AUX GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 22 of 281

Downloaded from www.Manualslib.com manuals search engine 15Overall Parameters

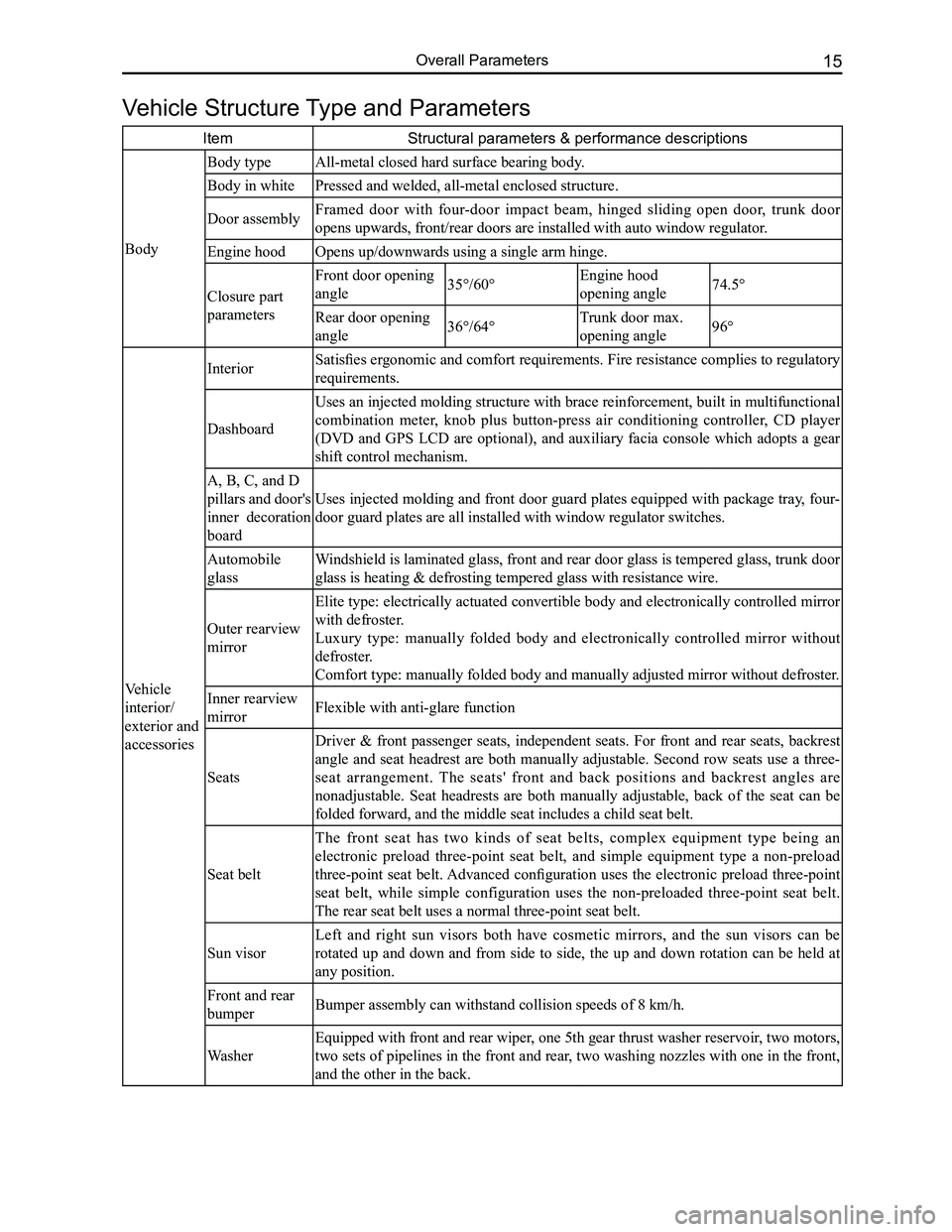

Vehicle Structure Type and Parameters

ItemStructural parameters & performance descriptions

Body

Body typeAll-metal closed hard surface bearing body.

Body in whitePressed and welded, all-metal enclosed structure.

Door assemblyFramed door with four-door impact beam, hinged sliding open door, trunk door

opens upwards, front/rear doors are installed with auto window regulator\

.

Engine hoodOpens up/downwards using a single arm hinge.

Closure part

parameters

Front door opening

angle35°/60°Engine hood

opening angle74.5°

Rear door opening

angle36°/64°Trunk door max.

opening angle96°

Vehicle

interior/

exterior and

accessories

Interior Satisfies ergonomic and comfort requirements. Fire resistance complies to regulatory

requirements.

Dashboard

Uses an injected molding structure with brace reinforcement, built in multifunctional

combination meter, knob plus button-press air conditioning controller, CD player

(DVD and GPS LCD are optional), and auxiliary facia console which adopts a gear

shift control mechanism.

A, B, C, and D

pillars and door's

inner decoration

board

Uses injected molding and front door guard plates equipped with package tray, four-

door guard plates are all installed with window regulator switches.

Automobile

glass

Windshield is laminated glass, front and rear door glass is tempered glass, trunk door

glass is heating & defrosting tempered glass with resistance wire.

Outer rearview

mirror

Elite type: electrically actuated convertible body and electronically controlled mirror

with defroster.

Luxury type: manually folded body and electronically controlled mirror without

defroster.

Comfort type: manually folded body and manually adjusted mirror without \

defroster.

Inner rearview

mirrorFlexible with anti-glare function

Seats

Driver & front passenger seats, independent seats. For front and rear seats, backrest

angle and seat headrest are both manually adjustable. Second row seats use a three-

seat arrangement. The seats' front and back positions and backrest angles are

nonadjustable. Seat headrests are both manually adjustable, back of the seat can be

folded forward, and the middle seat includes a child seat belt.

Seat belt

The front seat has two kinds of seat belts, complex equipment type being an

electronic preload three-point seat belt, and simple equipment type a non-preload

three-point seat belt. Advanced configuration uses the electronic preload three-point

seat belt, while simple configuration uses the non-preloaded three-point seat belt.

The rear seat belt uses a normal three-point seat belt.

