steering GREAT WALL FLORID 2008 Owner's Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 144 of 281

Downloaded from www.Manualslib.com manuals search engine 137Steering System

Steering System Maintenance

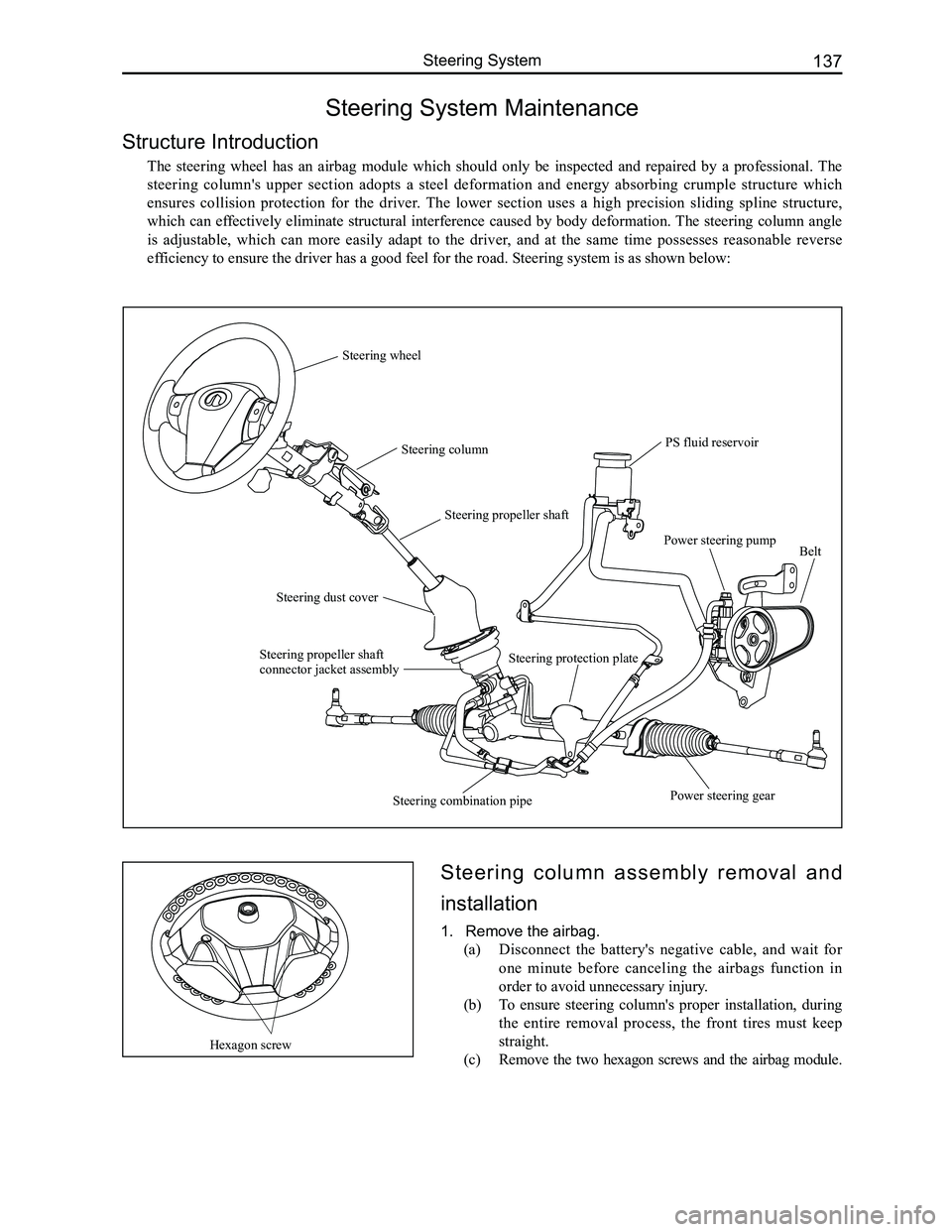

Structure Introduction

The steering wheel has an airbag module which should only be inspected and repaired by a professional. The

steering column's upper section adopts a steel deformation and energy absorbing crumple structure which

ensures collision protection for the driver. The lower section uses a high precision sliding spline structure,

which can effectively eliminate structural interference caused by body deformation. The steering column angle

is adjustable, which can more easily adapt to the driver, and at the same time possesses reasonable reverse

efficiency to ensure the driver has a good feel for the road. Steering sys\

tem is as shown below:

Steering column assembly removal and

installation

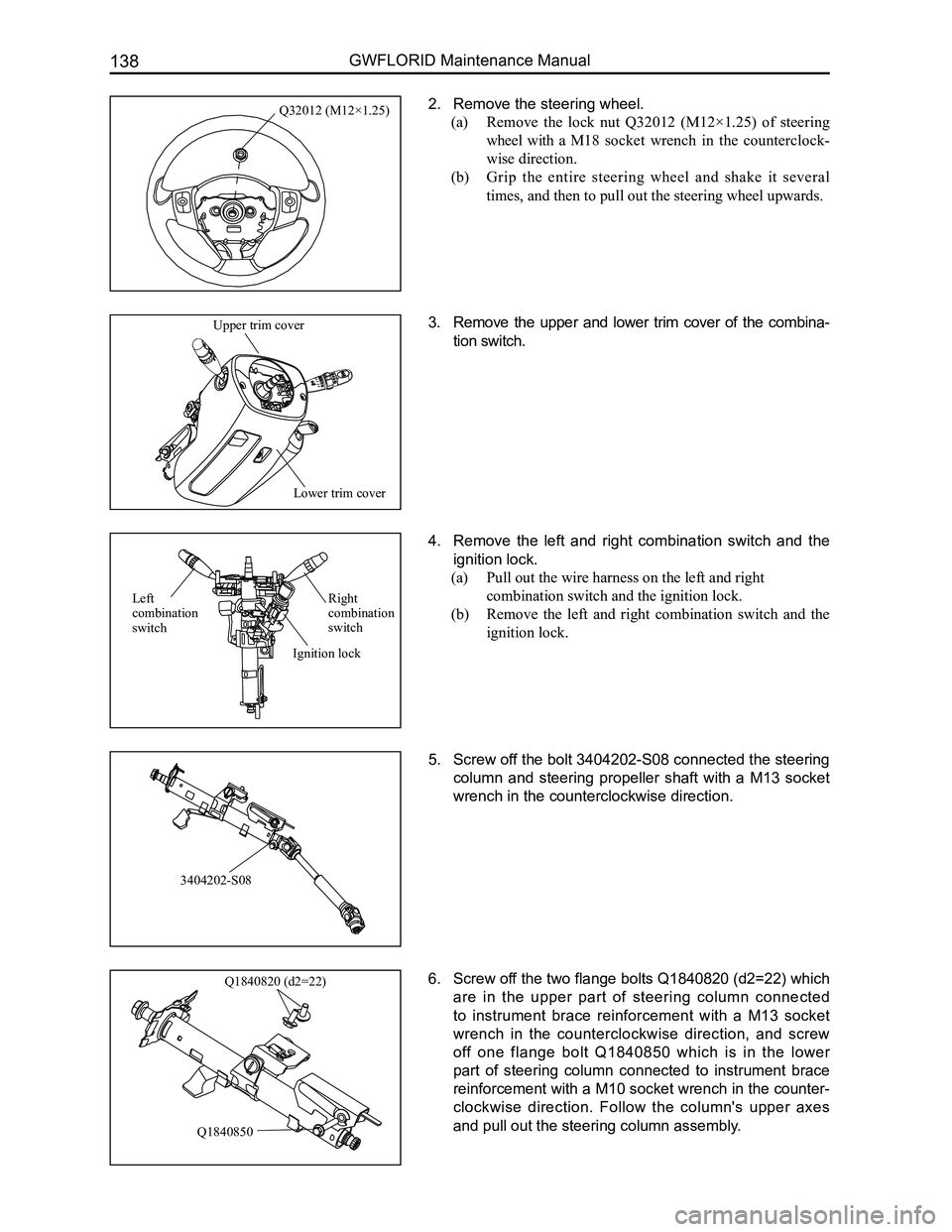

1. Remove the airbag.

(a) Disconnect the battery's negative cable, and wait for

one minute before canceling the airbags function in

order to avoid unnecessary injury.

(b) To ensure steering column's proper installation, during

the entire removal process, the front tires must keep

straight.

(c) Remove the two hexagon screws and the airbag module.

Hexagon screw

Steering wheel

Steering column

Steering propeller shaft

PS fluid reservoir

Power steering pumpBelt

Power steering gearSteering combination pipe

Steering propeller shaft connector jacket assembly

Steering dust cover

Steering protection plate

Page 145 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual138

2. Remove the steering wheel.

(a) Remove the lock nut Q32012 (M12×1.25) of steering

wheel with a M18 socket wrench in the counterclock-

wise direction.

(b) Grip the entire steering wheel and shake it several

times, and then to pull out the steering wheel upwards.

3. Remove the upper and lower trim cover of the combina-

tion switch.

4. Remove the left and right combination switch and the

ignition lock.

(a) Pull out the wire harness on the left and right

combination switch and the ignition lock.

(b) Remove the left and right combination switch and the

ignition lock.

5. Screw off the bolt 3404202-S08 connected the steering

column and steering propeller shaft with a M13 socket

wrench in the counterclockwise direction.

6. Screw off the two flange bolts Q1840820 (d2=22) which

are in the upper part of steering column connected

to instrument brace reinforcement with a M13 socket

wrench in the counterclockwise direction, and screw

off one flange bolt Q1840850 which is in the lower

part of steering column connected to instrument brace

reinforcement with a M10 socket wrench in the counter-

clockwise direction. Follow the column's upper axes

and pull out the steering column assembly.

Q32012 (M12×1.25)

Lower trim cover

Upper trim cover

3404202-S08

Q1840820 (d2=22)

Q1840850

Right combination switch

Left combination switch

Ignition lock

Page 146 of 281

Downloaded from www.Manualslib.com manuals search engine 139Steering System

7. Manually rotate the two plastic buckles 3412012-S08 in

the counterclockwise direction, and remove the steer-

ing dust cover installed on the steering propeller shaft.

8. Remove the bolt 3404202-S08 connecting the steering

propeller shaft and steering drive connection shaft with

a M13 socket wrench, and then pull out the propeller

shaft.

9. Pull out the steering propeller connection shaft's jacket

assembly 3412100-S08. Remove the bolts 3404202-

S08 which are on the steering propeller connection

shaft and steering gear with a M13 socket wrench, and

then pull out steering propeller connection shaft.

