transmission GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 75 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual68

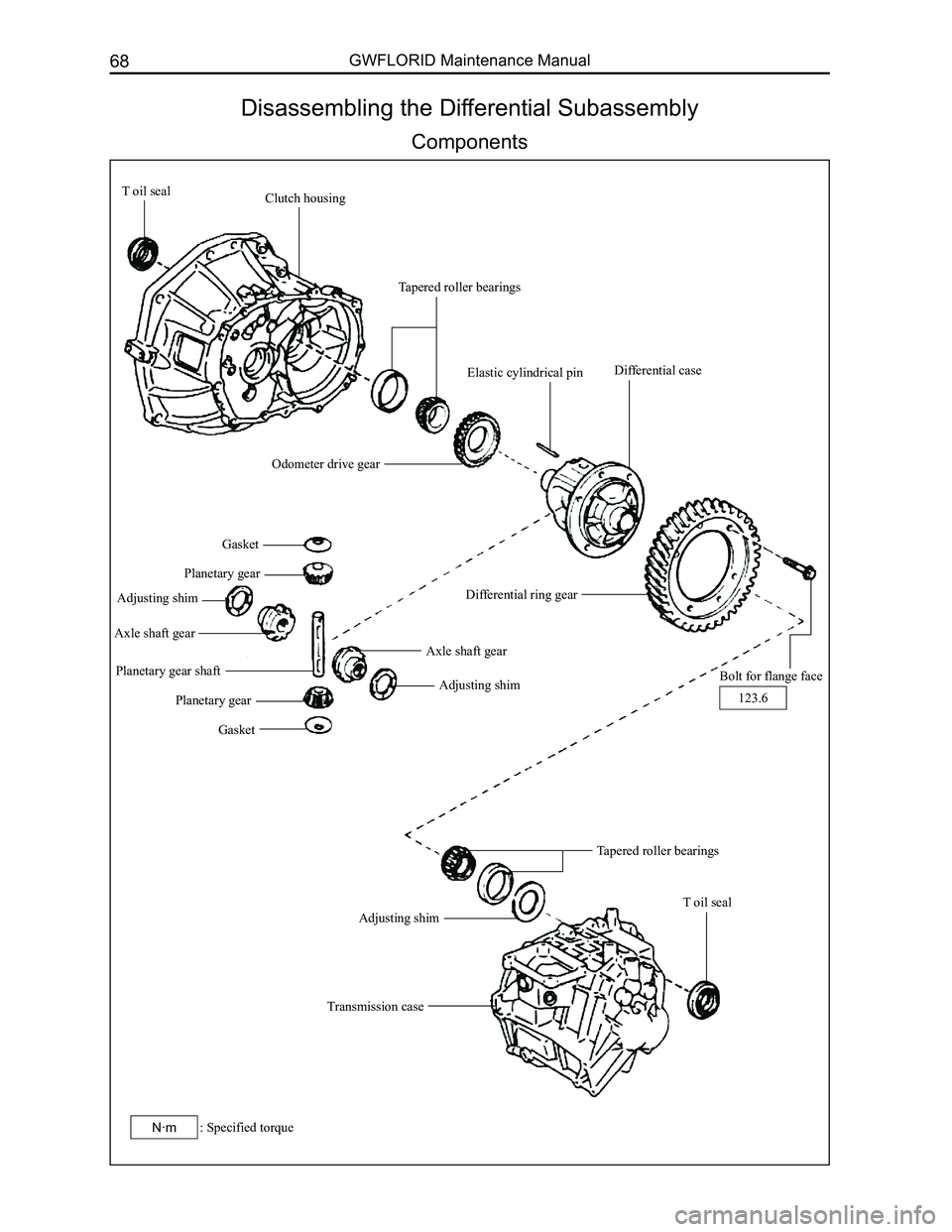

Disassembling the Differential Subassembly

Components

T oil sealClutch housing

Tapered roller bearings

Elastic cylindrical pin

Odometer drive gear

Differential case

Differential ring gear

Bolt for flange face

Gasket

Planetary gear

Adjusting shim

Axle shaft gear

Planetary gear shaft

Planetary gear

Gasket

Axle shaft gear

Adjusting shim

