wheel torque GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 92 of 281

Downloaded from www.Manualslib.com manuals search engine 85Suspension System

Drive shaft installation

1. Insert the drive shaft.

First, align the inner end of the drive shaft and differential

spline. Keep the drive shaft axes and the differential axes

bases uniform, then hammer towards the direction of the

differential drive shaft's outer end until a clear and sharp

clicking sound is heard. Here, the drive shaft and the

transmission should have a clearance of about 1 mm.

2. According to the front suspension and wheel assembly

installation specifications, properly install the front

shock absorber with coil spring assembly LH and

wheel.

3. Use an M32 sleeve, ratchet wrench, and extension bar

to tighten front drive shaft nut LH.

Tightening torque: 225±20 N·m

F

F

Page 100 of 281

Downloaded from www.Manualslib.com manuals search engine 93Suspension System

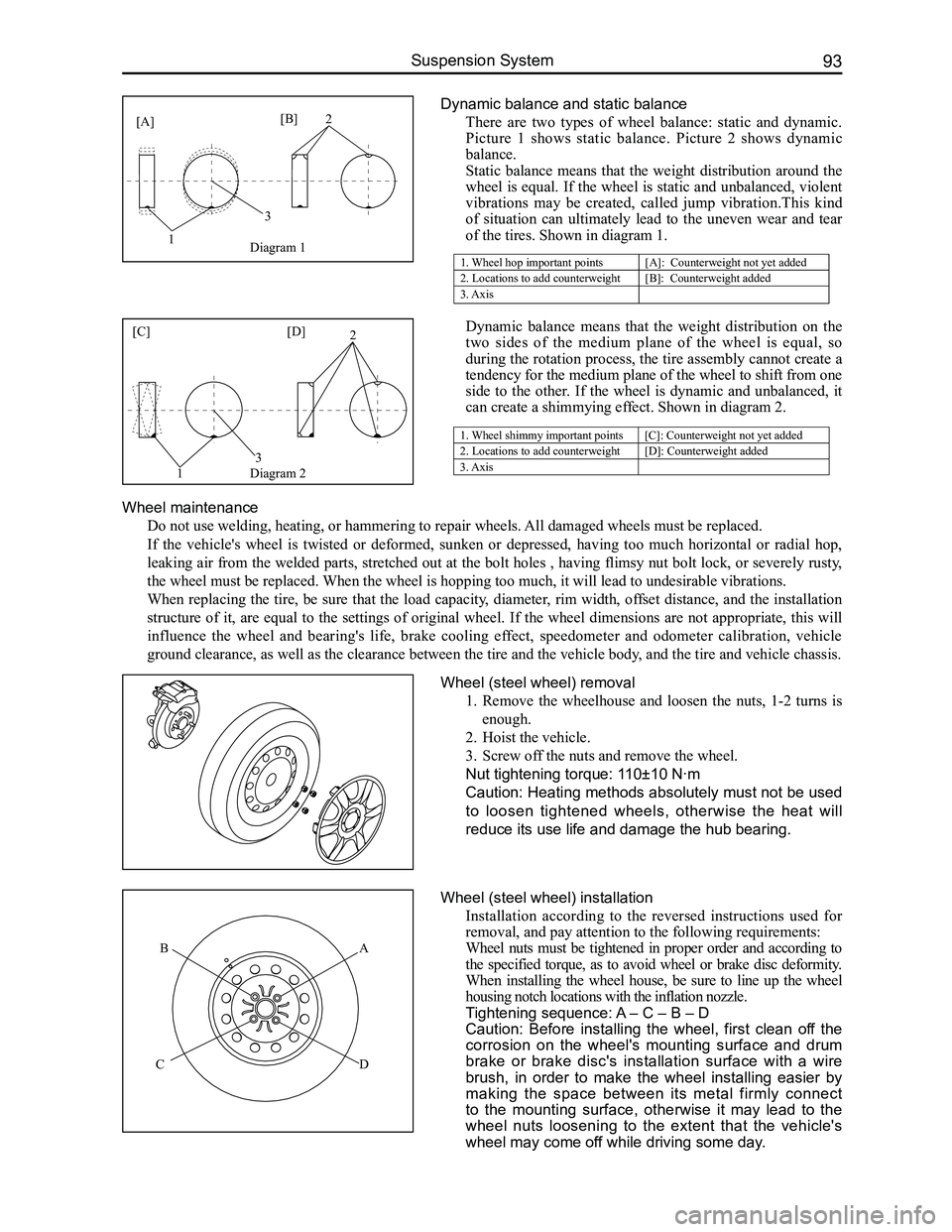

Dynamic balance and static balance

There are two types of wheel balance: static and dynamic.

Picture 1 shows static balance. Picture 2 shows dynamic

balance.

Static balance means that the weight distribution around the

wheel is equal. If the wheel is static and unbalanced, violent

vibrations may be created, called jump vibration.This kind

of situation can ultimately lead to the uneven wear and tear

of the tires. Shown in diagram 1.

Dynamic balance means that the weight distribution on the

two sides of the medium plane of the wheel is equal, so

during the rotation process, the tire assembly cannot create a

tendency for the medium plane of the wheel to shift from one

side to the other. If the wheel is dynamic and unbalanced, it

can create a shimmying effect. Shown in diagram 2.

1. Wheel shimmy important points[C]: Counterweight not yet added

2. Locations to add counterweight[D]: Counterweight added

3. Axis

Wheel maintenance

Do not use welding, heating, or hammering to repair wheels. All damaged wheels must be replaced.

If the vehicle's wheel is twisted or deformed, sunken or depressed, having too much horizontal or radial hop,

leaking air from the welded parts, stretched out at the bolt holes , having flimsy nut bolt lock, or severely rusty,

the wheel must be replaced. When the wheel is hopping too much, it will lead to undesirable vibratio\

ns.

