service GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 95 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual88

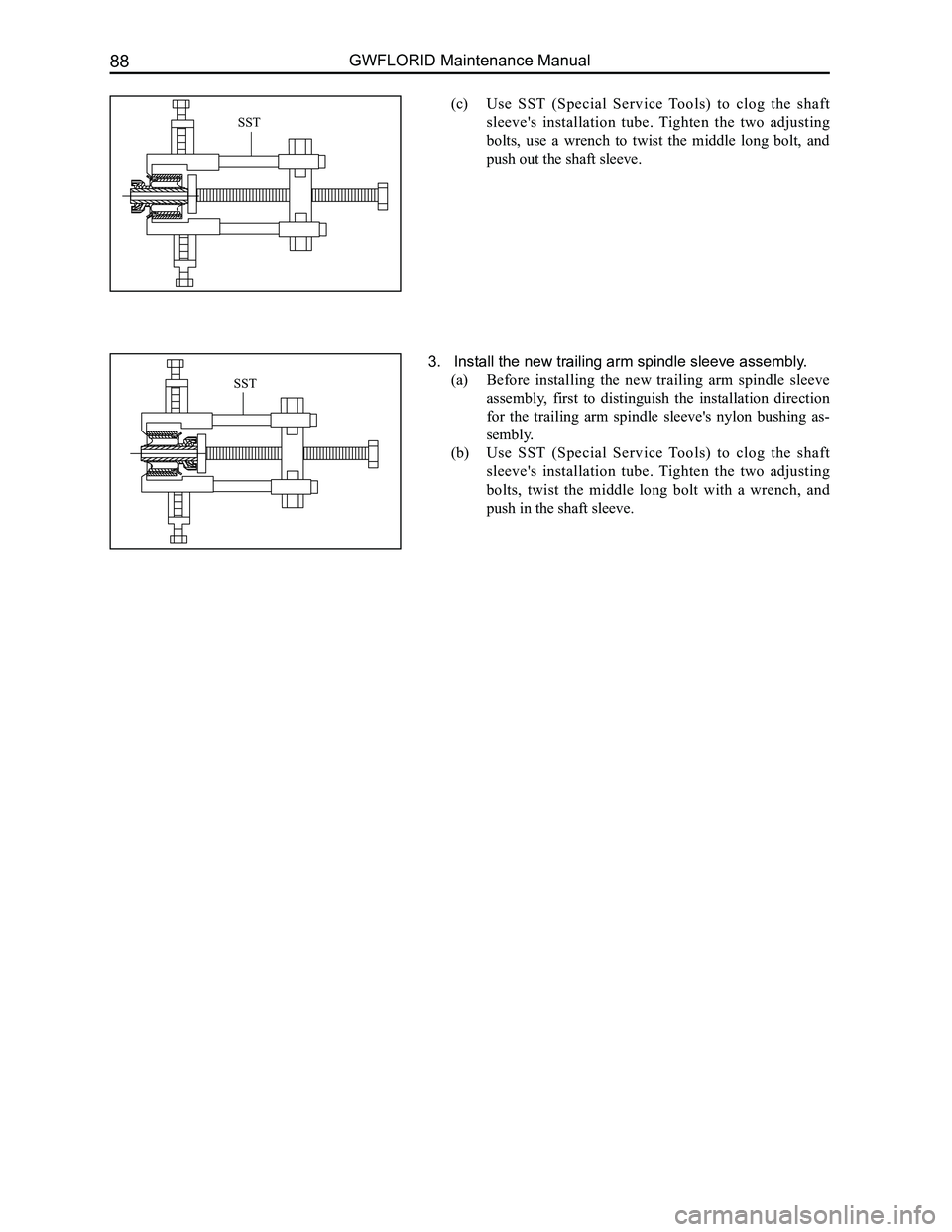

(c) Use SST (Special Service Tools) to clog the shaft

sleeve's installation tube. Tighten the two adjusting

bolts, use a wrench to twist the middle long bolt, and

push out the shaft sleeve.

SST

3. Install the new trailing arm spindle sleeve assembly.

(a) Before installing the new trailing arm spindle sleeve

assembly, first to distinguish the installation direction

for the trailing arm spindle sleeve's nylon bushing as-

sembly.

(b) Use SST (Special Service Tools) to clog the shaft

sleeve's installation tube. Tighten the two adjusting

bolts, twist the middle long bolt with a wrench, and

push in the shaft sleeve.

SST

Page 99 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual92

Wheel

General tire balancing procedures

Clean out the accumulated dirt and debris from the inside of the rim.

Warning:

The gravel on the tread must be eliminated to avoid flying out and injuring the operator when

undergoing rotational balancing. This is also a good way to acquire better balance. First thoroughly

inspect the tire's damaged condition, then according to the balancing device manufacture's

recommendations, carry out the balancing operation.

Off-vehicle balancing

Most off-vehicle balancers are more accurate and convenient than on-vehicle rotational balancers. They are

also able to perform dynamic (two sided) balancing. Although it does not correct drum brake and brake disc

imbalance like on-vehicle balancing, it achieves the same effect based on its accuracy.

On-vehicle balancing

On-vehicle balancing is different based on equipment and tool manufacturer. Therefore, when performing

balancing operations, be sure to comply to each manufacturer's operating\

instructions.

Warning: Control the wheel rotation speed to make sure the speedometer stays within 55 km/h.

This restriction is necessary because when a driven wheel slides while the other one stays still, the

speedometer will display only half of the actual wheel speed. When a wheel is sliding, be extremely

careful, because sliding wheels can reach very high speeds. This may lead to the tire rubber peeling

or differential damage, which may cause serious personal injury, or damage to the vehicle.

Tire installation and removal

• Install or remove tires with a tire changer. When operating machinery, make sure to comply to the machine

manufacturers operation manual. Please do not change tires merely with manual hand tools or tire installation

crowbars. This will damage the tire chafer or the vehicle wheel's rim.

• Use a wire brush or coarse steel wool to clean off grease and old rubber, as well as light rust or corrosion from

the rim tire bead's tire chafer seat. Before tire installation or removal, first use the indicated tire lubricant to

thoroughly lube the tire chafer portions one time.

• After installing the tire, inflate it to the specified pressure and make\

sure the tire bead is properly seated.