Tapered roller bearings

Transmission case

Adjusting shim

T oil seal

123.6

: Specified torqueN·m

Page 76 of 281

Downloaded from www.Manualslib.com manuals search engine 69Transmission

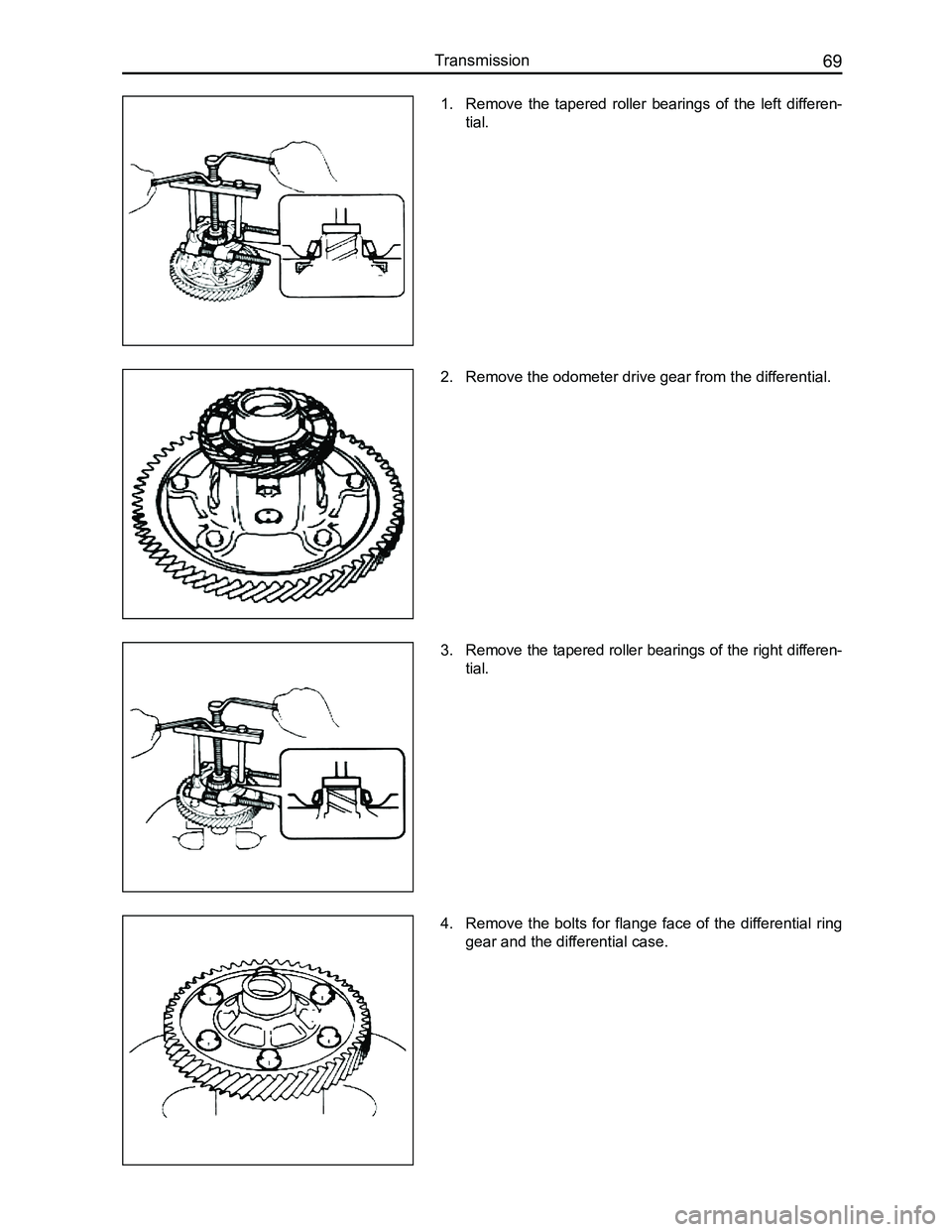

1. Remove the tapered roller bearings of the left differen-

tial.

2. Remove the odometer drive gear from the differential.

3. Remove the tapered roller bearings of the right differen-

tial.

4. Remove the bolts for flange face of the differential ring

gear and the differential case.