Sun visor

Left and right sun visors both have cosmetic mirrors, and the sun visors can be

rotated up and down and from side to side, the up and down rotation can be held at

any position.

Front and rear

bumperBumper assembly can withstand collision speeds of 8 km/h.

Washer

Equipped with front and rear wiper, one 5th gear thrust washer reservoir, two motors,

two sets of pipelines in the front and rear, two washing nozzles with one in the front,

and the other in the back.

Page 24 of 281

Downloaded from www.Manualslib.com manuals search engine 17Overall Parameters

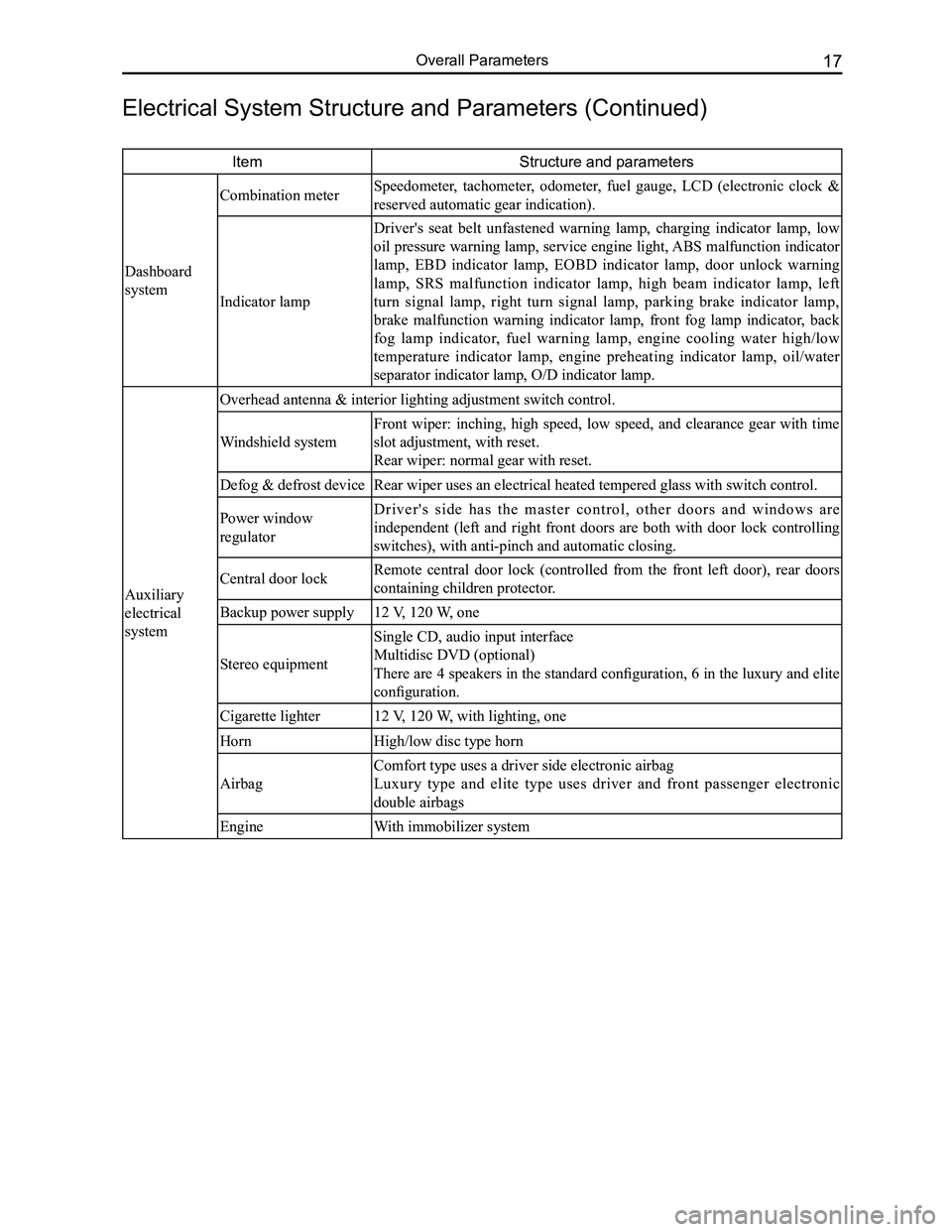

ItemStructure and parameters

Dashboard

system

Combination meter Speedometer, tachometer, odometer, fuel gauge, LCD (electronic clock &

reserved automatic gear indication).

Indicator lamp

Driver's seat belt unfastened warning lamp, charging indicator lamp, low

oil pressure warning lamp, service engine light, ABS malfunction indicator

lamp, EBD indicator lamp, EOBD indicator lamp, door unlock warning

lamp, SRS malfunction indicator lamp, high beam indicator lamp, left

turn signal lamp, right turn signal lamp, parking brake indicator lamp,

brake malfunction warning indicator lamp, front fog lamp indicator, back

fog lamp indicator, fuel warning lamp, engine cooling water high/low

temperature indicator lamp, engine preheating indicator lamp, oil/water

separator indicator lamp, O/D indicator lamp.

Auxiliary

electrical

system

Overhead antenna & interior lighting adjustment switch control.

Windshield system

Front wiper: inching, high speed, low speed, and clearance gear with time

slot adjustment, with reset.

Rear wiper: normal gear with reset.

Defog & defrost deviceRear wiper uses an electrical heated tempered glass with switch control.\

Power window

regulator

D r i v e r ' s s i d e h a s t h e m a s t e r c o n t r o l , o t h e r d o o r s a n d w i n d o w s a r e

independent (left and right front doors are both with door lock controlling

switches), with anti-pinch and automatic closing.

Central door lockRemote central door lock (controlled from the front left door), rear doors

containing children protector.

Backup power supply12 V, 120 W, one

Stereo equipment

Single CD, audio input interface

Multidisc DVD (optional)

There are 4 speakers in the standard configuration, 6 in the luxury and elite

configuration.