When replacing the tire, be sure that the load capacity, diameter, rim width, offset distance, and the installation

structure of it, are equal to the settings of original wheel. If the wheel dimensions are not appropriate, this will

influence the wheel and bearing's life, brake cooling effect, speedometer and odometer calibration, vehicle

ground clearance, as well as the clearance between the tire and the vehi\

cle body, and the tire and vehicle chassis.

Wheel (steel wheel) removal

1. Remove the wheelhouse and loosen the nuts, 1-2 turns is

enough.

2. Hoist the vehicle.

3. Screw off the nuts and remove the wheel.

Nut tightening torque: 110±10 N·m

Caution: Heating methods absolutely must not be used

to loosen tightened wheels, otherwise the heat will

reduce its use life and damage the hub bearing.

Wheel (steel wheel) installation

Installation according to the reversed instructions used for

removal, and pay attention to the following requirements:

Wheel nuts must be tightened in proper order and according to

the specified torque, as to avoid wheel or brake disc deformity.

When installing the wheel house, be sure to line up the wheel

housing notch locations with the inflation nozzle.

Tightening sequence: A – C – B – D

Caution: Before installing the wheel, first clean off the

corrosion on the wheel's mounting surface and drum

brake or brake disc's installation surface with a wire

brush, in order to make the wheel installing easier by

making the space between its metal firmly connect

to the mounting surface, otherwise it may lead to the

wheel nuts loosening to the extent that the vehicle's

wheel may come off while driving some day.

1

3

2[A][B]

1. Wheel hop important points[A]: Counterweight not yet added

2. Locations to add counterweight[B]: Counterweight added

3. Axis

Diagram 1

Diagram 2

[C][D]

1

3

2

AB

CD

Page 119 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual112

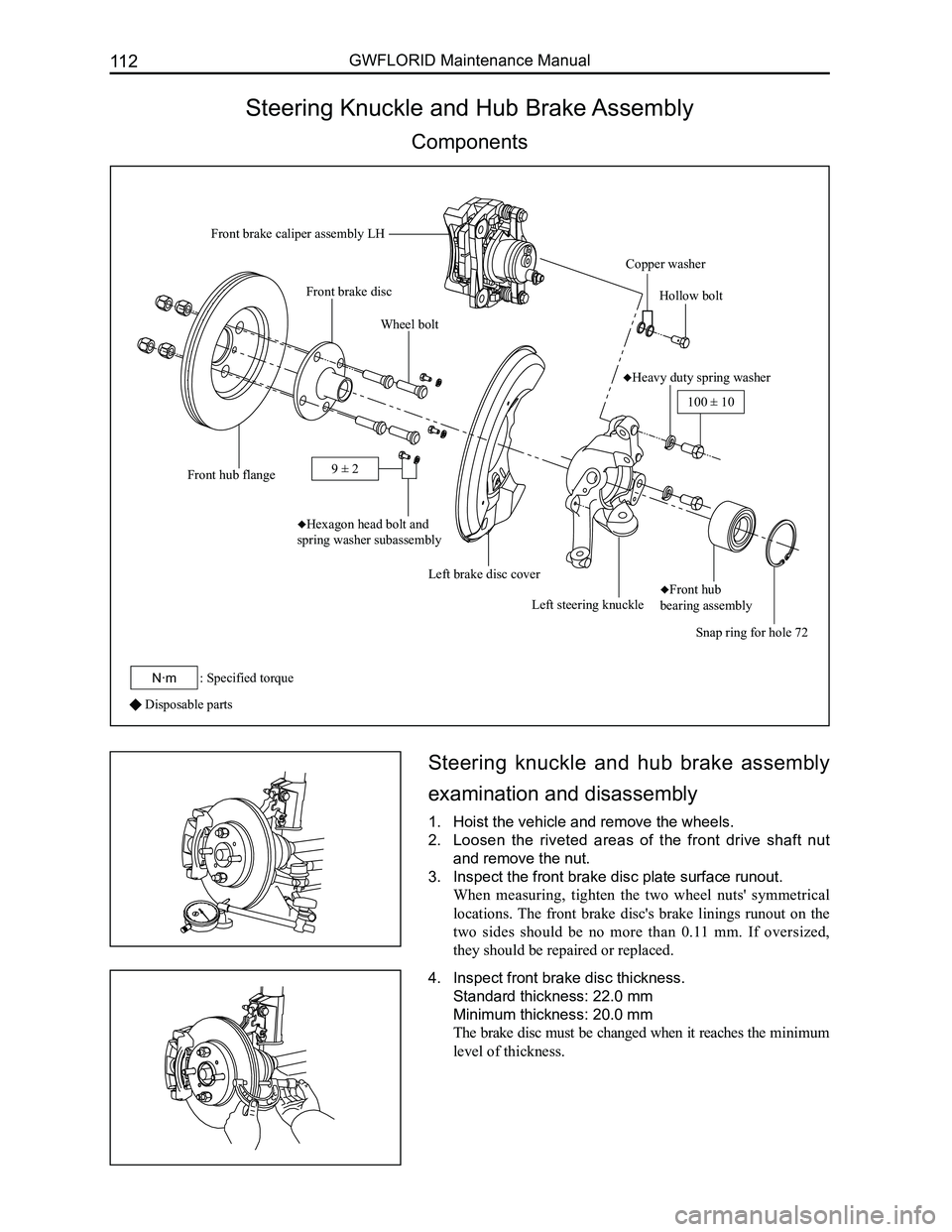

Steering Knuckle and Hub Brake Assembly

Components

Disposable parts

Steering knuckle and hub brake assembly

examination and disassembly

1. Hoist the vehicle and remove the wheels.

2. Loosen the riveted areas of the front drive shaft nut

and remove the nut.

3. Inspect the front brake disc plate surface runout.

When measuring, tighten the two wheel nuts' symmetrical

locations. The front brake disc's brake linings runout on the

two sides should be no more than 0.11 mm. If oversized,

they should be repaired or replaced.

