sensor GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 102 of 281

Downloaded from www.Manualslib.com manuals search engine 95Brake System

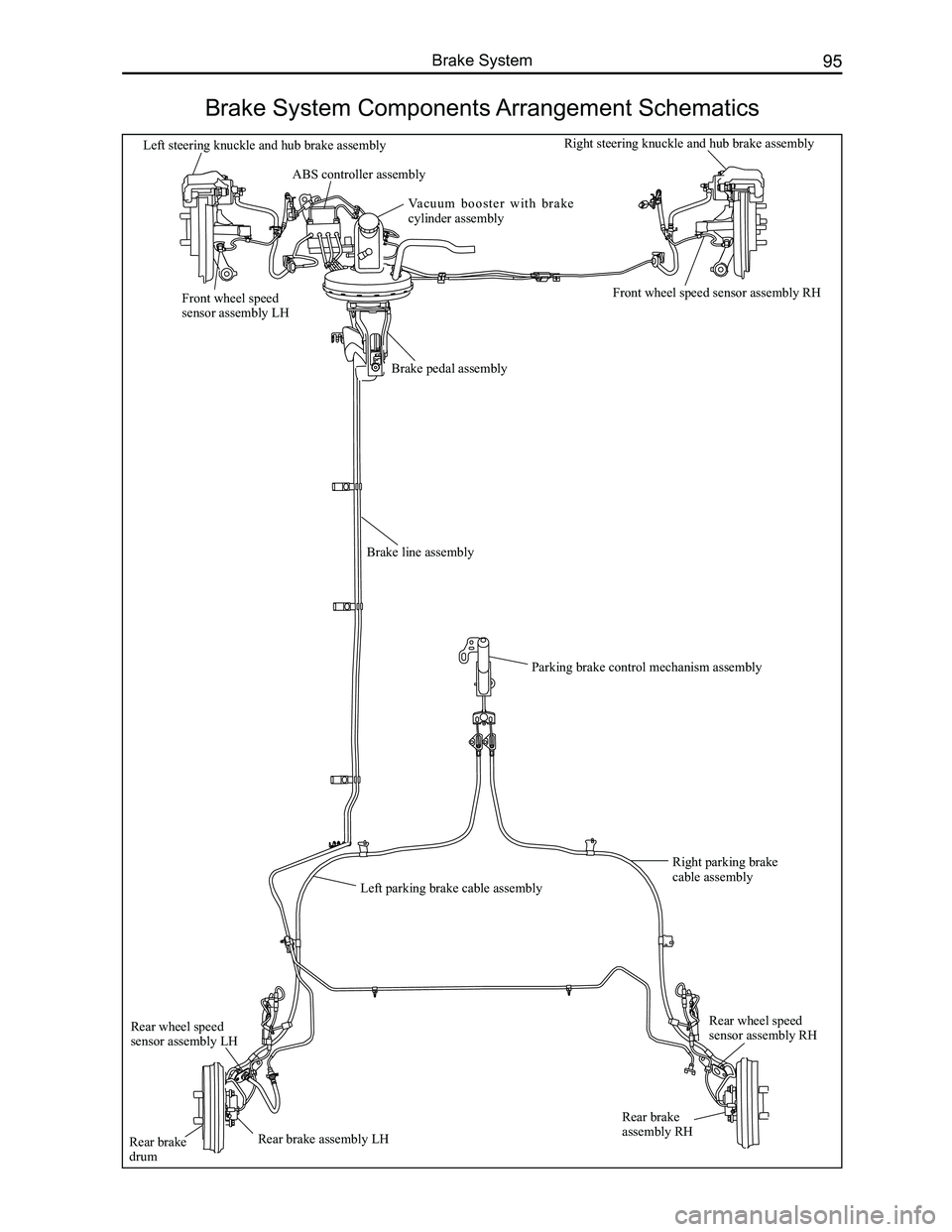

Brake System Components Arrangement Schematics

Brake pedal assembly

Vacuum booster with brake cylinder assembly

Left steering knuckle and hub brake assembly

Left parking brake cable assembly

Rear brake assembly RHRear brake drum

Rear wheel speed sensor assembly RH

Right parking brake cable assembly

ABS controller assembly

Right steering knuckle and hub brake assembly

Brake line assembly

Rear wheel speed

sensor assembly LH

Front wheel speed sensor assembly RHFront wheel speed sensor assembly LH

Rear brake assembly LH

Parking brake control mechanism assembly

Page 114 of 281

Downloaded from www.Manualslib.com manuals search engine 107Brake System

Anti-lock Brake System

ABS/EBD introduction

1. Operation

The vehicle's Anti-lock Brake System (ABS) is a type of increasingly popular brake safety device. It detects the

wheel's speed using wheel speed sensor detection. After signal processing, the wheel speed will be transferred

to the computer, which controls the solenoid valve’s operating condition and the pressure inside the brake wheel

cylinder to avoid wheel locking by using certain calculations and control methods based on the wheel speed.

ABS helps the vehicle to avoid sliding, deviation, fishtailing, and losing steering control capacity. ABS improves

the vehicle’s handling capability, stability and shortens braking distance. It also helps the vehicle to avoid the

partial wear and tear of wheels, hence improves the tire's useful life.

Electronic Brake Distribution (EBD) is used to adjust the vehicle's rear wheel brake pressure by using the ABS

components when the ABS does not respond to vehicle braking. It is also used to balance the vehicle’s front and

rear wheel brake pressure, maximizing the vehicle's braking efficiency. EBD uses the ABS components, yet its

controlling logic is independent from the ABS. After the ABS responds, the EBD will disengage.

