fuse GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 226 of 281

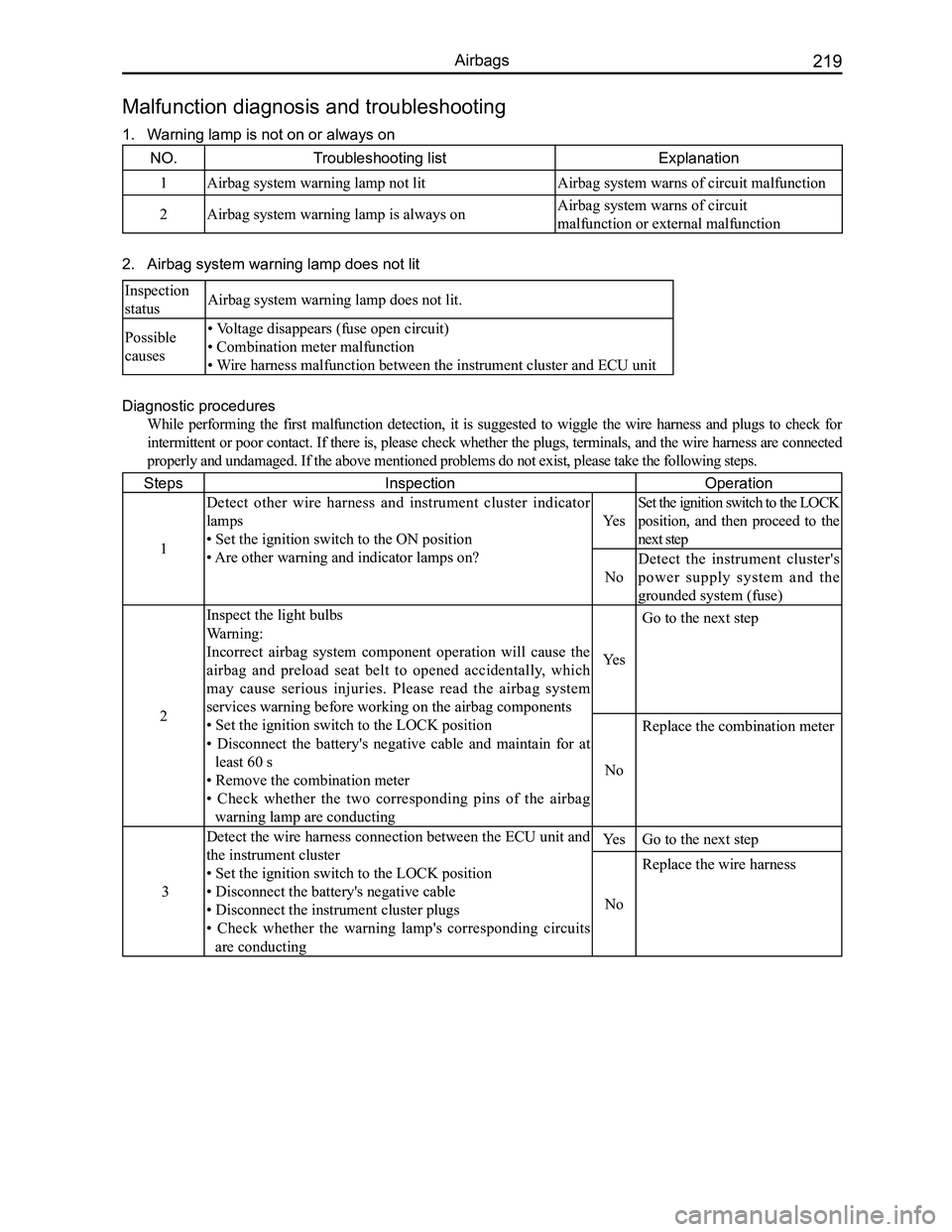

Downloaded from www.Manualslib.com manuals search engine 219Airbags

NO.Troubleshooting listExplanation

1Airbag system warning lamp not litAirbag system warns of circuit malfunction

2Airbag system warning lamp is always onAirbag system warns of circuit

malfunction or external malfunction

2. Airbag system warning lamp does not lit

Inspection

statusAirbag system warning lamp does not lit.