4. Inspect front brake disc thickness.

Standard thickness: 22.0 mm

Minimum thickness: 20.0 mm

The brake disc must be changed when it reaches the minimum

level of thickness.

Front brake caliper assembly LH

Copper washer

Hollow bolt

♦Heavy duty spring washer

Snap ring for hole 72

♦Front hub

bearing assemblyLeft steering knuckle

Left brake disc cover

♦Hexagon head bolt and

spring washer subassembly

Wheel bolt

Front hub flange

Front brake disc

100 ± 10

: Specified torqueN·m

9 ± 2

Page 121 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual114

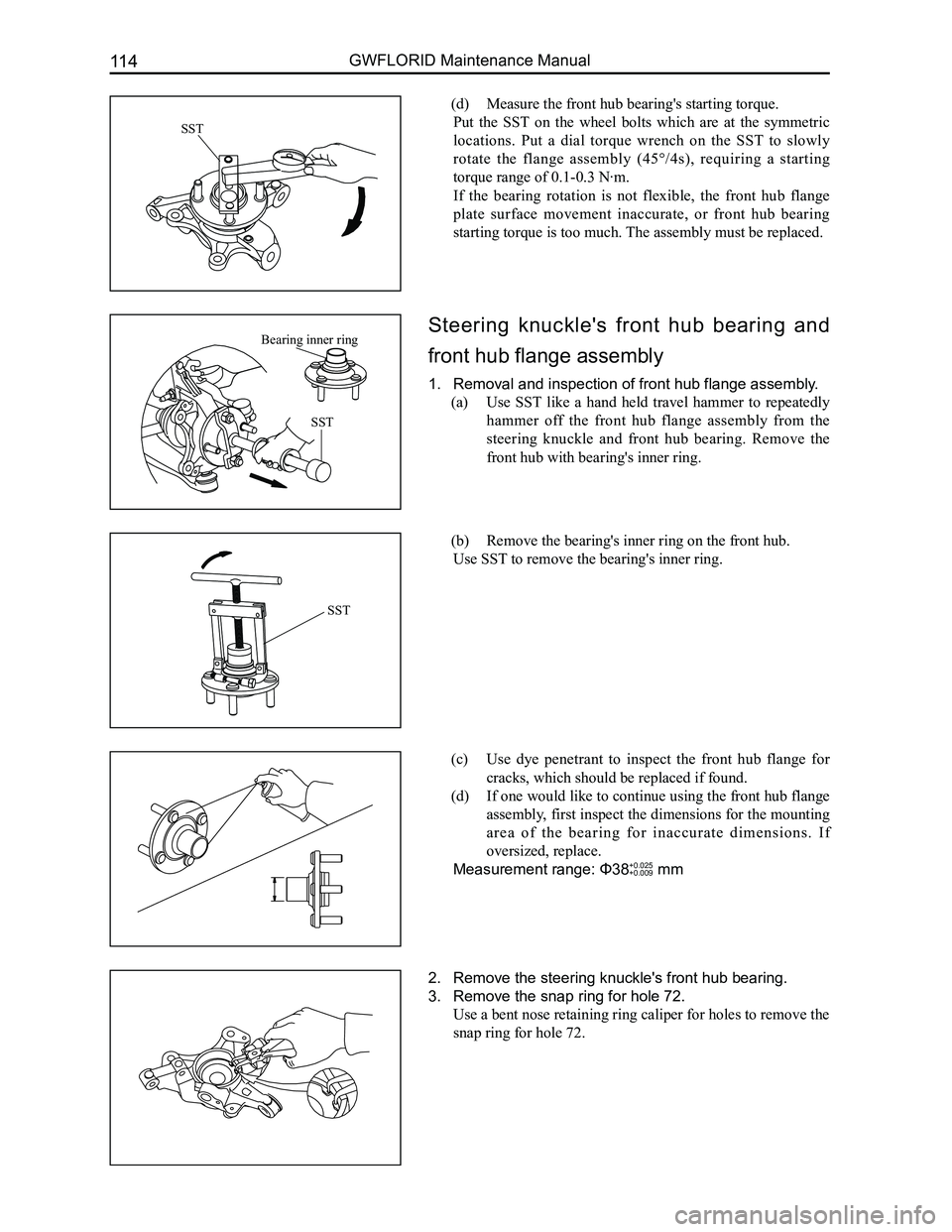

(d) Measure the front hub bearing's starting torque.

Put the SST on the wheel bolts which are at the symmetric

locations. Put a dial torque wrench on the SST to slowly

rotate the flange assembly (45°/4s), requiring a starting

torque range of 0.1-0.3 N·m.

If the bearing rotation is not flexible, the front hub flange

plate surface movement inaccurate, or front hub bearing

starting torque is too much. The assembly must be replaced.

Steering knuckle's front hub bearing and

front hub flange assembly

1. Removal and inspection of front hub flange assembly.

(a) Use SST like a hand held travel hammer to repeatedly

hammer off the front hub flange assembly from the

steering knuckle and front hub bearing. Remove the

front hub with bearing's inner ring.

(b) Remove the bearing's inner ring on the front hub.

Use SST to remove the bearing's inner ring.

SST

SST

Bearing inner ring

SST

(c) Use dye penetrant to inspect the front hub flange for

cracks, which should be replaced if found.

(d) If one would like to continue using the front hub flange

assembly, first inspect the dimensions for the mounting

area of the bearing for inaccurate dimensions. If

oversized, replace.

Measurement range: Φ38+0.025 +0.009 mm

2. Remove the steering knuckle's front hub bearing.

3. Remove the snap ring for hole 72.

Use a bent nose retaining ring caliper for holes to remove the

snap ring for hole 72.