Warning: Do not over-inflate the tire. If the tire bead severally expands and exceeds the safety limit,

it may burst and cause serious personal injury. While inflating, do not exceed the specified pressure.

If the specified pressure does not allow the tire bead to sit properly, deflate the tire, re-lubricate, and

then re-inflate.

Spare tire usage

• Spare tire standard inflation pressure: 420 kPa.

• Spare tire pressure measurements should be taken under normal temperatur\

e conditions.

• After inflating the spare tire, soapy water should be used to check if the air nozzles core is leaking air, then

lock on the air nozzle cap.

• The spare tire should always be kept in a useable state. Check the air p\

ressure at least once a month.

• When the spare tire's working limit, indicated by the remaining pattern's depth, reaches 1.6 mm (and its pat-

tern groove bottom protrudes to the same level), for your safety, please stop using the spare tire.

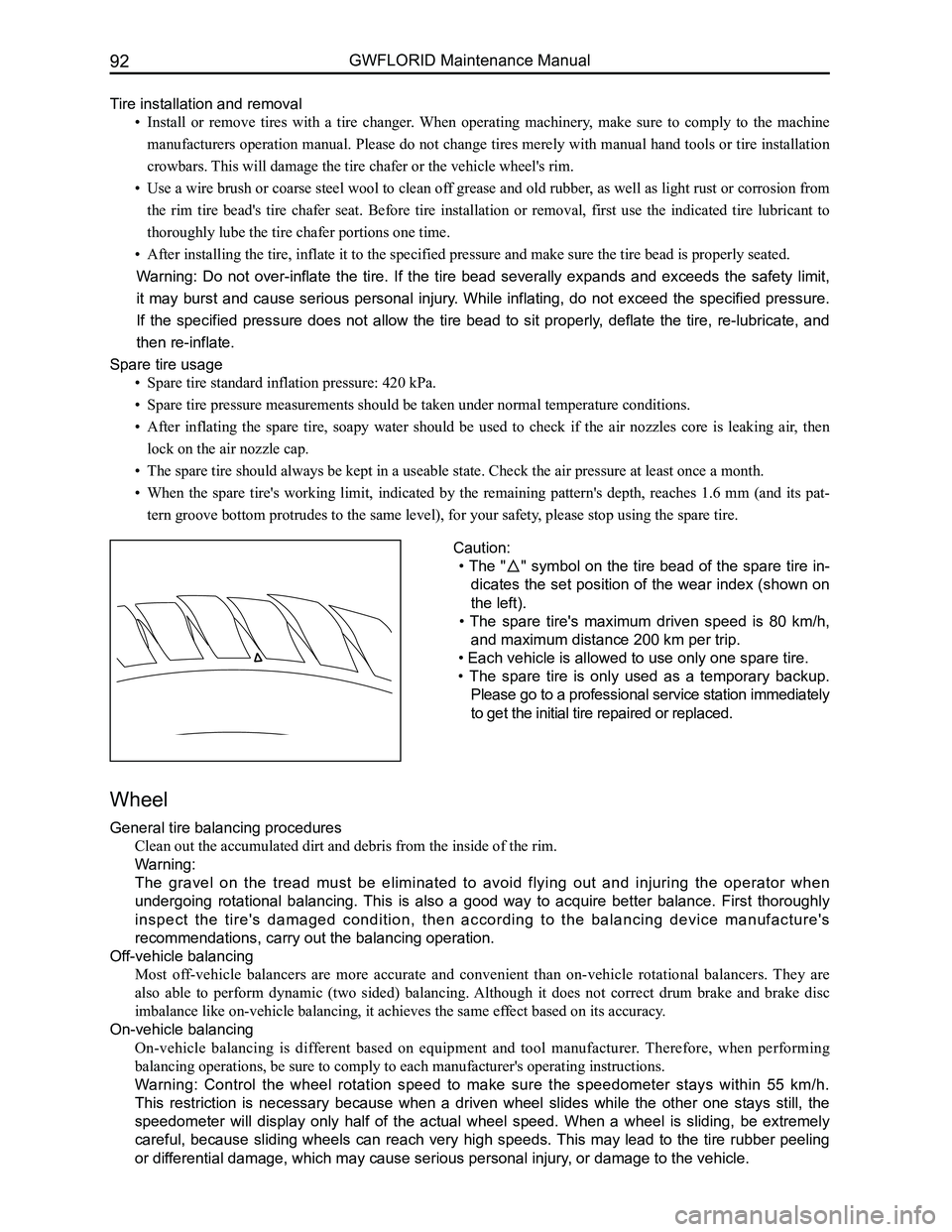

Caution:

• The "" symbol on the tire bead of the spare tire in-

dicates the set position of the wear index (shown on

the left).

• The spare tire's maximum driven speed is 80 km/h,

and maximum distance 200 km per trip.

• Each vehicle is allowed to use only one spare tire.

• The spare tire is only used as a temporary backup.

Please go to a professional service station immediately

to get the initial tire repaired or replaced.

Page 114 of 281

Downloaded from www.Manualslib.com manuals search engine 107Brake System

Anti-lock Brake System

ABS/EBD introduction

1. Operation

The vehicle's Anti-lock Brake System (ABS) is a type of increasingly popular brake safety device. It detects the

wheel's speed using wheel speed sensor detection. After signal processing, the wheel speed will be transferred

to the computer, which controls the solenoid valve’s operating condition and the pressure inside the brake wheel

cylinder to avoid wheel locking by using certain calculations and control methods based on the wheel speed.

ABS helps the vehicle to avoid sliding, deviation, fishtailing, and losing steering control capacity. ABS improves

the vehicle’s handling capability, stability and shortens braking distance. It also helps the vehicle to avoid the

partial wear and tear of wheels, hence improves the tire's useful life.

Electronic Brake Distribution (EBD) is used to adjust the vehicle's rear wheel brake pressure by using the ABS

components when the ABS does not respond to vehicle braking. It is also used to balance the vehicle’s front and

rear wheel brake pressure, maximizing the vehicle's braking efficiency. EBD uses the ABS components, yet its

controlling logic is independent from the ABS. After the ABS responds, the EBD will disengage.