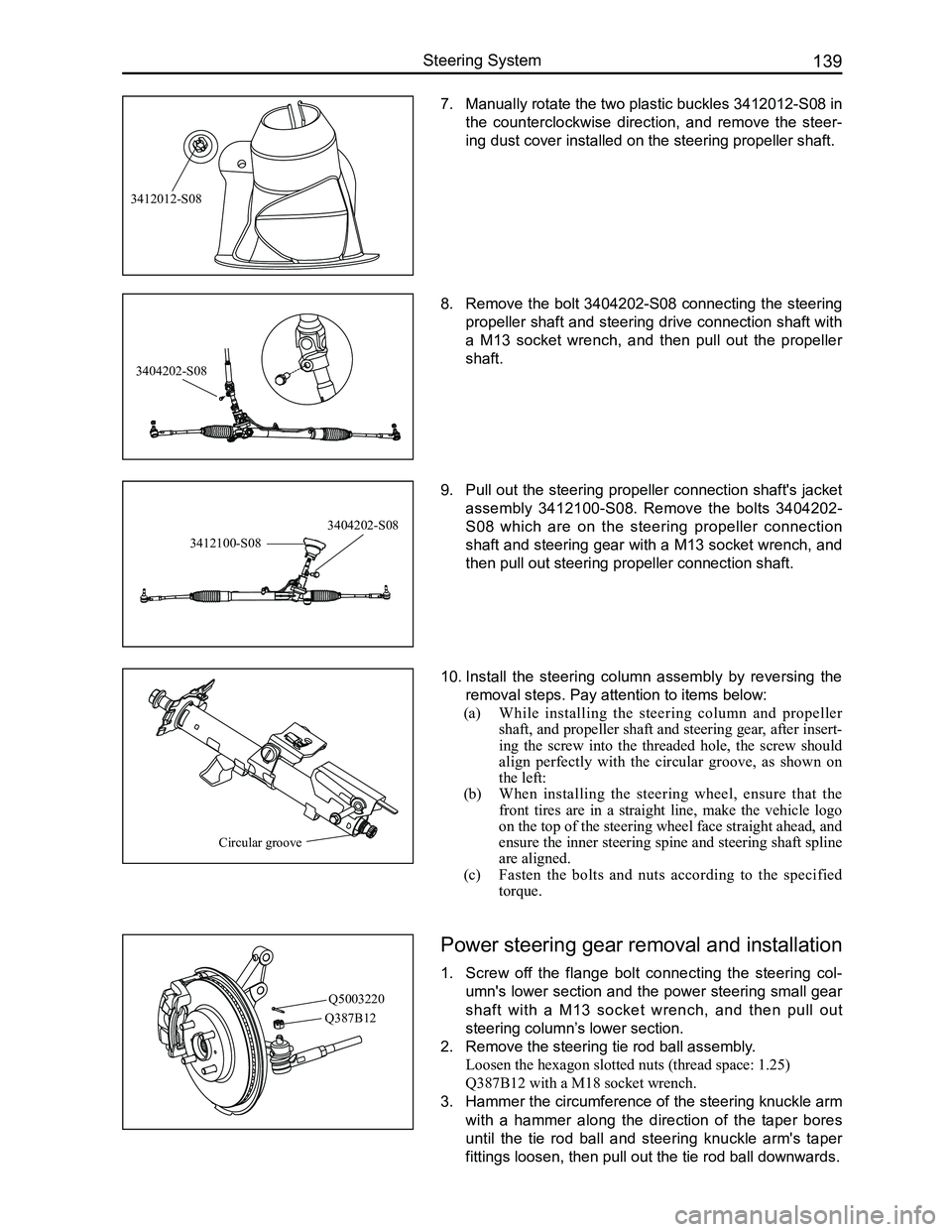

10. Install the steering column assembly by reversing the

removal steps. Pay attention to items below:

(a) While installing the steering column and propeller

shaft, and propeller shaft and steering gear, after insert-

ing the screw into the threaded hole, the screw should

align perfectly with the circular groove, as shown on

the left:

(b) When installing the steering wheel, ensure that the

front tires are in a straight line, make the vehicle logo

on the top of the steering wheel face straight ahead, and

ensure the inner steering spine and steering shaft spline

are aligned.

(c) Fasten the bolts and nuts according to the specified

torque.

3412012-S08

Circular groove

3412100-S08

3404202-S08

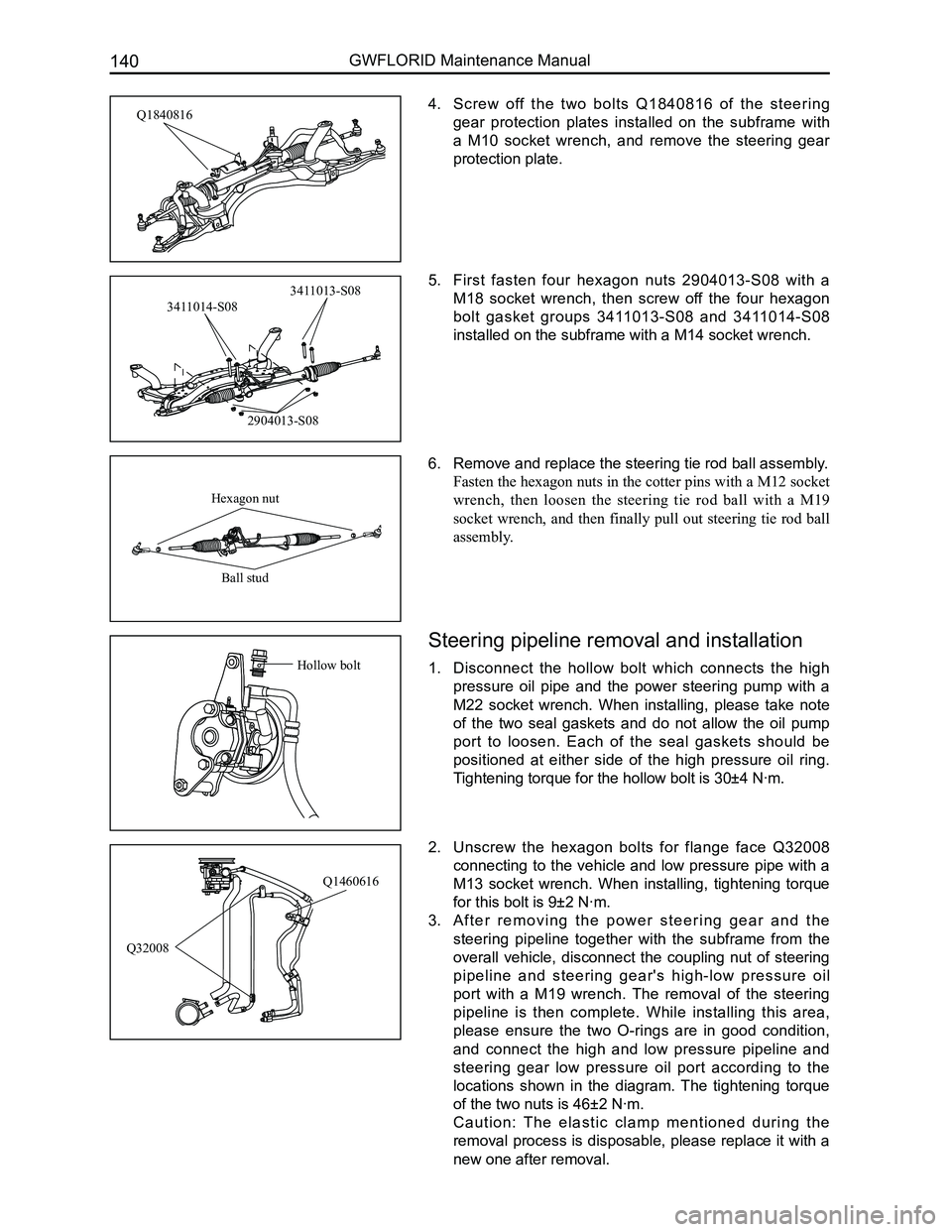

Power steering gear removal and installation

1. Screw off the flange bolt connecting the steering col-

umn's lower section and the power steering small gear

shaft with a M13 socket wrench, and then pull out

steering column’s lower section.