Page 123 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual116

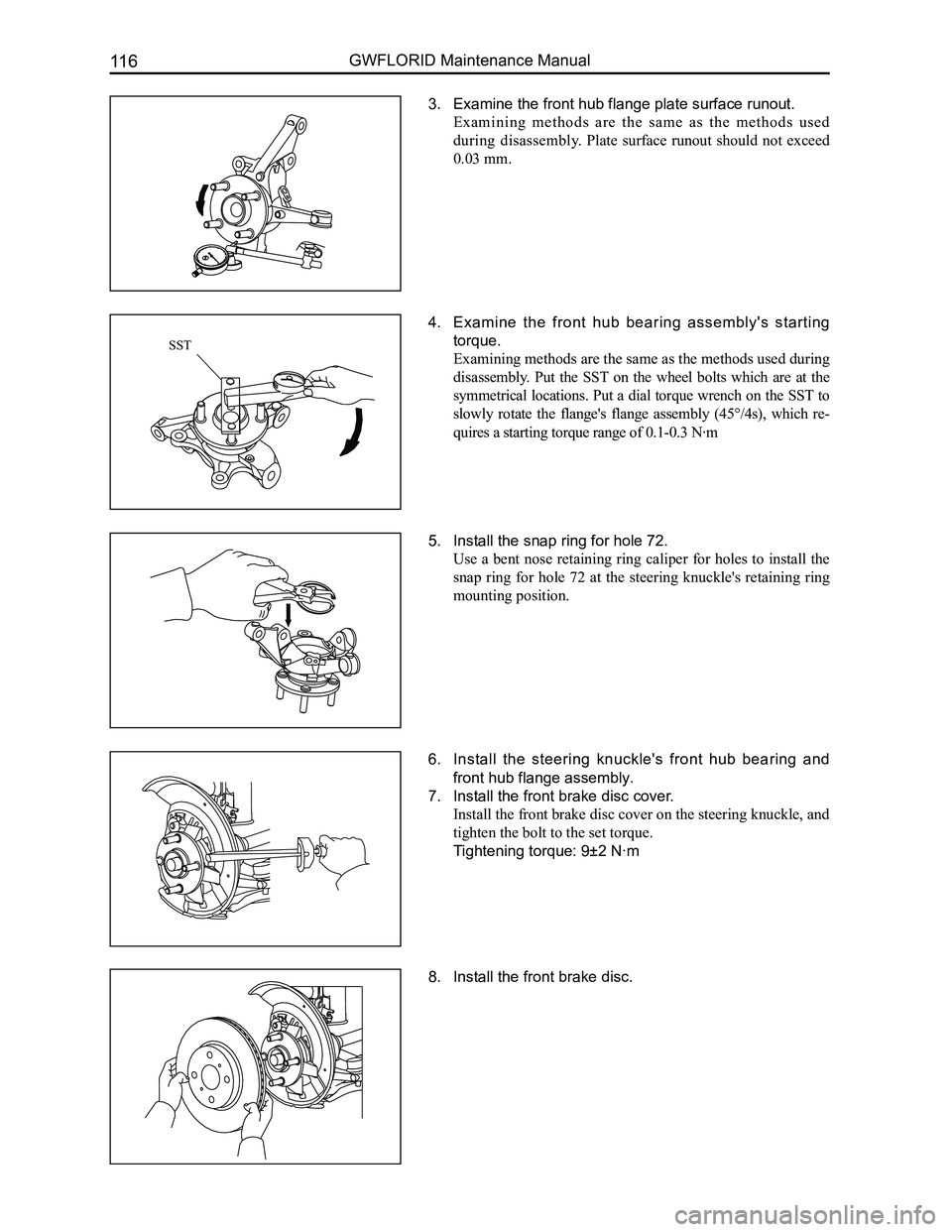

3. Examine the front hub flange plate surface runout.

Examining methods are the same as the methods used

during disassembly. Plate surface runout should not exceed

0.03 mm.

4. Examine the front hub bearing assembly's starting

torque.

Examining methods are the same as the methods used during

disassembly. Put the SST on the wheel bolts which are at the

symmetrical locations. Put a dial torque wrench on the SST to

slowly rotate the flange's flange assembly (45°/4s), which re-

quires a starting torque range of 0.1-0.3 N·m

5. Install the snap ring for hole 72.

Use a bent nose retaining ring caliper for holes to install the

snap ring for hole 72 at the steering knuckle's retaining ring

mounting position.

6. Install the steering knuckle's front hub bearing and

front hub flange assembly.

7. Install the front brake disc cover.

Install the front brake disc cover on the steering knuckle, and

tighten the bolt to the set torque.