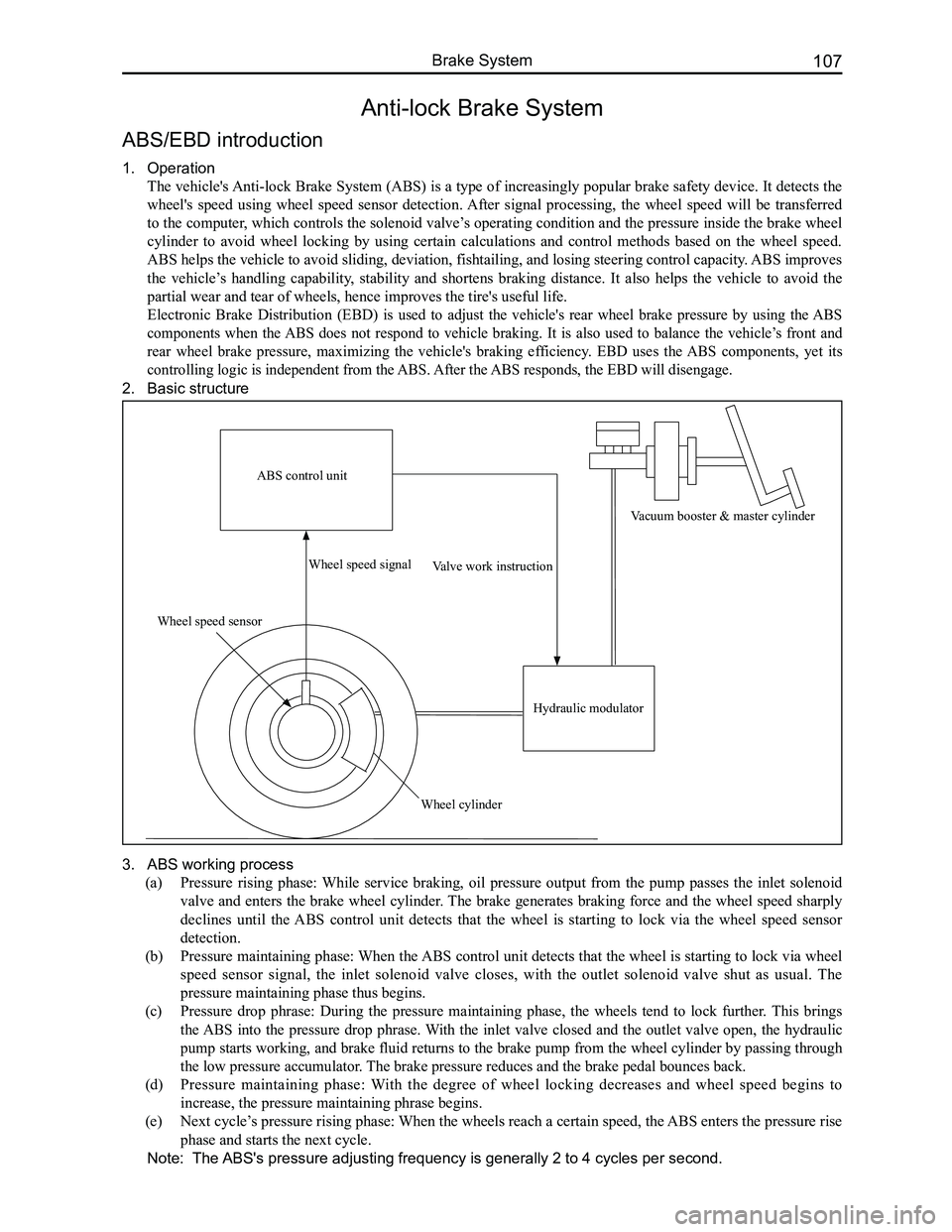

2. Basic structure

3. ABS working process

(a) Pressure rising phase: While service braking, oil pressure output from the pump passes the inlet solenoid

valve and enters the brake wheel cylinder. The brake generates braking force and the wheel speed sharply

declines until the ABS control unit detects that the wheel is starting to lock via the wheel speed sensor

detection.

(b) Pressure maintaining phase: When the ABS control unit detects that the wheel is starting to lock via wheel

speed sensor signal, the inlet solenoid valve closes, with the outlet solenoid valve shut as usual. The

pressure maintaining phase thus begins.

(c) Pressure drop phrase: During the pressure maintaining phase, the wheels tend to lock further. This brings

the ABS into the pressure drop phrase. With the inlet valve closed and the outlet valve open, the hydraulic

pump starts working, and brake fluid returns to the brake pump from the wheel cylinder by passing through

the low pressure accumulator. The brake pressure reduces and the brake pedal bounces back.

(d) Pressure maintaining phase: With the degree of wheel locking decreases and wheel speed begins to

increase, the pressure maintaining phrase begins.

(e) Next cycle’s pressure rising phase: When the wheels reach a certain speed, the ABS enters the pressure rise

phase and starts the next cycle.

Note: The ABS's pressure adjusting frequency is generally 2 to 4 cycles per second.

ABS control unit

Wheel speed sensor

Wheel speed signal

Wheel cylinder

Valve work instruction

Hydraulic modulator

Vacuum booster & master cylinder

Page 115 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual108

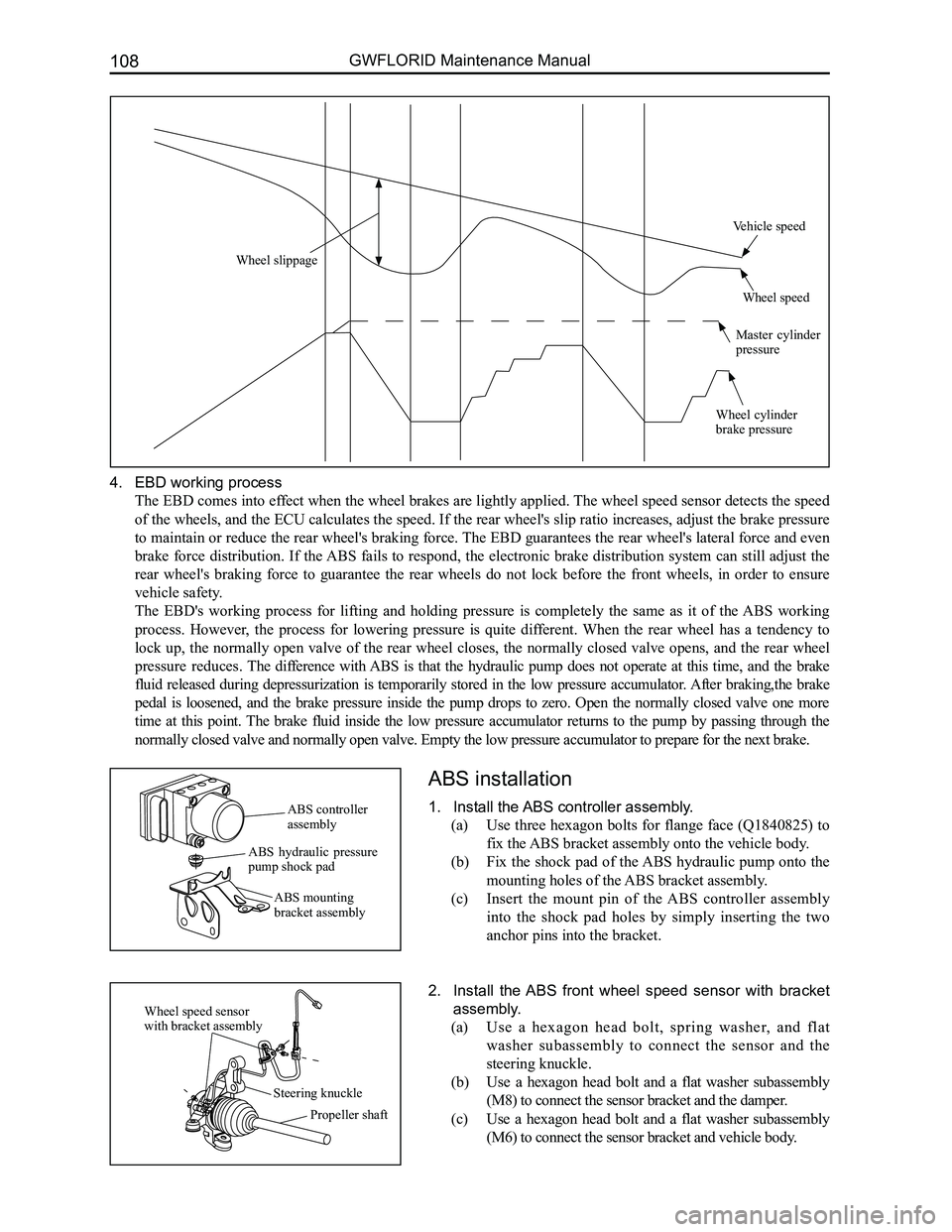

4. EBD working process

The EBD comes into effect when the wheel brakes are lightly applied. The wheel speed sensor detects the speed

