diagram GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 200 of 281

Downloaded from www.Manualslib.com manuals search engine 193Electrical Accessories

SymptomsCausesSolutions

Cannot start

Burnt fuseReplace with a new fuse of the same

specification

Vehicle supply battery fuse is burntReplace the vehicle supply battery fuse

Illegal operation and other factorsPress the reset button to reset the system

No sound or sound is too low

The volume of the head unit or the

connected component is too low

Raise the volume of the head unit or the

connected component

Speaker possibly damagedCheck the speaker

The sound balance settings lean to one

side

Adjust the sound balance

Speaker's connection wire touches the

vehicle body

Use insulated conductor to connect the

speaker and use insulating cement to cover

the exposed connections

Disc is not genuineUse a genuine disc

Speaker is incorrectly connectedPlease refer to the "Electrical connection

diagram" to correct the connection

Common faults and solutions

General problems

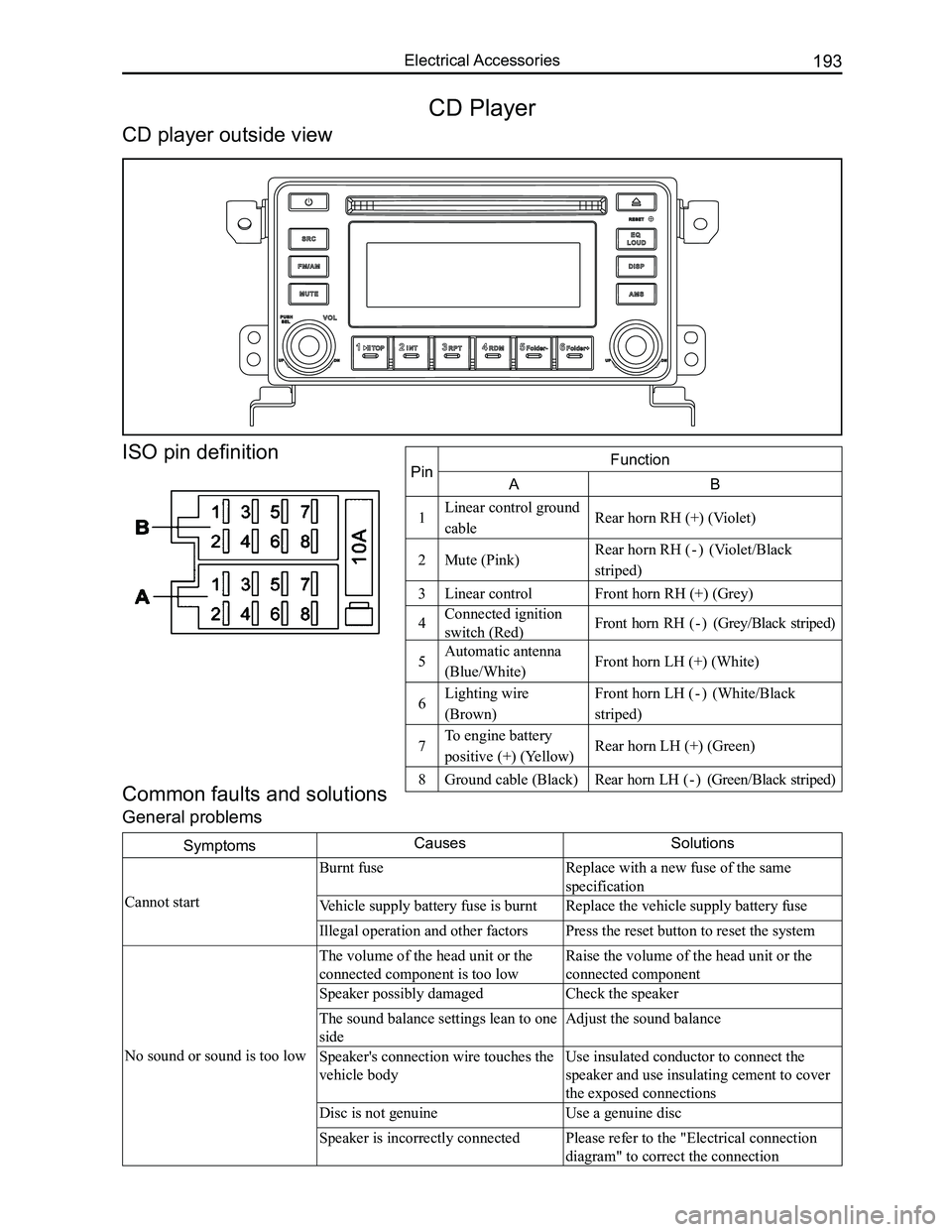

CD Player

CD player outside view

ISO pin definition

PinFunction

AB

1Linear control ground

cableRear horn RH (+) (Violet)

2Mute (Pink)Rear horn RH ( - ) (Violet/Black

striped)

3Linear controlFront horn RH (+) (Grey)

4Connected ignition

switch (Red)Front horn RH ( - ) (Grey/Black striped)

5Automatic antenna

(Blue/White)Front horn LH (+) (White)

6Lighting wire

(Brown)

Front horn LH ( - ) (White/Black

striped)

7To engine battery

positive (+) (Yellow)Rear horn LH (+) (Green)

8Ground cable (Black)Rear horn LH ( - ) (Green/Black striped)