Page 91 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual84

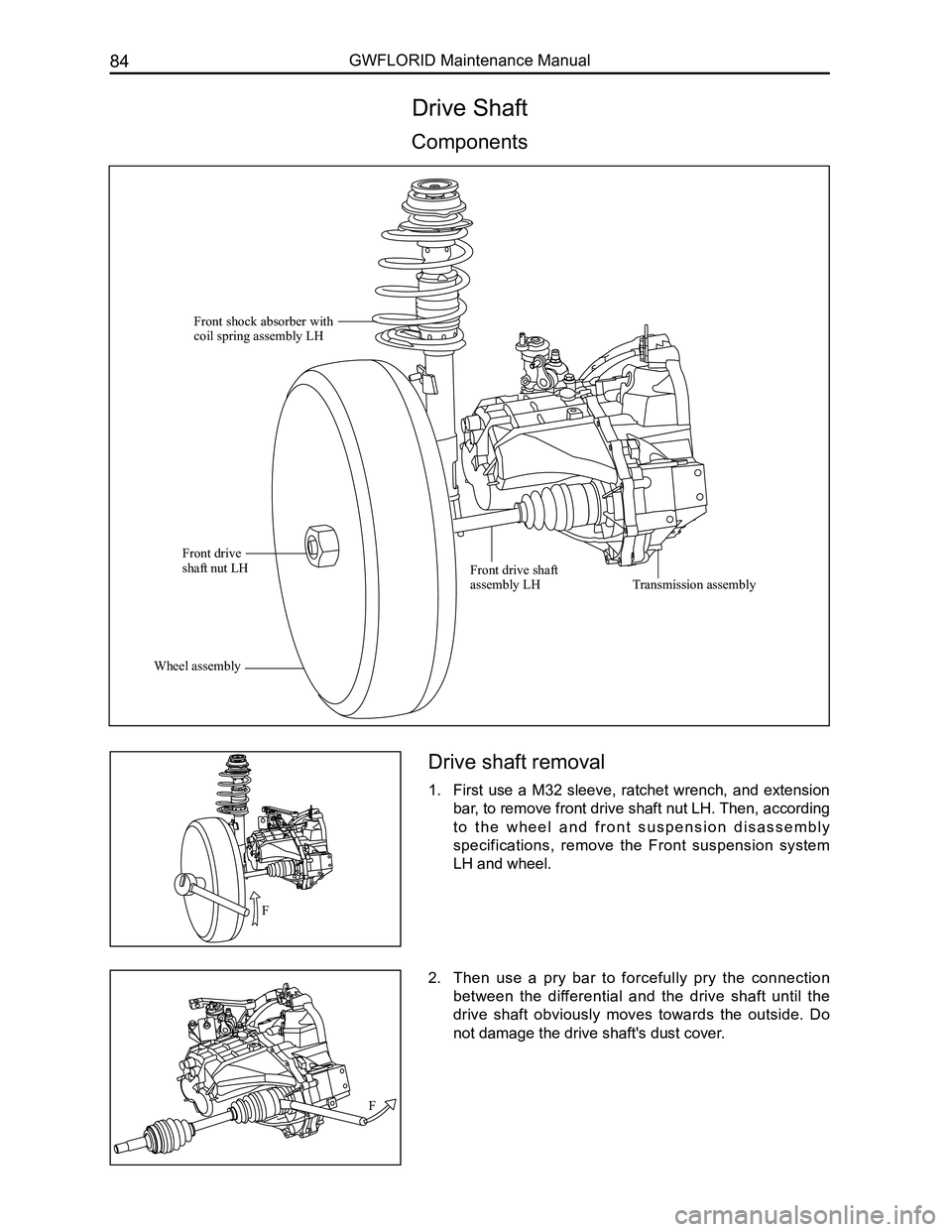

Drive Shaft

Components

Drive shaft removal

1. First use a M32 sleeve, ratchet wrench, and extension

bar, to remove front drive shaft nut LH. Then, according

t o t h e w h e e l a n d f r o n t s u s p e n s i o n d i s a s s e m b l y

specifications, remove the Front suspension system

LH and wheel.

2. Then use a pry bar to forcefully pry the connection

between the differential and the drive shaft until the

drive shaft obviously moves towards the outside. Do

not damage the drive shaft's dust cover.