Cigarette lighter12 V, 120 W, with lighting, one

HornHigh/low disc type horn

Airbag

Comfort type uses a driver side electronic airbag

Luxury type and elite type uses driver and front passenger electronic

double airbags

EngineWith immobilizer system

Electrical System Structure and Parameters (Continued)

Page 109 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual102

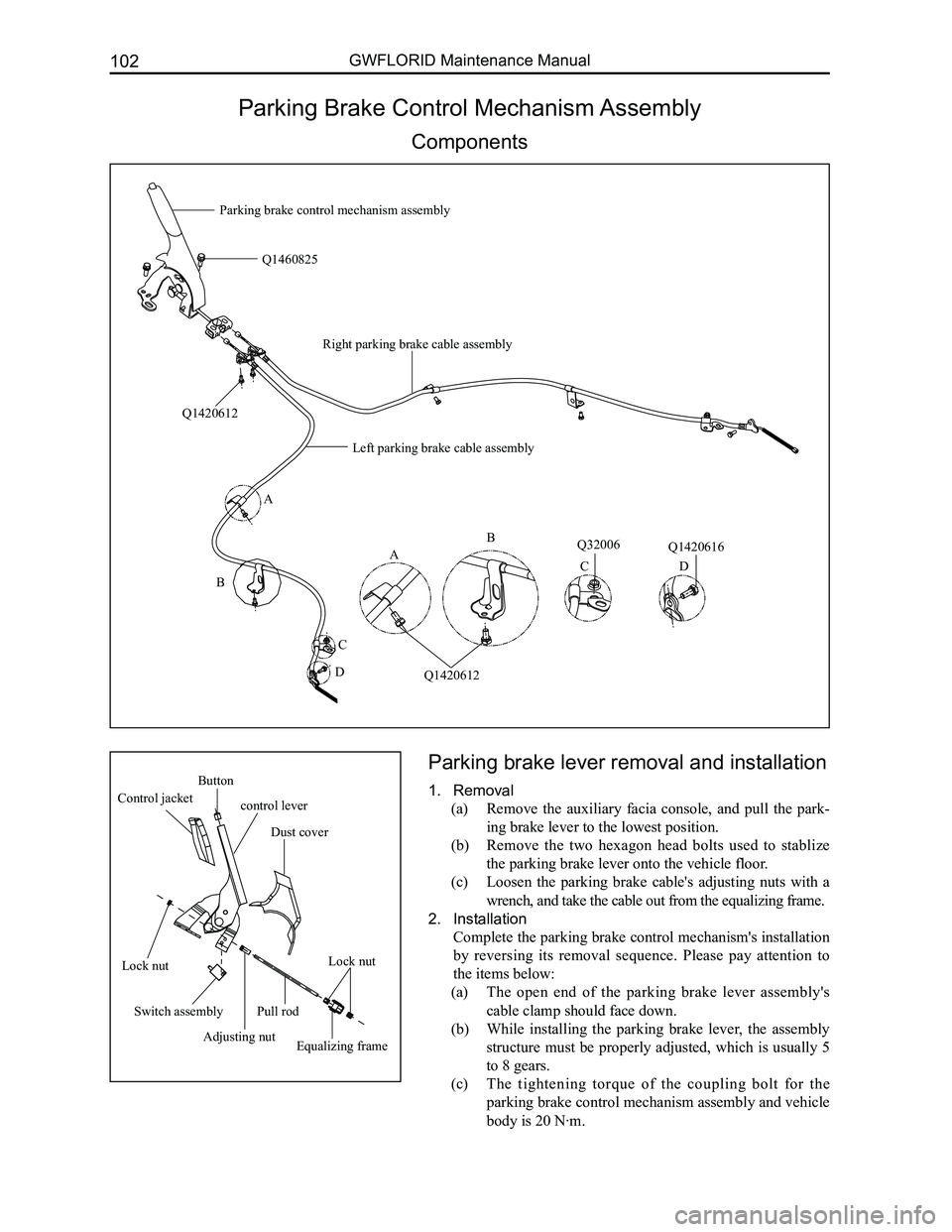

Parking Brake Control Mechanism Assembly

Components

Parking brake lever removal and installation

1. Removal

(a) Remove the auxiliary facia console, and pull the park-

ing brake lever to the lowest position.

(b) Remove the two hexagon head bolts used to stablize

the parking brake lever onto the vehicle floor.

(c) Loosen the parking brake cable's adjusting nuts with a

wrench, and take the cable out from the equalizing frame.

2. Installation

Complete the parking brake control mechanism's installation

by reversing its removal sequence. Please pay attention to

the items below:

(a) The open end of the parking brake lever assembly's

cable clamp should face down.

(b) While installing the parking brake lever, the assembly

structure must be properly adjusted, which is usually 5

to 8 gears.

(c) The tightening torque of the coupling bolt for the

parking brake control mechanism assembly and vehicle

body is 20 N·m.