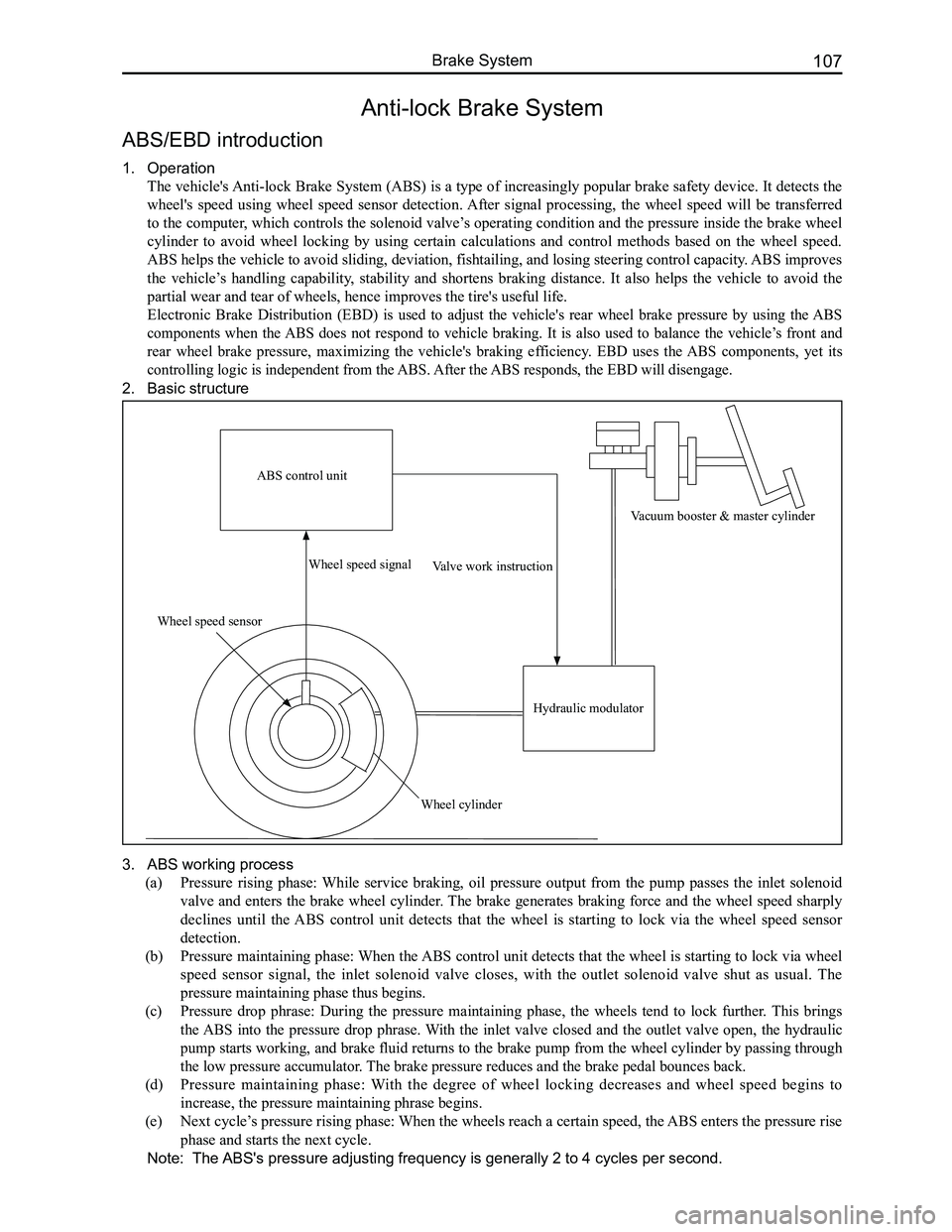

2. Basic structure

3. ABS working process

(a) Pressure rising phase: While service braking, oil pressure output from the pump passes the inlet solenoid

valve and enters the brake wheel cylinder. The brake generates braking force and the wheel speed sharply

declines until the ABS control unit detects that the wheel is starting to lock via the wheel speed sensor

detection.

(b) Pressure maintaining phase: When the ABS control unit detects that the wheel is starting to lock via wheel

speed sensor signal, the inlet solenoid valve closes, with the outlet solenoid valve shut as usual. The

pressure maintaining phase thus begins.

(c) Pressure drop phrase: During the pressure maintaining phase, the wheels tend to lock further. This brings

the ABS into the pressure drop phrase. With the inlet valve closed and the outlet valve open, the hydraulic

pump starts working, and brake fluid returns to the brake pump from the wheel cylinder by passing through

the low pressure accumulator. The brake pressure reduces and the brake pedal bounces back.

(d) Pressure maintaining phase: With the degree of wheel locking decreases and wheel speed begins to

increase, the pressure maintaining phrase begins.

(e) Next cycle’s pressure rising phase: When the wheels reach a certain speed, the ABS enters the pressure rise

phase and starts the next cycle.

Note: The ABS's pressure adjusting frequency is generally 2 to 4 cycles per second.