Front shock absorber with coil spring assembly LH

Front drive shaft nut LH

Wheel assembly

Front drive shaft assembly LHTransmission assembly

F

F

Page 92 of 281

Downloaded from www.Manualslib.com manuals search engine 85Suspension System

Drive shaft installation

1. Insert the drive shaft.

First, align the inner end of the drive shaft and differential

spline. Keep the drive shaft axes and the differential axes

bases uniform, then hammer towards the direction of the

differential drive shaft's outer end until a clear and sharp

clicking sound is heard. Here, the drive shaft and the

transmission should have a clearance of about 1 mm.

2. According to the front suspension and wheel assembly

installation specifications, properly install the front

shock absorber with coil spring assembly LH and

wheel.

3. Use an M32 sleeve, ratchet wrench, and extension bar

to tighten front drive shaft nut LH.

Tightening torque: 225±20 N·m

F

F

Page 193 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual186

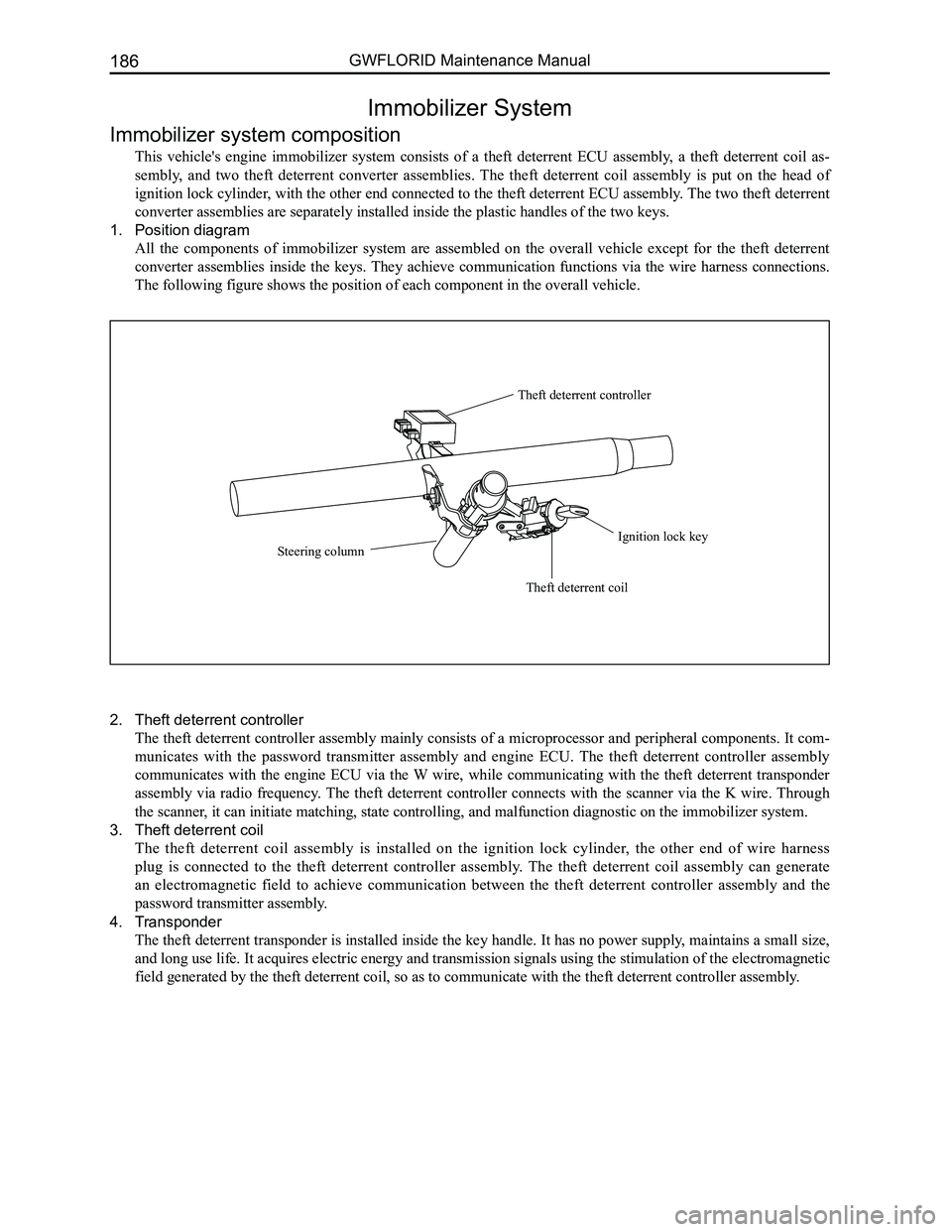

Immobilizer System

Immobilizer system composition

This vehicle's engine immobilizer system consists of a theft deterrent ECU assembly, a theft deterrent coil as-