of the wheels, and the ECU calculates the speed. If the rear wheel's slip ratio increases, adjust the brake pressure

to maintain or reduce the rear wheel's braking force. The EBD guarantees the rear wheel's lateral force and even

brake force distribution. If the ABS fails to respond, the electronic brake distribution system can still adjust the

rear wheel's braking force to guarantee the rear wheels do not lock before the front wheels, in order to ensure

vehicle safety.

The EBD's working process for lifting and holding pressure is completely the same as it of the ABS working

process. However, the process for lowering pressure is quite different. When the rear wheel has a tendency to

lock up, the normally open valve of the rear wheel closes, the normally closed valve opens, and the rear wheel

pressure reduces. The difference with ABS is that the hydraulic pump does not operate at this time, and the brake

fluid released during depressurization is temporarily stored in the low pressure accumulator. After braking,the brake

pedal is loosened, and the brake pressure inside the pump drops to zero. Open the normally closed valve one more

time at this point. The brake fluid inside the low pressure accumulator returns to the pump by passing through the

normally closed valve and normally open valve. Empty the low pressure ac\

cumulator to prepare for the next brake.

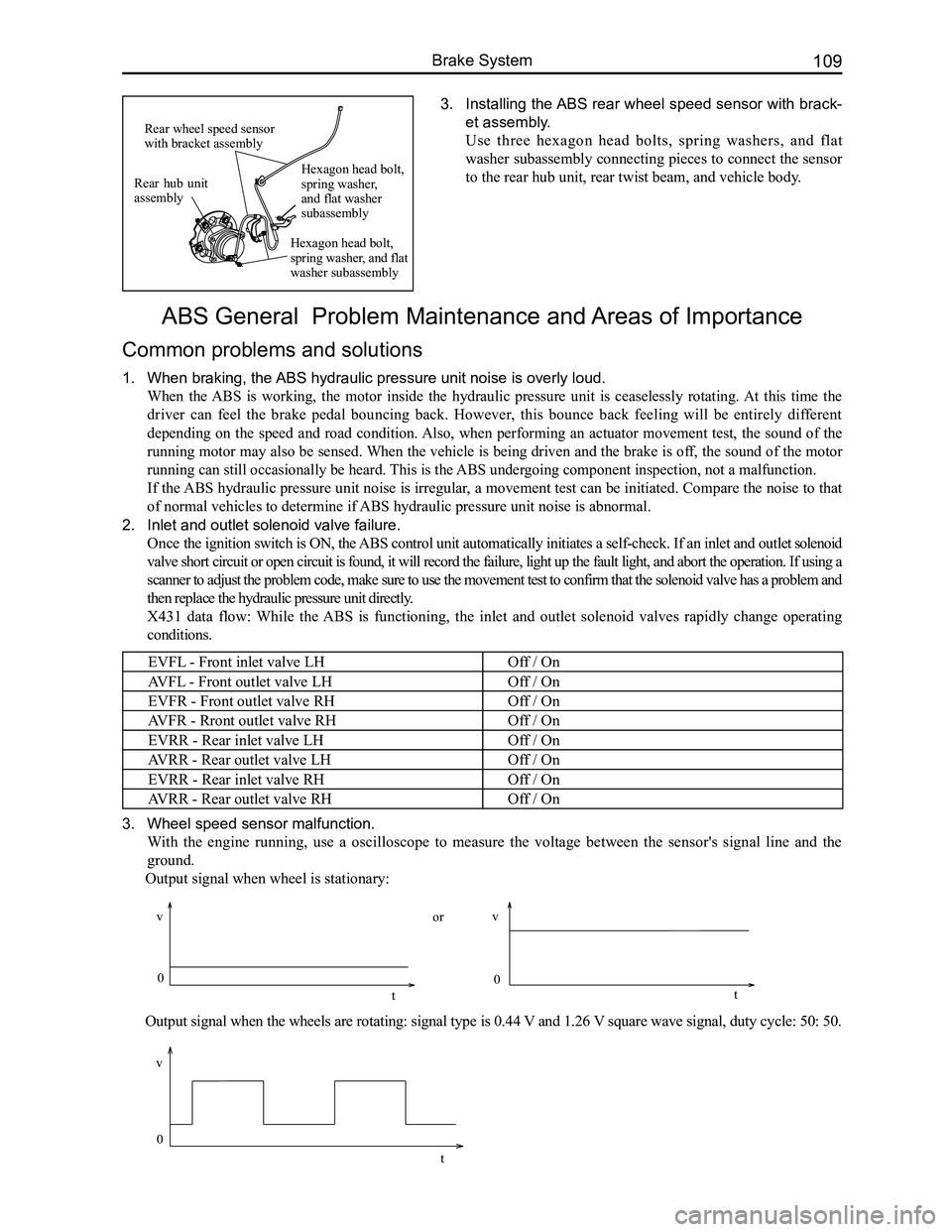

ABS installation

1. Install the ABS controller assembly.

(a) Use three hexagon bolts for flange face (Q1840825) to

fix the ABS bracket assembly onto the vehicle body.

(b) Fix the shock pad of the ABS hydraulic pump onto the

mounting holes of the ABS bracket assembly.

(c) Insert the mount pin of the ABS controller assembly

into the shock pad holes by simply inserting the two

anchor pins into the bracket.

2. Install the ABS front wheel speed sensor with bracket

assembly.

(a) Use a hexagon head bolt, spring washer, and flat

washer subassembly to connect the sensor and the

steering knuckle.

(b) Use a hexagon head bolt and a flat washer subassembly

(M8) to connect the sensor bracket and the damper.

(c) Use a hexagon head bolt and a flat washer subassembly

(M6) to connect the sensor bracket and vehicle body.

ABS controller assembly

ABS hydraulic pressure pump shock pad

ABS mounting bracket assembly

Wheel speed sensor with bracket assembly

Steering knuckle

Propeller shaft

Wheel slippage

Vehicle speed

Wheel speed

Master cylinder pressure

Wheel cylinder brake pressure

Page 116 of 281

Downloaded from www.Manualslib.com manuals search engine 109Brake System

3. Installing the ABS rear wheel speed sensor with brack-

et assembly.