Page 201 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual194

Display characterMalfunctionSolutions

ERR3Disc is placed upside downEject the disc and reload

ERR4Incompatible disc file or formatCheck the disc format

ERR1

ERR1Disc structure errorEject the disc and replay

Trouble code

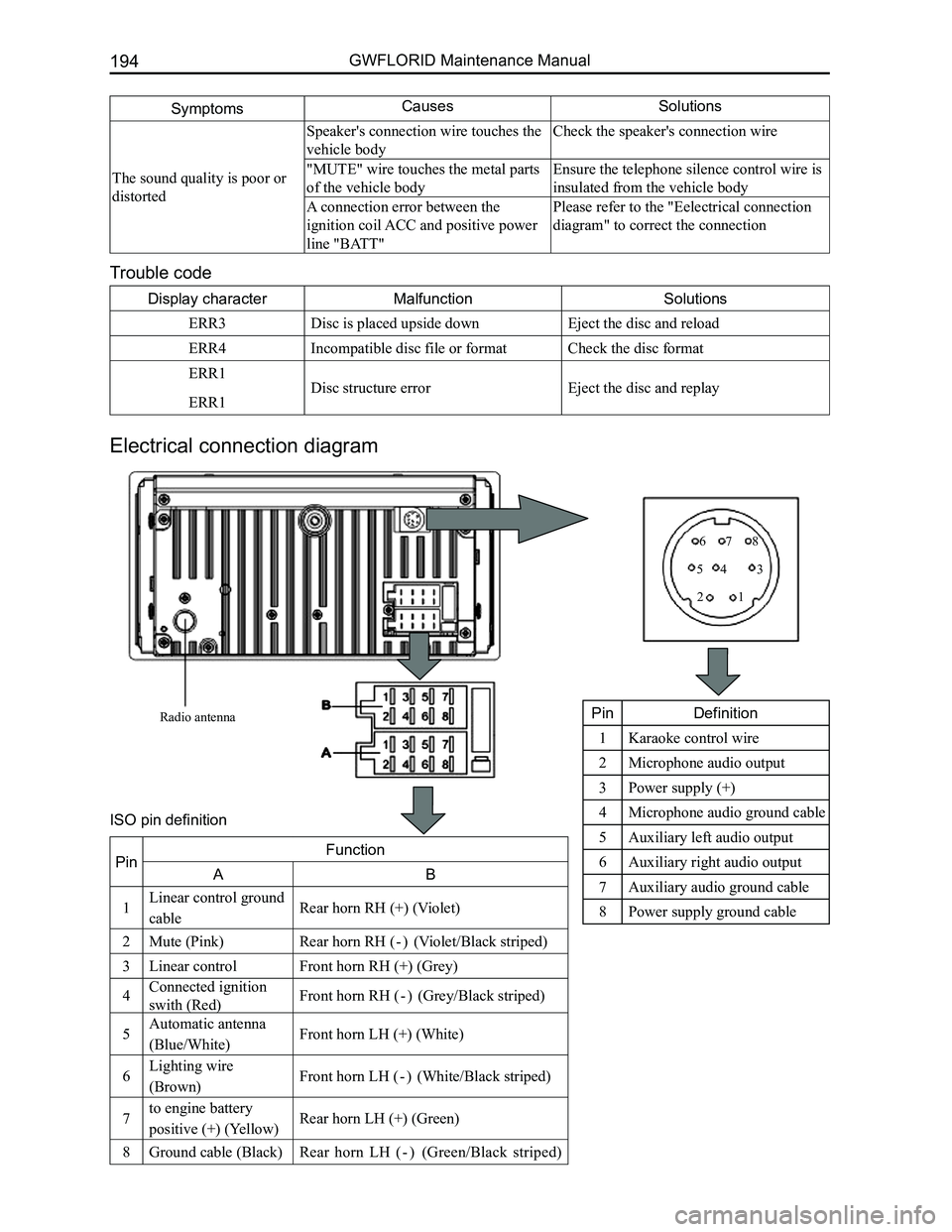

Electrical connection diagram

SymptomsCausesSolutions

The sound quality is poor or

distorted

Speaker's connection wire touches the

vehicle body

Check the speaker's connection wire

"MUTE" wire touches the metal parts

of the vehicle body

Ensure the telephone silence control wire is

insulated from the vehicle body

A connection error between the

ignition coil ACC and positive power

line "BATT"

Please refer to the "Eelectrical connection

diagram" to correct the connection

Radio antenna

12

345

678

PinDefinition

1Karaoke control wire

2Microphone audio output

3Power supply (+)

4Microphone audio ground cable

5Auxiliary left audio output

6Auxiliary right audio output

7Auxiliary audio ground cable

8Power supply ground cable

PinFunction

AB

1Linear control ground

cableRear horn RH (+) (Violet)

2Mute (Pink)Rear horn RH ( - ) (Violet/Black striped)

3Linear controlFront horn RH (+) (Grey)

4Connected ignition

swith (Red)Front horn RH ( - ) (Grey/Black striped)

5Automatic antenna

(Blue/White)Front horn LH (+) (White)

6Lighting wire

(Brown)Front horn LH ( - ) (White/Black striped)

7to engine battery

positive (+) (Yellow)Rear horn LH (+) (Green)

8Ground cable (Black)Rear horn LH ( - ) (Green/Black striped)