sembly, and two theft deterrent converter assemblies. The theft deterrent coil assembly is put on the head of

ignition lock cylinder, with the other end connected to the theft deterrent ECU assembly. The two theft deterrent

converter assemblies are separately installed inside the plastic handles\

of the two keys.

1. Position diagram

All the components of immobilizer system are assembled on the overall vehicle except for the theft deterrent

converter assemblies inside the keys. They achieve communication functions via the wire harness connections.

The following figure shows the position of each component in the overall\

vehicle.

Theft deterrent controller

Ignition lock key

Theft deterrent coil

Steering column

2. Theft deterrent controller

The theft deterrent controller assembly mainly consists of a microprocessor and peripheral components. It com-

municates with the password transmitter assembly and engine ECU. The theft deterrent controller assembly

communicates with the engine ECU via the W wire, while communicating with the theft deterrent transponder

assembly via radio frequency. The theft deterrent controller connects with the scanner via the K wire. Through

the scanner, it can initiate matching, state controlling, and malfunction diagnosti\

c on the immobilizer system.

3. Theft deterrent coil

The theft deterrent coil assembly is installed on the ignition lock cylinder, the other end of wire harness

plug is connected to the theft deterrent controller assembly. The theft deterrent coil assembly can generate

an electromagnetic field to achieve communication between the theft deterrent controller assembly and the

password transmitter assembly.

4. Transponder

The theft deterrent transponder is installed inside the key handle. It has no power supply, maintains a small size,

and long use life. It acquires electric energy and transmission signals using the stimulation of the electromagnetic

field generated by the theft deterrent coil, so as to communicate with t\

he theft deterrent controller assembly.