ABS control unit

Wheel speed sensor

Wheel speed signal

Wheel cylinder

Valve work instruction

Hydraulic modulator

Vacuum booster & master cylinder

Page 118 of 281

Downloaded from www.Manualslib.com manuals search engine 111Brake System

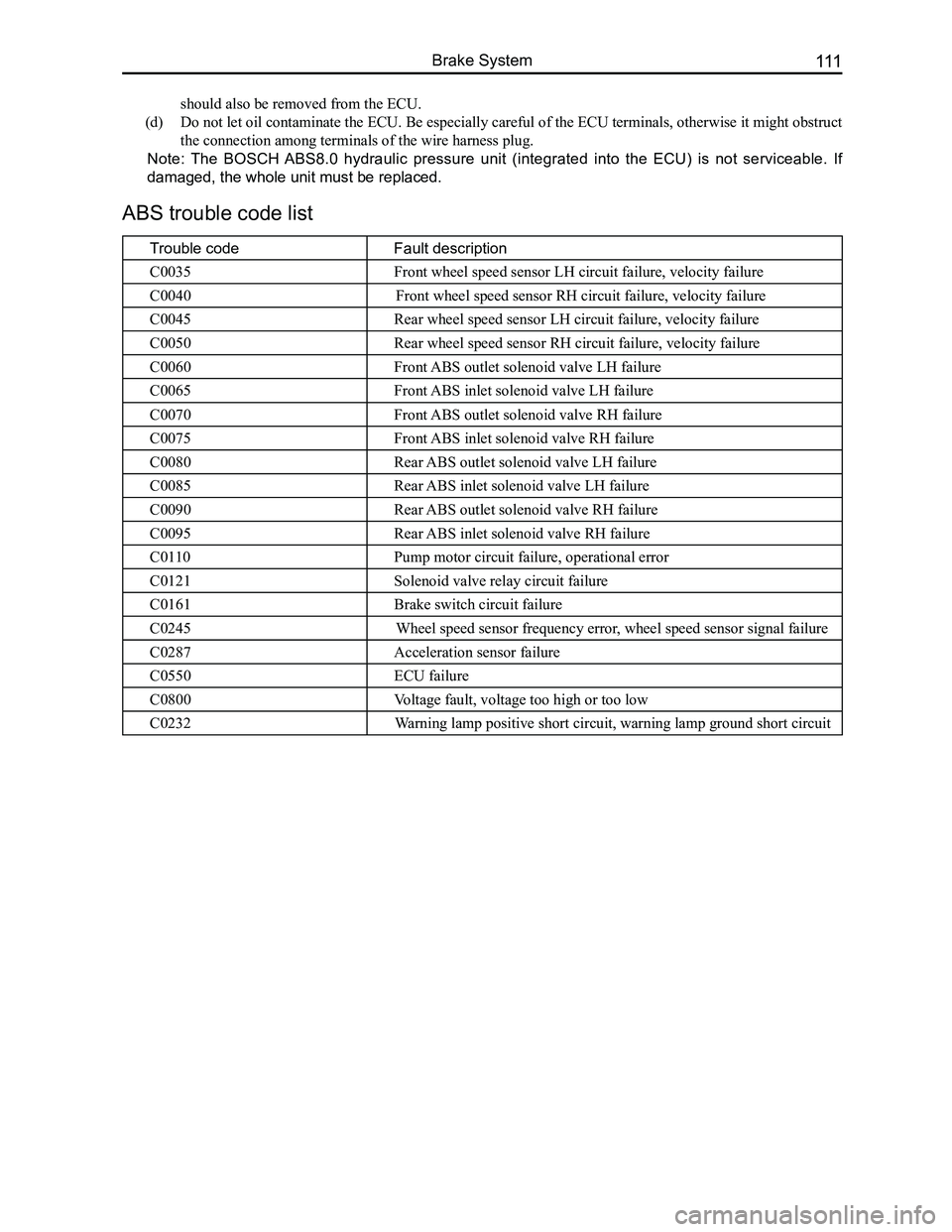

ABS trouble code list

Trouble codeFault description

C0035Front wheel speed sensor LH circuit failure, velocity failure

C0040Front wheel speed sensor RH circuit failure, velocity failure

C0045Rear wheel speed sensor LH circuit failure, velocity failure

C0050Rear wheel speed sensor RH circuit failure, velocity failure

C0060Front ABS outlet solenoid valve LH failure

C0065Front ABS inlet solenoid valve LH failure

C0070Front ABS outlet solenoid valve RH failure

C0075Front ABS inlet solenoid valve RH failure

C0080Rear ABS outlet solenoid valve LH failure

C0085Rear ABS inlet solenoid valve LH failure

C0090Rear ABS outlet solenoid valve RH failure

C0095Rear ABS inlet solenoid valve RH failure

C0110Pump motor circuit failure, operational error

C0121Solenoid valve relay circuit failure

C0161Brake switch circuit failure

C0245Wheel speed sensor frequency error, wheel speed sensor signal failure

C0287Acceleration sensor failure

C0550ECU failure

C0800Voltage fault, voltage too high or too low

C0232Warning lamp positive short circuit, warning lamp ground short circuit

should also be removed from the ECU.

(d) Do not let oil contaminate the ECU. Be especially careful of the ECU terminals, otherwise it might obstruct

the connection among terminals of the wire harness plug.

Note: The BOSCH ABS8.0 hydraulic pressure unit (integrated into the ECU) is not serviceable. If

damaged, the whole unit must be replaced.