ISO pin definition

Page 209 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual202

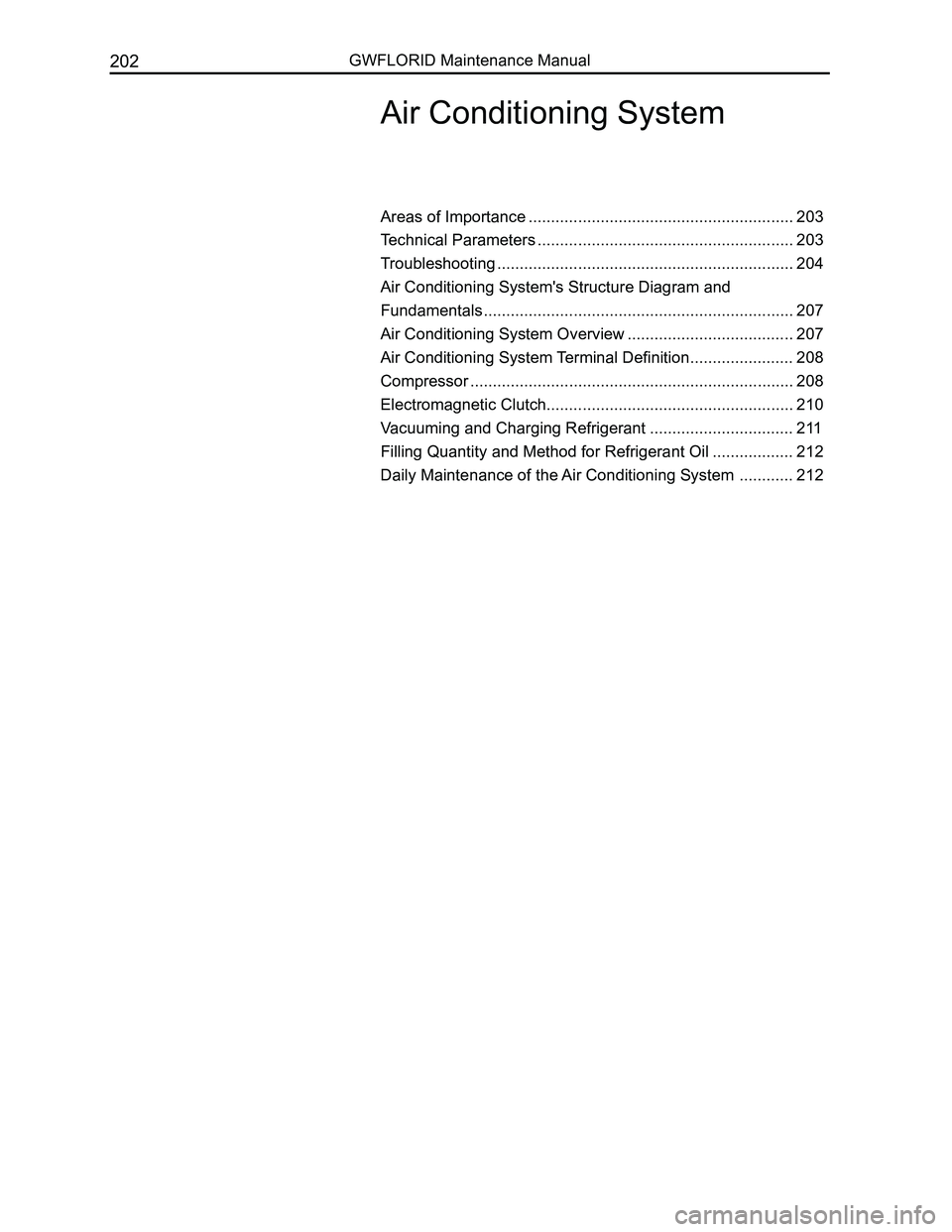

Air Conditioning System

Areas of Importance ...........................................................203

Technical Parameters .........................................................203

Troubleshooting ..................................................................204

Air Conditioning System's Structure Diagram and

Fundamentals .....................................................................207

Air Conditioning System Overview .....................................207

Air Conditioning System Terminal Definition .......................208

Compressor ........................................................................\

208

Electromagnetic Clutch.......................................................210

Vacuuming and Charging Refrigerant ................................211

Filling Quantity and Method for Refrigerant Oil ..................212

Daily Maintenance of the Air Conditioning System ............212

Page 214 of 281

Downloaded from www.Manualslib.com manuals search engine 207Air Conditioning System

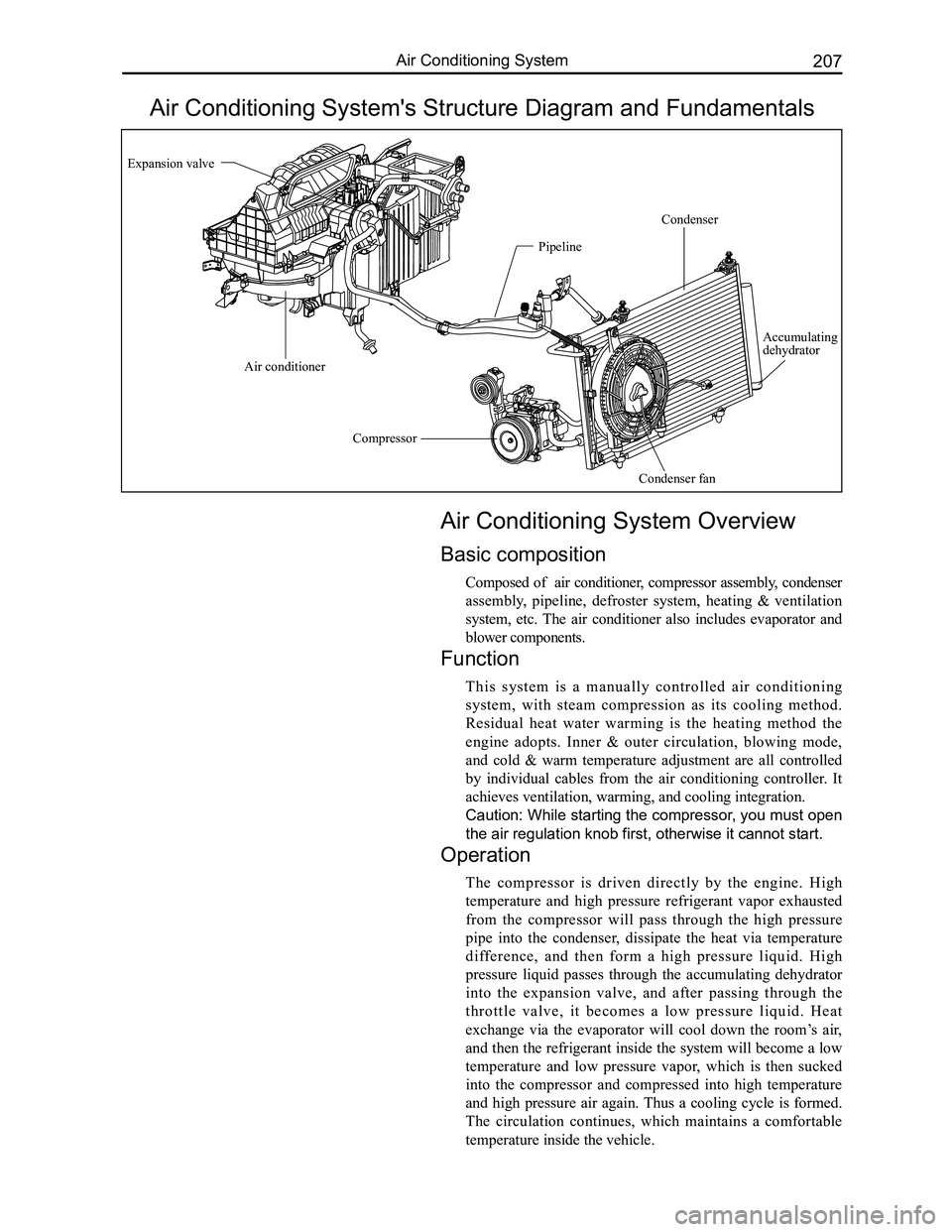

Air Conditioning System's Structure Diagram and Fundamentals

Air Conditioning System Overview

Basic composition

Composed of air conditioner, compressor assembly, condenser

assembly, pipeline, defroster system, heating & ventilation

system, etc. The air conditioner also includes evaporator and

blower components.

