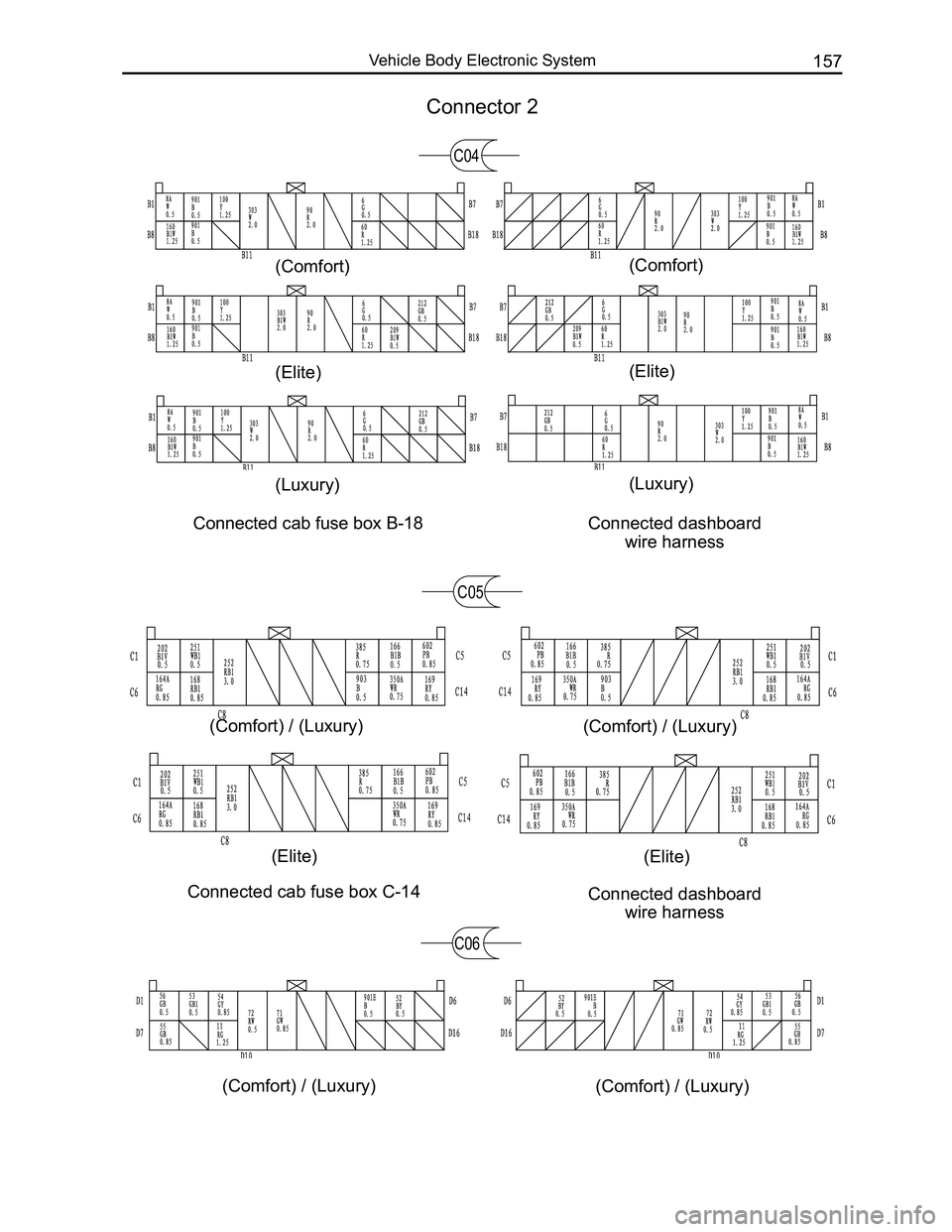

Downloaded from www.Manualslib.com manuals search engine 157Vehicle Body Electronic System

Connected cab fuse box C-14Connected dashboard

wire harness

C05

C06

Connector 2

C04

Connected cab fuse box B-18 Connected dashboard

wire harness

(Luxury)

(Elite)

(Comfort)

(Luxury)

(Elite)

(Comfort)

(Elite)

(Comfort) / (Luxury)

(Elite)

(Comfort) / (Luxury)

(Comfort) / (Luxury)(Comfort) / (Luxury)