Tightening torque: 9±2 N·m

SST

8. Install the front brake disc.

Page 124 of 281

Downloaded from www.Manualslib.com manuals search engine 117Brake System

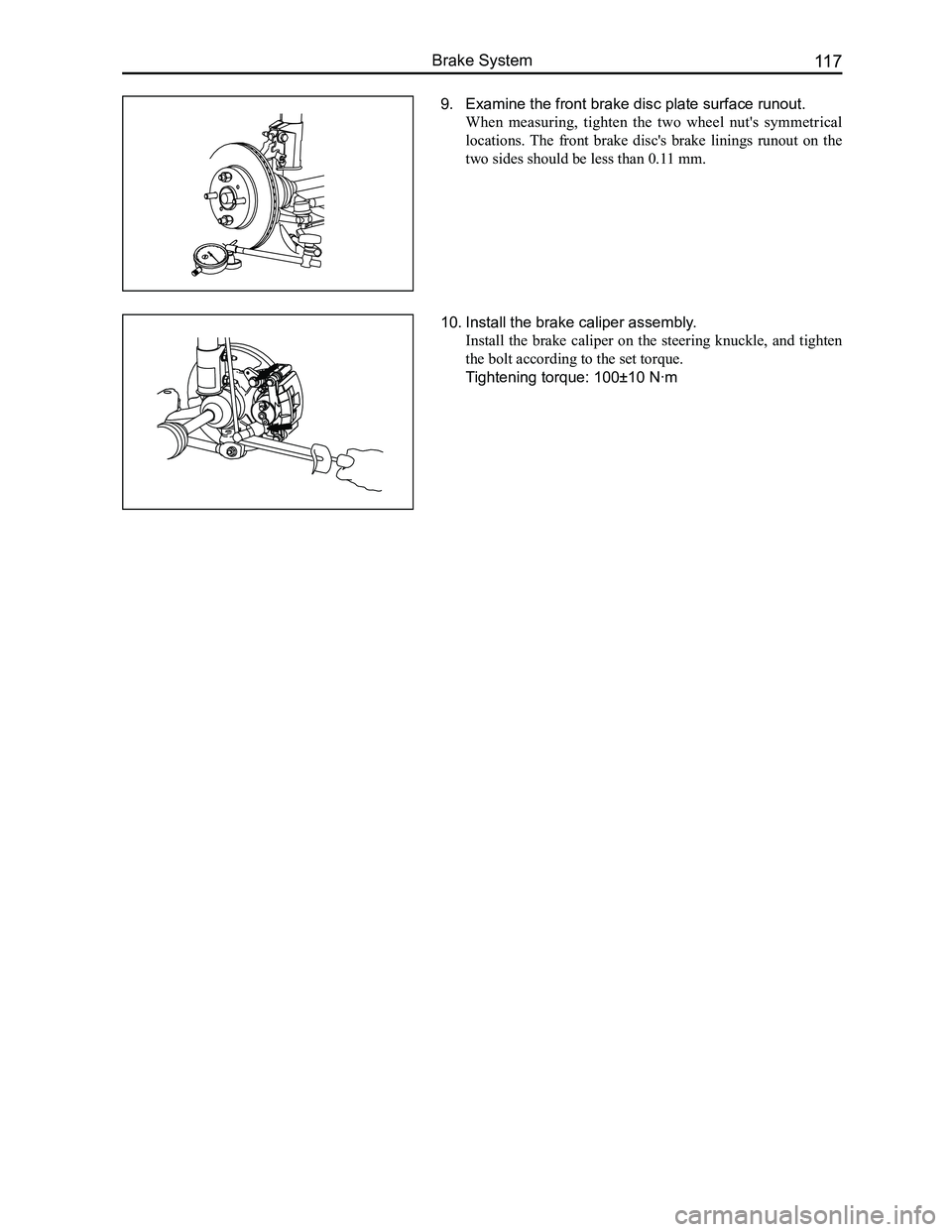

9. Examine the front brake disc plate surface runout.

When measuring, tighten the two wheel nut's symmetrical

locations. The front brake disc's brake linings runout on the

two sides should be less than 0.11 mm.

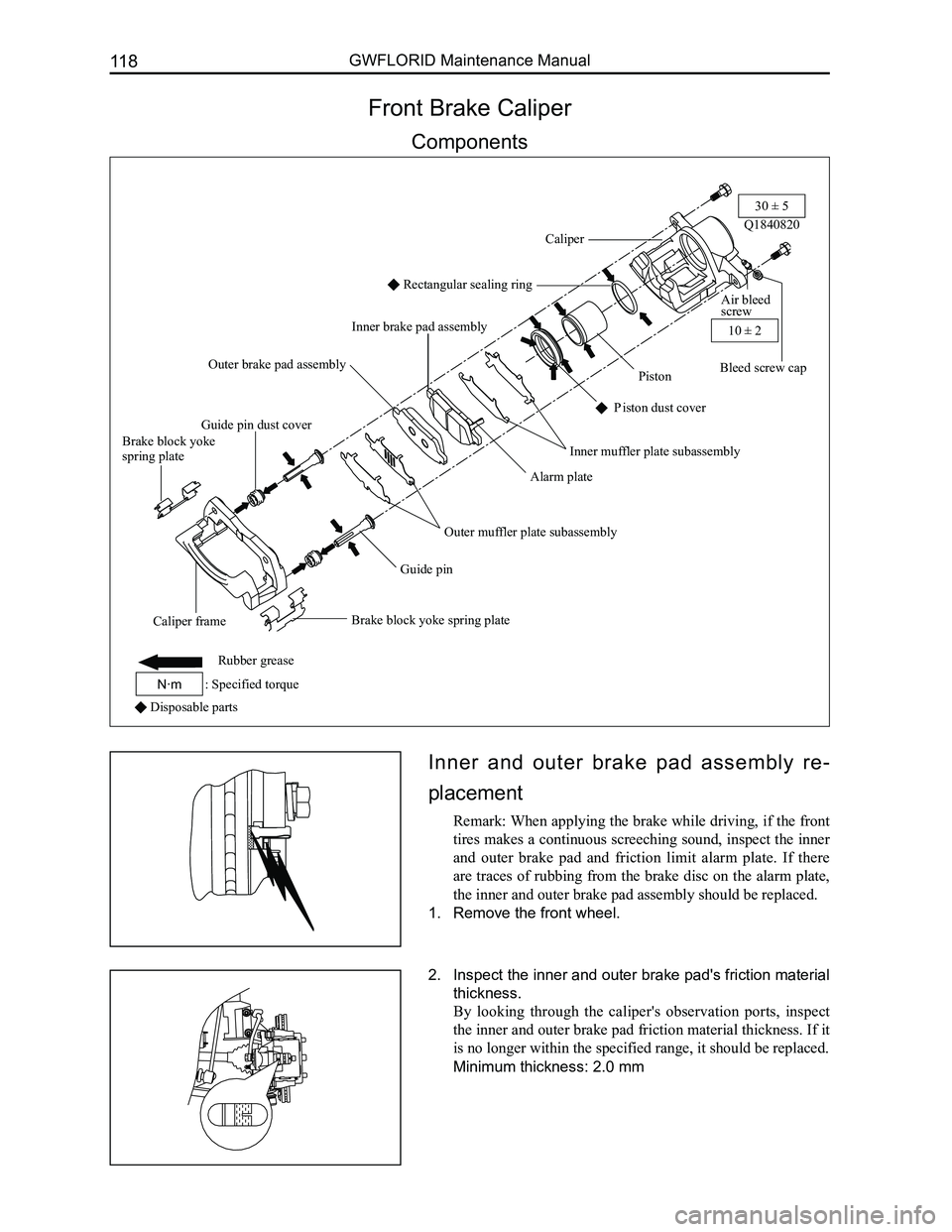

10. Install the brake caliper assembly.

Install the brake caliper on the steering knuckle, and tighten

the bolt according to the set torque.