Use three hexagon head bolts, spring washers, and flat

washer subassembly connecting pieces to connect the sensor

to the rear hub unit, rear twist beam, and vehicle body.

ABS General Problem Maintenance and Areas of Importance

Common problems and solutions

1. When braking, the ABS hydraulic pressure unit noise is overly loud.

When the ABS is working, the motor inside the hydraulic pressure unit is ceaselessly rotating. At this time the

driver can feel the brake pedal bouncing back. However, this bounce back feeling will be entirely different

depending on the speed and road condition. Also, when performing an actuator movement test, the sound of the

running motor may also be sensed. When the vehicle is being driven and the brake is off, the sound of the motor

running can still occasionally be heard. This is the ABS undergoing component inspection, not a malfunction.

If the ABS hydraulic pressure unit noise is irregular, a movement test can be initiated. Compare the noise to that

of normal vehicles to determine if ABS hydraulic pressure unit noise is abnormal.

2. Inlet and outlet solenoid valve failure.

Once the ignition switch is ON, the ABS control unit automatically initiates a self-check. If an inlet and outlet solenoid

valve short circuit or open circuit is found, it will record the failure, light up the fault light, and abort the operation. If using a

scanner to adjust the problem code, make sure to use the movement test t\

o confirm that the solenoid valve has a problem and

then replace the hydraulic pressure unit directly.

X431 data flow: While the ABS is functioning, the inlet and outlet solenoid valves rapidly change operating

conditions.

EVFL - Front inlet valve LHOff / On

AVFL - Front outlet valve LHOff / On

EVFR - Front outlet valve RHOff / On

AVFR - Rront outlet valve RHOff / On

EVRR - Rear inlet valve LHOff / On

AVRR - Rear outlet valve LHOff / On

EVRR - Rear inlet valve RHOff / On

AVRR - Rear outlet valve RHOff / On

3. Wheel speed sensor malfunction.

With the engine running, use a oscilloscope to measure the voltage between the sensor's signal line and the

ground.

Output signal when wheel is stationary:

Output signal when the wheels are rotating: signal type is 0.44 V and 1.26 V square wave signal, duty cycle: 50: 50.

Rear hub unit assembly

Rear wheel speed sensor with bracket assembly

Hexagon head bolt, spring washer, and flat washer subassembly

Hexagon head bolt, spring washer, and flat washer subassembly

0

v

t

vv

0 0

tt

or

Page 117 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual110

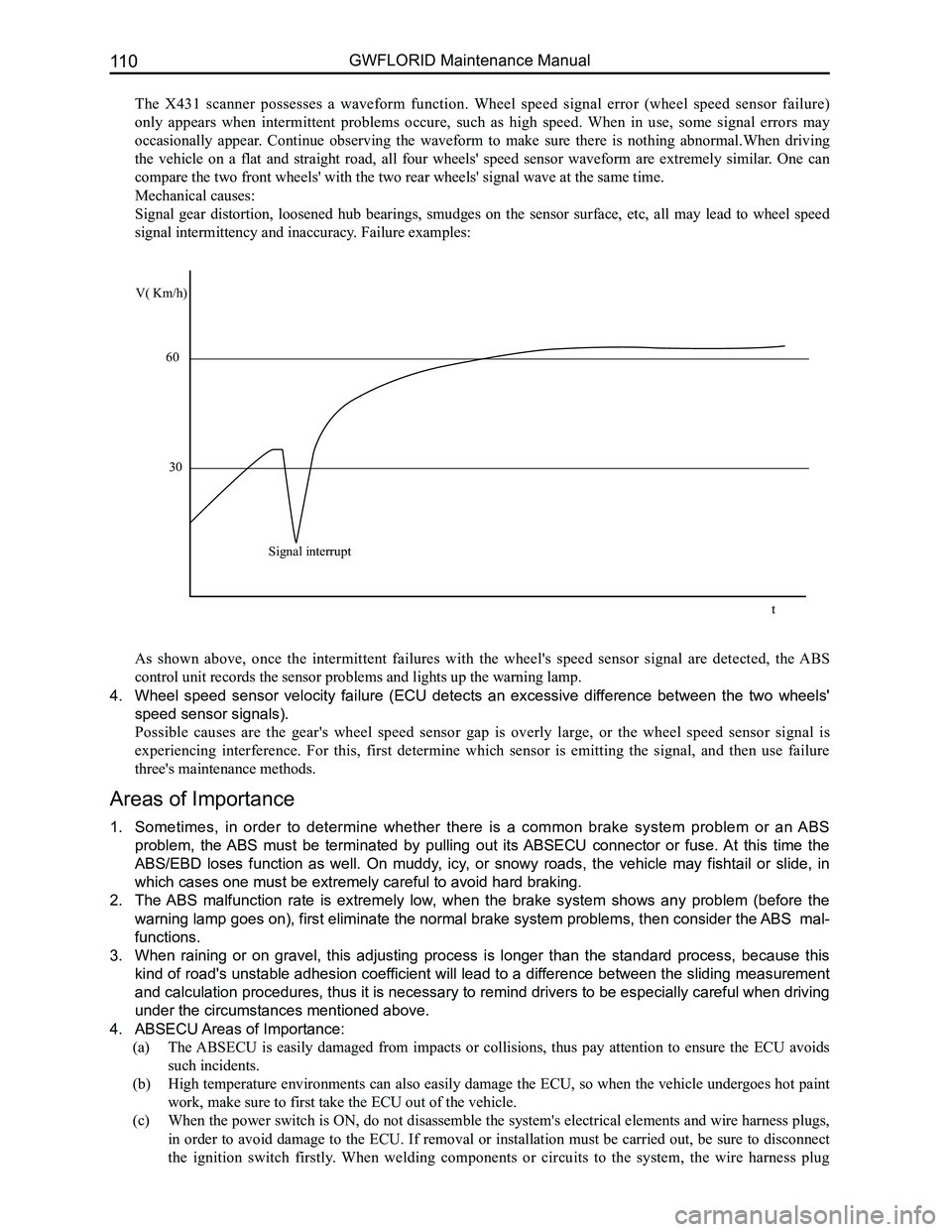

The X431 scanner possesses a waveform function. Wheel speed signal error (wheel speed sensor failure)

only appears when intermittent problems occure, such as high speed. When in use, some signal errors may

occasionally appear. Continue observing the waveform to make sure there is nothing abnormal.When driving

the vehicle on a flat and straight road, all four wheels' speed sensor waveform are extremely similar. One can

compare the two front wheels' with the two rear wheels' signal wave at t\

he same time.

Mechanical causes:

Signal gear distortion, loosened hub bearings, smudges on the sensor surface, etc, all may lead to wheel speed

signal intermittency and inaccuracy. Failure examples:

As shown above, once the intermittent failures with the wheel's speed sensor signal are detected, the ABS

control unit records the sensor problems and lights up the warning lamp.\

4. Wheel speed sensor velocity failure (ECU detects an excessive difference between the two wheels'

speed sensor signals).