Page 165 of 281

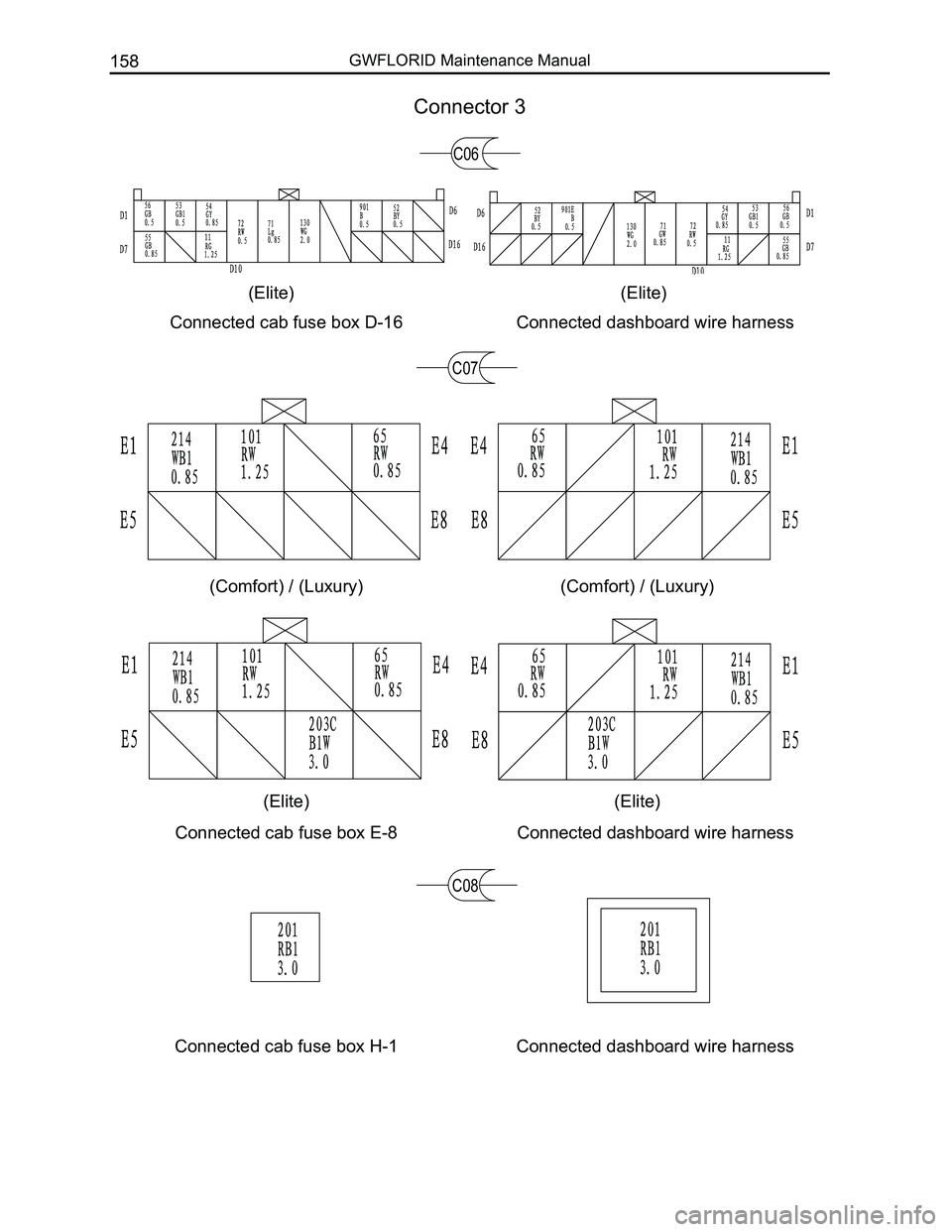

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual158

Connected cab fuse box D-16Connected dashboard wire harness

Connector 3

(Elite)(Elite)

C07

Connected dashboard wire harnessConnected cab fuse box E-8

C08

Connected cab fuse box H-1Connected dashboard wire harness

(Comfort) / (Luxury)(Comfort) / (Luxury)

(Elite)(Elite)

C06

Page 166 of 281

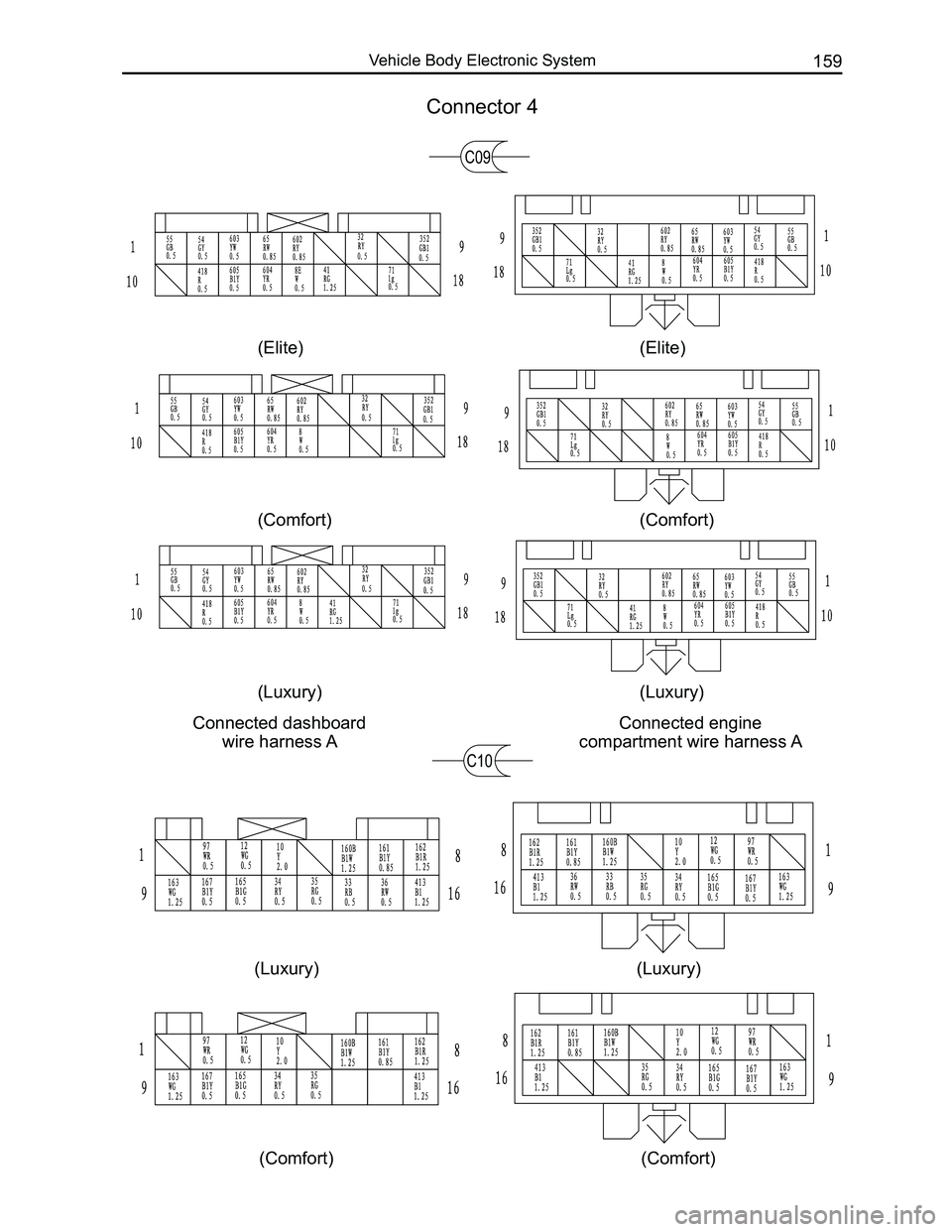

Downloaded from www.Manualslib.com manuals search engine 159Vehicle Body Electronic System

Connected dashboard

wire harness A

Connected engine

compartment wire harness A

C09

C10

Connector 4

(Luxury)

(Elite)

(Comfort)

(Luxury)

(Elite)

(Comfort)

(Luxury)(Luxury)

(Comfort)(Comfort)