Page 132 of 281

Downloaded from www.Manualslib.com manuals search engine 125Brake System

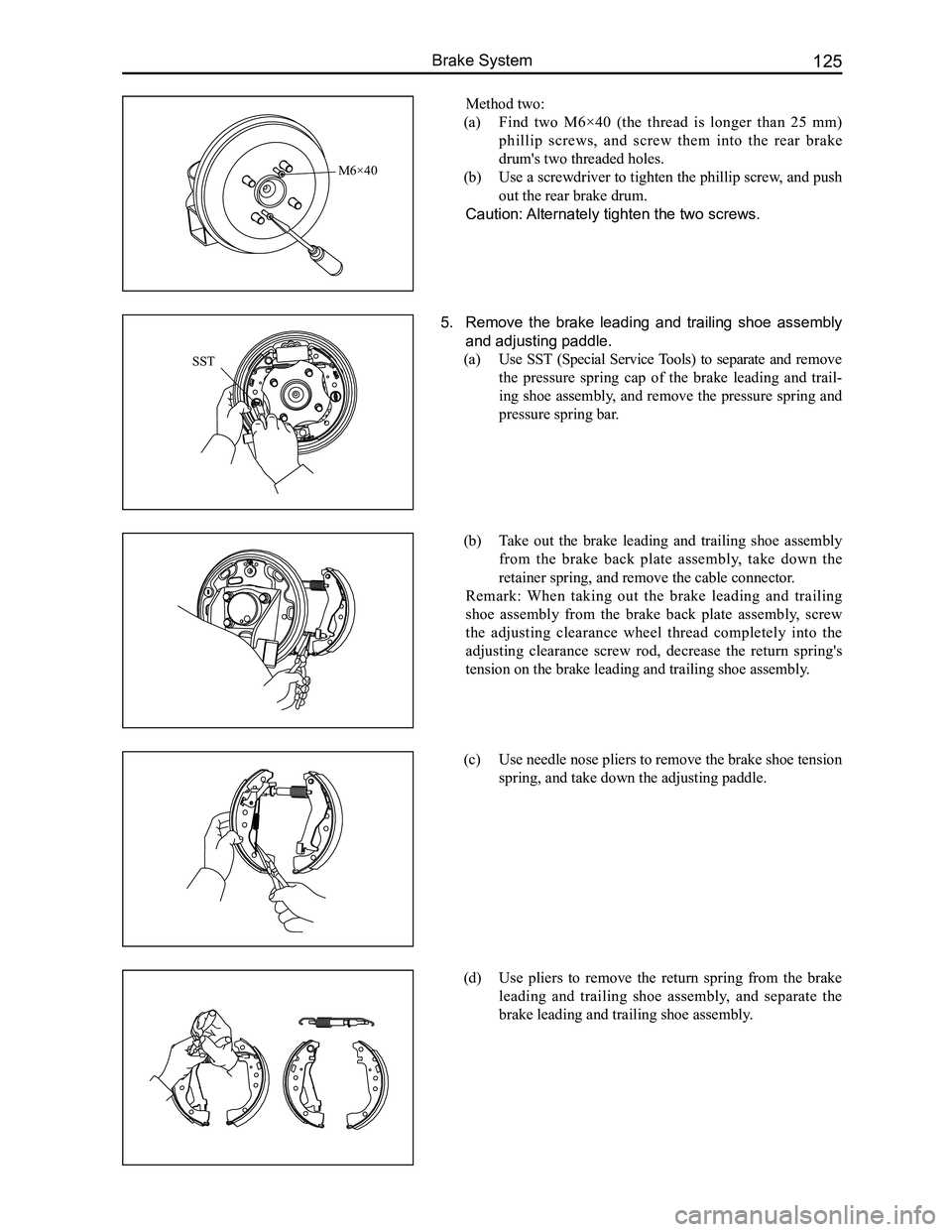

Method two:

(a) Find two M6×40 (the thread is longer than 25 mm)

phillip screws, and screw them into the rear brake

drum's two threaded holes.

(b) Use a screwdriver to tighten the phillip screw, and push

out the rear brake drum.

Caution: Alternately tighten the two screws.

5. Remove the brake leading and trailing shoe assembly

and adjusting paddle.

(a) Use SST (Special Service Tools) to separate and remove

the pressure spring cap of the brake leading and trail-

ing shoe assembly, and remove the pressure spring and

pressure spring bar.

(b) Take out the brake leading and trailing shoe assembly

from the brake back plate assembly, take down the

retainer spring, and remove the cable connector.

Remark: When taking out the brake leading and trailing

shoe assembly from the brake back plate assembly, screw

the adjusting clearance wheel thread completely into the

adjusting clearance screw rod, decrease the return spring's

tension on the brake leading and trailing shoe assembly.

(c) Use needle nose pliers to remove the brake shoe tension

spring, and take down the adjusting paddle.

(d) Use pliers to remove the return spring from the brake

leading and trailing shoe assembly, and separate the

brake leading and trailing shoe assembly.

SST

M6×40

Page 137 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual130

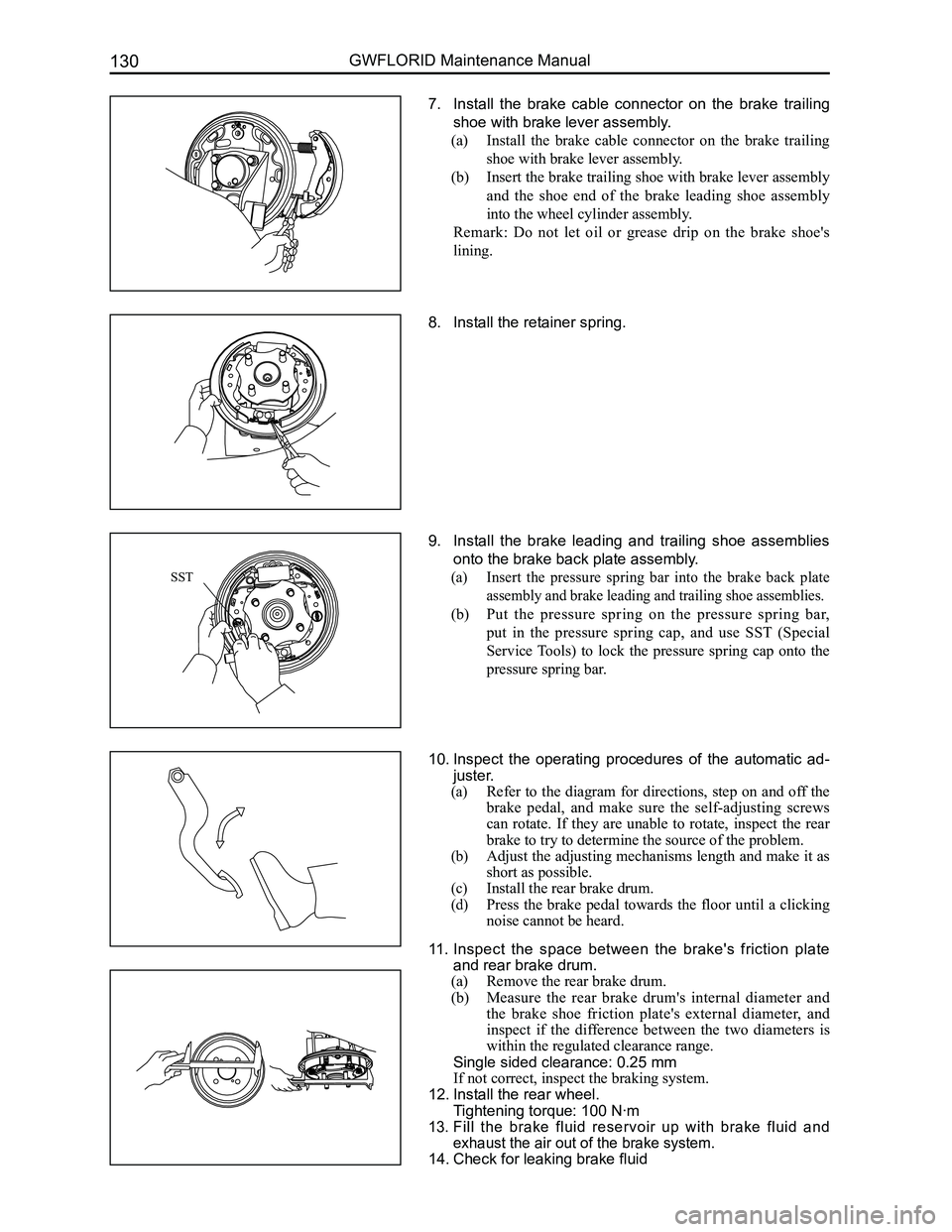

7. Install the brake cable connector on the brake trailing

shoe with brake lever assembly.