Possible causes are the gear's wheel speed sensor gap is overly large, or the wheel speed sensor signal is

experiencing interference. For this, first determine which sensor is emitting the signal, and then use failure

three's maintenance methods.

Areas of Importance

1. Sometimes, in order to determine whether there is a common brake system problem or an ABS

problem, the ABS must be terminated by pulling out its ABSECU connector or fuse. At this time the

ABS/EBD loses function as well. On muddy, icy, or snowy roads, the vehicle may fishtail or slide, in

which cases one must be extremely careful to avoid hard braking.

2. The ABS malfunction rate is extremely low, when the brake system shows any problem (before the

warning lamp goes on), first eliminate the normal brake system problems, then consider the ABS mal-

functions.

3. When raining or on gravel, this adjusting process is longer than the standard process, because this

kind of road's unstable adhesion coefficient will lead to a difference between the sliding measurement

and calculation procedures, thus it is necessary to remind drivers to be especially careful when driving

under the circumstances mentioned above.

4. ABSECU Areas of Importance:

(a) The ABSECU is easily damaged from impacts or collisions, thus pay attention to ensure the ECU avoids

such incidents.

(b) High temperature environments can also easily damage the ECU, so when the vehicle undergoes hot paint

work, make sure to first take the ECU out of the vehicle.

(c) When the power switch is ON, do not disassemble the system's electrical elements and wire harness plugs,

in order to avoid damage to the ECU. If removal or installation must be carried out, be sure to disconnect

the ignition switch firstly. When welding components or circuits to the system, the wire harness plug

V( Km/h)

60

30

Signal interrupt

t

Page 118 of 281

Downloaded from www.Manualslib.com manuals search engine 111Brake System

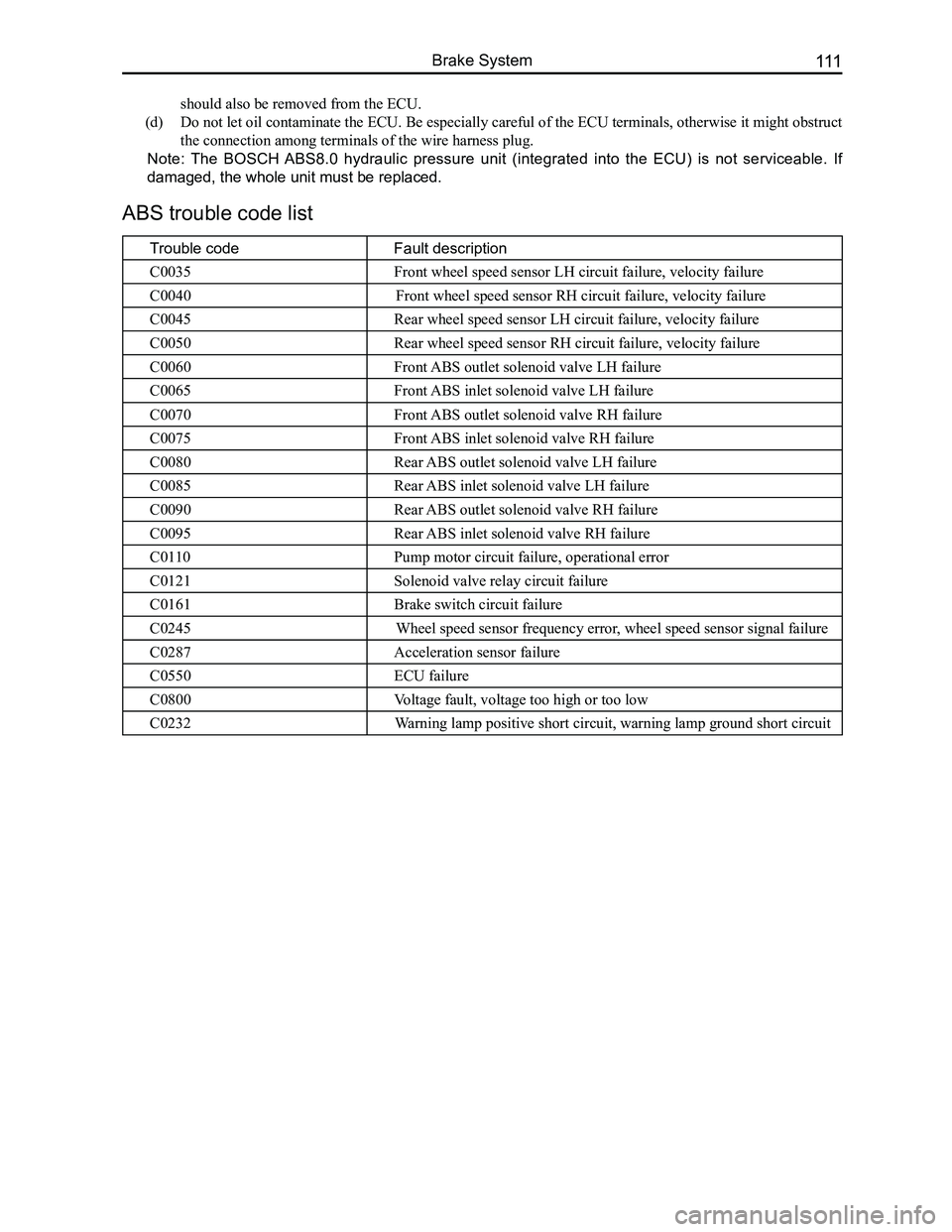

ABS trouble code list

Trouble codeFault description

C0035Front wheel speed sensor LH circuit failure, velocity failure

C0040Front wheel speed sensor RH circuit failure, velocity failure

C0045Rear wheel speed sensor LH circuit failure, velocity failure

C0050Rear wheel speed sensor RH circuit failure, velocity failure

C0060Front ABS outlet solenoid valve LH failure

C0065Front ABS inlet solenoid valve LH failure

C0070Front ABS outlet solenoid valve RH failure

C0075Front ABS inlet solenoid valve RH failure

C0080Rear ABS outlet solenoid valve LH failure

C0085Rear ABS inlet solenoid valve LH failure

C0090Rear ABS outlet solenoid valve RH failure

C0095Rear ABS inlet solenoid valve RH failure

C0110Pump motor circuit failure, operational error

C0121Solenoid valve relay circuit failure

C0161Brake switch circuit failure

C0245Wheel speed sensor frequency error, wheel speed sensor signal failure

C0287Acceleration sensor failure

C0550ECU failure

C0800Voltage fault, voltage too high or too low

C0232Warning lamp positive short circuit, warning lamp ground short circuit

should also be removed from the ECU.

(d) Do not let oil contaminate the ECU. Be especially careful of the ECU terminals, otherwise it might obstruct

the connection among terminals of the wire harness plug.