2. Remove the steering tie rod ball assembly.

Loosen the hexagon slotted nuts (thread space: 1.25)

Q387B12 with a M18 socket wrench.

3. Hammer the circumference of the steering knuckle arm

with a hammer along the direction of the taper bores

until the tie rod ball and steering knuckle arm's taper

fittings loosen, then pull out the tie rod ball downwards.

Q5003220

Q387B12

3404202-S08

Page 147 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual140

4. Screw off the two bolts Q1840816 of the steering

gear protection plates installed on the subframe with

a M10 socket wrench, and remove the steering gear

protection plate.

5. First fasten four hexagon nuts 2904013-S08 with a

M18 socket wrench, then screw off the four hexagon

bolt gasket groups 3411013-S08 and 3411014-S08

installed on the subframe with a M14 socket wrench.

6. Remove and replace the steering tie rod ball assembly.

Fasten the hexagon nuts in the cotter pins with a M12 socket

wrench, then loosen the steering tie rod ball with a M19

socket wrench, and then finally pull out steering tie rod ball

assembly.

2. Unscrew the hexagon bolts for flange face Q32008

connecting to the vehicle and low pressure pipe with a

M13 socket wrench. When installing, tightening torque

for this bolt is 9±2 N·m.

3. A f t e r r e m o v i n g t h e p o w e r s t e e r i n g g e a r a n d t h e

steering pipeline together with the subframe from the

overall vehicle, disconnect the coupling nut of steering

pipeline and steering gear's high-low pressure oil

port with a M19 wrench. The removal of the steering

pipeline is then complete. While installing this area,

please ensure the two O-rings are in good condition,

and connect the high and low pressure pipeline and

steering gear low pressure oil port according to the

locations shown in the diagram. The tightening torque

of the two nuts is 46±2 N·m.

C a u t i o n : T h e e l a s t i c c l a m p m e n t i o n e d d u r i n g t h e

removal process is disposable, please replace it with a

new one after removal.

Q1460616

Q32008

Q1840816

2904013-S08

3411014-S08

3411013-S08

Hexagon nut

Ball stud

Steering pipeline removal and installation

1. Disconnect the hollow bolt which connects the high

pressure oil pipe and the power steering pump with a

M22 socket wrench. When installing, please take note

of the two seal gaskets and do not allow the oil pump

port to loosen. Each of the seal gaskets should be

positioned at either side of the high pressure oil ring.

Tightening torque for the hollow bolt is 30±4 N·m.

Hollow bolt

Page 148 of 281

Downloaded from www.Manualslib.com manuals search engine 141Steering System

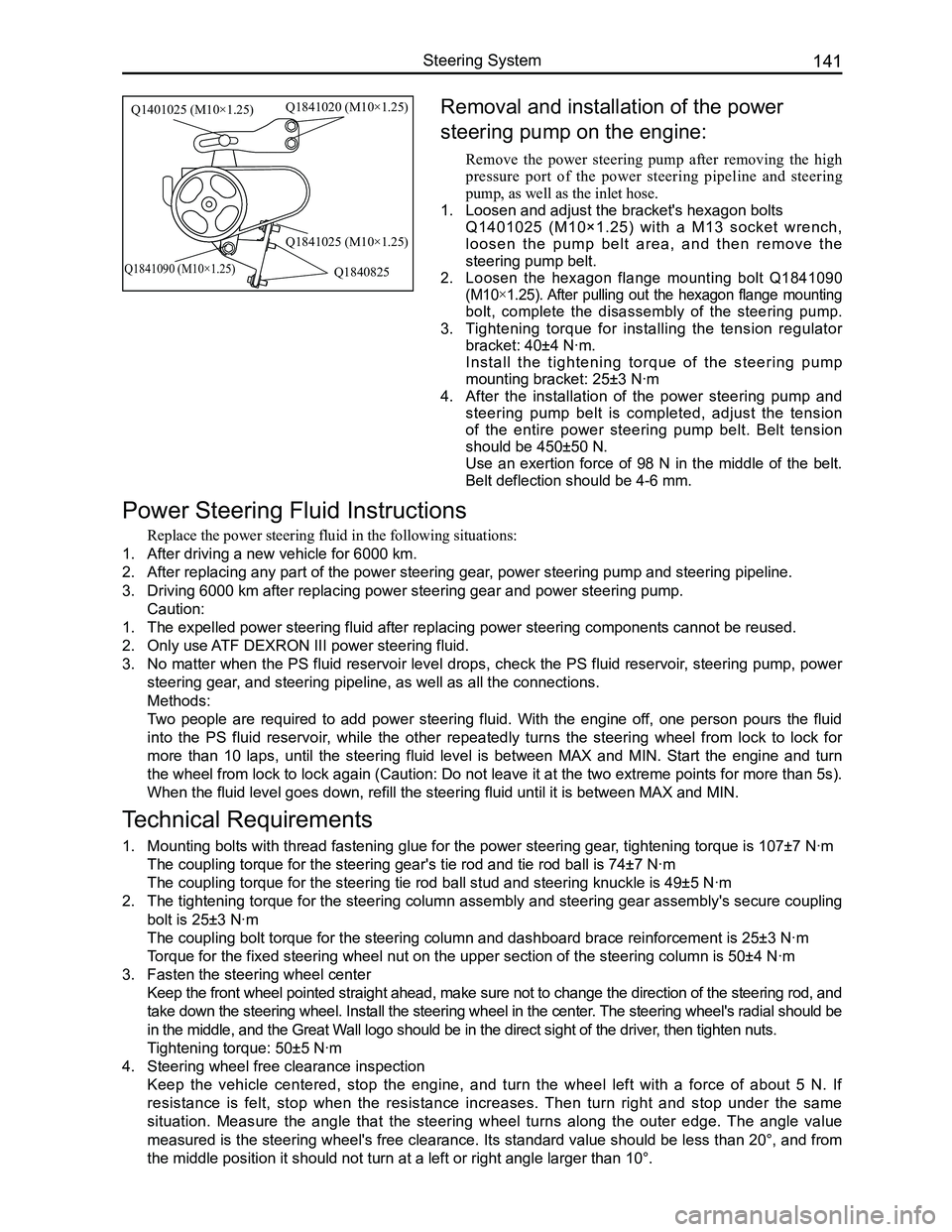

Removal and installation of the power

steering pump on the engine:

Remove the power steering pump after removing the high

pressure port of the power steering pipeline and steering

pump, as well as the inlet hose.