Function

This system is a manually controlled air conditioning

system, with steam compression as its cooling method.

Residual heat water warming is the heating method the

engine adopts. Inner & outer circulation, blowing mode,

and cold & warm temperature adjustment are all controlled

by individual cables from the air conditioning controller. It

achieves ventilation, warming, and cooling integration.

Caution: While starting the compressor, you must open

the air regulation knob first, otherwise it cannot start.

Operation

The compressor is driven directly by the engine. High

temperature and high pressure refrigerant vapor exhausted

from the compressor will pass through the high pressure

pipe into the condenser, dissipate the heat via temperature

difference, and then form a high pressure liquid. High

pressure liquid passes through the accumulating dehydrator

into the expansion valve, and after passing through the

throttle valve, it becomes a low pressure liquid. Heat

exchange via the evaporator will cool down the room’s air,

and then the refrigerant inside the system will become a low

temperature and low pressure vapor, which is then sucked

into the compressor and compressed into high temperature

and high pressure air again. Thus a cooling cycle is formed.

The circulation continues, which maintains a comfortable

temperature inside the vehicle.

Expansion valve

Compressor

Condenser fan

Condenser

Pipeline

Air conditioner

Accumulating dehydrator

Page 215 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual208

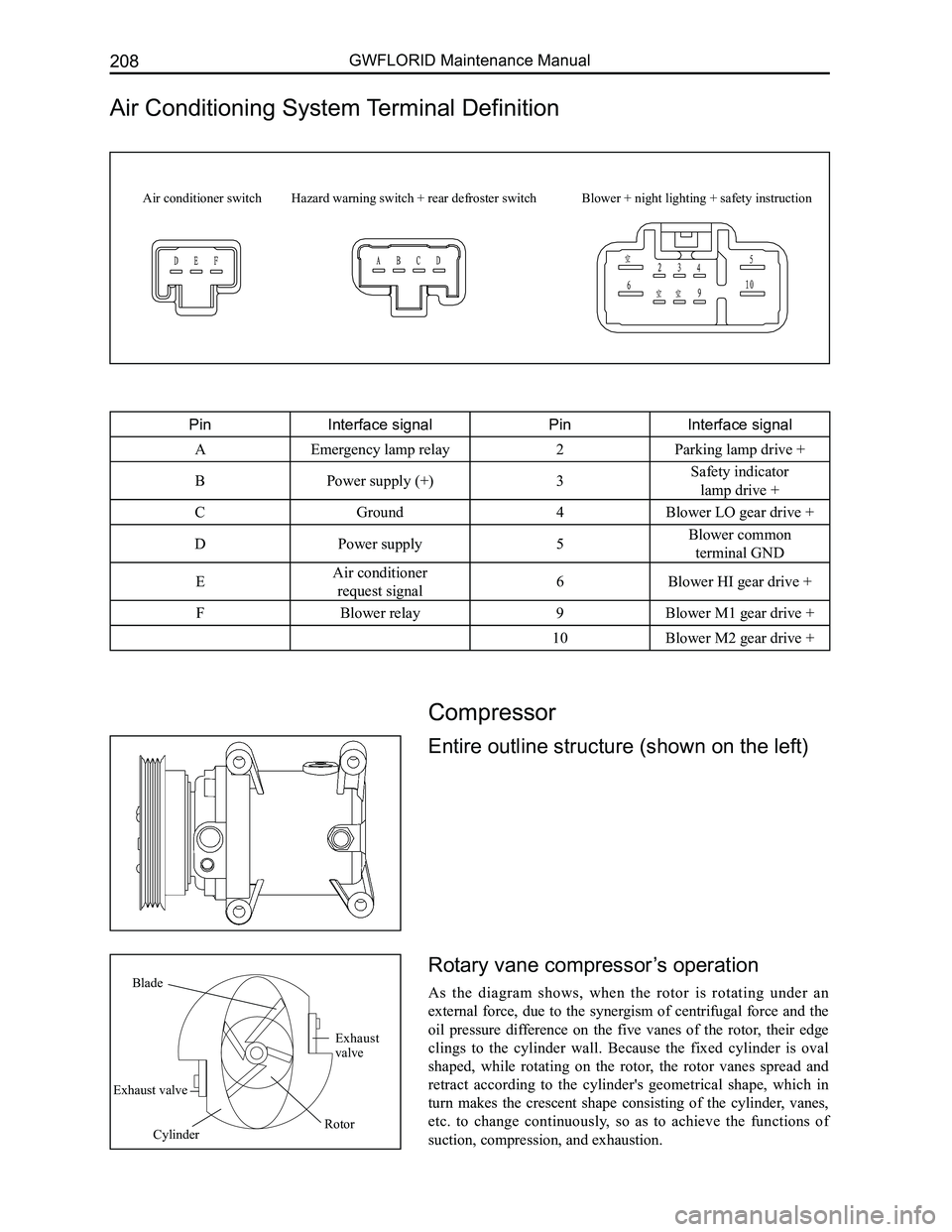

Air Conditioning System Terminal Definition

PinInterface signalPinInterface signal

AEmergency lamp relay2Parking lamp drive +

BPower supply (+)3Safety indicator

lamp drive +

CGround4Blower LO gear drive +

DPower supply5Blower common

terminal GND

EAir conditioner

request signal6Blower HI gear drive +

FBlower relay9Blower M1 gear drive +

10Blower M2 gear drive +

Air conditioner switchHazard warning switch + rear defroster switchBlower + night lighting + safety instruction