(a) Install the brake cable connector on the brake trailing

shoe with brake lever assembly.

(b) Insert the brake trailing shoe with brake lever assembly

and the shoe end of the brake leading shoe assembly

into the wheel cylinder assembly.

Remark: Do not let oil or grease drip on the brake shoe's

lining.

8. Install the retainer spring.

9. Install the brake leading and trailing shoe assemblies

onto the brake back plate assembly.

(a) Insert the pressure spring bar into the brake back plate

assembly and brake leading and trailing shoe assemblies.

(b) Put the pressure spring on the pressure spring bar,

put in the pressure spring cap, and use SST (Special

Service Tools) to lock the pressure spring cap onto the

pressure spring bar.

10. Inspect the operating procedures of the automatic ad-

juster.

(a) Refer to the diagram for directions, step on and off the

brake pedal, and make sure the self-adjusting screws

can rotate. If they are unable to rotate, inspect the rear

brake to try to determine the source of the problem.

(b) Adjust the adjusting mechanisms length and make it as

short as possible.

(c) Install the rear brake drum.

(d) Press the brake pedal towards the floor until a clicking

noise cannot be heard.

11. Inspect the space between the brake's friction plate

and rear brake drum.

(a) Remove the rear brake drum.

(b) Measure the rear brake drum's internal diameter and

the brake shoe friction plate's external diameter, and

inspect if the difference between the two diameters is

within the regulated clearance range.

Single sided clearance: 0.25 mm

If not correct, inspect the braking system.

12. Install the rear wheel.

Tightening torque: 100 N·m

13. Fill the brake fluid reservoir up with brake fluid and

exhaust the air out of the brake system.

14. Check for leaking brake fluid

SST

Page 140 of 281

Downloaded from www.Manualslib.com manuals search engine 133Brake System

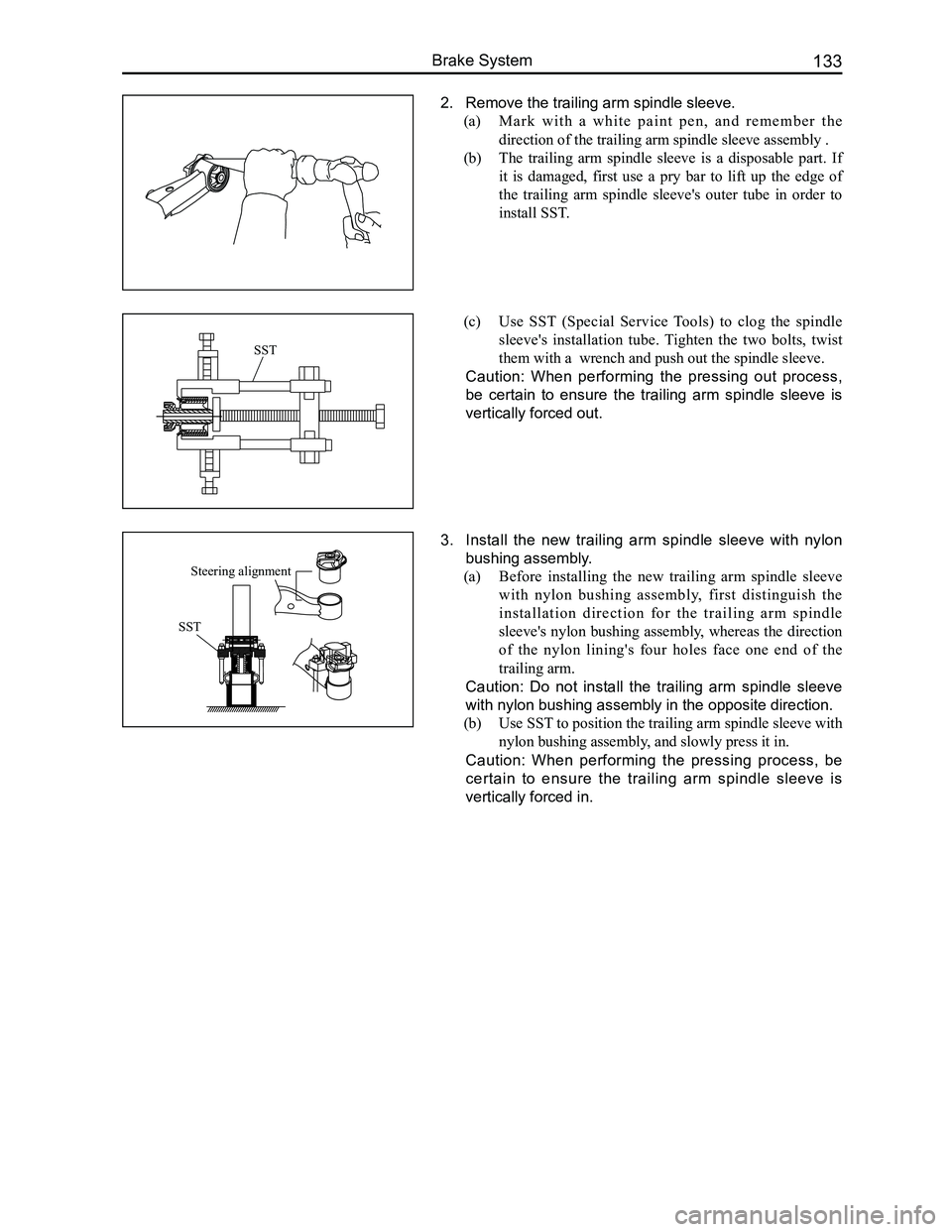

2. Remove the trailing arm spindle sleeve.

(a) M a r k w i t h a w h i t e p a i n t p e n , a n d r e m e m b e r t h e

direction of the trailing arm spindle sleeve assembly .

(b) The trailing arm spindle sleeve is a disposable part. If

it is damaged, first use a pry bar to lift up the edge of

the trailing arm spindle sleeve's outer tube in order to

install SST.

(c) Use SST (Special Service Tools) to clog the spindle

sleeve's installation tube. Tighten the two bolts, twist

them with a wrench and push out the spindle sleeve.

Caution: When performing the pressing out process,

be certain to ensure the trailing arm spindle sleeve is

vertically forced out.

3. Install the new trailing arm spindle sleeve with nylon

bushing assembly.