Possible

causes

• Voltage disappears (fuse open circuit)

• Combination meter malfunction

• Wire harness malfunction between the instrument cluster and ECU unit

Diagnostic procedures

While performing the first malfunction detection, it is suggested to wiggle the wire harness and plugs to check for

intermittent or poor contact. If there is, please check whether the plugs, terminals, and the wire harness are connected

properly and undamaged. If the above mentioned problems do not exist, pl\

ease take the following steps.

StepsInspectionOperation

1

Detect other wire harness and instrument cluster indicator

lamps

• Set the ignition switch to the ON position

• Are other warning and indicator lamps on?

Yes

Set the ignition switch to the LOCK

position, and then proceed to the

next step

No

Detect the instrument cluster's

power supply system and the

grounded system (fuse)

2

Inspect the light bulbs

Warning:

Incorrect airbag system component operation will cause the

airbag and preload seat belt to opened accidentally, which

may cause serious injuries. Please read the airbag system

services warning before working on the airbag components

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 60 s

• Remove the combination meter

• Check whether the two corresponding pins of the airbag

warning lamp are conducting

Yes

Go to the next step

No

Replace the combination meter

3

Detect the wire harness connection between the ECU unit and

the instrument cluster

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable

• Disconnect the instrument cluster plugs

• Check whether the warning lamp's corresponding circuits

are conducting

YesGo to the next step

No

Replace the wire harness

Malfunction diagnosis and troubleshooting

1. Warning lamp is not on or always on

Page 227 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual220

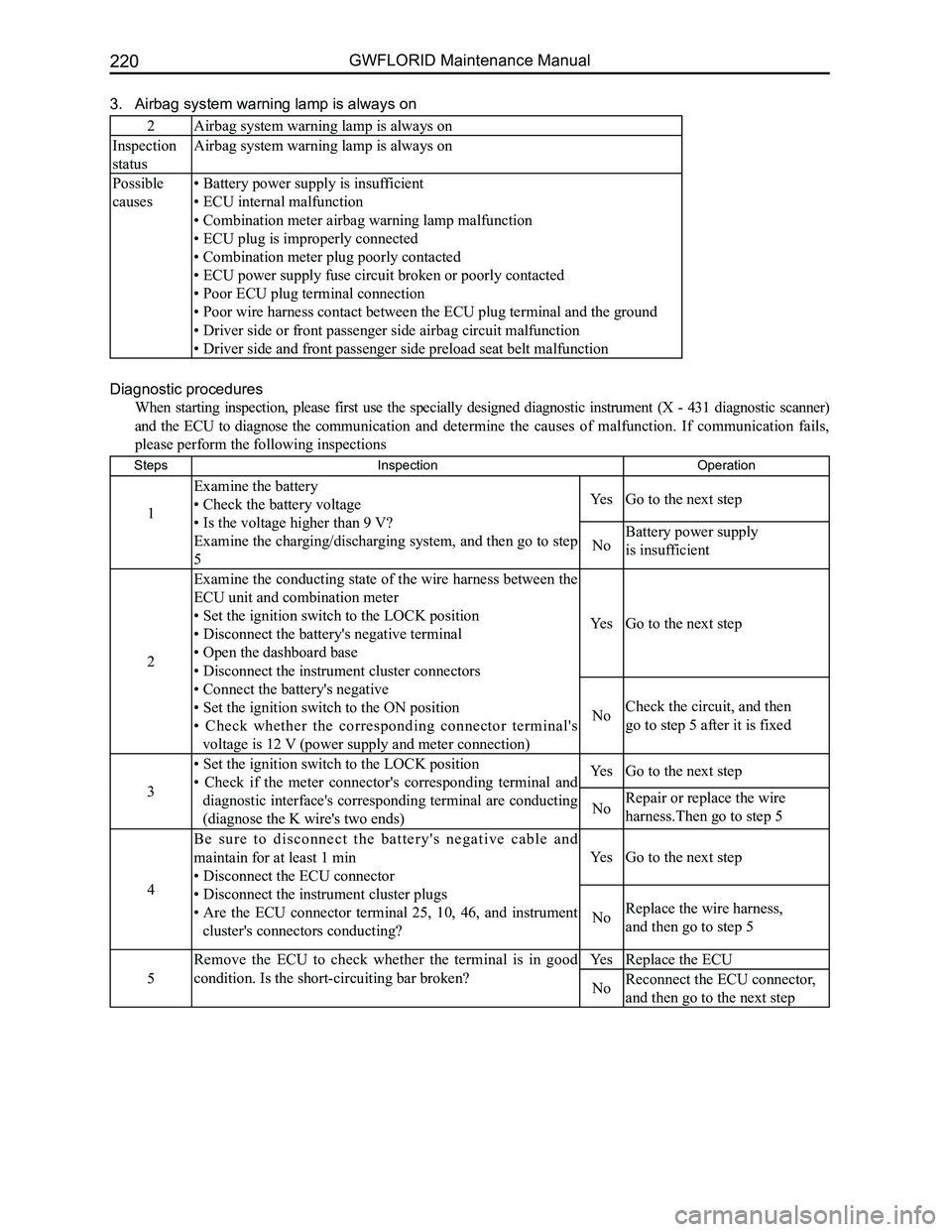

3. Airbag system warning lamp is always on

2Airbag system warning lamp is always on

Inspection

status

Airbag system warning lamp is always on

Possible

causes

• Battery power supply is insufficient

• ECU internal malfunction

• Combination meter airbag warning lamp malfunction