Tightening torque: 100±10 N·m

Page 125 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual118

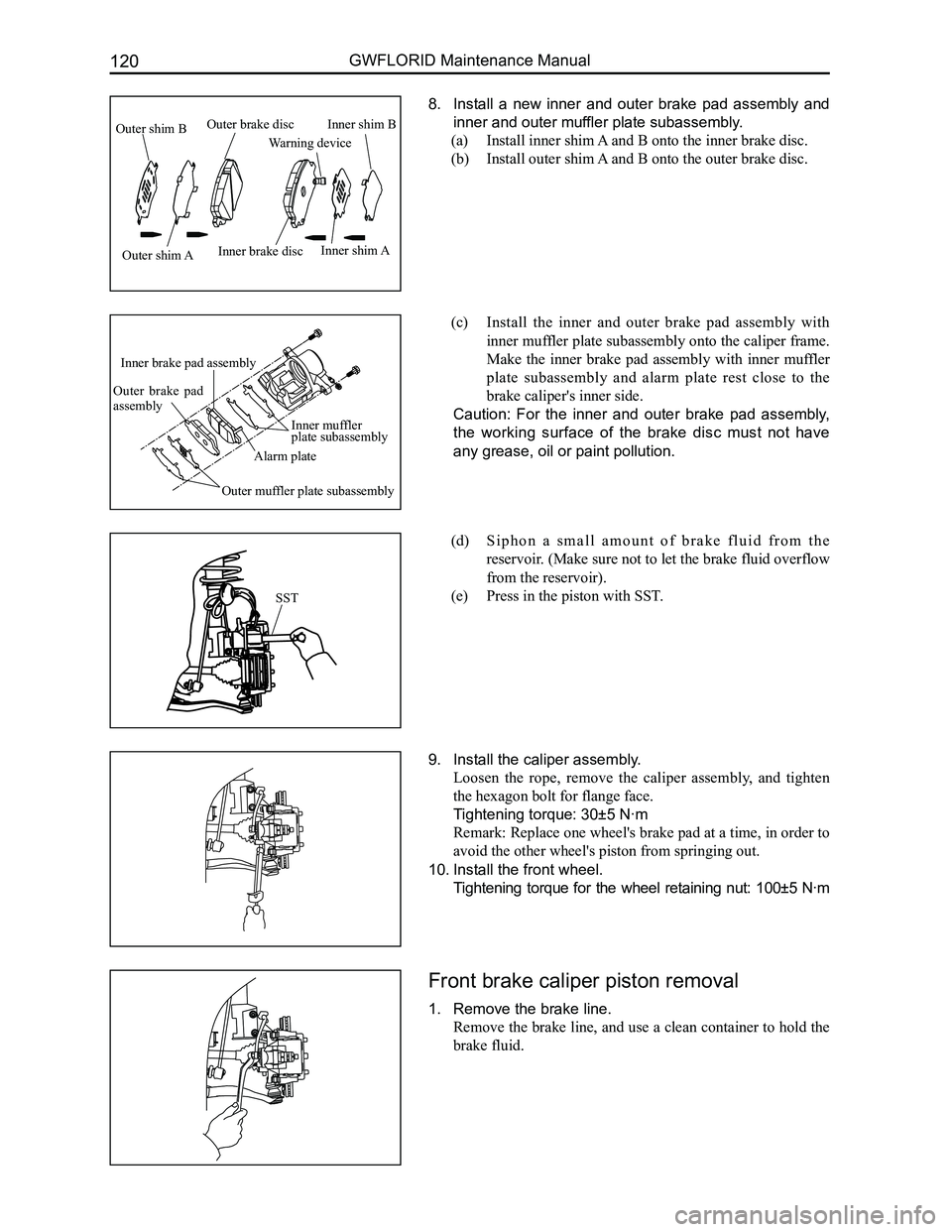

Front Brake Caliper

Components

Disposable parts

Inner and outer brake pad assembly re-

placement

Remark: When applying the brake while driving, if the front

tires makes a continuous screeching sound, inspect the inner

and outer brake pad and friction limit alarm plate. If there

are traces of rubbing from the brake disc on the alarm plate,

the inner and outer brake pad assembly should be replaced.

1. Remove the front wheel.

2. Inspect the inner and outer brake pad's friction material

thickness.

By looking through the caliper's observation ports, inspect

the inner and outer brake pad friction material thickness. If it

is no longer within the specified range, it should be replaced.

Minimum thickness: 2.0 mm

Bleed screw cap

Air bleed screw

Caliper

Rectangular sealing ring

Piston

P iston dust cover

Inner muffler plate subassembly

Alarm plate

Inner brake pad assembly

Outer brake pad assembly

Outer muffler plate subassembly

Guide pin

Guide pin dust cover

Caliper frame

Brake block yoke spring plate

Brake block yoke spring plate

30 ± 5

: Specified torqueN·m

10 ± 2

Q1840820

Rubber grease

Page 127 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual120

8. Install a new inner and outer brake pad assembly and

inner and outer muffler plate subassembly.