A

B

C

D

Q1420612

Q1460825

Q32006Q1420616

Parking brake control mechanism assembly

Q1420612

A

B

CD

Left parking brake cable assembly

Right parking brake cable assembly

Button

control lever Control jacket

Dust cover

Lock nutLock nut

Switch assembly

Adjusting nutEqualizing frame

Pull rod

Page 183 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual176

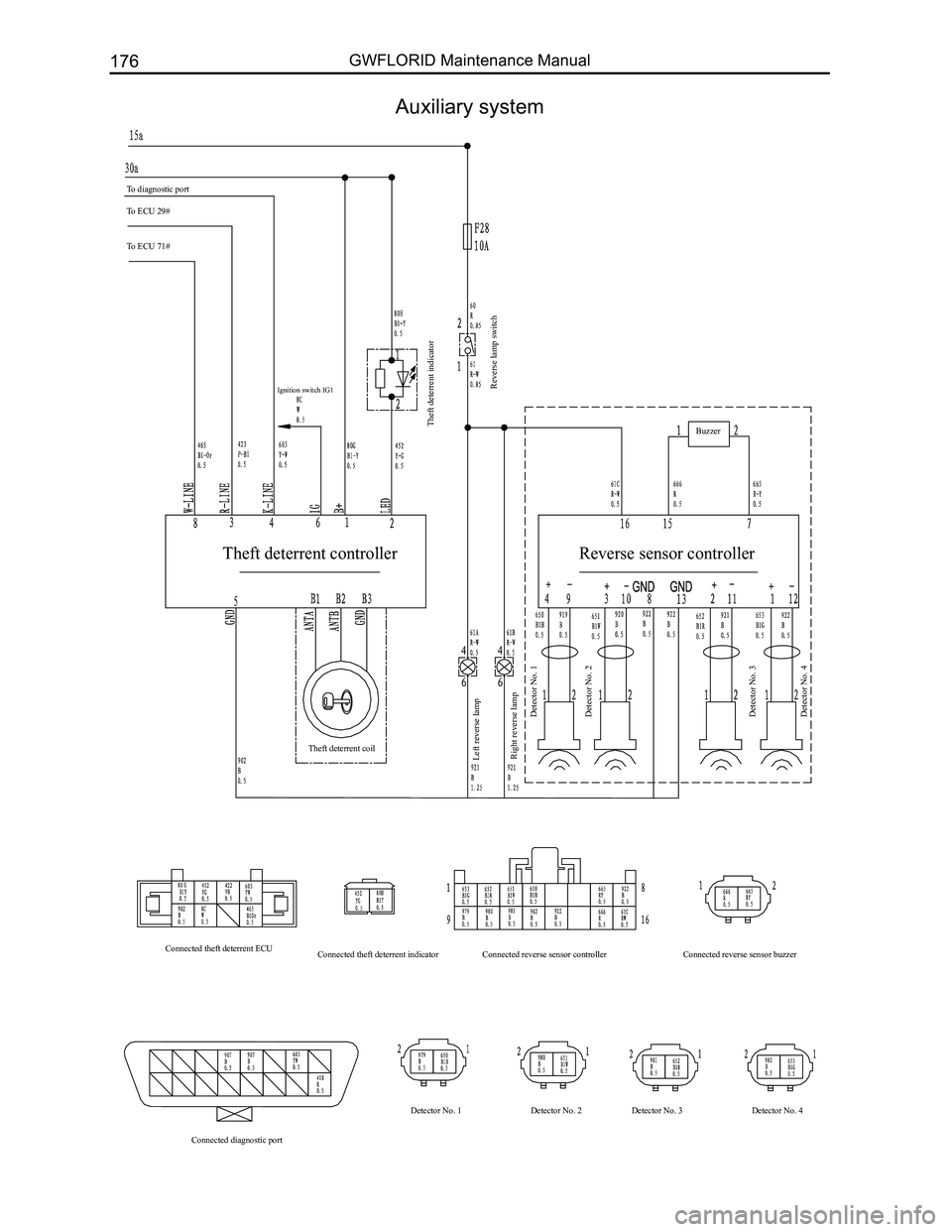

Auxiliary system

To diagnostic port

To ECU 29#

To ECU 71#

Theft deterrent indicatorReverse lamp switch

Left reverse lamp

Right reverse lamp Detector No. 1

Detector No. 2

Detector No. 3

Detector No. 4

Theft deterrent coil

Connected theft deterrent ECU Connected diagnostic port Detector No. 1

Detector No. 2Detector No. 3 Detector No. 4

Connected theft deterrent indicator

Connected reverse sensor controller Connected reverse sensor buzzerBuzzer

Ignition switch IG1

Theft deterrent controller

Reverse sensor controller

Page 201 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual194

Display characterMalfunctionSolutions

ERR3Disc is placed upside downEject the disc and reload

ERR4Incompatible disc file or formatCheck the disc format

ERR1

ERR1Disc structure errorEject the disc and replay

Trouble code

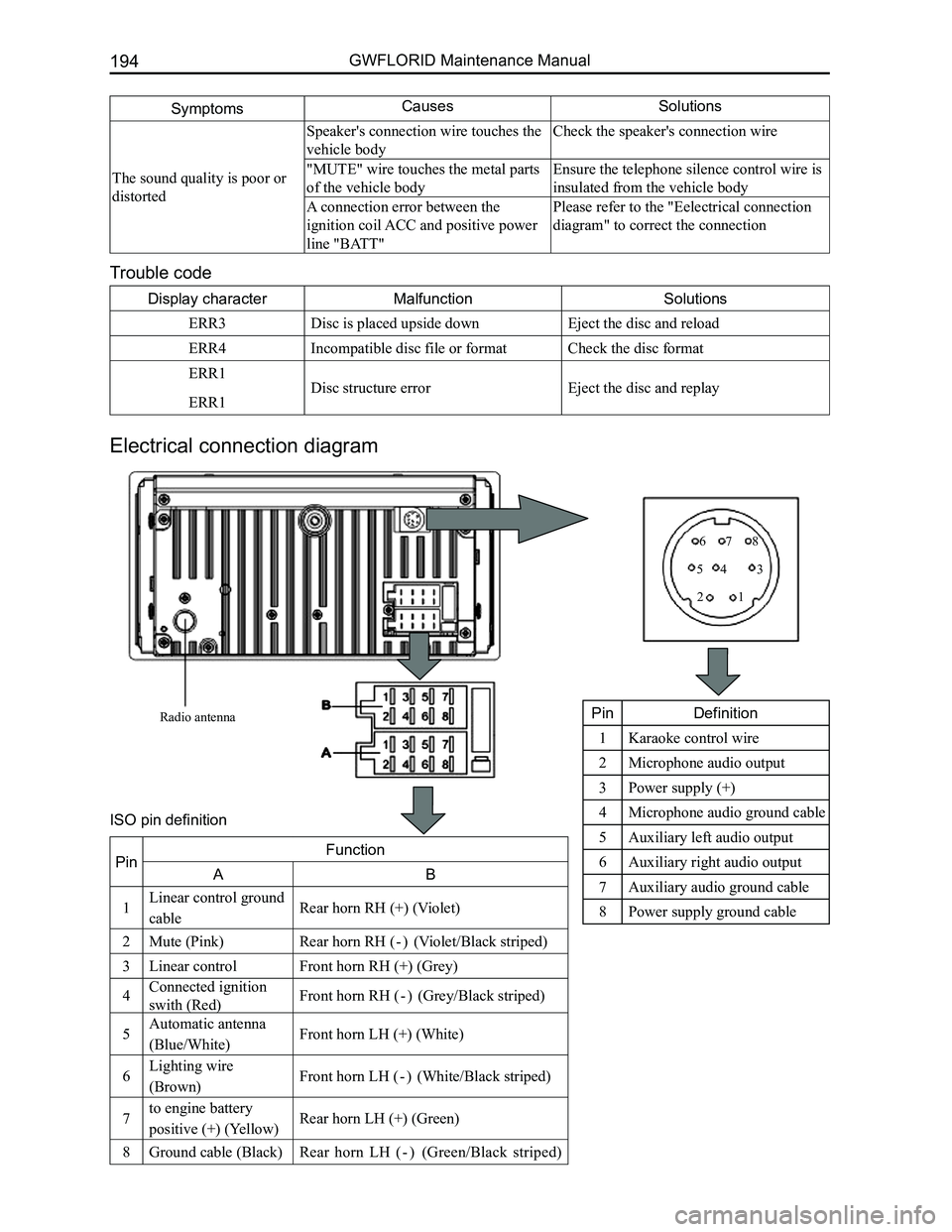

Electrical connection diagram

SymptomsCausesSolutions

The sound quality is poor or

distorted

Speaker's connection wire touches the

vehicle body