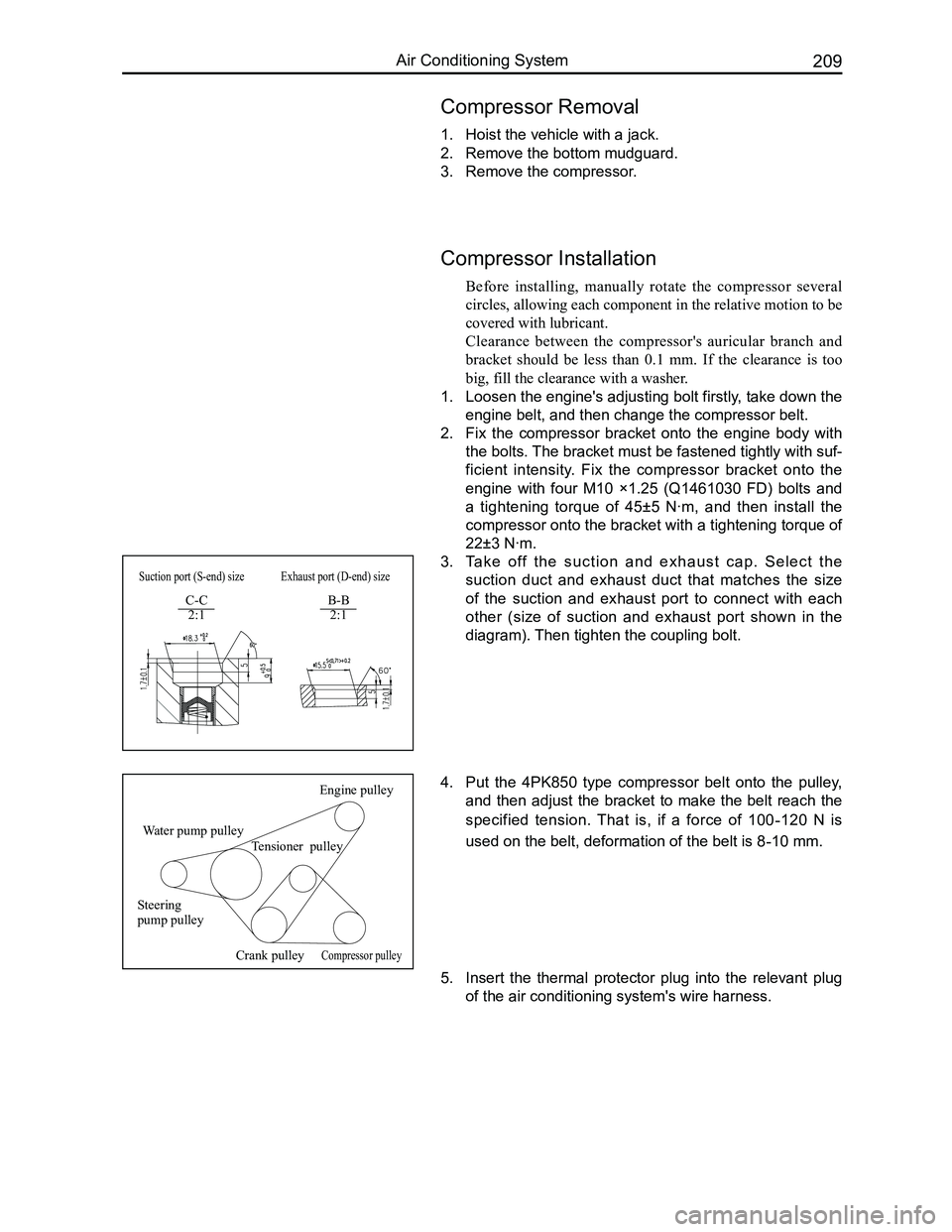

Cylinder

Blade

Exhaust valve

Rotor

Exhaust valve

Compressor

Entire outline structure (shown on the left)

Rotary vane compressor’s operation

As the diagram shows, when the rotor is rotating under an

external force, due to the synergism of centrifugal force and the

oil pressure difference on the five vanes of the rotor, their edge

clings to the cylinder wall. Because the fixed cylinder is oval

shaped, while rotating on the rotor, the rotor vanes spread and

retract according to the cylinder's geometrical shape, which in

turn makes the crescent shape consisting of the cylinder, vanes,

etc. to change continuously, so as to achieve the functions of

suction, compression, and exhaustion.

Page 216 of 281

Downloaded from www.Manualslib.com manuals search engine 209Air Conditioning System

Compressor Removal

1. Hoist the vehicle with a jack.

2. Remove the bottom mudguard.

3. Remove the compressor.

Compressor Installation

Before installing, manually rotate the compressor several

circles, allowing each component in the relative motion to be

covered with lubricant.

Clearance between the compressor's auricular branch and

bracket should be less than 0.1 mm. If the clearance is too

big, fill the clearance with a washer.

1. Loosen the engine's adjusting bolt firstly, take down the

engine belt, and then change the compressor belt.

2. Fix the compressor bracket onto the engine body with

the bolts. The bracket must be fastened tightly with suf-

ficient intensity. Fix the compressor bracket onto the

engine with four M10 ×1.25 (Q1461030 FD) bolts and

a tightening torque of 45±5 N·m, and then install the

compressor onto the bracket with a tightening torque of

22±3 N·m.

3. Ta k e o ff t h e s u c t i o n a n d e x h a u s t c a p . S e l e c t t h e

suction duct and exhaust duct that matches the size

of the suction and exhaust port to connect with each

other (size of suction and exhaust port shown in the

diagram). Then tighten the coupling bolt.