(a) Install inner shim A and B onto the inner brake disc.

(b) Install outer shim A and B onto the outer brake disc.

(c) Install the inner and outer brake pad assembly with

inner muffler plate subassembly onto the caliper frame.

Make the inner brake pad assembly with inner muffler

plate subassembly and alarm plate rest close to the

brake caliper's inner side.

Caution: For the inner and outer brake pad assembly,

the working surface of the brake disc must not have

any grease, oil or paint pollution.

(d) S i p h o n a s m a l l a m o u n t o f b r a k e f l u i d f r o m t h e

reservoir. (Make sure not to let the brake fluid overflow

from the reservoir).

(e) Press in the piston with SST.

9. Install the caliper assembly.

Loosen the rope, remove the caliper assembly, and tighten

the hexagon bolt for flange face.

Tightening torque: 30±5 N·m

Remark: Replace one wheel's brake pad at a time, in order to

avoid the other wheel's piston from springing out.

10. Install the front wheel.

Tightening torque for the wheel retaining nut: 100±5 N·m

Front brake caliper piston removal

1. Remove the brake line.

Remove the brake line, and use a clean container to hold the

brake fluid.

SST

Outer shim B

Outer shim AInner brake disc

Warning device

Inner shim B

Inner shim A

Outer brake disc

Inner muffler plate subassembly

Alarm plate

Inner brake pad assembly

Outer brake pad assembly

Outer muffler plate subassembly

Page 131 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual124

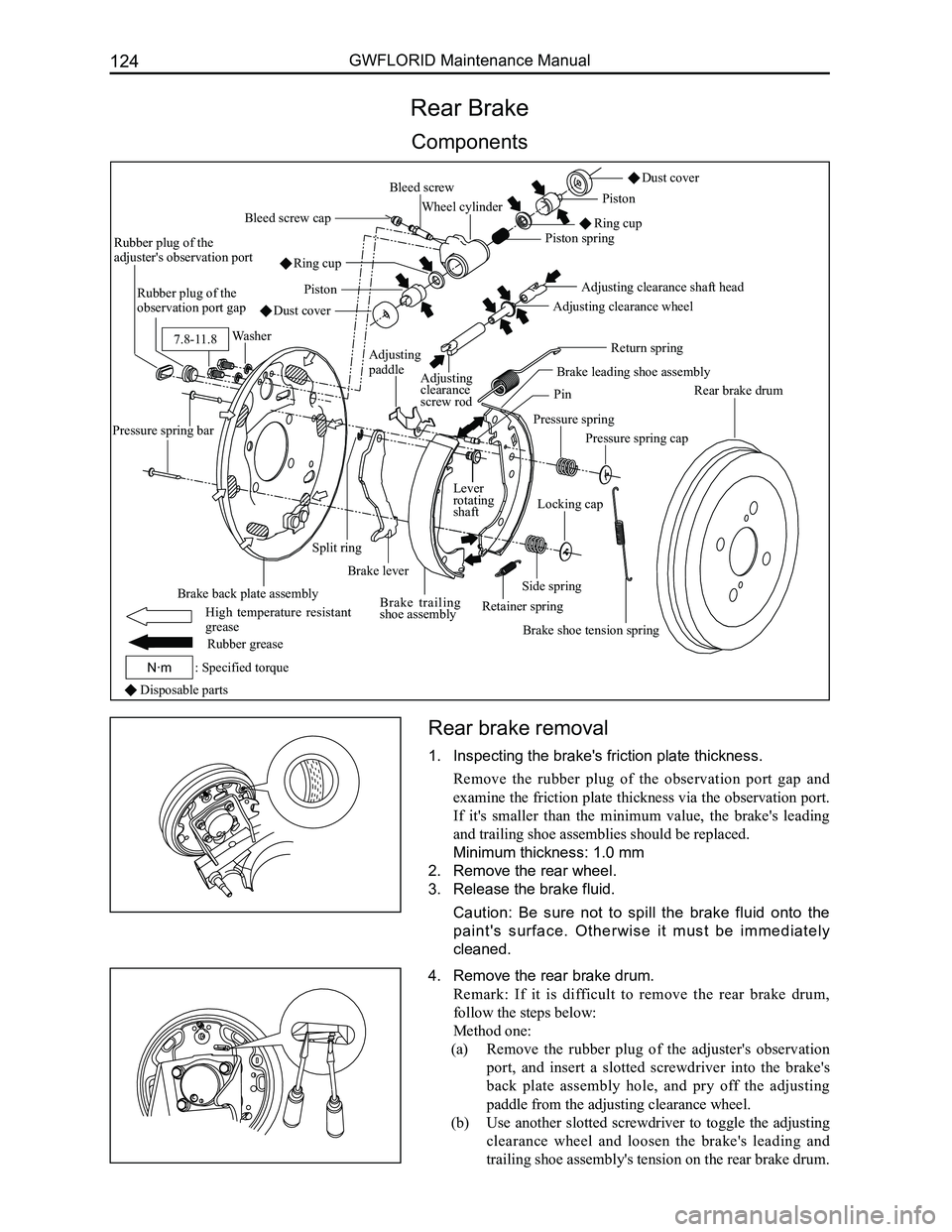

Rear Brake

Components

4. Remove the rear brake drum.

Remark: If it is difficult to remove the rear brake drum,

follow the steps below:

Method one:

(a) Remove the rubber plug of the adjuster's observation

port, and insert a slotted screwdriver into the brake's

back plate assembly hole, and pry off the adjusting

paddle from the adjusting clearance wheel.

(b) Use another slotted screwdriver to toggle the adjusting

clearance wheel and loosen the brake's leading and

trailing shoe assembly's tension on the rear brake drum.