Check the speaker's connection wire

"MUTE" wire touches the metal parts

of the vehicle body

Ensure the telephone silence control wire is

insulated from the vehicle body

A connection error between the

ignition coil ACC and positive power

line "BATT"

Please refer to the "Eelectrical connection

diagram" to correct the connection

Radio antenna

12

345

678

PinDefinition

1Karaoke control wire

2Microphone audio output

3Power supply (+)

4Microphone audio ground cable

5Auxiliary left audio output

6Auxiliary right audio output

7Auxiliary audio ground cable

8Power supply ground cable

PinFunction

AB

1Linear control ground

cableRear horn RH (+) (Violet)

2Mute (Pink)Rear horn RH ( - ) (Violet/Black striped)

3Linear controlFront horn RH (+) (Grey)

4Connected ignition

swith (Red)Front horn RH ( - ) (Grey/Black striped)

5Automatic antenna

(Blue/White)Front horn LH (+) (White)

6Lighting wire

(Brown)Front horn LH ( - ) (White/Black striped)

7to engine battery

positive (+) (Yellow)Rear horn LH (+) (Green)

8Ground cable (Black)Rear horn LH ( - ) (Green/Black striped)

ISO pin definition

Page 203 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual196

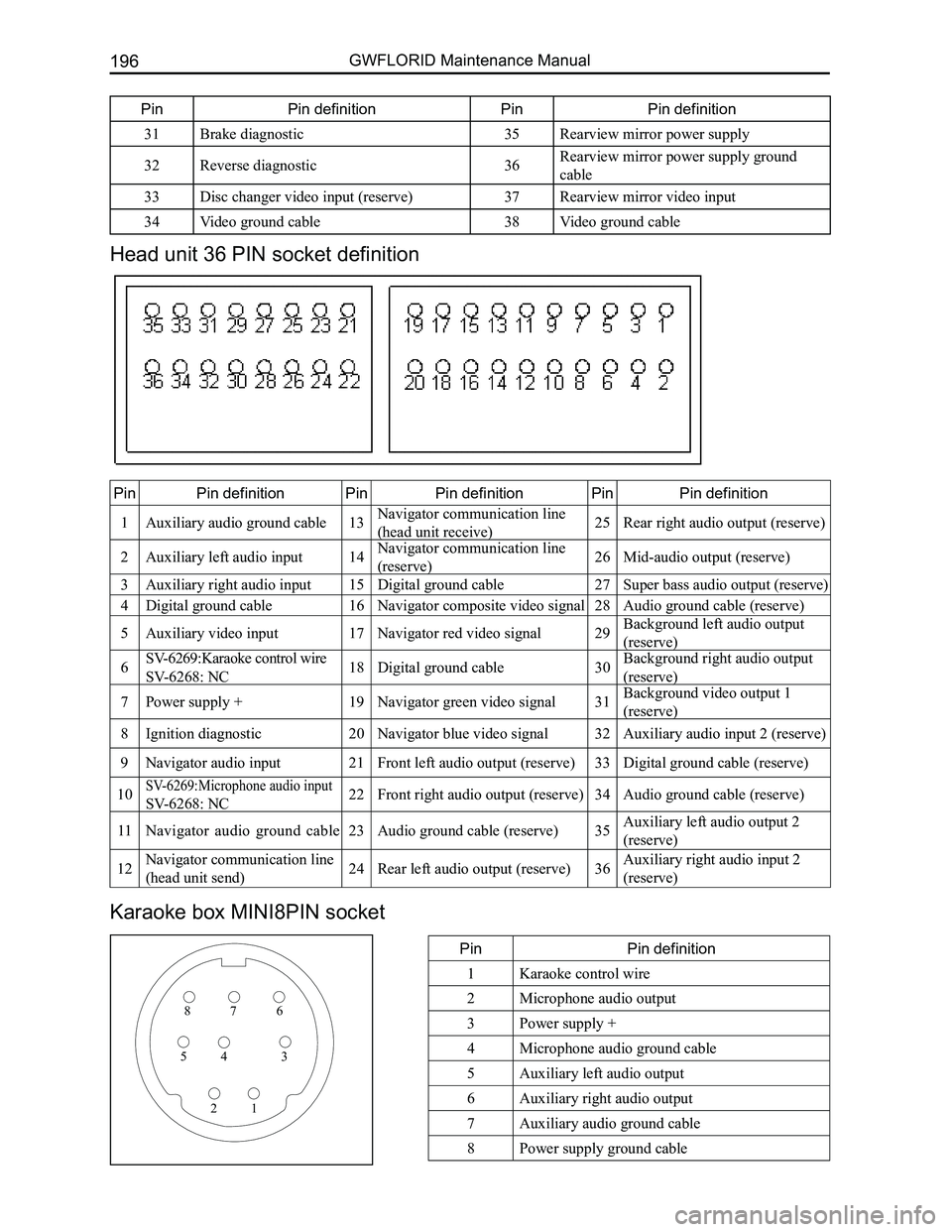

Head unit 36 PIN socket definition

PinPin definitionPinPin definitionPinPin definition

1Auxiliary audio ground cable13Navigator communication line

(head unit receive)25Rear right audio output (reserve)