1. Loosen and adjust the bracket's hexagon bolts

Q1401025 (M10×1.25) with a M13 socket wrench,

l o o s e n t h e p u m p b e l t a r e a , a n d t h e n r e m o v e t h e

steering pump belt.

2. Loosen the hexagon flange mounting bolt Q1841090

(M10×1.25). After pulling out the hexagon flange mounting

bolt, complete the disassembly of the steering pump.

3. Tightening torque for installing the tension regulator

bracket: 40±4 N·m.

Install the tightening torque of the steering pump

mounting bracket: 25±3 N·m

4. After the installation of the power steering pump and

steering pump belt is completed, adjust the tension

of the entire power steering pump belt. Belt tension

should be 450±50 N.

Use an exertion force of 98 N in the middle of the belt.

Belt deflection should be 4-6 mm.

Power Steering Fluid Instructions

Replace the power steering fluid in the following situations:

1. After driving a new vehicle for 6000 km.

2. After replacing any part of the power steering gear, power steering pump and steering pipeline.

3. Driving 6000 km after replacing power steering gear and power steering p\

ump.

Caution:

1. The expelled power steering fluid after replacing power steering compone\

nts cannot be reused.

2. Only use ATF DEXRON III power steering fluid.

3. No matter when the PS fluid reservoir level drops, check the PS fluid reservoir, steering pump, power

steering gear, and steering pipeline, as well as all the connections.

Methods:

Two people are required to add power steering fluid. With the engine off, one person pours the fluid

into the PS fluid reservoir, while the other repeatedly turns the steering wheel from lock to lock for

more than 10 laps, until the steering fluid level is between MAX and MIN. Start the engine and turn

the wheel from lock to lock again (Caution: Do not leave it at the two extreme points for more than 5s).

When the fluid level goes down, refill the steering fluid until it is be\

tween MAX and MIN.

Technical Requirements

1. Mounting bolts with thread fastening glue for the power steering gear, tightening torque is 107±7 N·m

The coupling torque for the steering gear's tie rod and tie rod ball is \

74±7 N·m

The coupling torque for the steering tie rod ball stud and steering knuc\

kle is 49±5 N·m

2. The tightening torque for the steering column assembly and steering gear assembly's secure coupling

bolt is 25±3 N·m

The coupling bolt torque for the steering column and dashboard brace rei\

nforcement is 25±3 N·m

Torque for the fixed steering wheel nut on the upper section of the steer\

ing column is 50±4 N·m

3. Fasten the steering wheel center

Keep the front wheel pointed straight ahead, make sure not to change the direction of the steering rod, and

take down the steering wheel. Install the steering wheel in the center. The steering wheel's radial should be

in the middle, and the Great Wall logo should be in the direct sight of the driver, then tighten nuts.

Tightening torque: 50±5 N·m

4. Steering wheel free clearance inspection

Keep the vehicle centered, stop the engine, and turn the wheel left with a force of about 5 N. If

resistance is felt, stop when the resistance increases. Then turn right and stop under the same

situation. Measure the angle that the steering wheel turns along the outer edge. The angle value

measured is the steering wheel's free clearance. Its standard value should be less than 20°, and from

the middle position it should not turn at a left or right angle larger t\

han 10°.

Q1401025 (M10×1.25)Q1841020 (M10×1.25)

Q1841025 (M10×1.25)

Q1840825Q1841090 (M10×1.25)

Page 178 of 281

Downloaded from www.Manualslib.com manuals search engine 171Vehicle Body Electronic System