Disposable parts

Dust cover

Brake leading shoe assembly

Pressure spring

Pressure spring cap

Brake shoe tension spring

Rear brake drum

Lever rotating shaft

Retainer spring

Locking cap

Split ring

Brake lever

Brake trailing shoe assembly

Brake back plate assembly

Pressure spring bar

Rubber plug of the adjuster's observation port

Rubber plug of the observation port gap

Washer

Bleed screw cap

Bleed screwPiston

Ring cup

Piston spring

Wheel cylinder

Adjusting clearance shaft head

Adjusting clearance wheel

Adjusting clearance screw rod

Return springAdjusting paddle

Pin

Side spring

Dust cover

Piston

Ring cup

Rubber grease

: Specified torqueN·m

7.8-11.8

High temperature resistant grease

Rear brake removal

1. Inspecting the brake's friction plate thickness.

Remove the rubber plug of the observation port gap and

examine the friction plate thickness via the observation port.

If it's smaller than the minimum value, the brake's leading

and trailing shoe assemblies should be replaced.

Minimum thickness: 1.0 mm

2. Remove the rear wheel.

3. Release the brake fluid.

Caution: Be sure not to spill the brake fluid onto the

paint's surface. Otherwise it must be immediately

cleaned.

Page 135 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual128

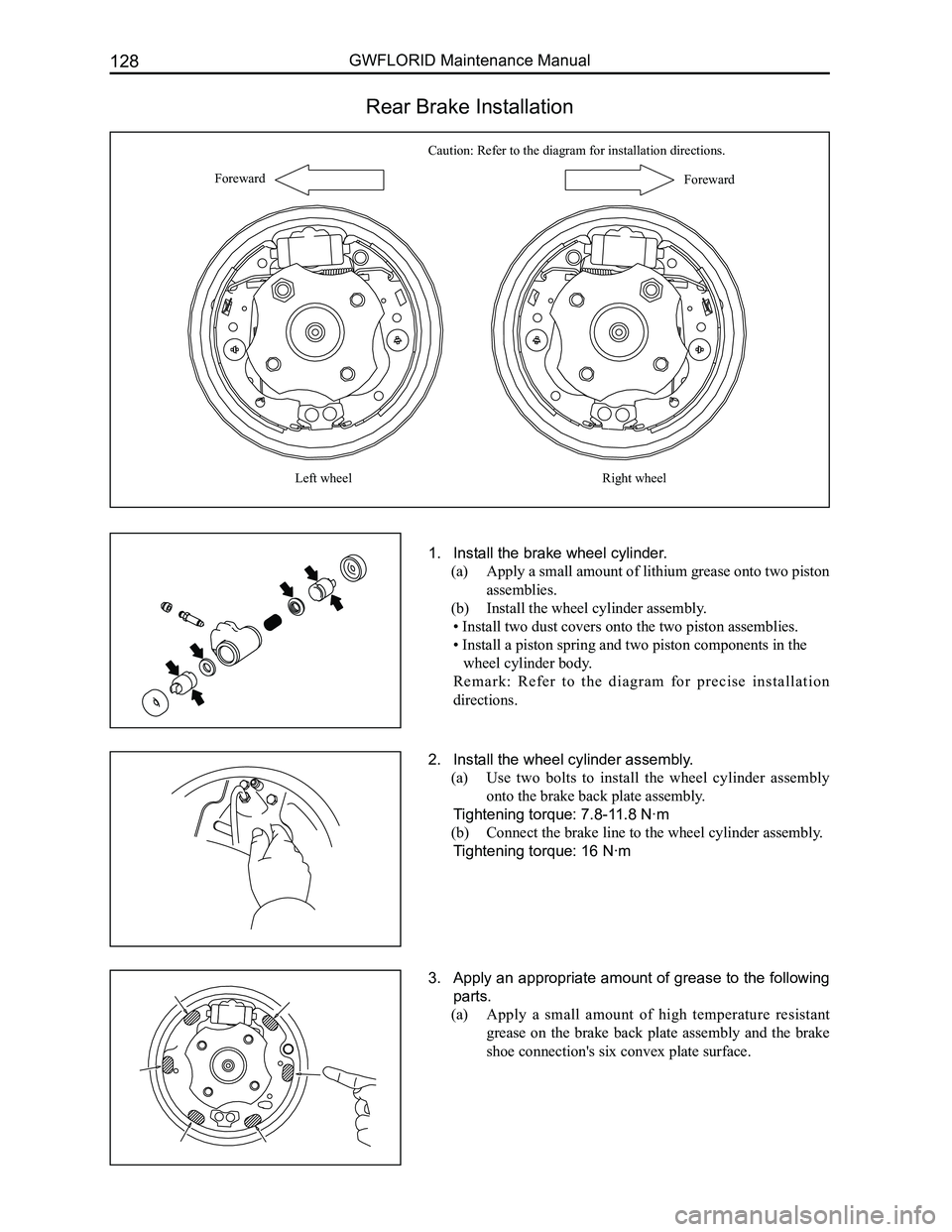

Rear Brake Installation

1. Install the brake wheel cylinder.

(a) Apply a small amount of lithium grease onto two piston

assemblies.

(b) Install the wheel cylinder assembly.

• Install two dust covers onto the two piston assemblies.

• Install a piston spring and two piston components in the

wheel cylinder body.

R e m a r k : R e f e r t o t h e d i a g r a m f o r p r e c i s e i n s t a l l a t i o n

directions.

2. Install the wheel cylinder assembly.

(a) Use two bolts to install the wheel cylinder assembly

onto the brake back plate assembly.

Tightening torque: 7.8-11.8 N·m

(b) Connect the brake line to the wheel cylinder assembly.

Tightening torque: 16 N·m

3. Apply an appropriate amount of grease to the following

parts.

(a) Apply a small amount of high temperature resistant

grease on the brake back plate assembly and the brake

shoe connection's six convex plate surface.

Caution: Refer to the diagram for installation directions.

ForewardForeward

Left wheelRight wheel