Page 167 of 281

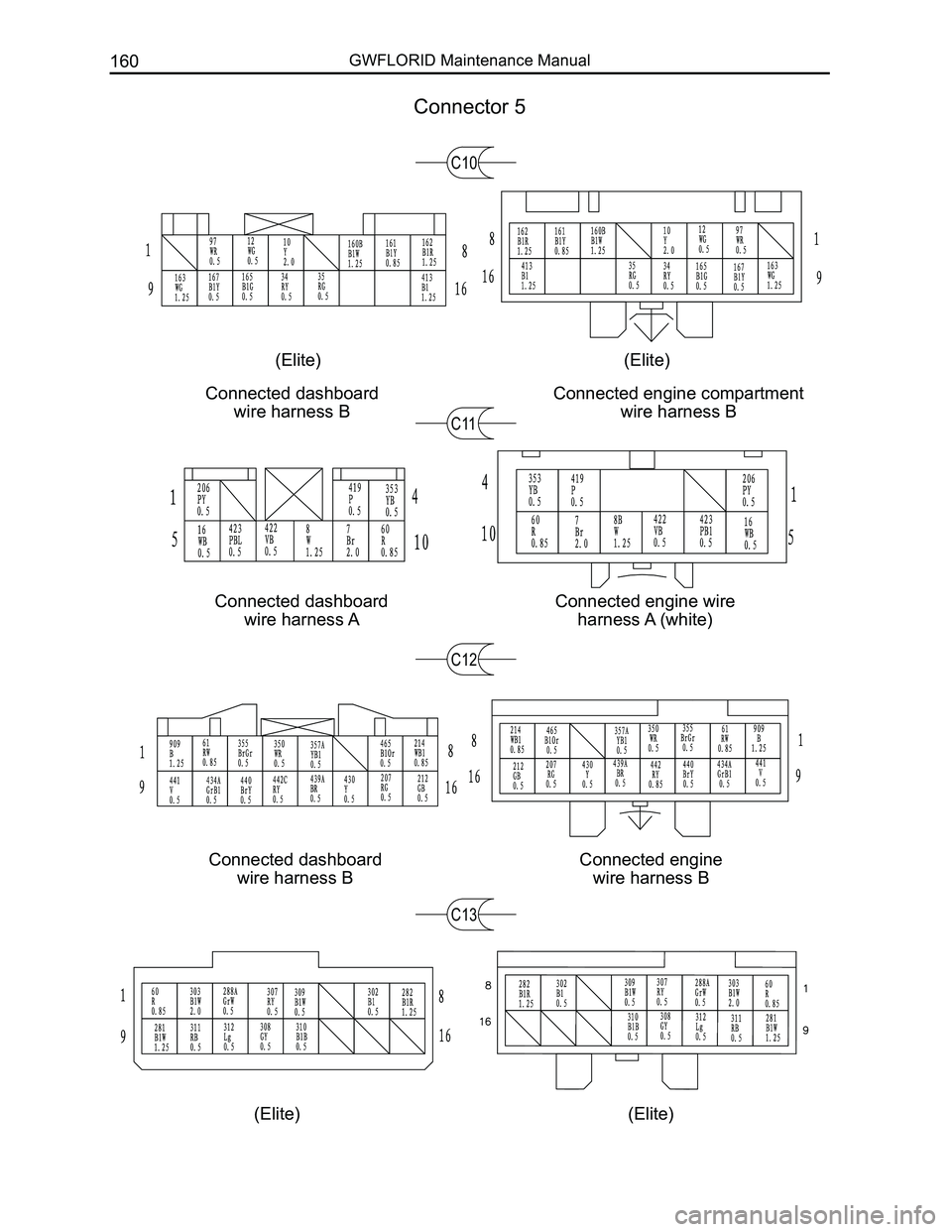

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual160

Connected dashboard

wire harness B

Connected engine compartment

wire harness B

Connected dashboard

wire harness A

Connected engine wire

harness A (white)

Connected dashboard

wire harness B

Connected engine

wire harness B

C10

C 11

C12

C13

Connector 5

(Elite)(Elite)

(Elite)(Elite)