Note: The BOSCH ABS8.0 hydraulic pressure unit (integrated into the ECU) is not serviceable. If

damaged, the whole unit must be replaced.

Page 151 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual144

Double-colored wire: Primary color is Red, secondary color is Blue, mark\

ed as RBl.

0.5BrGr means Brown wire with a Gray fine wire, and sectional area is 0.\

5 mm2.

Areas of importance in circuit maintenance

1. Before operating any electronic devices, and when tools or maintenance devices may easily make

contact with an uncovered electronic terminal, please make sure to turn the ignition switch to the LOCK

position, and then disconnect the battery's negative cable to avoid injury or vehicle damage. When the

ignition switch is on the ON position, please do not disconnect the battery's connecting wire or take out

the power's fuse, regardless if the engine is running or not.Otherwise it would seriously damage the

ECU and related microelectronic devices such as sensors.

2. When changing the fuse, please make sure that the new fuse possesses the proper current rating,

and is not above or below this rating.

3. When repairing the wire harnesses of the airbag and pretensioner, only specified contact points,

plugs, and wires are allowed to be used.

4. Before repairing the wire harness, make sure to eliminate any factor that might cause damage,

for example, the edge of a vehicle body part is too sharp, or the used electronics are damaged or

corroded.

5. Shielded wire should not be repaired, it must be replaced entirely once it is damaged.

6. Unless it is specified during the test, please do not use an analog multimeter to test the ECU and

sensor, instead use a high-impedance digital multimeter (internal resistance should be ≥10 kΩ) or a

vehicle multimeter for inspection.

7. When inspecting the connector with a digital multimeter, take the waterproof rubber cover off the

connector, and tightly insert the test pen along the connecting terminal. Don't use too much force, as

to avoid cracking the connector.

Circuit inspection steps

The principle of troubleshooting is to confirm the "possible cause". Once the possible cause is confirmed, the

components that need to be inspected are limited to the components that are related to the possible cause. The

confirmed possible cause should be based on theory and be supported by facts, but not just by intuition. If

one tries to solve the problem but does not adopt the proper troubleshooting steps, it may make the problem

worse. Then the possible cause not only can't be confirmed, but also maintenance can't be performed properly.

Troubleshooting should adhere to the four steps below:

1. Observe the symptoms carefully, inspect if there is anything else abnormal, and record it.

2. While confirming the possible causes, study the circuit diagram carefully, and regard it as a whole

system in order to understand the circuit. Thorough knowledge of switches, relays, and other

electronic components is obligatory for proper analysis.

3. Inspect and eliminate the problems one by one until the cause is found.

4. After the malfunction is fixed, make sure to check if the inspected system is working properly, and also

check if the maintenance may have caused any new problems.