Water pump pulley

Engine pulley

Tensioner pulley

Steering pump pulley

Crank pulleyCompressor pulley

Suction port (S-end) sizeExhaust port (D-end) size

C-C 2:1B-B 2:1

4. Put the 4PK850 type compressor belt onto the pulley,

and then adjust the bracket to make the belt reach the

specified tension. That is, if a force of 100-120 N is

used on the belt, deformation of the belt is 8-10 mm.

5. Insert the thermal protector plug into the relevant plug

of the air conditioning system's wire harness.

Page 242 of 281

Downloaded from www.Manualslib.com manuals search engine 235Vehicle Body

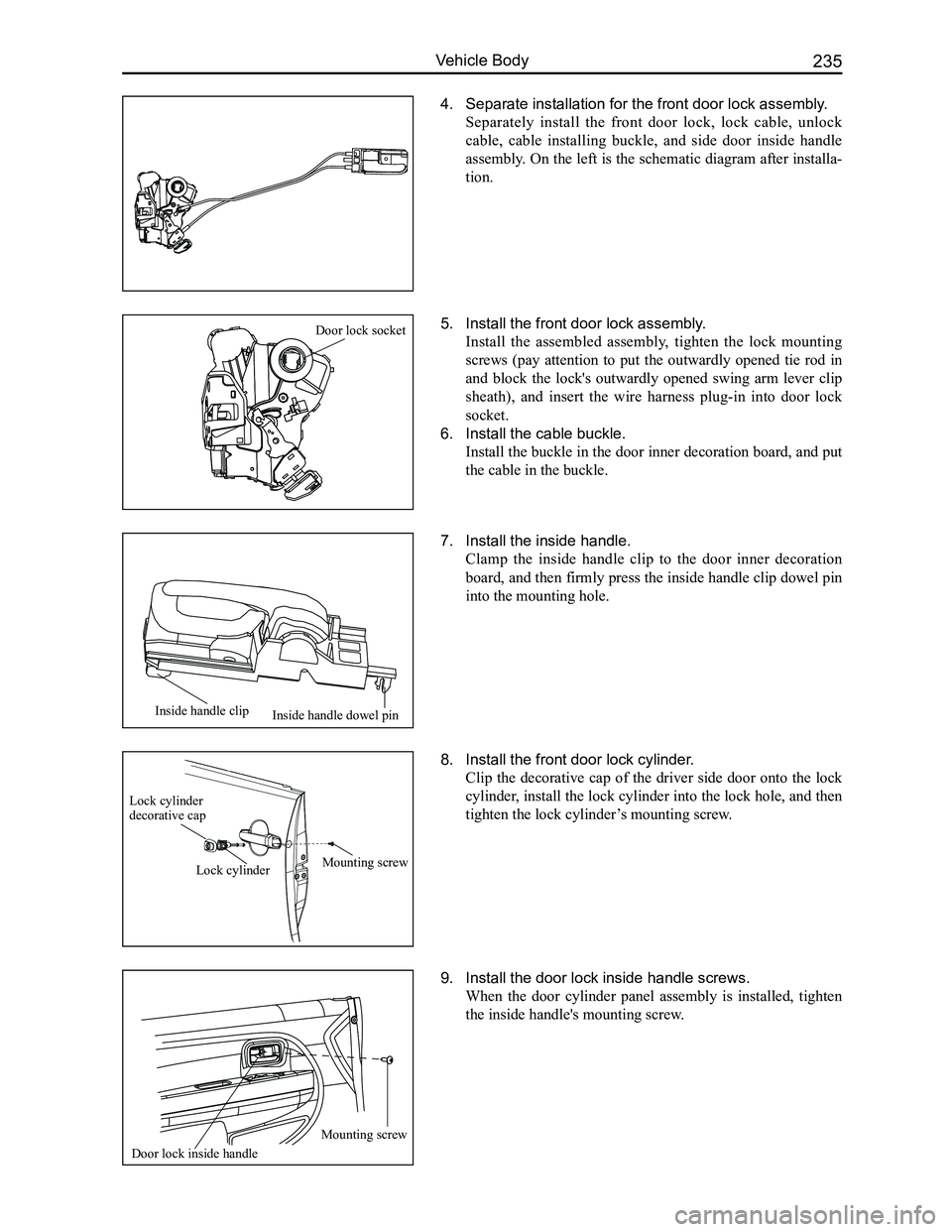

4. Separate installation for the front door lock assembly.

Separately install the front door lock, lock cable, unlock

cable, cable installing buckle, and side door inside handle

assembly. On the left is the schematic diagram after installa-

tion.

7. Install the inside handle.

Clamp the inside handle clip to the door inner decoration

board, and then firmly press the inside handle clip dowel pin

into the mounting hole.

8. Install the front door lock cylinder.

Clip the decorative cap of the driver side door onto the lock

cylinder, install the lock cylinder into the lock hole, and then

tighten the lock cylinder’s mounting screw.

5. Install the front door lock assembly.

Install the assembled assembly, tighten the lock mounting

screws (pay attention to put the outwardly opened tie rod in

and block the lock's outwardly opened swing arm lever clip

sheath), and insert the wire harness plug-in into door lock

socket.

6. Install the cable buckle.

Install the buckle in the door inner decoration board, and put

the cable in the buckle.

9. Install the door lock inside handle screws.

When the door cylinder panel assembly is installed, tighten

the inside handle's mounting screw.

Door lock socket

Inside handle dowel pinInside handle clip

Lock cylinder decorative cap

Lock cylinderMounting screw

Mounting screw

Door lock inside handle

Page 276 of 281

Downloaded from www.Manualslib.com manuals search engine 269Vehicle Body

Fault classificationFault symptomFault diagnosisFault maintenance

Window panel

motion failure

Window panel (sunroof)

cannot open, rise, or close

from its initial position

Check if anything is blocking the guide rail

for window panel movement. Check whether

the mechanism moves smoothly or stiffly.

Check whether the mechanism is broken.

Check whether the guide rail is deformed.

Check whether the motor works normally.

Replace the sunroof guide rail assem-

bly. Replace the motor.

The window panel can-

not close while half-

opened or half-tilted

Diagnosis: Check whether there are oddities

impeding the window panel's movement .