Page 169 of 281

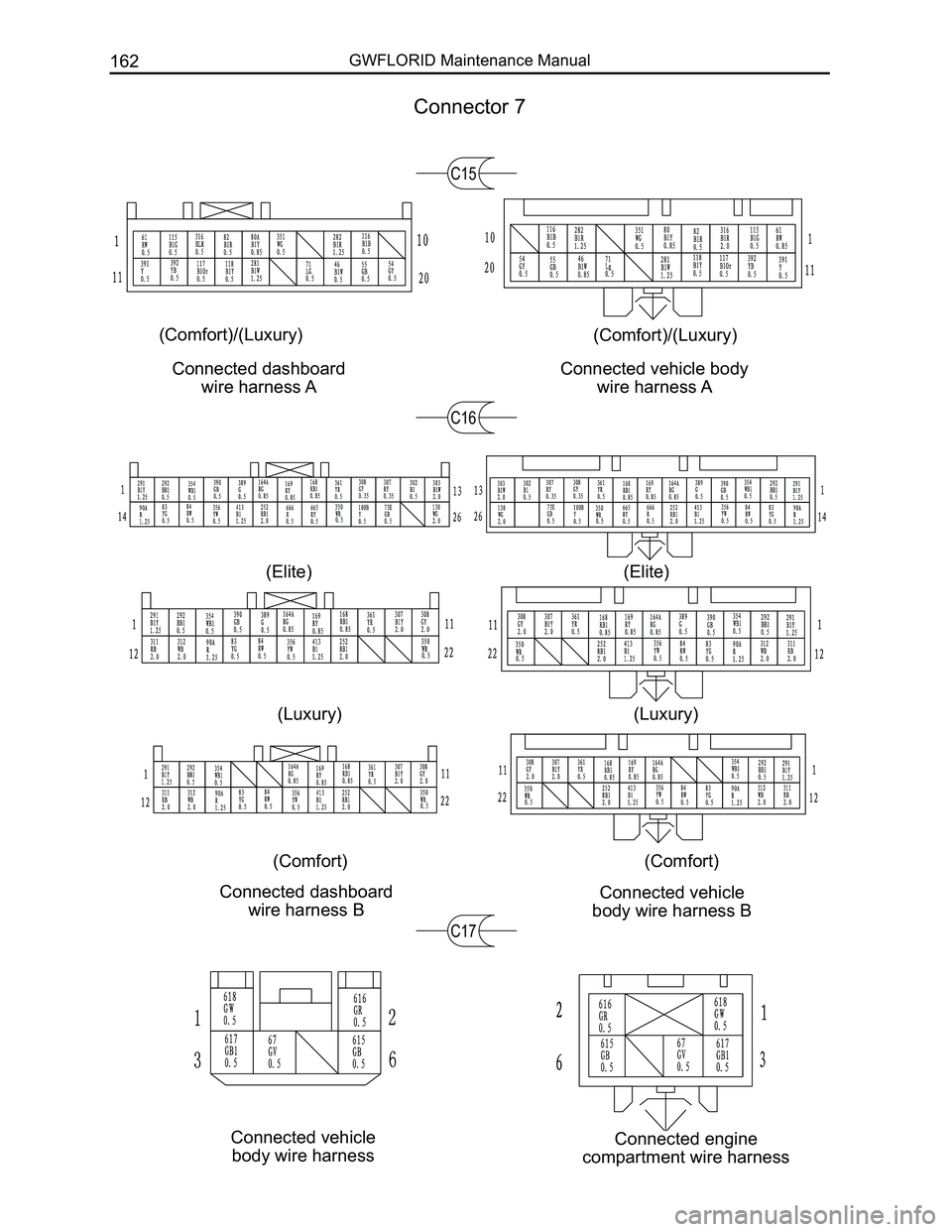

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual162

Connected vehicle

body wire harness B

Connected dashboard

wire harness B

Connected vehicle

body wire harness

Connected engine

compartment wire harness

C15

C16

C17

Connector 7

Connected dashboard

wire harness A

Connected vehicle body

wire harness A

(Comfort)/(Luxury)(Comfort)/(Luxury)

(Luxury)

(Elite)

(Comfort)

(Luxury)

(Elite)

(Comfort)

Page 195 of 281

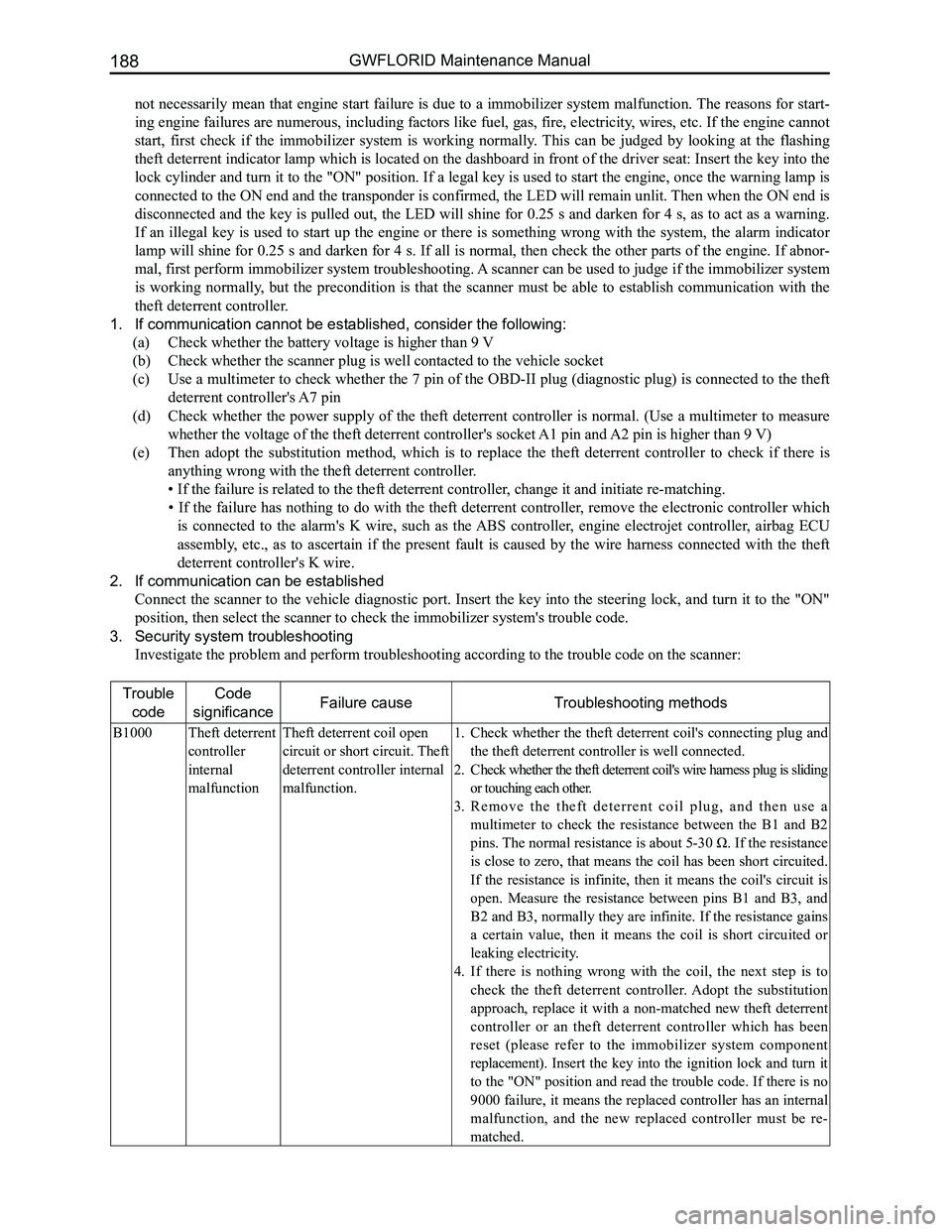

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual188

not necessarily mean that engine start failure is due to a immobilizer system malfunction. The reasons for start-

ing engine failures are numerous, including factors like fuel, gas, fire, electricity, wires, etc. If the engine cannot

start, first check if the immobilizer system is working normally. This can be judged by looking at the flashing

theft deterrent indicator lamp which is located on the dashboard in front of the driver seat: Insert the key into the

lock cylinder and turn it to the "ON" position. If a legal key is used to start the engine, once the warning lamp is

connected to the ON end and the transponder is confirmed, the LED will remain unlit. Then when the ON end is

disconnected and the key is pulled out, the LED will shine for 0.25 s and darken for 4 s, as to act as a warning.

If an illegal key is used to start up the engine or there is something wrong with the system, the alarm indicator

lamp will shine for 0.25 s and darken for 4 s. If all is normal, then check the other parts of the engine. If abnor-

mal, first perform immobilizer system troubleshooting. A scanner can be used to judge if the immobilizer system

is working normally, but the precondition is that the scanner must be able to establish communication with the

theft deterrent controller.

1. If communication cannot be established, consider the following:

(a) Check whether the battery voltage is higher than 9 V

(b) Check whether the scanner plug is well contacted to the vehicle socket

(c) Use a multimeter to check whether the 7 pin of the OBD-II plug (diagnostic plug) is connected to the theft

deterrent controller's A7 pin

(d) Check whether the power supply of the theft deterrent controller is normal. (Use a multimeter to measure

whether the voltage of the theft deterrent controller's socket A1 pin and A2 pin is higher than 9 V)

(e) Then adopt the substitution method, which is to replace the theft deterrent controller to check if there is

anything wrong with the theft deterrent controller.