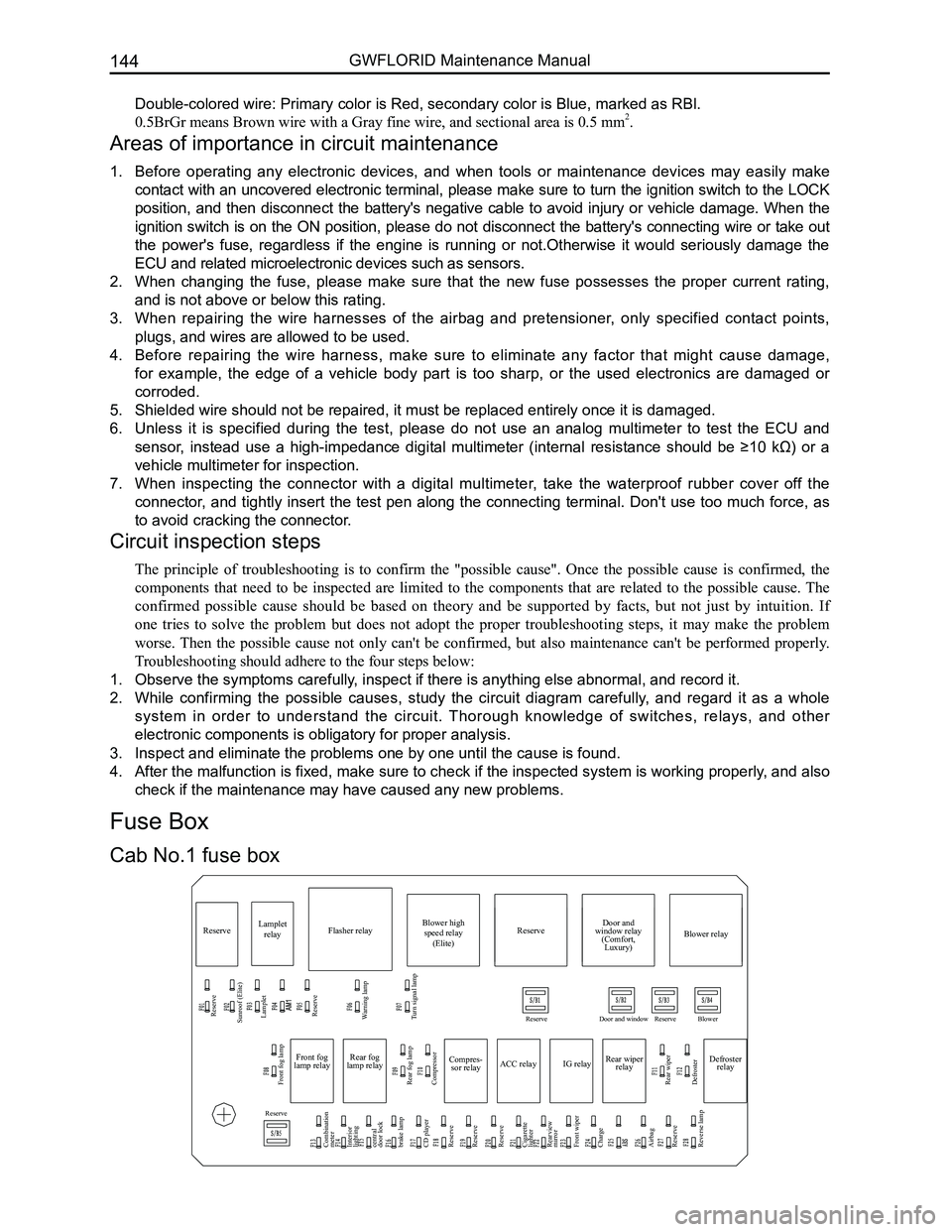

Compres-

sor relay

Reserve

Sunroof (Elite) Lamplet

Reserve

Reserve

Reserve

Reserve Door and window Reserve Blower

Lamplet

relay Flasher relay Blower high

speed relay (Elite) Door and

window relay (Comfort, Luxury) Blower relay

Reserve

Front fog lamp

Combination

meter

Interior

lighting

central

door lock

brake lamp

CD player

Reserve

Reserve

Reserve

Cigarette

lighter

Rearview

mirror

Front wiper

Charge

Airbag

Reserve

Reverse lamp Rear fog lamp

Rear wiper

Defroster Compressor

ACC relay

IG relayRear wiper

relay Defroster

relay

Front fog

lamp relay Rear fog

lamp relay

Warning lamp

Turn signal lamp

Cab No.1 fuse box

Fuse Box

Page 159 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual152

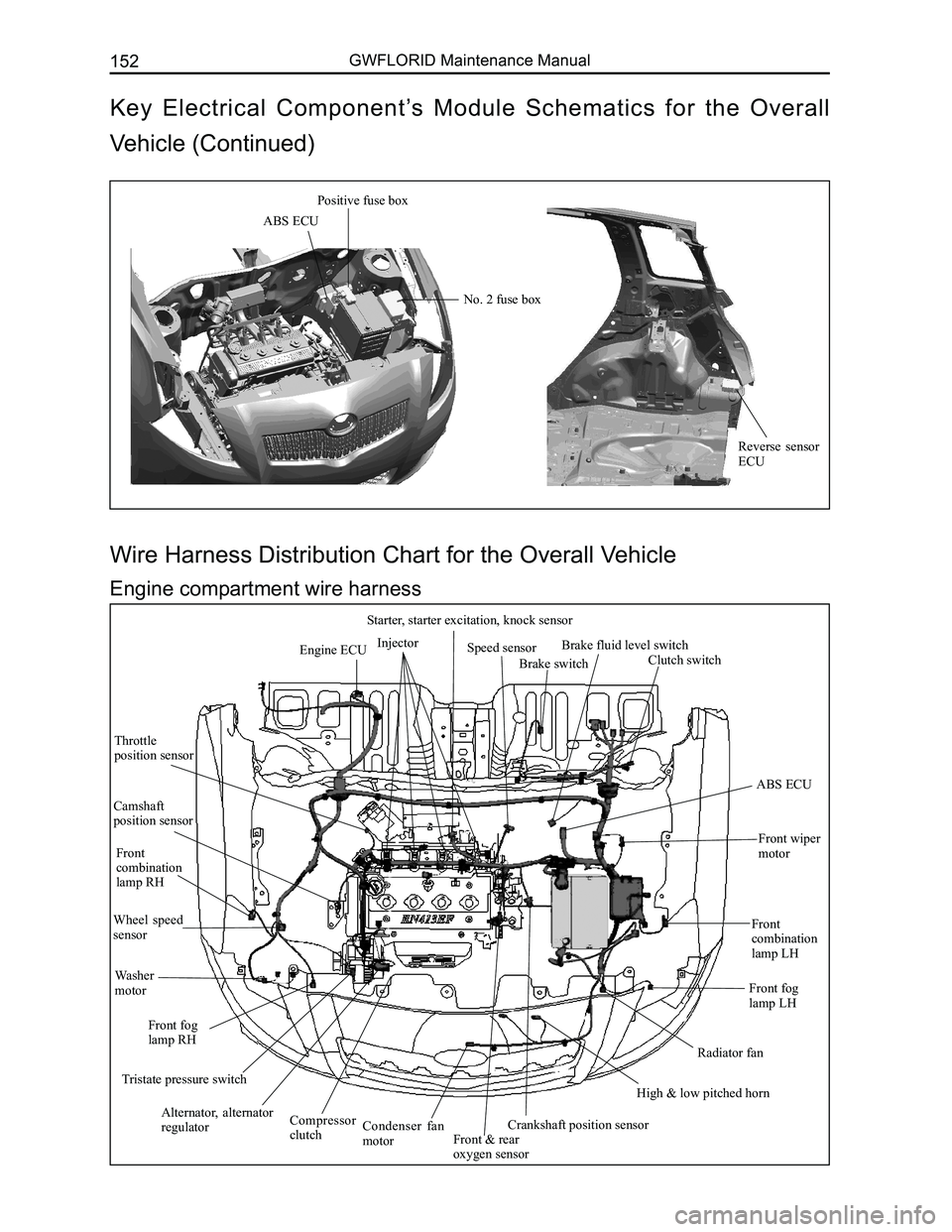

Engine ECUInjector

Starter, starter excitation, knock sensor

Speed sensor

Brake switch

Brake fluid level switch

Clutch switch

ABS ECU

Front wiper

motor

Front combination lamp LH

Front fog lamp LH

Radiator fan

High & low pitched horn

Crankshaft position sensorFront & rear oxygen sensor

Condenser fan motor

Compressor clutch

Alternator, alternator regulator

Tristate pressure switch

Front fog lamp RH

Washer motor

Wheel speed sensor

Front combination lamp RH

Camshaft position sensor

Throttle position sensor

Wire Harness Distribution Chart for the Overall Vehicle

Engine compartment wire harness

ABS ECU

Positive fuse box

No. 2 fuse box

Reverse sensor ECU

Key Electrical Component’s Module Schematics for the Overall

Vehicle (Continued)