• ECU plug is improperly connected

• Combination meter plug poorly contacted

• ECU power supply fuse circuit broken or poorly contacted

• Poor ECU plug terminal connection

• Poor wire harness contact between the ECU plug terminal and the ground

• Driver side or front passenger side airbag circuit malfunction

• Driver side and front passenger side preload seat belt malfunction

Diagnostic procedures

When starting inspection, please first use the specially designed diagnostic instrument (X - 431 diagnostic scanner)

and the ECU to diagnose the communication and determine the causes of malfunction. If communication fails,

please perform the following inspections

StepsInspection Operation

1

Examine the battery

• Check the battery voltage

• Is the voltage higher than 9 V?

Examine the charging/discharging system, and then go to step

5

YesGo to the next step

NoBattery power supply

is insufficient

2

Examine the conducting state of the wire harness between the

ECU unit and combination meter

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative terminal

• Open the dashboard base

• Disconnect the instrument cluster connectors

• Connect the battery's negative

• Set the ignition switch to the ON position

• Check whether the corresponding connector terminal's

voltage is 12 V (power supply and meter connection)

YesGo to the next step

NoCheck the circuit, and then

go to step 5 after it is fixed

3

• Set the ignition switch to the LOCK position

• Check if the meter connector's corresponding terminal and

diagnostic interface's corresponding terminal are conducting

(diagnose the K wire's two ends)

YesGo to the next step

NoRepair or replace the wire

harness.Then go to step 5

4

B e s u r e t o d i s c o n n e c t t h e b a t t e r y ' s n e g a t i v e c a b l e a n d

maintain for at least 1 min

• Disconnect the ECU connector

• Disconnect the instrument cluster plugs

• Are the ECU connector terminal 25, 10, 46, and instrument

cluster's connectors conducting?

YesGo to the next step

NoReplace the wire harness,

and then go to step 5

5

Remove the ECU to check whether the terminal is in good

condition. Is the short-circuiting bar broken?