• If the failure is related to the theft deterrent controller, change it and initiate re-matching.

• If the failure has nothing to do with the theft deterrent controller, remove the electronic controller which

is connected to the alarm's K wire, such as the ABS controller, engine electrojet controller, airbag ECU

assembly, etc., as to ascertain if the present fault is caused by the wire harness connected with the theft

deterrent controller's K wire.

2. If communication can be established

Connect the scanner to the vehicle diagnostic port. Insert the key into the steering lock, and turn it to the "ON"

position, then select the scanner to check the immobilizer system's trou\

ble code.

3. Security system troubleshooting

Investigate the problem and perform troubleshooting according to the tro\

uble code on the scanner:

Trouble

code

Code

significanceFailure causeTroubleshooting methods

B1000Theft deterrent

controller

internal

malfunction

Theft deterrent coil open

circuit or short circuit. Theft

deterrent controller internal

malfunction.

Check whether the theft deterrent coil's connecting plug and 1.

the theft deterrent controller is well connected.

Check whether the theft deterrent coil's wire harness plug is sliding 2.

or touching each other.

R e m o v e t h e t h e f t d e t e r r e n t c o i l p l u g , a n d t h e n u s e a 3.

multimeter to check the resistance between the B1 and B2

pins. The normal resistance is about 5-30 Ω. If the resistance

is close to zero, that means the coil has been short circuited.

If the resistance is infinite, then it means the coil's circuit is

open. Measure the resistance between pins B1 and B3, and

B2 and B3, normally they are infinite. If the resistance gains

a certain value, then it means the coil is short circuited or

leaking electricity.

If there is nothing wrong with the coil, the next step is to 4.

check the theft deterrent controller. Adopt the substitution

approach, replace it with a non-matched new theft deterrent

controller or an theft deterrent controller which has been

reset (please refer to the immobilizer system component

replacement). Insert the key into the ignition lock and turn it

to the "ON" position and read the trouble code. If there is no

9000 failure, it means the replaced controller has an internal

malfunction, and the new replaced controller must be re-

matched.

Page 227 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual220

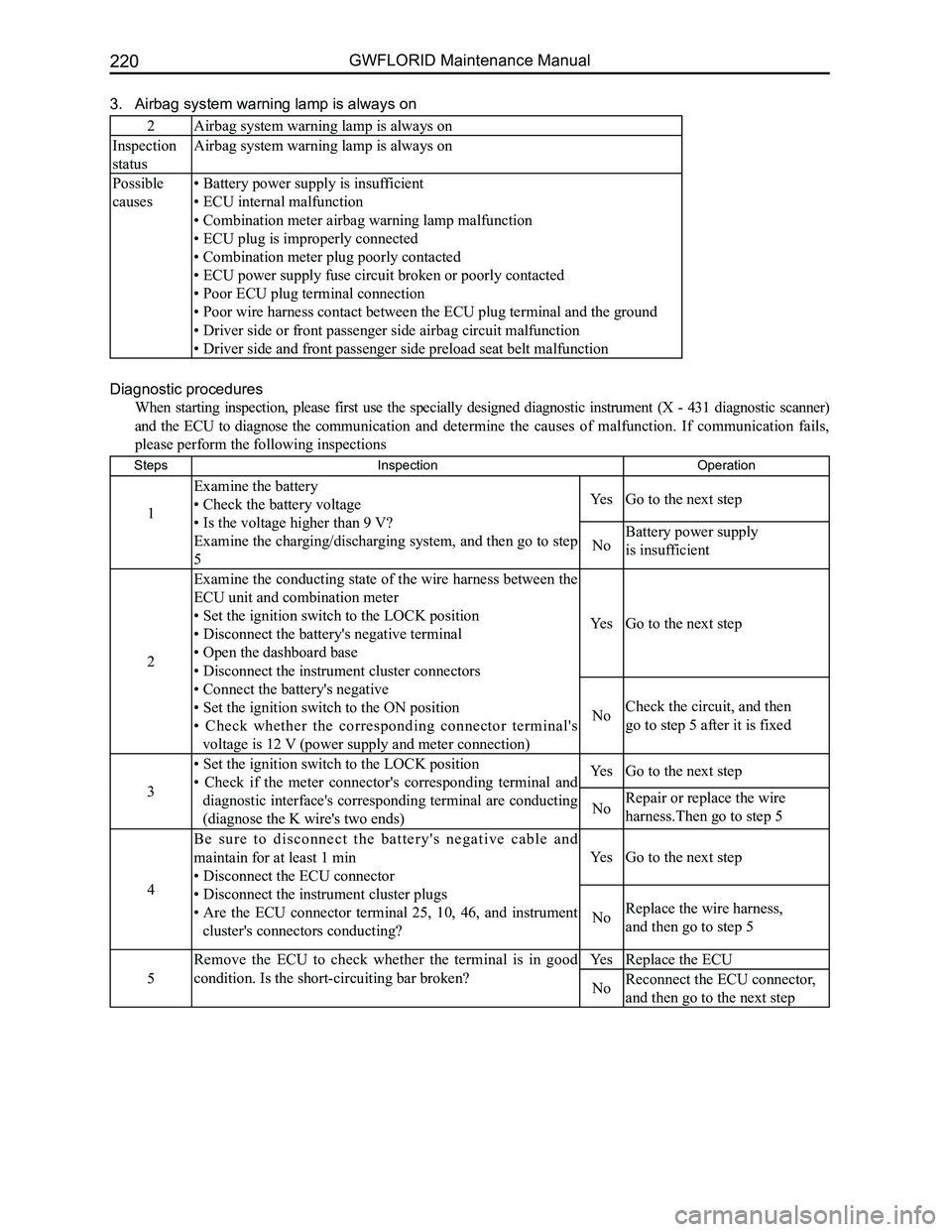

3. Airbag system warning lamp is always on

2Airbag system warning lamp is always on

Inspection

status

Airbag system warning lamp is always on

Possible

causes

• Battery power supply is insufficient

• ECU internal malfunction

• Combination meter airbag warning lamp malfunction

• ECU plug is improperly connected

• Combination meter plug poorly contacted

• ECU power supply fuse circuit broken or poorly contacted

• Poor ECU plug terminal connection

• Poor wire harness contact between the ECU plug terminal and the ground

• Driver side or front passenger side airbag circuit malfunction

• Driver side and front passenger side preload seat belt malfunction

Diagnostic procedures

When starting inspection, please first use the specially designed diagnostic instrument (X - 431 diagnostic scanner)

and the ECU to diagnose the communication and determine the causes of malfunction. If communication fails,

please perform the following inspections

StepsInspection Operation

1

Examine the battery

• Check the battery voltage

• Is the voltage higher than 9 V?