(a) Before installing the new trailing arm spindle sleeve

with nylon bushing assembly, first distinguish the

installation direction for the trailing arm spindle

sleeve's nylon bushing assembly, whereas the direction

of the nylon lining's four holes face one end of the

trailing arm.

Caution: Do not install the trailing arm spindle sleeve

with nylon bushing assembly in the opposite direction.

(b) Use SST to position the trailing arm spindle sleeve with

nylon bushing assembly, and slowly press it in.

Caution: When performing the pressing process, be

certain to ensure the trailing arm spindle sleeve is

vertically forced in.

SST

Steering alignment

SST

Page 180 of 281

Downloaded from www.Manualslib.com manuals search engine 173Vehicle Body Electronic System

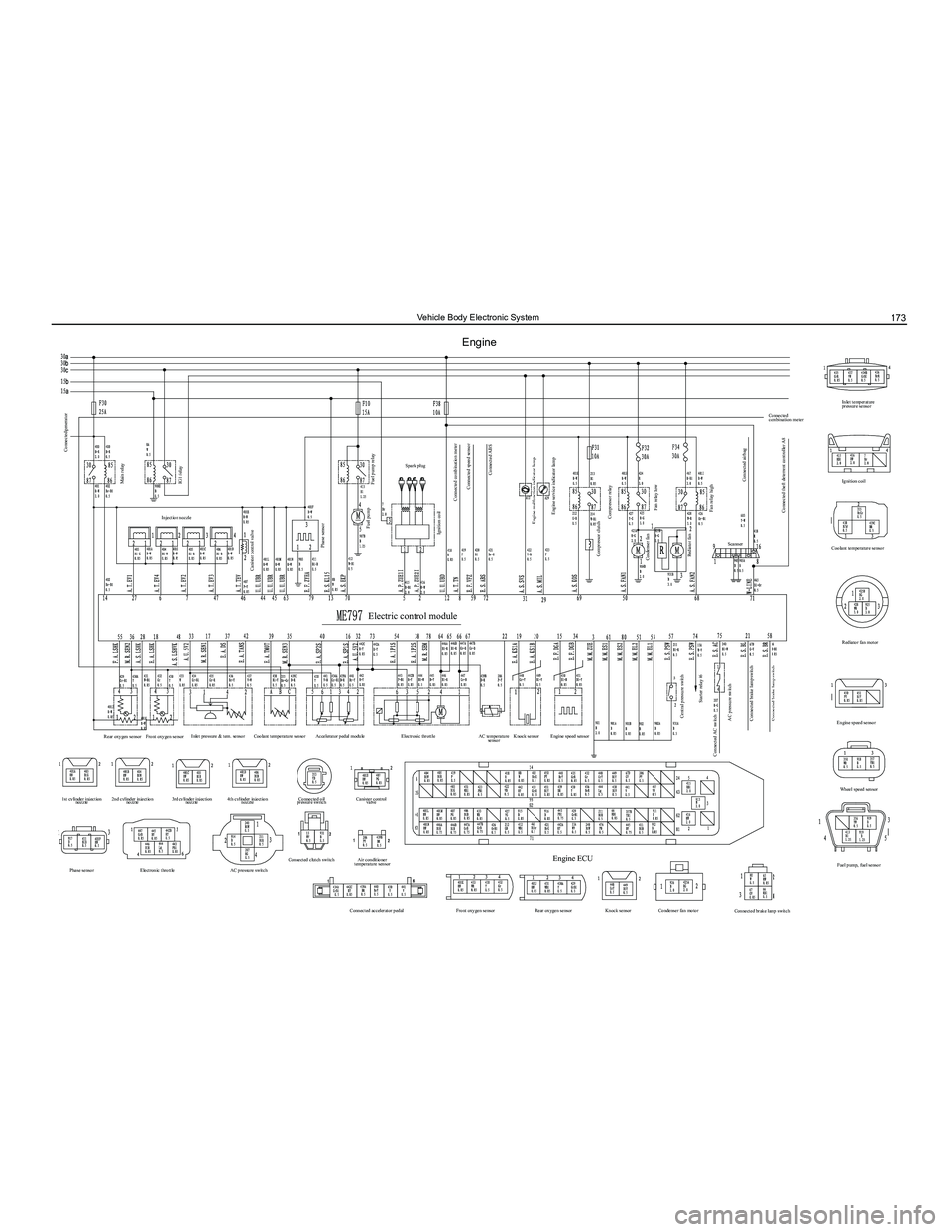

Engine

Connected generator

Canister control valve

Rear oxygen sensor

1st cylinder injection nozzle

Phase sensor Electronic throttle AC pressure switchConnected clutch switch

Air conditioner

temperature sensor

Connected accelerator pedal Front oxygen sensorRear oxygen sensorKnock sensorCondenser fan motor

Connected brake lamp switch

Engine ECU

2nd cylinder injection

nozzle 3rd cylinder injection

nozzle 4th cylinder injection

nozzle Connected oil

pressure switch Canister control

valve

Front oxygen sensor

Inlet pressure & tem. sensor

Coolant temperature sensor Accelerator pedal module Electronic throttle AC temperature

sensor Knock sensor

Engine speed sensor

Phase sensor

Fuel pump relay

Connected combination meter Connected speed sensor

Engine malfunction indicator lamp Engine service indicator lamp

Compressor relay

Compressor clutch

Central pressure switch Starter relay 86

Connected AC switch AC pressure switch

Connected brake lamp switch

Connected brake lamp switch Condenser fan

Rediator fan Fan relay lowScanner

Fan relay high

Connected airbag

Connected theft deterrent controller A8

Connected

combination meter

Ignition coil

Coolant temperature sensor

Rediator fan motor

Engine speed sensor Wheel speed sensor

Fuel pump, fuel sensor Inlet temperature

pressure sensor

Connected ABS

Spark plug

Fuel pump

Electric control module

Ignition coil

Main relay

Injection nozzle

IG1 relay

Page 199 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual192

(b) Input the PIN code and the key matching instructions with the scanner

(c) If the PIN code is correct, after receiving the key matching instructions, transponder learning will be

complete

(d) Switch off the ignition switch

2. Check the key quantity:

Check the alarm's currently matched key quantity and matchable key quantity with the scanner .