YesReplace the ECU

NoReconnect the ECU connector,

and then go to the next step

Page 228 of 281

Downloaded from www.Manualslib.com manuals search engine 221Airbags

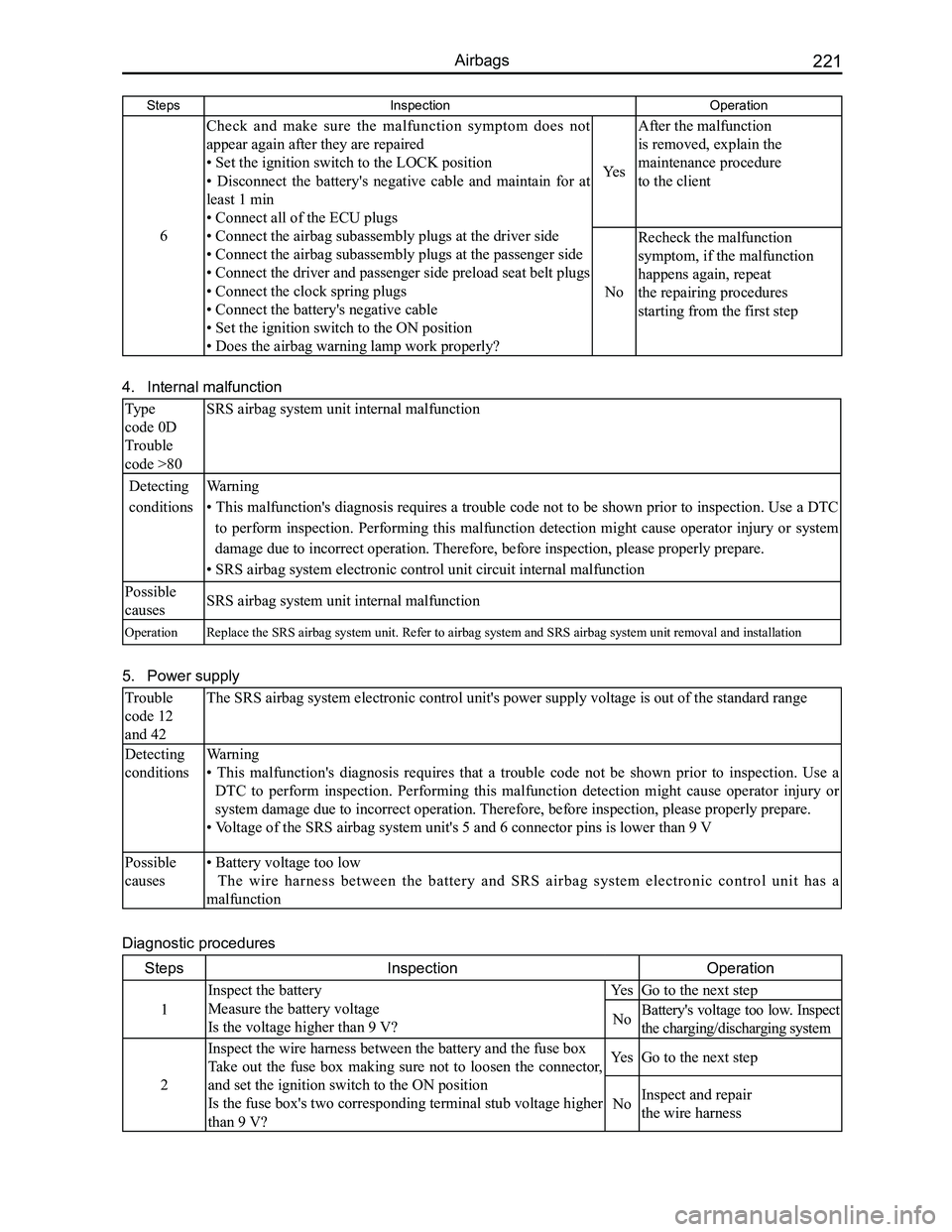

StepsInspection Operation

6

Check and make sure the malfunction symptom does not

appear again after they are repaired

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 1 min

• Connect all of the ECU plugs

• Connect the airbag subassembly plugs at the driver side

• Connect the airbag subassembly plugs at the passenger side

• Connect the driver and passenger side preload seat belt plugs

• Connect the clock spring plugs

• Connect the battery's negative cable

• Set the ignition switch to the ON position

• Does the airbag warning lamp work properly?