Examine the charging/discharging system, and then go to step

5

YesGo to the next step

NoBattery power supply

is insufficient

2

Examine the conducting state of the wire harness between the

ECU unit and combination meter

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative terminal

• Open the dashboard base

• Disconnect the instrument cluster connectors

• Connect the battery's negative

• Set the ignition switch to the ON position

• Check whether the corresponding connector terminal's

voltage is 12 V (power supply and meter connection)

YesGo to the next step

NoCheck the circuit, and then

go to step 5 after it is fixed

3

• Set the ignition switch to the LOCK position

• Check if the meter connector's corresponding terminal and

diagnostic interface's corresponding terminal are conducting

(diagnose the K wire's two ends)

YesGo to the next step

NoRepair or replace the wire

harness.Then go to step 5

4

B e s u r e t o d i s c o n n e c t t h e b a t t e r y ' s n e g a t i v e c a b l e a n d

maintain for at least 1 min

• Disconnect the ECU connector

• Disconnect the instrument cluster plugs

• Are the ECU connector terminal 25, 10, 46, and instrument

cluster's connectors conducting?

YesGo to the next step

NoReplace the wire harness,

and then go to step 5

5

Remove the ECU to check whether the terminal is in good

condition. Is the short-circuiting bar broken?

YesReplace the ECU

NoReconnect the ECU connector,

and then go to the next step

Page 229 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual222

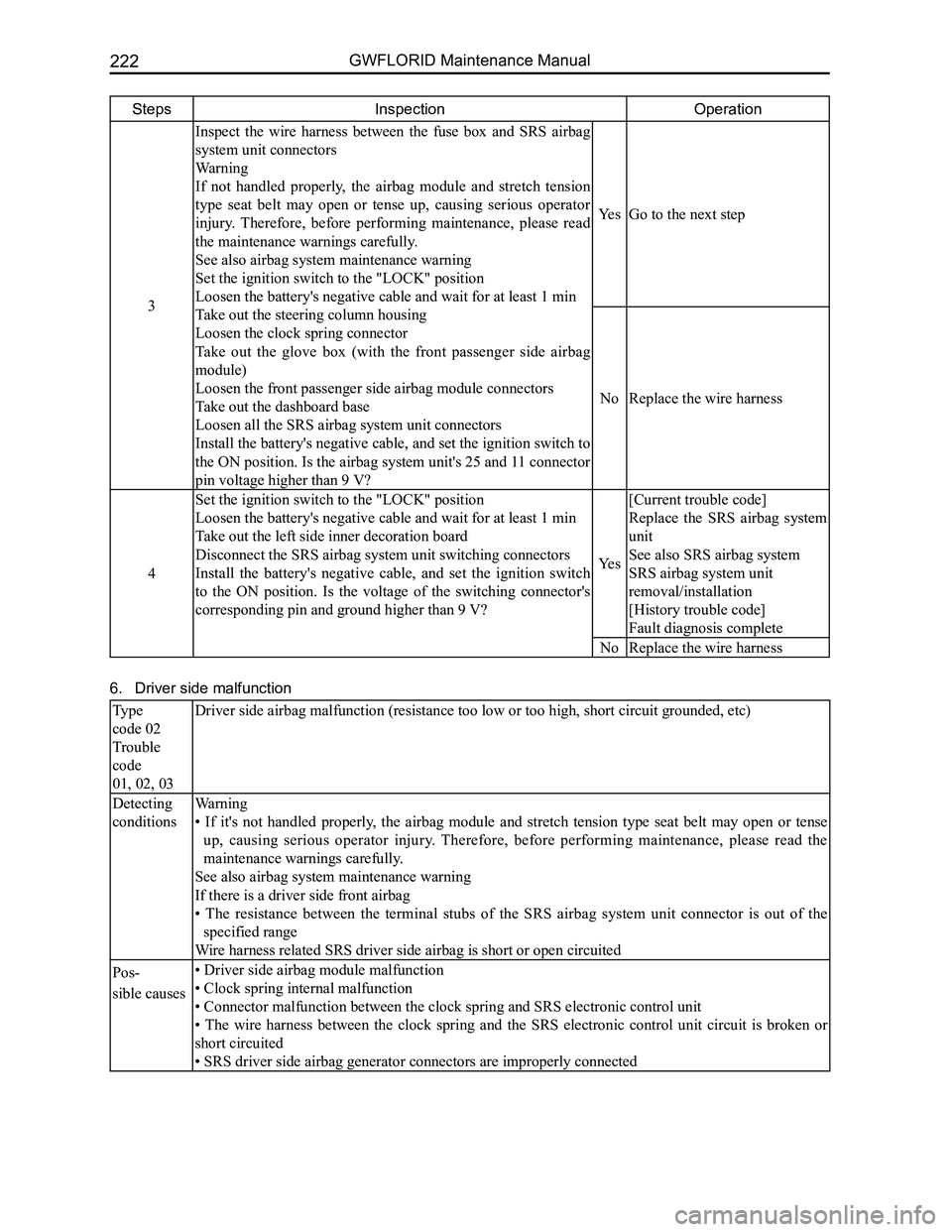

StepsInspectionOperation

3

Inspect the wire harness between the fuse box and SRS airbag

system unit connectors

Warning

If not handled properly, the airbag module and stretch tension

type seat belt may open or tense up, causing serious operator

injury. Therefore, before performing maintenance, please read

the maintenance warnings carefully.

See also airbag system maintenance warning

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the steering column housing

Loosen the clock spring connector

Take out the glove box (with the front passenger side airbag

module)

Loosen the front passenger side airbag module connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Install the battery's negative cable, and set the ignition switch to

the ON position. Is the airbag system unit's 25 and 11 connector

pin voltage higher than 9 V?

YesGo to the next step

NoReplace the wire harness

4

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the left side inner decoration board

Disconnect the SRS airbag system unit switching connectors

Install the battery's negative cable, and set the ignition switch

to the ON position. Is the voltage of the switching connector's

corresponding pin and ground higher than 9 V?