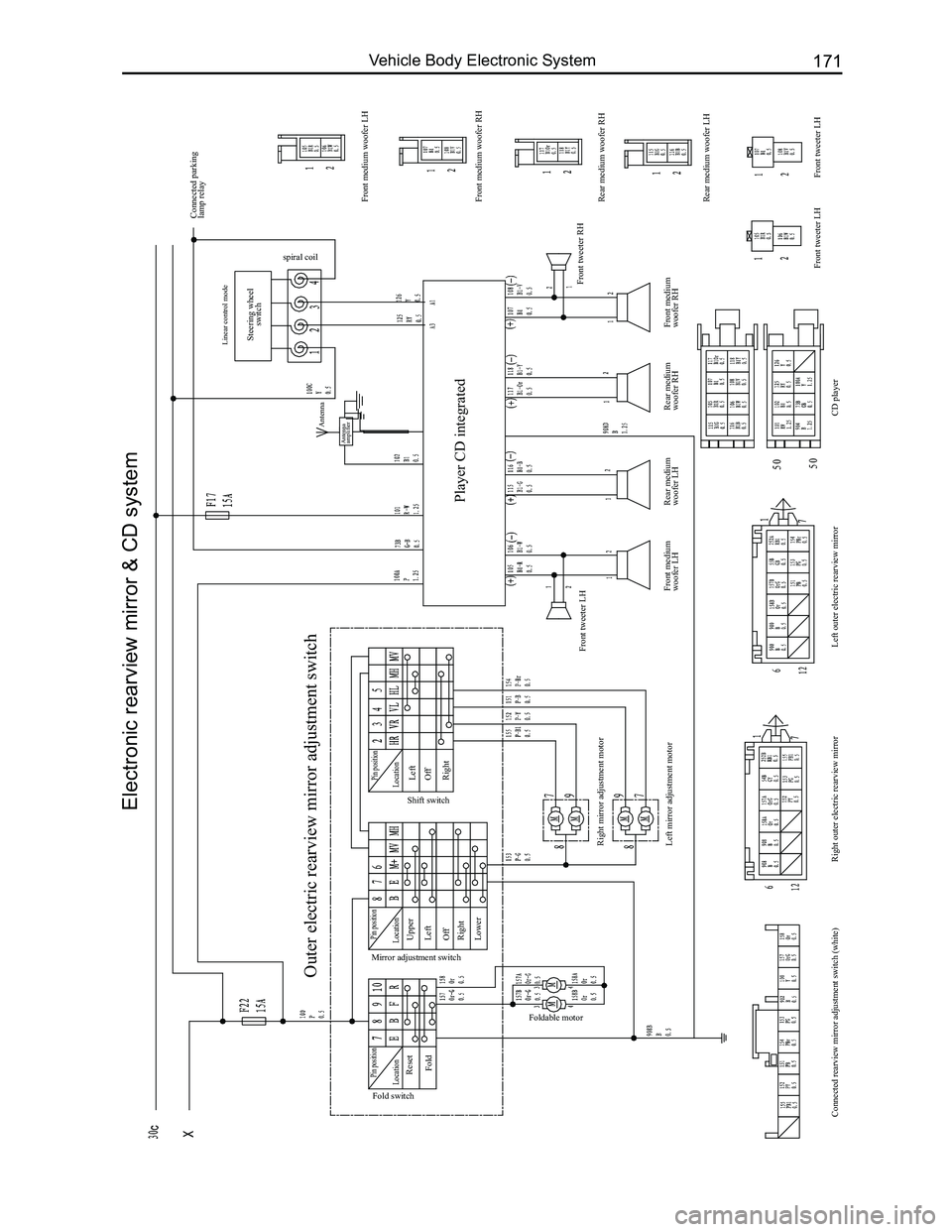

Electronic rearview mirror & CD system

Outer electric rearview mirror adjustment switch

Player CD integrated

Fold switch

Mirror adjustment switch

Foldable motor

Right mirror adjustment motor Steering wheel

switch Connected parking

lamp relay

Front medium woofer LH

Front medium woofer RH

Rear medium woofer RH

Rear medium woofer LH

Front tweeter LH Front tweeter LH

Front tweeter LH

Front medium

woofer LH Rear medium

woofer LH Rear medium

woofer RH Front medium

woofer RH Front tweeter RH

Linear control mode

Antenna

Antenna

amplifier

Left mirror adjustment motor

Connected rearview mirror adjustment switch (white) Right outer electric rearview mirror Left outer electric rearview mirror CD player

Shift switch

spiral coil

Location Reset

Upper

Left Left

Off Off

Right Right

Lower

Fold Pin position

Location

Location Pin position

Pin position

Page 182 of 281

Downloaded from www.Manualslib.com manuals search engine 175Vehicle Body Electronic System

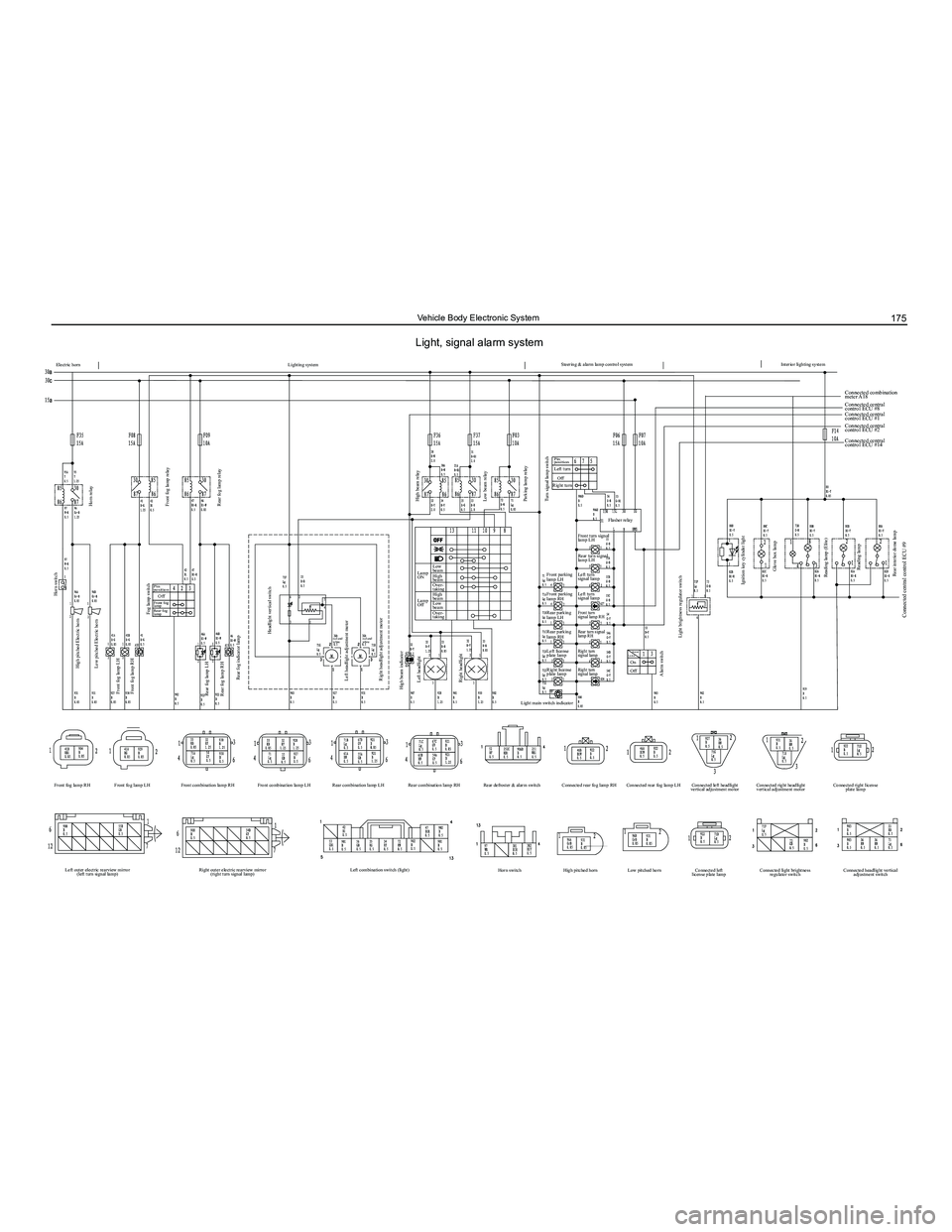

Electric horn

Horn switch

High pitched Electric horn

Low pitched Electric horn

Front fog lamp LH

Front fog lamp RH

Left outer electric rearview mirror (left turn signal lamp) Right outer electric rearview mirror