Yes

After the malfunction

is removed, explain the

maintenance procedure

to the client

No

Recheck the malfunction

symptom, if the malfunction

happens again, repeat

the repairing procedures

starting from the first step

4. Internal malfunction

Type

code 0D

Trouble

code >80

SRS airbag system unit internal malfunction

Detecting

conditions

Warning

• This malfunction's diagnosis requires a trouble code not to be shown prior to inspection. Use a DTC

to perform inspection. Performing this malfunction detection might cause operator injury or system

damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• SRS airbag system electronic control unit circuit internal malfunction

Possible

causesSRS airbag system unit internal malfunction

OperationReplace the SRS airbag system unit. Refer to airbag system and SRS airba\

g system unit removal and installation

5. Power supply

Trouble

code 12

and 42

The SRS airbag system electronic control unit's power supply voltage is \

out of the standard range

Detecting

conditions

Warning

• This malfunction's diagnosis requires that a trouble code not be shown prior to inspection. Use a

DTC to perform inspection. Performing this malfunction detection might cause operator injury or

system damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• Voltage of the SRS airbag system unit's 5 and 6 connector pins is lower than 9 V

Possible

causes

• Battery voltage too low

The wire harness between the battery and SRS airbag system electronic control unit has a

malfunction

Diagnostic procedures

StepsInspectionOperation

1

Inspect the battery

Measure the battery voltage

Is the voltage higher than 9 V?

YesGo to the next step

NoBattery's voltage too low. Inspect

the charging/discharging system

2

Inspect the wire harness between the battery and the fuse box

Take out the fuse box making sure not to loosen the connector,

and set the ignition switch to the ON position

Is the fuse box's two corresponding terminal stub voltage higher

than 9 V?