Check whether the wind guard or rear roof

drip channel is arched or deformed.

Clean the objects and close the sun-

roof by force when the jam protection

function is started, then open it again

for operation. Replace the wind guard

and rear roof drip channel.

Sun visor push/pull

fault

Sun visor cannot open

or close normally

Check whether the guide rail for the sun visor

is blocked by oddities. Check whether the sun

visor bracket is broken.

Clean the oddities in the guide rail.

Change the sun visor. Change the sun

visor bracket.

The sun visor cannot open

and close completely

Check whether the front part of sun visor

arches. Check whether the sun visor lever has

been broken off.

Replace the sun visor. Replace the

sun visor lever.

Sunroof leakage fault Sunroof leakageCheck the clearance between the window

panel and the car roof hatch.

Adjust and enlarge the window panel

weatherstrip.

Check whether a build up of sand or dust ex-

ists on the surface of window panel weather-

strip.

Clean the weatherstrip surface and

car roof hatch.

Check the sealing conditions between the

guide rail & front roof drip channel and rear

roof drip channel.

Replace the sunroof guide rail assem-

bly.

Check whether the front roof drip channel

and rear roof drip channel are broken.

Replace the sunroof guide rail assem-

bly or rear roof drip channel.

Abnormal noiseThere is abnormal noise

when closing the sunroof

(1) Check the positioning of the closed win-

dow panel.

(2) Check whether the wind deflector spring is

in the right position.

(3) Check whether the rear roof drip channel's

fixed spring has broken off.

(4) Check whether the wind deflector buffer

rubber block has broken off.

(1) Adjust the window panel's position.

(2) Place the wind deflector spring in

the right position .

(3) Re-install the fixed spring.

(4) Re-install the rubber block.

There is abnormal

noise when the sun-

roof is operating

(1) Check whether the motor is working nor-

mally.

(2) Check whether oddities exist in the guide

rail for mechanism movement .

(3) Check the grease's conditions on the mov-

ing components .

(4) Check whether the moving components

are broken.

(1) Replace the motor.

(2) Clean out any contamination.

(3) Lubricate the components.

(4) Replace the components or the

sunroof guide rail assembly.

Troubleshooting

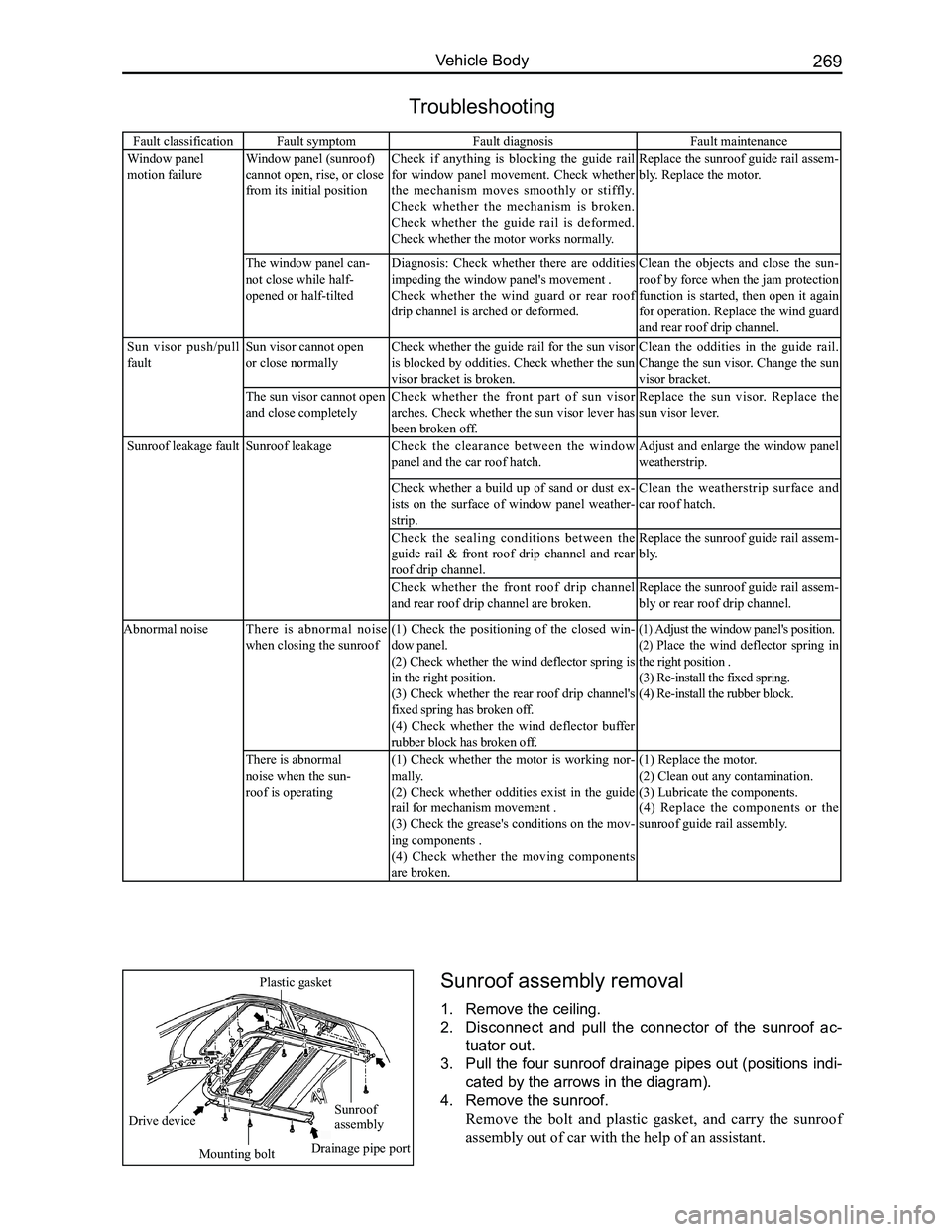

Sunroof assembly removal

1. Remove the ceiling.

2. Disconnect and pull the connector of the sunroof ac-

tuator out.