2Auxiliary left audio input14Navigator communication line

(reserve)26Mid-audio output (reserve)

3Auxiliary right audio input15Digital ground cable27Super bass audio output (reserve)

4Digital ground cable16Navigator composite video signal28Audio ground cable (reserve)

5Auxiliary video input17Navigator red video signal29Background left audio output

(reserve)

6SV-6269:Karaoke control wire

SV-6268: NC18Digital ground cable30Background right audio output

(reserve)

7Power supply +19Navigator green video signal31Background video output 1

(reserve)

8Ignition diagnostic20Navigator blue video signal32Auxiliary audio input 2 (reserve)

9Navigator audio input21Front left audio output (reserve)33Digital ground cable (reserve)

10SV-6269:Microphone audio input

SV-6268: NC22Front right audio output (reserve)34Audio ground cable (reserve)

11Navigator audio ground cable23Audio ground cable (reserve)35Auxiliary left audio output 2

(reserve)

12Navigator communication line

(head unit send)24Rear left audio output (reserve)36Auxiliary right audio input 2

(reserve)

Karaoke box MINI8PIN socket

PinPin definition

1Karaoke control wire

2Microphone audio output

3Power supply +

4Microphone audio ground cable

5Auxiliary left audio output

6Auxiliary right audio output

7Auxiliary audio ground cable

8Power supply ground cable

876

345

21

PinPin definitionPinPin definition

31Brake diagnostic35Rearview mirror power supply

32Reverse diagnostic36Rearview mirror power supply ground

cable

33Disc changer video input (reserve)37Rearview mirror video input

34Video ground cable38Video ground cable

Page 207 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual200

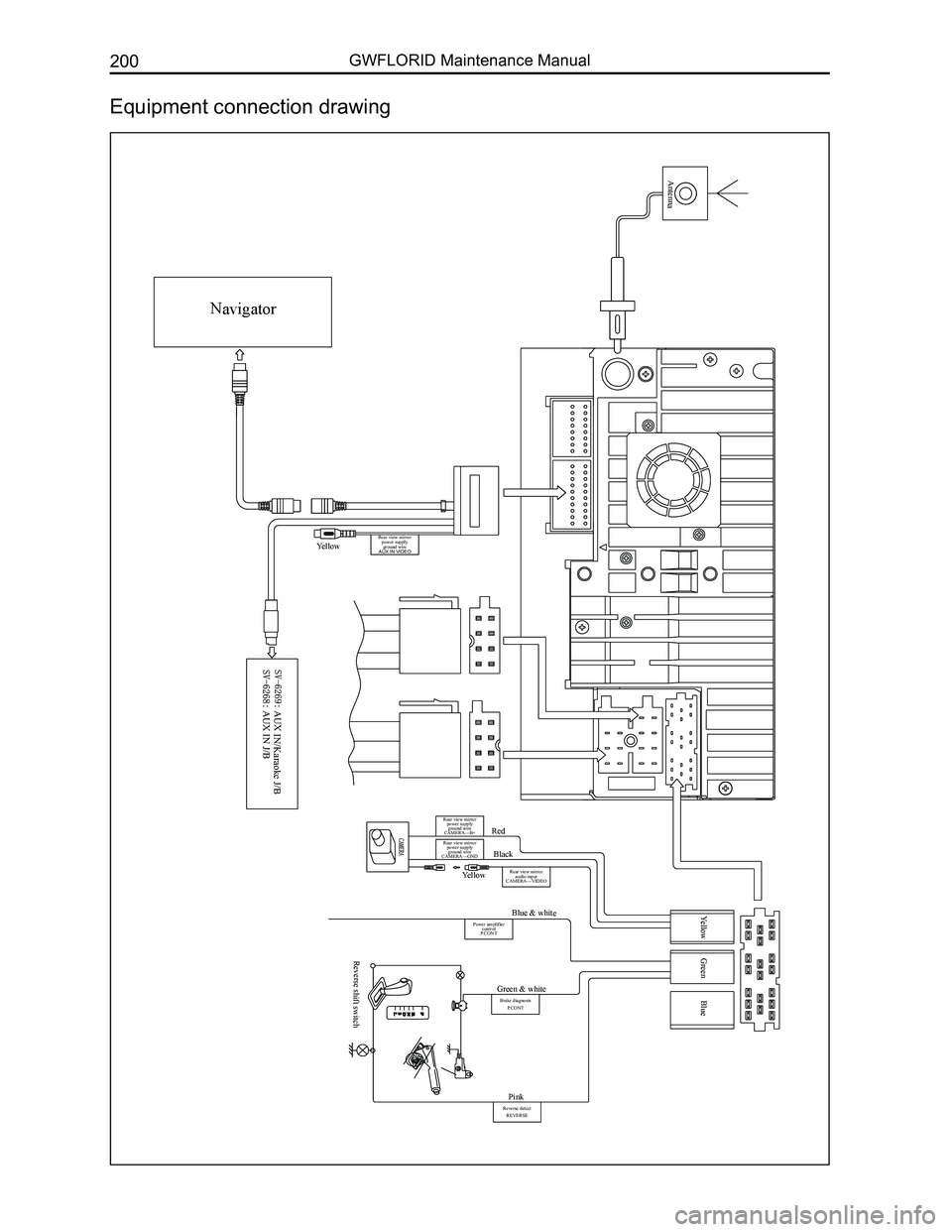

Equipment connection drawing

Navigator

Antenna

Yellow

AUX IN/Karaoke J/B AUX IN J/B

Red

Black

Yellow Green BlueBlue & white

Green & white

Pink

Reverse shift switch

Yellow

Rear view mirror power supply ground wire

CAMERA—B+

Rear view mirror power supply ground wire

CAMERA—GND

Rear view mirror audio input

CAMERA—VIDEO

Power amplifier control

P.CONT

Brake diagnosis

P.CONT

Reverse detectREVERSE

Rear view mirror power supply ground wire

AUX IN VIDEO

Page 219 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual212

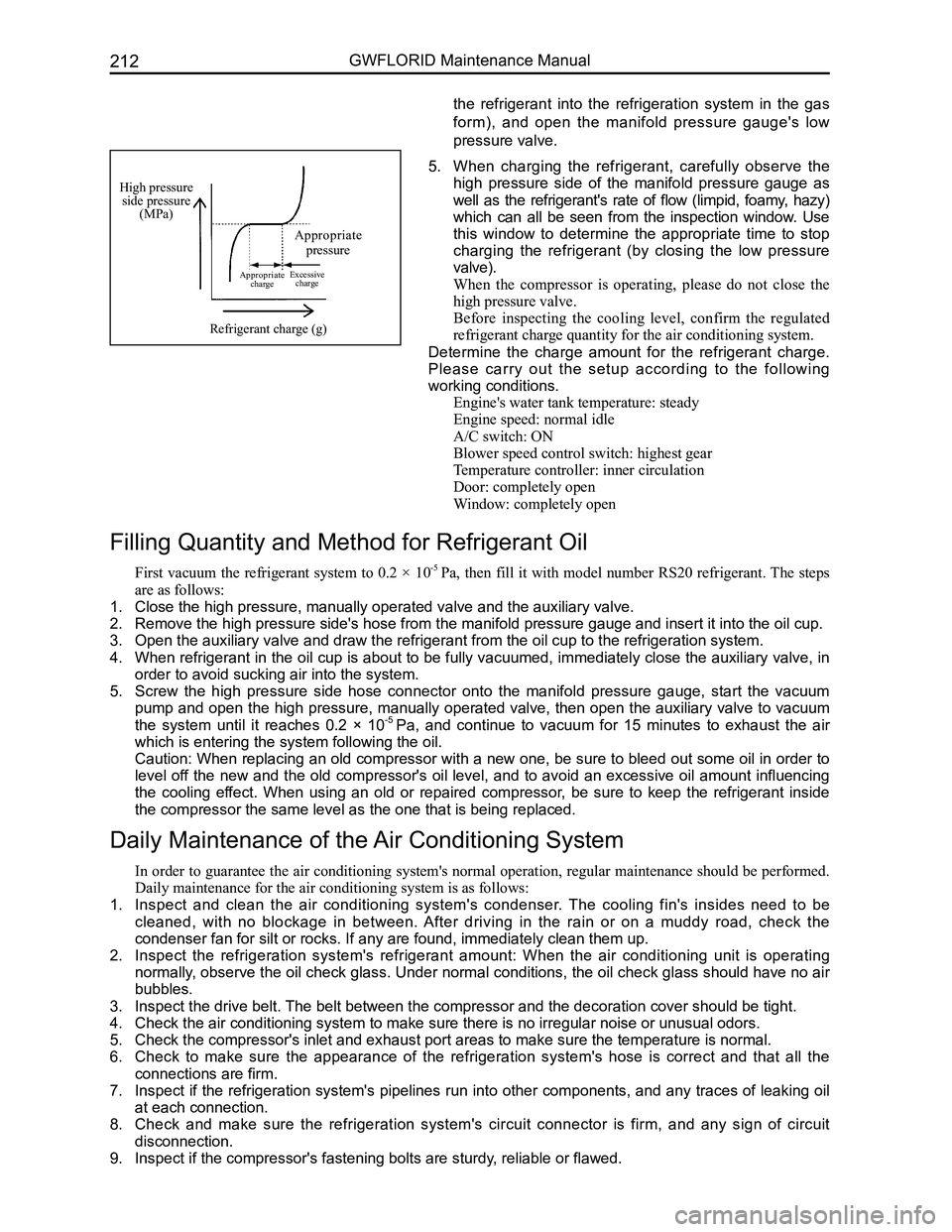

High pressure side pressure(MPa)

Appropriate pressure

Appropriate chargeExcessive charge

Refrigerant charge (g)

5. When charging the refrigerant, carefully observe the

high pressure side of the manifold pressure gauge as

well as the refrigerant's rate of flow (limpid, foamy, hazy)