Yes

[Current trouble code]

Replace the SRS airbag system

unit

See also SRS airbag system

SRS airbag system unit

removal/installation

[History trouble code]

Fault diagnosis complete

NoReplace the wire harness

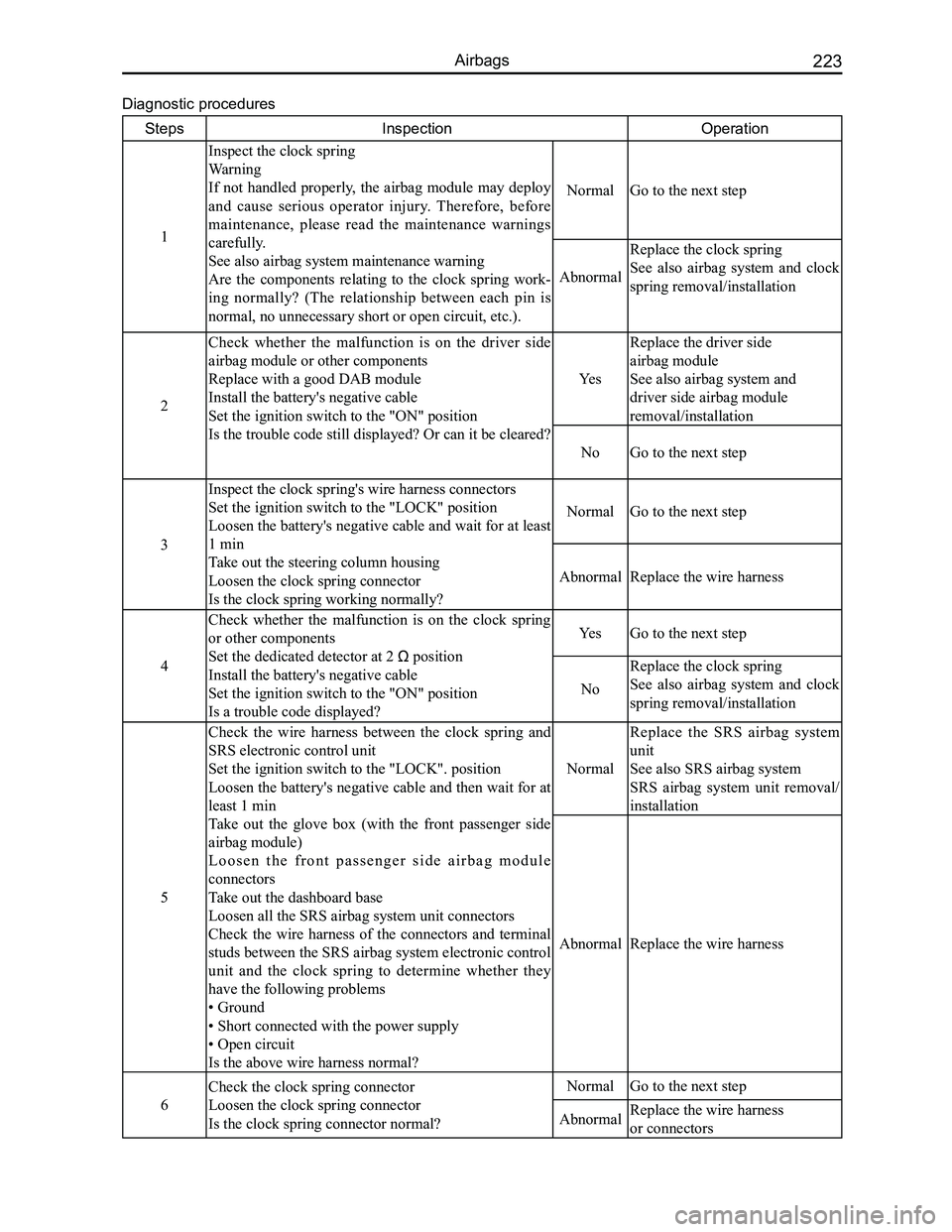

6. Driver side malfunction

Type

code 02

Trouble

code

01, 02, 03

Driver side airbag malfunction (resistance too low or too high, short c\

ircuit grounded, etc)

Detecting

conditions

Warning

• If it's not handled properly, the airbag module and stretch tension type seat belt may open or tense

up, causing serious operator injury. Therefore, before performing maintenance, please read the

maintenance warnings carefully.

See also airbag system maintenance warning

If there is a driver side front airbag

• The resistance between the terminal stubs of the SRS airbag system unit connector is out of the

specified range

Wire harness related SRS driver side airbag is short or open circuited

Pos-

sible causes

• Driver side airbag module malfunction

• Clock spring internal malfunction

• Connector malfunction between the clock spring and SRS electronic control unit

• The wire harness between the clock spring and the SRS electronic control unit circuit is broken or

short circuited

• SRS driver side airbag generator connectors are improperly connected

Page 230 of 281

Downloaded from www.Manualslib.com manuals search engine 223Airbags

Diagnostic procedures

StepsInspectionOperation

1

Inspect the clock spring

Warning

If not handled properly, the airbag module may deploy

and cause serious operator injury. Therefore, before

maintenance, please read the maintenance warnings

carefully.

See also airbag system maintenance warning

Are the components relating to the clock spring work-

ing normally? (The relationship between each pin is

normal, no unnecessary short or open circuit, etc.).

NormalGo to the next step

Abnormal

Replace the clock spring

See also airbag system and clock

spring removal/installation

2

Check whether the malfunction is on the driver side

airbag module or other components

Replace with a good DAB module

Install the battery's negative cable

Set the ignition switch to the "ON" position

Is the trouble code still displayed? Or can it be cleared?

Yes

Replace the driver side

airbag module

See also airbag system and

driver side airbag module

removal/installation

NoGo to the next step

3

Inspect the clock spring's wire harness connectors

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least

1 min

Take out the steering column housing

Loosen the clock spring connector

Is the clock spring working normally?

NormalGo to the next step

AbnormalReplace the wire harness

4

Check whether the malfunction is on the clock spring

or other components

Set the dedicated detector at 2 Ω position

Install the battery's negative cable

Set the ignition switch to the "ON" position

Is a trouble code displayed?

YesGo to the next step

No

Replace the clock spring

See also airbag system and clock

spring removal/installation

5

Check the wire harness between the clock spring and

SRS electronic control unit

Set the ignition switch to the "LOCK". position

Loosen the battery's negative cable and then wait for at

least 1 min

Take out the glove box (with the front passenger side

airbag module)

L o o s e n t h e f r o n t p a s s e n g e r s i d e a i r b a g m o d u l e

connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Check the wire harness of the connectors and terminal

studs between the SRS airbag system electronic control

unit and the clock spring to determine whether they

have the following problems

• Ground

• Short connected with the power supply

• Open circuit

Is the above wire harness normal?