YesGo to the next step

NoInspect and repair

the wire harness

Page 229 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual222

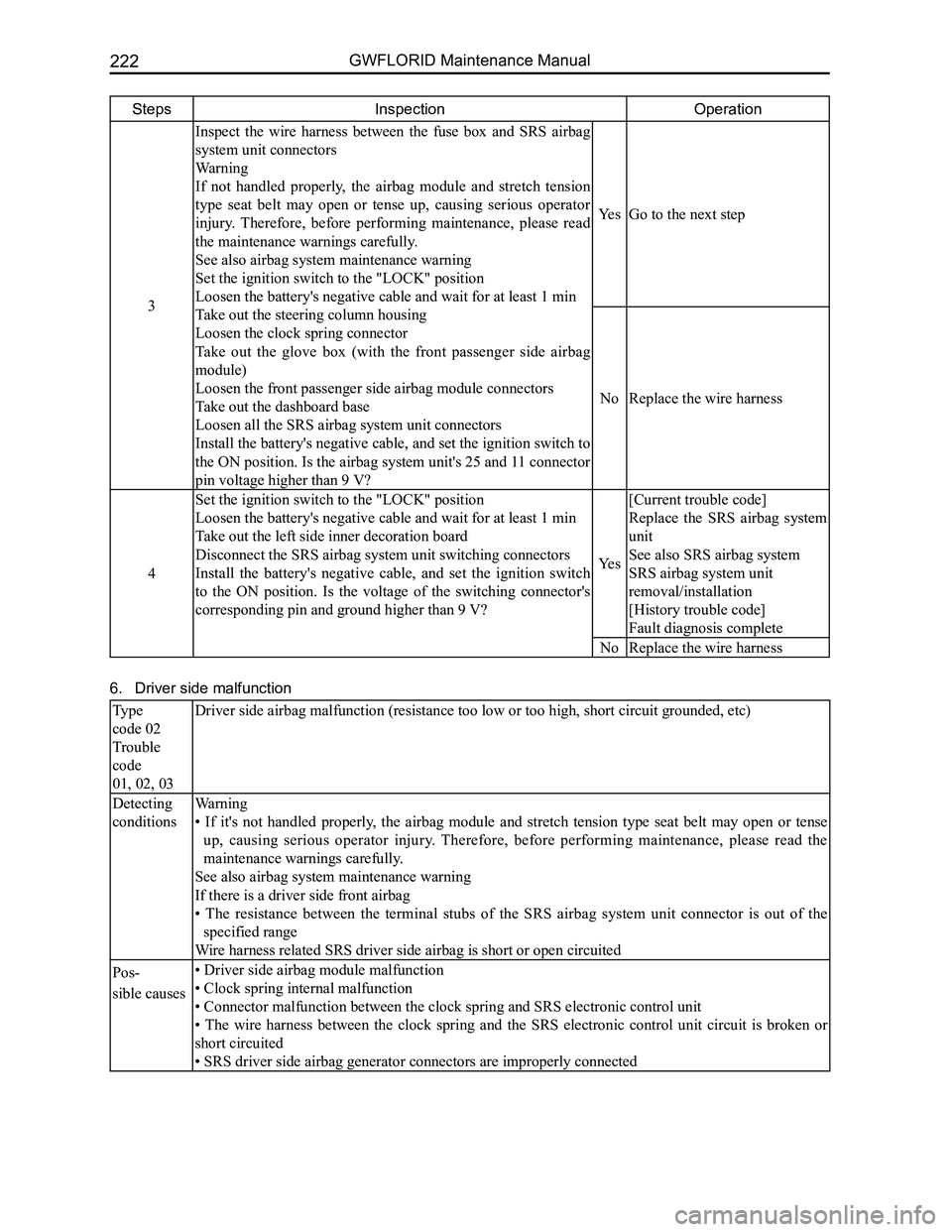

StepsInspectionOperation

3

Inspect the wire harness between the fuse box and SRS airbag

system unit connectors

Warning

If not handled properly, the airbag module and stretch tension

type seat belt may open or tense up, causing serious operator

injury. Therefore, before performing maintenance, please read

the maintenance warnings carefully.

See also airbag system maintenance warning

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the steering column housing

Loosen the clock spring connector

Take out the glove box (with the front passenger side airbag

module)

Loosen the front passenger side airbag module connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Install the battery's negative cable, and set the ignition switch to

the ON position. Is the airbag system unit's 25 and 11 connector

pin voltage higher than 9 V?

YesGo to the next step

NoReplace the wire harness

4

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the left side inner decoration board

Disconnect the SRS airbag system unit switching connectors

Install the battery's negative cable, and set the ignition switch

to the ON position. Is the voltage of the switching connector's

corresponding pin and ground higher than 9 V?

Yes

[Current trouble code]

Replace the SRS airbag system

unit

See also SRS airbag system

SRS airbag system unit

removal/installation

[History trouble code]

Fault diagnosis complete

NoReplace the wire harness

6. Driver side malfunction

Type

code 02

Trouble

code

01, 02, 03

Driver side airbag malfunction (resistance too low or too high, short c\

ircuit grounded, etc)

Detecting

conditions

Warning

• If it's not handled properly, the airbag module and stretch tension type seat belt may open or tense

up, causing serious operator injury. Therefore, before performing maintenance, please read the

maintenance warnings carefully.

See also airbag system maintenance warning

If there is a driver side front airbag

• The resistance between the terminal stubs of the SRS airbag system unit connector is out of the

specified range

Wire harness related SRS driver side airbag is short or open circuited

Pos-

sible causes

• Driver side airbag module malfunction

• Clock spring internal malfunction

• Connector malfunction between the clock spring and SRS electronic control unit

• The wire harness between the clock spring and the SRS electronic control unit circuit is broken or