3. Match the theft deterrent controller:

(a) Properly connect the engine ECU and the theft deterrent controller

(b) Input the PIN code and theft deterrent controller matching instructions with the scanner

(c) If the PIN code is correct, after receiving the theft deterrent controller matching instructions, matching will

be complete.

After theft deterrent controller matching is done, it needs to re-learn each key if the original key is still to be

used. If the original key will not be in use any more, then it needs to \

rematch the new key.

4. Match the engine ECU

(a) Properly connect the engine ECU and the theft deterrent controller.

(b) Input the PIN code and engine ECU matching instruction with the scanner.

(c) If the PIN code and instructions are correct, the matching process will be completed automatically.

5. PIN code scan-resisting strategy

From the matching process above, it's apparently that the PIN code is a security code for the matching process.

This code is passed to the vehicle owner in document format during the sales service. If it is lost accidentally,

the customer service staff can check the vehicle identification code stored in the theft deterrent controller with a

scanner, and then send it to the authorized staff in the factory to check the PIN code. In order to prevent someone

from illegally scanning the PIN code, it uses a forced time-delay method to prevent divulgence of information.

Page 221 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual214

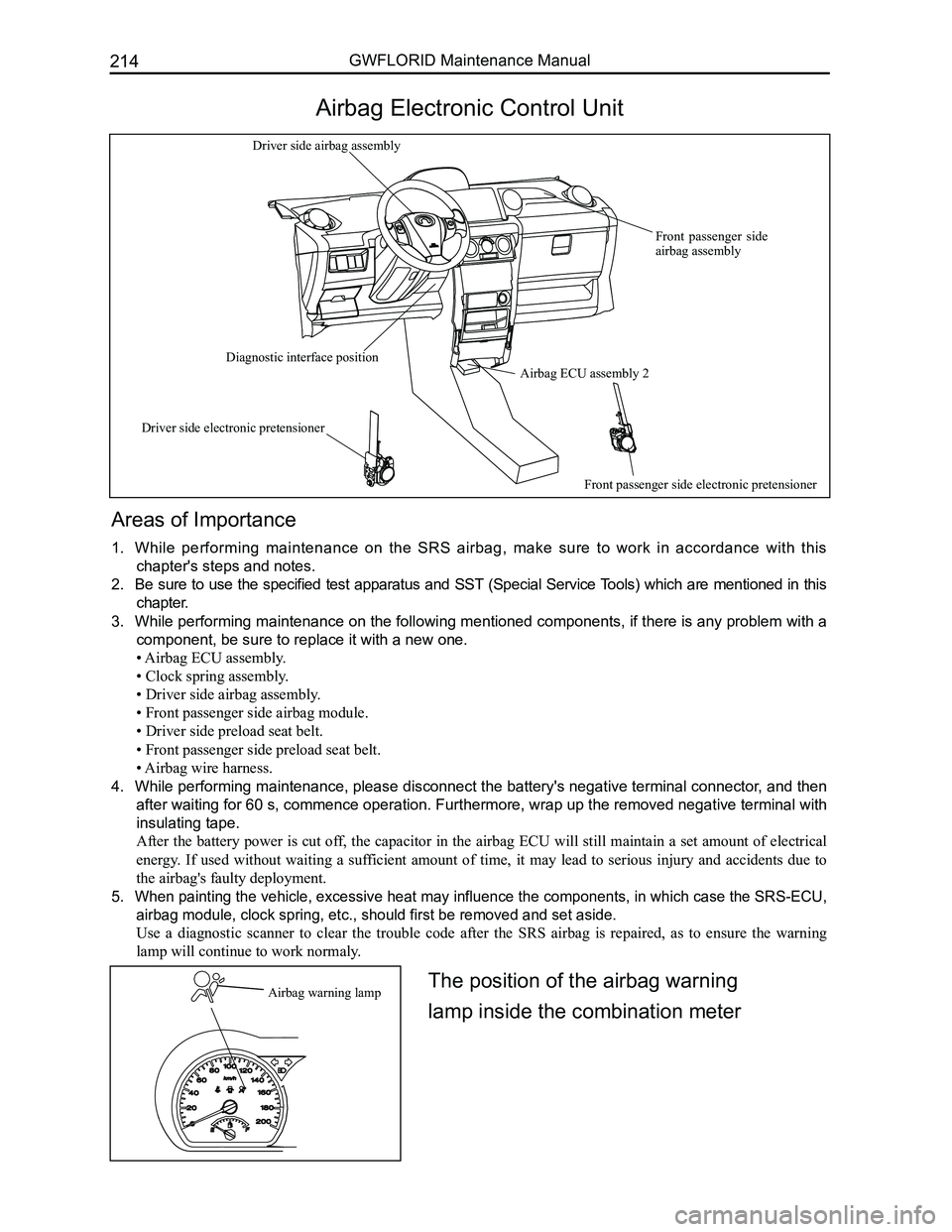

Areas of Importance

1. While performing maintenance on the SRS airbag, make sure to work in accordance with this

chapter's steps and notes.

2. Be sure to use the specified test apparatus and SST (Special Service Tools) which are mentioned in this

chapter.

3. While performing maintenance on the following mentioned components, if there is any problem with a

component, be sure to replace it with a new one.

• Airbag ECU assembly.

• Clock spring assembly.

• Driver side airbag assembly.

• Front passenger side airbag module.

• Driver side preload seat belt.

• Front passenger side preload seat belt.

• Airbag wire harness.

4. While performing maintenance, please disconnect the battery's negative terminal connector, and then

after waiting for 60 s, commence operation. Furthermore, wrap up the removed negative terminal with

insulating tape.

After the battery power is cut off, the capacitor in the airbag ECU will still maintain a set amount of electrical

energy. If used without waiting a sufficient amount of time, it may lead to serious injury and accidents due to

the airbag's faulty deployment.

5. When painting the vehicle, excessive heat may influence the components, in which case the SRS-ECU,

airbag module, clock spring, etc., should first be removed and set aside\

.

Use a diagnostic scanner to clear the trouble code after the SRS airbag is repaired, as to ensure the warning

lamp will continue to work normaly.

Airbag Electronic Control Unit

Airbag warning lamp

Airbag ECU assembly 2

Front passenger side airbag assembly

Driver side airbag assembly

Diagnostic interface position

Driver side electronic pretensioner

Front passenger side electronic pretensioner

The position of the airbag warning

lamp inside the combination meter