Page 160 of 281

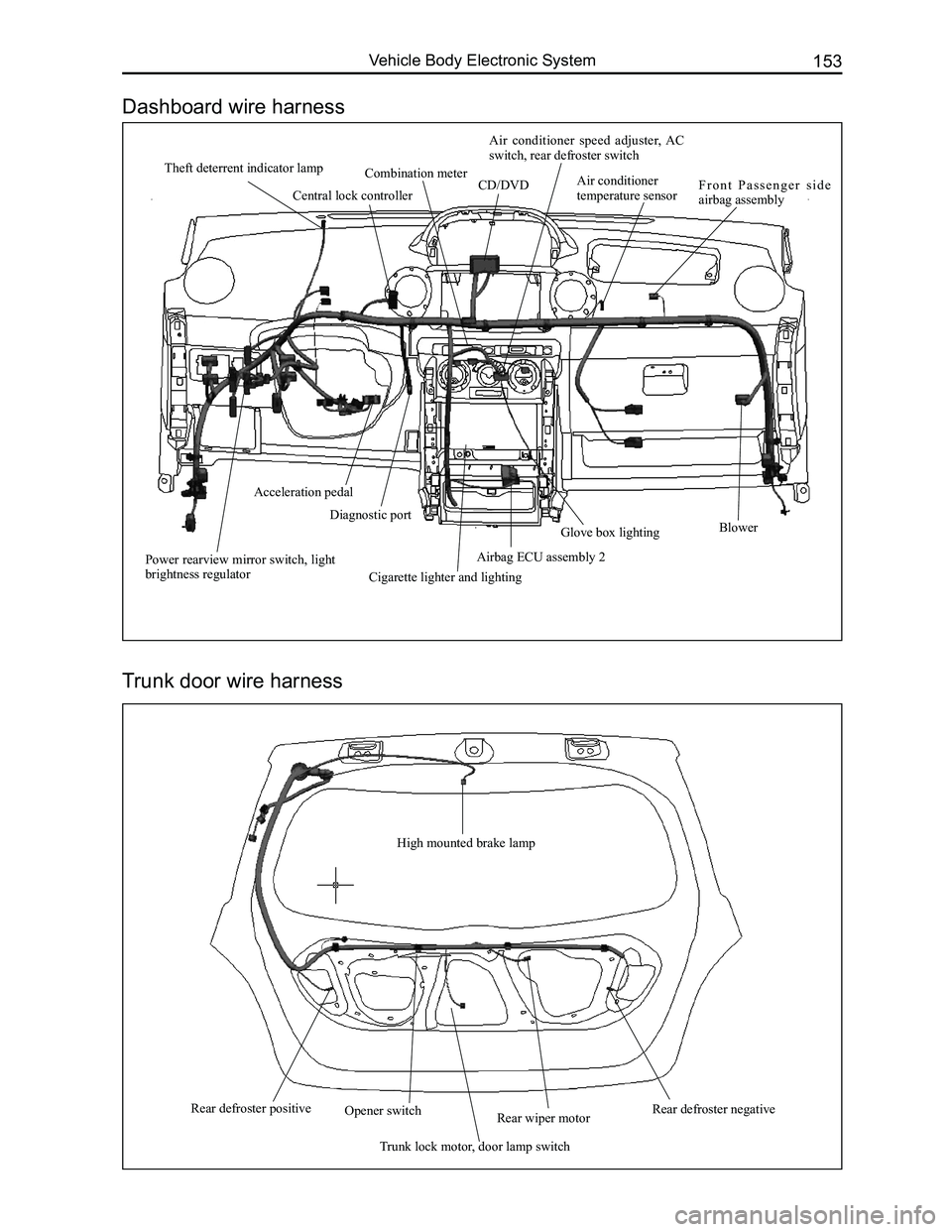

Downloaded from www.Manualslib.com manuals search engine 153Vehicle Body Electronic System

High mounted brake lamp

Rear defroster positiveRear wiper motor

Trunk lock motor, door lamp switch

Opener switchRear defroster negative

Theft deterrent indicator lampCombination meter CD/DVD

Air conditioner speed adjuster, AC switch, rear defroster switch

Air conditioner temperature sensorF r o n t P a s s e n g e r s i d e airbag assembly

BlowerGlove box lighting

Cigarette lighter and lighting

Airbag ECU assembly 2

Diagnostic port

Acceleration pedal

Power rearview mirror switch, light brightness regulator

Trunk door wire harness

Central lock controller

Dashboard wire harness

Page 161 of 281

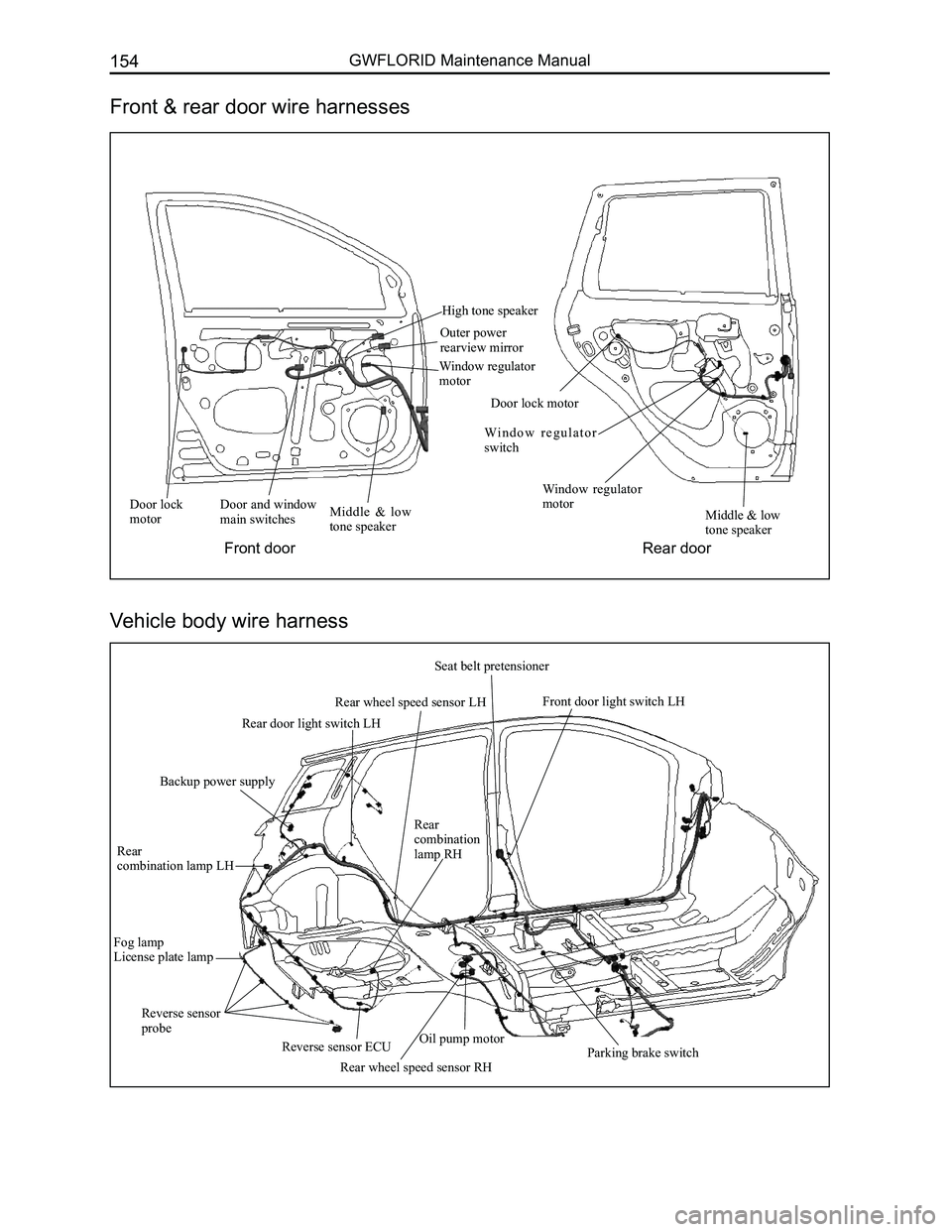

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual154

Door lock motorDoor and window main switchesMiddle & low tone speaker

High tone speaker

Outer power rearview mirror

Window regulator motor

Door lock motor

Wi n d o w r e g u l a t o r switch

Window regulator motorMiddle & low tone speaker

Fog lampLicense plate lamp

Rear

combination lamp LH

Rear combination lamp RH

Rear wheel speed sensor RHParking brake switch

Front door light switch LH

Seat belt pretensioner

Rear wheel speed sensor LH

Rear door light switch LH

Backup power supply

Front & rear door wire harnesses

Vehicle body wire harness

Front doorRear door

Reverse sensor ECU

Reverse sensor probeOil pump motor