Page 224 of 281

Downloaded from www.Manualslib.com manuals search engine 217Airbags

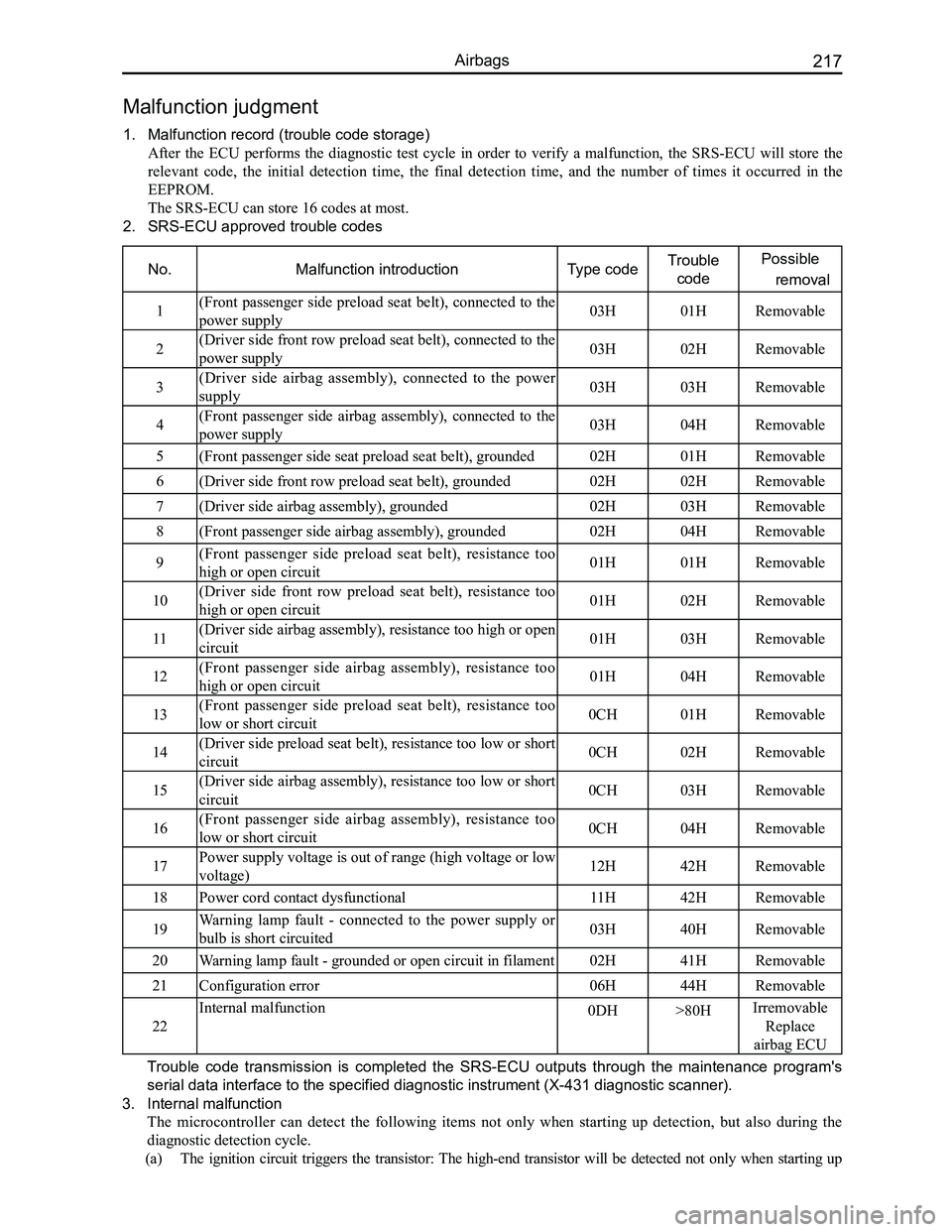

Malfunction judgment

1. Malfunction record (trouble code storage)

After the ECU performs the diagnostic test cycle in order to verify a malfunction, the SRS-ECU will store the

relevant code, the initial detection time, the final detection time, and the number of times it occurred in the

EEPROM.

The SRS-ECU can store 16 codes at most.

2. SRS-ECU approved trouble codes

No.Malfunction introductionType codeTrouble

code

Possible

removal

1(Front passenger side preload seat belt), connected to the

power supply03H01HRemovable

2(Driver side front row preload seat belt), connected to the

power supply03H02HRemovable

3(Driver side airbag assembly), connected to the power

supply03H03HRemovable

4(Front passenger side airbag assembly), connected to the

power supply03H04HRemovable

5(Front passenger side seat preload seat belt), grounded02H01HRemovable

6(Driver side front row preload seat belt), grounded02H02HRemovable

7(Driver side airbag assembly), grounded02H03HRemovable

8(Front passenger side airbag assembly), grounded02H04HRemovable

9(Front passenger side preload seat belt), resistance too

high or open circuit01H01HRemovable

10(Driver side front row preload seat belt), resistance too

high or open circuit01H02HRemovable

11(Driver side airbag assembly), resistance too high or open

circuit01H03HRemovable

12(Front passenger side airbag assembly), resistance too

high or open circuit01H04HRemovable

13(Front passenger side preload seat belt), resistance too

low or short circuit0CH01HRemovable

14(Driver side preload seat belt), resistance too low or short

circuit0CH02HRemovable

15(Driver side airbag assembly), resistance too low or short

circuit0CH03HRemovable

16(Front passenger side airbag assembly), resistance too

low or short circuit0CH04HRemovable

17Power supply voltage is out of range (high voltage or low

voltage)12H42HRemovable

18Power cord contact dysfunctional11H42HRemovable

19Warning lamp fault - connected to the power supply or

bulb is short circuited03H40HRemovable

20Warning lamp fault - grounded or open circuit in filament02H41HRemovable

21Configuration error06H44HRemovable

22

Internal malfunction0DH>80HIrremovable

Replace

airbag ECU

Trouble code transmission is completed the SRS-ECU outputs through the maintenance program's

serial data interface to the specified diagnostic instrument (X-431 dia\

gnostic scanner).

3. Internal malfunction

The microcontroller can detect the following items not only when starting up detection, but also during the

diagnostic detection cycle.

(a) The ignition circuit triggers the transistor: The high-end transistor will be detected not only when starting up