(right turn signal lamp) Left combination switch (light)

Horn switch High pitched horn Low pitched horn Connected left

license plate lamp Connected light brightness

regulator switch Connected headlight vertical

adjustment switch

Front fog lamp LH

Front combination lamp RH Front combination lamp LH Rear combination lamp LH Rear combination lamp RH Rear defroster & alarm switch Connected rear fog lamp RH Connected rear fog lamp LH Connected left headlight

vertical adjustment motor Connected right headlight

vertical adjustment motor Connected right license

plate lamp

Front fog lamp RH

Rear fog lamp LH

Rear fog lamp RH

Rear fog indicator lamp

Left headlight adjustment motor

Right headlight adjustment motor High beam relay

Lamp

ON Low

beam

Low

beam High

beam

High

beam Over-

taking

Over-

taking

Lamp

Off

Low beam relay

Parking lamp relay

Flasher relay

Connected combination

meter A18

Connected central

control ECU #8

Connected central

control ECU #1

Connected central

control ECU #2

Connected central

control ECU #14

Front parking

lamp LH Front turn signal

lamp LH

Rear turn signal

lamp LH

Left turn

signal lamp

Left turn

signal lamp

Front turn

signal lamp RH

Rear turn signal

lamp RH

Right turn

signal lamp

Right turn

signal lamp

Front parking

lamp RH

Rear parking

lamp LH

Rear parking

lamp RH

Left license

plate lamp

Right license

plate lamp

Light main switch indicator

Turn signal lamp switch

Alarm switch Light brightness regulator switch

Ignition key cylinder light Glove box lamp

Reading lamp (Elite) Reading lamp

Rear interior dome lamp

Connected central control ECU #9

High beam indicator Left headlight

Right headlight Headlight vertical switch

red and

white

red and

white

Fog lamp switch

Pin

position Pin

position

Left turn

Right turn Off

Front fog

lamp

Rear fog

lamp Off

Horn relay

Front fog lamp relay

Rear fog lamp relay

Lighting system Steering & alarm lamp control system

Interior lighting system

Terminal

Location

Off On

Light, signal alarm system

Page 193 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual186

Immobilizer System

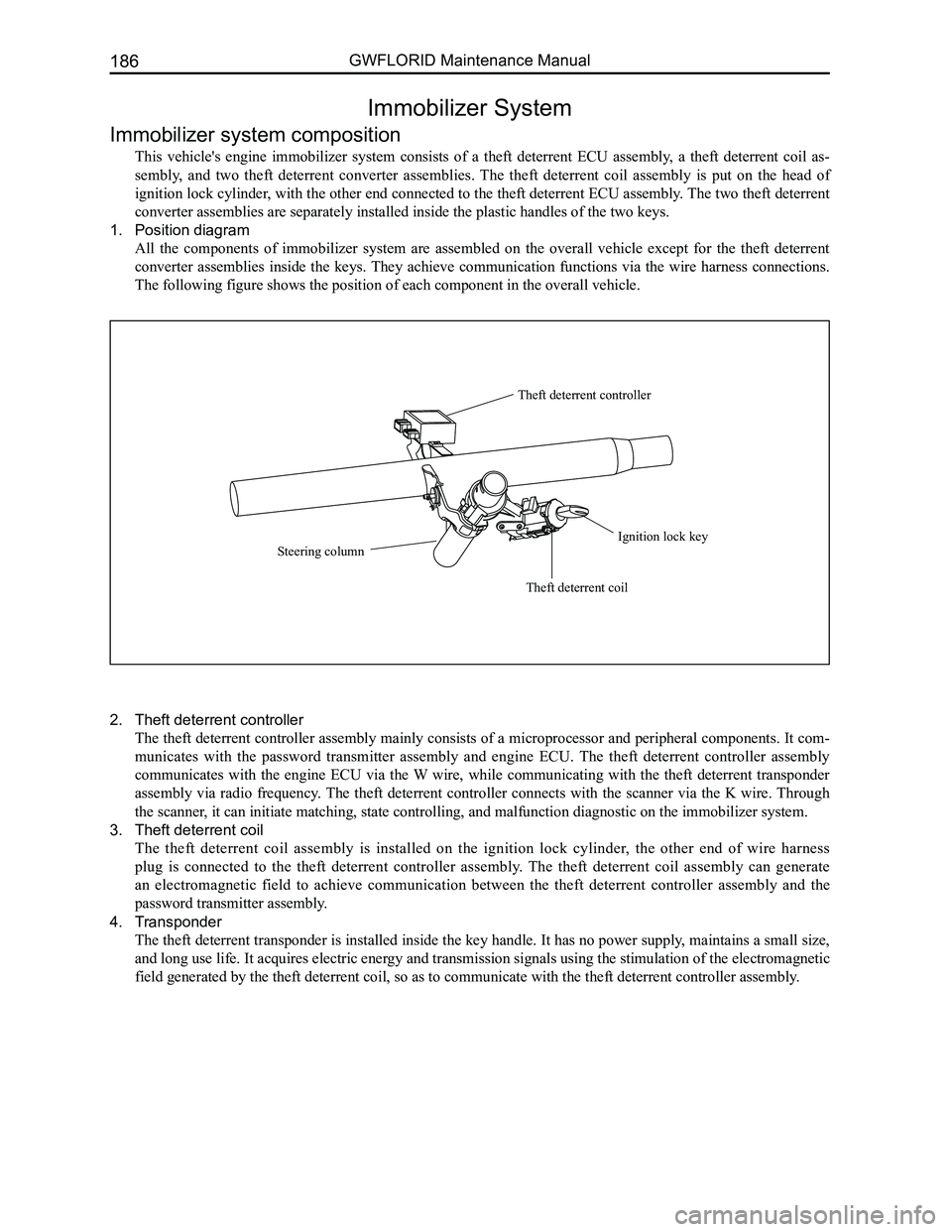

Immobilizer system composition

This vehicle's engine immobilizer system consists of a theft deterrent ECU assembly, a theft deterrent coil as-

sembly, and two theft deterrent converter assemblies. The theft deterrent coil assembly is put on the head of

ignition lock cylinder, with the other end connected to the theft deterrent ECU assembly. The two theft deterrent

converter assemblies are separately installed inside the plastic handles\

of the two keys.