3. Pull the four sunroof drainage pipes out (positions indi-

cated by the arrows in the diagram).

4. Remove the sunroof.

Remove the bolt and plastic gasket, and carry the sunroof

assembly out of car with the help of an assistant.

Sunroof assembly

Mounting bolt

Drive device

Plastic gasket

Drainage pipe port

Page 280 of 281

Downloaded from www.Manualslib.com manuals search engine 273Vehicle Body

Adjust the initial position of drive device

Precondition:

(a) Remove the drive device, but leave the electric plug-in

connected.

(b) The sunroof is on the initial position. Sunroof panel has

been installed correctly.

Caution: The gear of drive device cannot contact

anything while adjusting.

1. Select the "Tilt Sunroof" function (position 1) with the

rotary switch.

2. Select the "Close Sunroof" function (position 2) with the

rotary switch.

3. Select the "Open Sunroof" function (position 3) with the

rotary switch.

4. Select the "Close Sunroof" function (position 2) with the

rotary switch.

5. Mark "1" is shown on the observation panel.

6. The drive device is on the initial position.

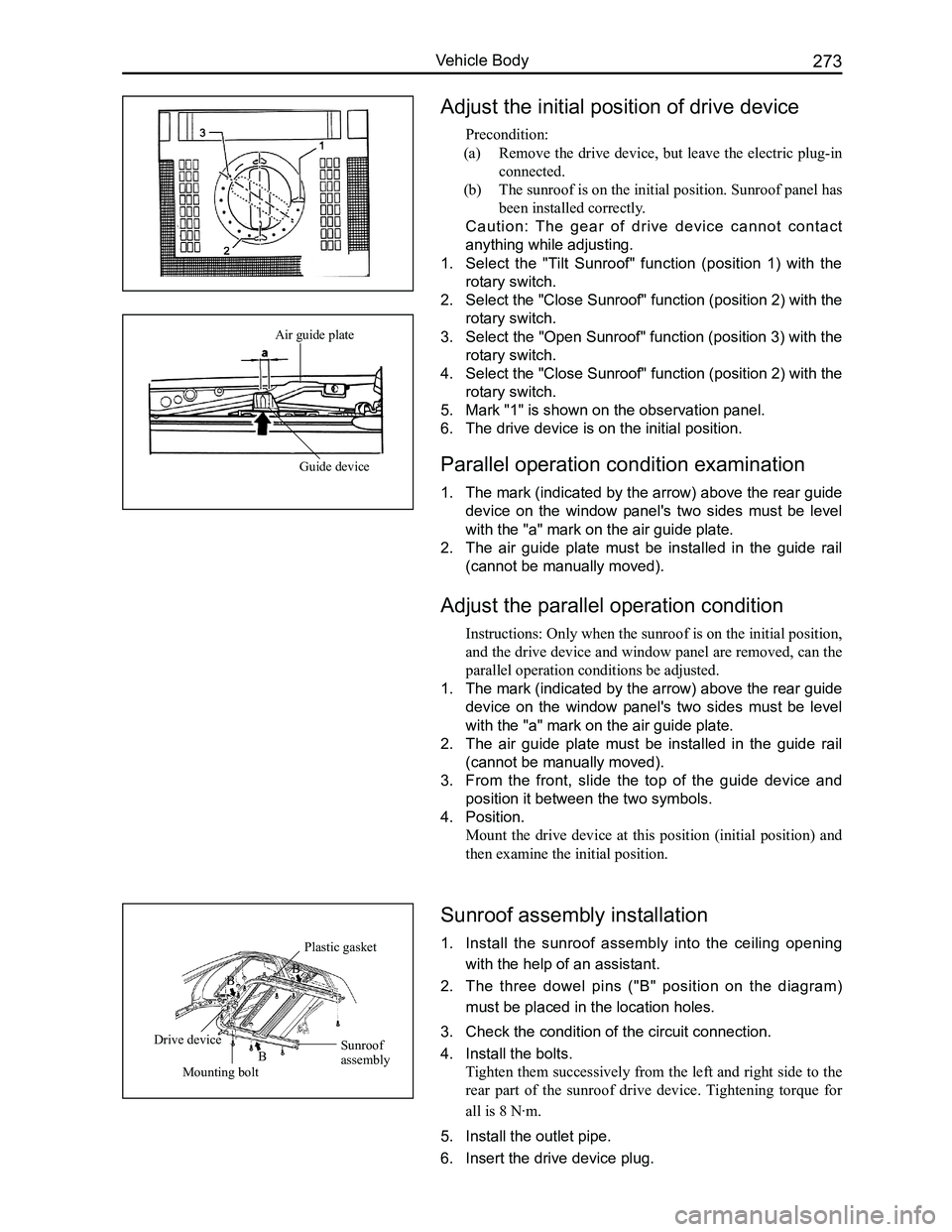

Parallel operation condition examination

1. The mark (indicated by the arrow) above the rear guide

device on the window panel's two sides must be level

with the "a" mark on the air guide plate.

2. The air guide plate must be installed in the guide rail

(cannot be manually moved).

Adjust the parallel operation condition

Instructions: Only when the sunroof is on the initial position,

and the drive device and window panel are removed, can the

parallel operation conditions be adjusted.

1. The mark (indicated by the arrow) above the rear guide

device on the window panel's two sides must be level

with the "a" mark on the air guide plate.

2. The air guide plate must be installed in the guide rail

(cannot be manually moved).

3. From the front, slide the top of the guide device and

position it between the two symbols.

4. Position.

Mount the drive device at this position (initial position) and

then examine the initial position.

Sunroof assembly installation

1. Install the sunroof assembly into the ceiling opening

with the help of an assistant.

2. The three dowel pins ("B" position on the diagram)

must be placed in the location holes.

3. Check the condition of the circuit connection.

4. Install the bolts.

Tighten them successively from the left and right side to the

rear part of the sunroof drive device. Tightening torque for

all is 8 N·m.

5. Install the outlet pipe.

6. Insert the drive device plug.

Air guide plate

Guide device

Sunroof assembly

Plastic gasket

Mounting bolt

Drive device

B

BB