which can all be seen from the inspection window. Use

this window to determine the appropriate time to stop

charging the refrigerant (by closing the low pressure

valve).

When the compressor is operating, please do not close the

high pressure valve.

Before inspecting the cooling level, confirm the regulated

refrigerant charge quantity for the air conditioning system.

Determine the charge amount for the refrigerant charge.

Please carry out the setup according to the following

working conditions.

Engine's water tank temperature: steady

Engine speed: normal idle

A/C switch: ON

Blower speed control switch: highest gear

Temperature controller: inner circulation

Door: completely open

Window: completely open

Filling Quantity and Method for Refrigerant Oil

First vacuum the refrigerant system to 0.2 × 10-5 Pa, then fill it with model number RS20 refrigerant. The steps

are as follows:

1. Close the high pressure, manually operated valve and the auxiliary valve\

.

2. Remove the high pressure side's hose from the manifold pressure gauge an\

d insert it into the oil cup.

3. Open the auxiliary valve and draw the refrigerant from the oil cup to th\

e refrigeration system.

4. When refrigerant in the oil cup is about to be fully vacuumed, immediately close the auxiliary valve, in

order to avoid sucking air into the system.

5. Screw the high pressure side hose connector onto the manifold pressure gauge, start the vacuum

pump and open the high pressure, manually operated valve, then open the auxiliary valve to vacuum

the system until it reaches 0.2 × 10-5 Pa, and continue to vacuum for 15 minutes to exhaust the air

which is entering the system following the oil.

Caution: When replacing an old compressor with a new one, be sure to bleed out some oil in order to

level off the new and the old compressor's oil level, and to avoid an excessive oil amount influencing

the cooling effect. When using an old or repaired compressor, be sure to keep the refrigerant inside

the compressor the same level as the one that is being replaced.

Daily Maintenance of the Air Conditioning System

In order to guarantee the air conditioning system's normal operation, regular maintenance should be performed.

Daily maintenance for the air conditioning system is as follows:

1. Inspect and clean the air conditioning system's condenser. The cooling fin's insides need to be

cleaned, with no blockage in between. After driving in the rain or on a muddy road, check the

condenser fan for silt or rocks. If any are found, immediately clean the\

m up.