Normal

Replace the SRS airbag system

unit

See also SRS airbag system

SRS airbag system unit removal/

installation

AbnormalReplace the wire harness

6

Check the clock spring connector

Loosen the clock spring connector

Is the clock spring connector normal?

NormalGo to the next step

AbnormalReplace the wire harness

or connectors

Page 231 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual224

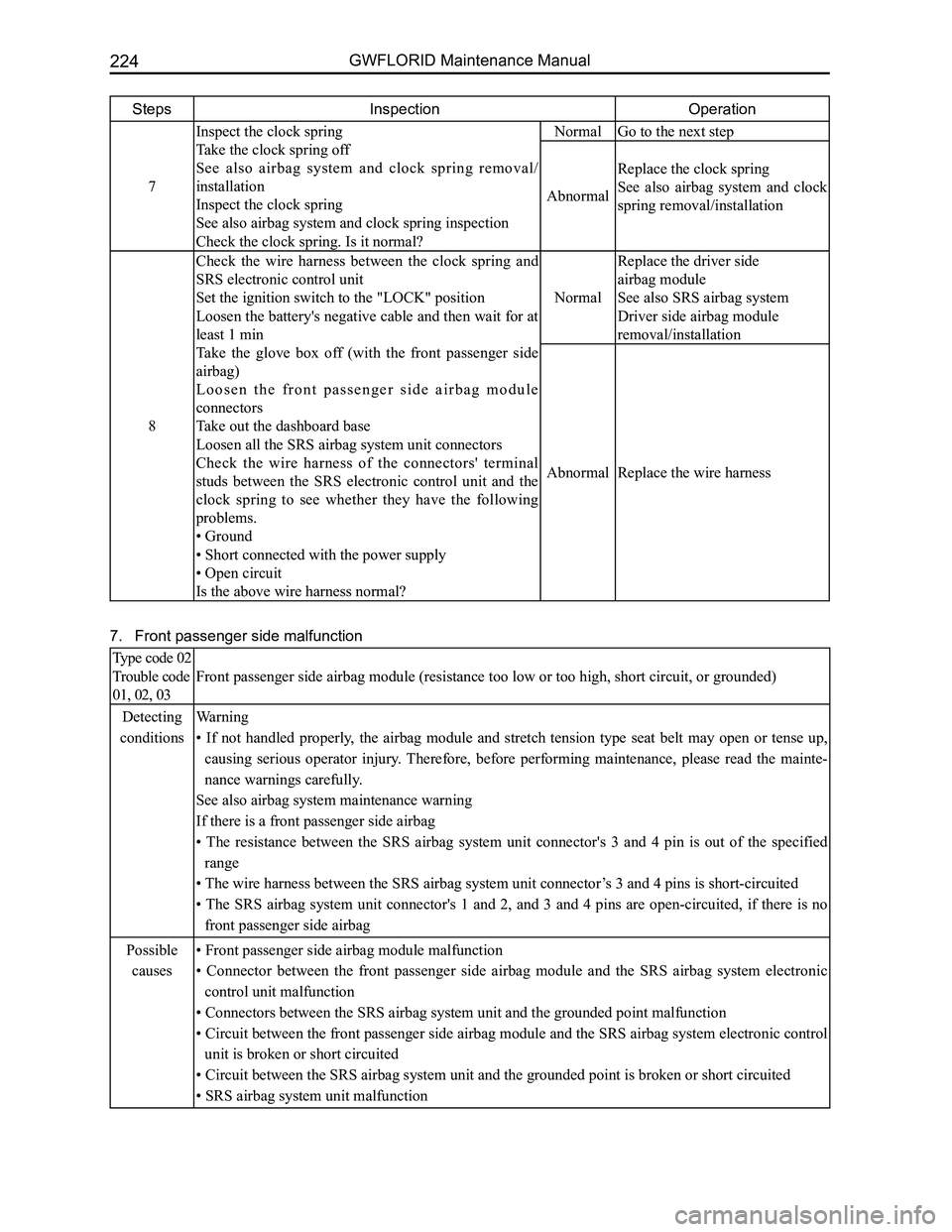

StepsInspectionOperation

7

Inspect the clock spring

Take the clock spring off

See also airbag system and clock spring removal/

installation

Inspect the clock spring

See also airbag system and clock spring inspection

Check the clock spring. Is it normal?

NormalGo to the next step

Abnormal

Replace the clock spring

See also airbag system and clock

spring removal/installation

8

Check the wire harness between the clock spring and

SRS electronic control unit

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and then wait for at

least 1 min

Take the glove box off (with the front passenger side

airbag)

L o o s e n t h e f r o n t p a s s e n g e r s i d e a i r b a g m o d u l e

connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Check the wire harness of the connectors' terminal

studs between the SRS electronic control unit and the

clock spring to see whether they have the following

problems.

• Ground

• Short connected with the power supply

• Open circuit

Is the above wire harness normal?

Normal

Replace the driver side

airbag module

See also SRS airbag system

Driver side airbag module

removal/installation

AbnormalReplace the wire harness

7. Front passenger side malfunction

Type code 02

Trouble code

01, 02, 03

Front passenger side airbag module (resistance too low or too high, sho\

rt circuit, or grounded)

Detecting

conditions

Warning

• If not handled properly, the airbag module and stretch tension type seat belt may open or tense up,

causing serious operator injury. Therefore, before performing maintenance, please read the mainte-

nance warnings carefully.

See also airbag system maintenance warning

If there is a front passenger side airbag

• The resistance between the SRS airbag system unit connector's 3 and 4 pin is out of the specified

range

• The wire harness between the SRS airbag system unit connector’s 3 and 4 pins is short-circuited

• The SRS airbag system unit connector's 1 and 2, and 3 and 4 pins are open-circuited, if there is no

front passenger side airbag

Possible

causes

• Front passenger side airbag module malfunction

• Connector between the front passenger side airbag module and the SRS airbag system electronic

control unit malfunction

• Connectors between the SRS airbag system unit and the grounded point malfunction

• Circuit between the front passenger side airbag module and the SRS airbag system electronic control

unit is broken or short circuited

• Circuit between the SRS airbag system unit and the grounded point is broken or short circuited

• SRS airbag system unit malfunction