short circuited

• SRS driver side airbag generator connectors are improperly connected

Page 249 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual242

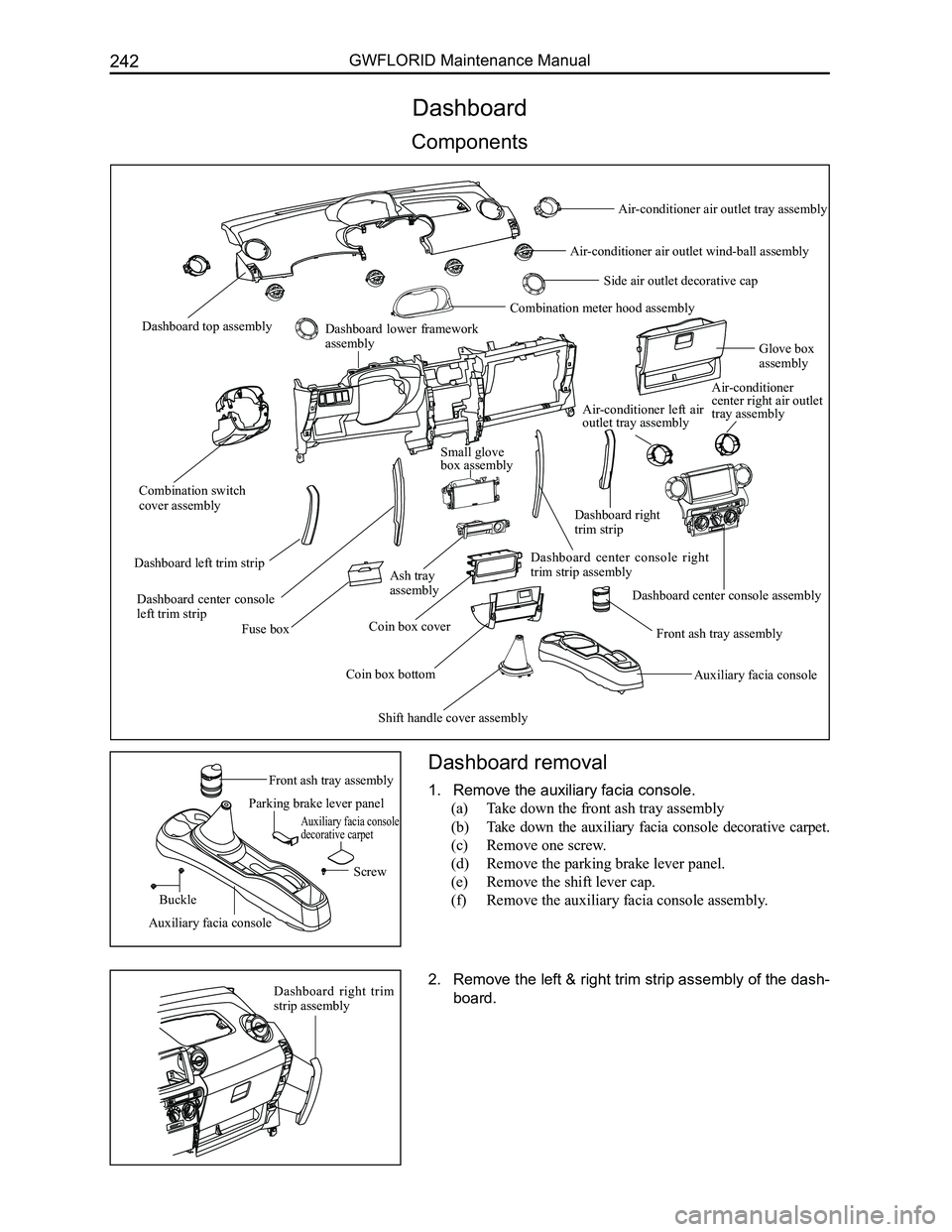

Dashboard

Components

Dashboard removal

1. Remove the auxiliary facia console.

(a) Take down the front ash tray assembly

(b) Take down the auxiliary facia console decorative carpet.

(c) Remove one screw.

(d) Remove the parking brake lever panel.

(e) Remove the shift lever cap.

(f) Remove the auxiliary facia console assembly.

2. Remove the left & right trim strip assembly of the dash-

board.

Front ash tray assembly

Dashboard top assembly

Combination switch cover assembly

Dashboard lower framework assemblyGlove box assembly

Fuse box

Dashboard left trim strip

Dashboard center console left trim strip

Ash tray assembly

Coin box bottom

Coin box coverFront ash tray assembly

Dashboard center console right trim strip assembly

Small glove box assembly

Shift handle cover assembly

Auxiliary facia console

Dashboard center console assembly

Air-conditioner center right air outlet tray assembly

Combination meter hood assembly

Side air outlet decorative cap

Air-conditioner air outlet wind-ball assembly

Air-conditioner air outlet tray assembly

Air-conditioner left air outlet tray assembly

Dashboard right trim strip

Parking brake lever panel

Auxiliary facia console decorative carpet

Screw

Buckle

Auxiliary facia console

Dashboard right trim strip assembly