2. Inspect the refrigeration system's refrigerant amount: When the air conditioning unit is operating

normally, observe the oil check glass. Under normal conditions, the oil check glass should have no air

bubbles.

3. Inspect the drive belt. The belt between the compressor and the decoration cover should be tight\

.

4. Check the air conditioning system to make sure there is no irregular noi\

se or unusual odors.

5. Check the compressor's inlet and exhaust port areas to make sure the tem\

perature is normal.

6. Check to make sure the appearance of the refrigeration system's hose is correct and that all the

connections are firm.

7. Inspect if the refrigeration system's pipelines run into other components, and any traces of leaking oil

at each connection.

8. Check and make sure the refrigeration system's circuit connector is firm, and any sign of circuit

disconnection.

9. Inspect if the compressor's fastening bolts are sturdy, reliable or flawed.

the refrigerant into the refrigeration system in the gas

form), and open the manifold pressure gauge's low

pressure valve.

Page 234 of 281

Downloaded from www.Manualslib.com manuals search engine 227Airbags

Removal Method for Individual Components

SRS airbag system electronic control component (SRS-ECU)

1. Areas of Importance

(a) After taking off the battery's negative (-) terminal, wait for 60 s before operating. Wrap the removed

negative (-) terminal in tape to insulate it.

(b) The SRS-ECU can not be dismantled or repaired. If there is any malfunction, please replace it with a new

one.

(c) Do not let the SRS-ECU vibrate or collide with anything. If sunken or depressed, cracked, deformed, etc.,

please replace with a new SRS-ECU.

(d) Every time the airbag is deployed, please replace with a new SRS-ECU.

(e) Do not knock the SRS-ECU while removing or performing maintenance on the SRS-ECU's surrounding

components.

2. Operation before removal

(a) Set the ignition switch to the LOCK position.

(b) After taking off the battery's negative (-) terminal, put them in a proper place or wrap them in\

tape.

3. Removal sequence

(a) Remove the auxiliary facia console.

(b) Reomve the connectors connected with the airbag ECU.

(c) Remove the SRS-ECU.

4. Installation sequence

(a) SRS-ECU.

(b) Install the connectors connected with the airbag ECU.

(c) Dashboard base.

(d) Connect the battery's negative (-) terminal.

5. Installation points

(a) Install the SRS-ECU

Caution: If SRS-ECU isn't installed correctly, the SRS airbag will not operate properly.

(b) Inspection after installation

• Set the ignition switch to the ON position.

• SRS warning lamp stays on for 6-7 s.

• If the lamp does not turn off, malfunction inspection and troubleshooting should be performed.

6. Inspection

(a) Whether the SRS-ECU cover has sunken or depressed, cracked, deformed, etc.

(b) Whether the connectors are damaged or deformed.

Caution: Please replace with a new SRS-ECU, if there is any sunkeness or depression, cracking, de-

formity, etc.

Except for the areas described above, to perform SRS-ECU inspections, please refer to the related troubleshooting

contents.

Page 236 of 281

Downloaded from www.Manualslib.com manuals search engine 229Airbags

3. Driver side airbag module installation sequence (after steering wheel i\

nstallation is completed)

(a) Install the horn's wire harness.

(b) Install the airbag module executing equipment's (gas generator) wire harness.

(c) Place the airbag module onto the steering wheel's proper installation position (avoid heavy knocking while

placing).

(d) Tighten the airbag module mounting bolt.

(e) Connect the battery's negative (-) terminal.

(f) Inspection after installation.

Auxiliary airbag removal and installation

1. Auxiliary airbag removal

(a) Remove the glove box.

(b) Pull out the dashboard wire harness and the auxiliary airbag wire harness connectors.

(c) Remove the airbag mounting bolt.

(d) Remove the upper dashboard.

(e) Remove the auxiliary airbag's two mounting nuts.

(f) Press the buckle and remove the auxiliary airbag.

2. Installation sequence for the auxiliary airbag is reverse to the removal\

sequence.

Caution: Please do not place anything on the auxiliary airbag, as to avoid accidents while deploying

the airbag.

Operation essentials

1. Driver side airbag and steering wheel removal

Caution: The following operations should only be performed after the battery's negative (-) terminal

has been disconnected, and after the ignition switch key has been pulled\

out for 60 s.

(a) Remove the mounting screws from the two holes under the steering wheel bottom cap, and lightly pick up

the driver side airbag module.

(b) Pull out the deployed airbag module's wire harness and the horn line, and remove the airbag module\

.

Attention: Diagnose the airbag module's circuit with an electrical measuring instruments but do not

dismantle it. Face the bottom of the removed passenger side airbag upwards and store it in a clean

and dry place.

(c) Remove the steering wheel mounting bolt on the steering column.

Caution: Due to the over-tight occlusion of the spline and column, the steering wheel and steering

column may be hard to separate, in which case make sure not to use force to remove the steering

wheel. The correct method is to tighten the screw into the column just a bit, and then pull up the

steering wheel (because the steering wheel bottom is connected to the clock spring, if force is used to

remove it, it may damage it).

2. Clock spring removal

(a) After steering wheel removal is completed, remove the combination switch hood.

(b) Pull out the dashboard wire harness connectors under the clock spring.

(c) Take off the clock spring.

Caution: Store the removed clock spring in a clean and dry place.

3. Installation notes

(a) Inspection before installation, inspection of driver side airbag module.

(b) Inspect the new airbag or clock spring before installing them.

4. Driver side airbag module inspection

Inspect each of the following items. If any faults are found, replace with a new corresponding airbag module

part. Discard the old components after they have been deployed in the pr\

oper order.

(a) Whether the cover sunken or depressed, cracked, or deformed.

(b) Whether the wire harness has broken connectors and deformed terminals.

(c) Whether the gas generator's housing is sunken or depressed, cracked, or deformed.

(d) Airbag module installation status.

Caution: The specified measuring instrument cannot measure the airbag module (tube rupture) circuit

resistance. Test the resistance with a testing instrument. There is an electric current in the tube rup-

ture which may lead to accidental deployment due to static electricity a\

nd cause serious accidents.

5. Clock spring inspection

Inspect each of the following items. If any fault is found, replace with\

a new clock spring.