1. Position diagram

All the components of immobilizer system are assembled on the overall vehicle except for the theft deterrent

converter assemblies inside the keys. They achieve communication functions via the wire harness connections.

The following figure shows the position of each component in the overall\

vehicle.

Theft deterrent controller

Ignition lock key

Theft deterrent coil

Steering column

2. Theft deterrent controller

The theft deterrent controller assembly mainly consists of a microprocessor and peripheral components. It com-

municates with the password transmitter assembly and engine ECU. The theft deterrent controller assembly

communicates with the engine ECU via the W wire, while communicating with the theft deterrent transponder

assembly via radio frequency. The theft deterrent controller connects with the scanner via the K wire. Through

the scanner, it can initiate matching, state controlling, and malfunction diagnosti\

c on the immobilizer system.

3. Theft deterrent coil

The theft deterrent coil assembly is installed on the ignition lock cylinder, the other end of wire harness

plug is connected to the theft deterrent controller assembly. The theft deterrent coil assembly can generate

an electromagnetic field to achieve communication between the theft deterrent controller assembly and the

password transmitter assembly.

4. Transponder

The theft deterrent transponder is installed inside the key handle. It has no power supply, maintains a small size,

and long use life. It acquires electric energy and transmission signals using the stimulation of the electromagnetic

field generated by the theft deterrent coil, so as to communicate with t\

he theft deterrent controller assembly.

Page 195 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual188

not necessarily mean that engine start failure is due to a immobilizer system malfunction. The reasons for start-

ing engine failures are numerous, including factors like fuel, gas, fire, electricity, wires, etc. If the engine cannot

start, first check if the immobilizer system is working normally. This can be judged by looking at the flashing

theft deterrent indicator lamp which is located on the dashboard in front of the driver seat: Insert the key into the

lock cylinder and turn it to the "ON" position. If a legal key is used to start the engine, once the warning lamp is

connected to the ON end and the transponder is confirmed, the LED will remain unlit. Then when the ON end is

disconnected and the key is pulled out, the LED will shine for 0.25 s and darken for 4 s, as to act as a warning.

If an illegal key is used to start up the engine or there is something wrong with the system, the alarm indicator

lamp will shine for 0.25 s and darken for 4 s. If all is normal, then check the other parts of the engine. If abnor-

mal, first perform immobilizer system troubleshooting. A scanner can be used to judge if the immobilizer system

is working normally, but the precondition is that the scanner must be able to establish communication with the

theft deterrent controller.

1. If communication cannot be established, consider the following:

(a) Check whether the battery voltage is higher than 9 V

(b) Check whether the scanner plug is well contacted to the vehicle socket

(c) Use a multimeter to check whether the 7 pin of the OBD-II plug (diagnostic plug) is connected to the theft

deterrent controller's A7 pin

(d) Check whether the power supply of the theft deterrent controller is normal. (Use a multimeter to measure

whether the voltage of the theft deterrent controller's socket A1 pin and A2 pin is higher than 9 V)

(e) Then adopt the substitution method, which is to replace the theft deterrent controller to check if there is

anything wrong with the theft deterrent controller.

• If the failure is related to the theft deterrent controller, change it and initiate re-matching.

• If the failure has nothing to do with the theft deterrent controller, remove the electronic controller which

is connected to the alarm's K wire, such as the ABS controller, engine electrojet controller, airbag ECU

assembly, etc., as to ascertain if the present fault is caused by the wire harness connected with the theft

deterrent controller's K wire.

2. If communication can be established

Connect the scanner to the vehicle diagnostic port. Insert the key into the steering lock, and turn it to the "ON"

position, then select the scanner to check the immobilizer system's trou\

ble code.

3. Security system troubleshooting

Investigate the problem and perform troubleshooting according to the tro\

uble code on the scanner:

Trouble

code

Code

significanceFailure causeTroubleshooting methods

B1000Theft deterrent

controller

internal

malfunction

Theft deterrent coil open

circuit or short circuit. Theft

deterrent controller internal

malfunction.

Check whether the theft deterrent coil's connecting plug and 1.

the theft deterrent controller is well connected.

Check whether the theft deterrent coil's wire harness plug is sliding 2.

or touching each other.

R e m o v e t h e t h e f t d e t e r r e n t c o i l p l u g , a n d t h e n u s e a 3.

multimeter to check the resistance between the B1 and B2

pins. The normal resistance is about 5-30 Ω. If the resistance

is close to zero, that means the coil has been short circuited.

If the resistance is infinite, then it means the coil's circuit is

open. Measure the resistance between pins B1 and B3, and

B2 and B3, normally they are infinite. If the resistance gains

a certain value, then it means the coil is short circuited or

leaking electricity.

If there is nothing wrong with the coil, the next step is to 4.

check the theft deterrent controller. Adopt the substitution

approach, replace it with a non-matched new theft deterrent

controller or an theft deterrent controller which has been

reset (please refer to the immobilizer system component

replacement). Insert the key into the ignition lock and turn it

to the "ON" position and read the trouble code. If there is no

9000 failure, it means the replaced controller has an internal

malfunction, and the new replaced controller must be re-

matched.

Page 216 of 281

Downloaded from www.Manualslib.com manuals search engine 209Air Conditioning System

Compressor Removal

1. Hoist the vehicle with a jack.

2. Remove the bottom mudguard.

3. Remove the compressor.

Compressor Installation

Before installing, manually rotate the compressor several

circles, allowing each component in the relative motion to be

covered with lubricant.

Clearance between the compressor's auricular branch and

bracket should be less than 0.1 mm. If the clearance is too

big, fill the clearance with a washer.

1. Loosen the engine's adjusting bolt firstly, take down the

engine belt, and then change the compressor belt.

2. Fix the compressor bracket onto the engine body with

the bolts. The bracket must be fastened tightly with suf-

ficient intensity. Fix the compressor bracket onto the

engine with four M10 ×1.25 (Q1461030 FD) bolts and

a tightening torque of 45±5 N·m, and then install the

compressor onto the bracket with a tightening torque of

22±3 N·m.

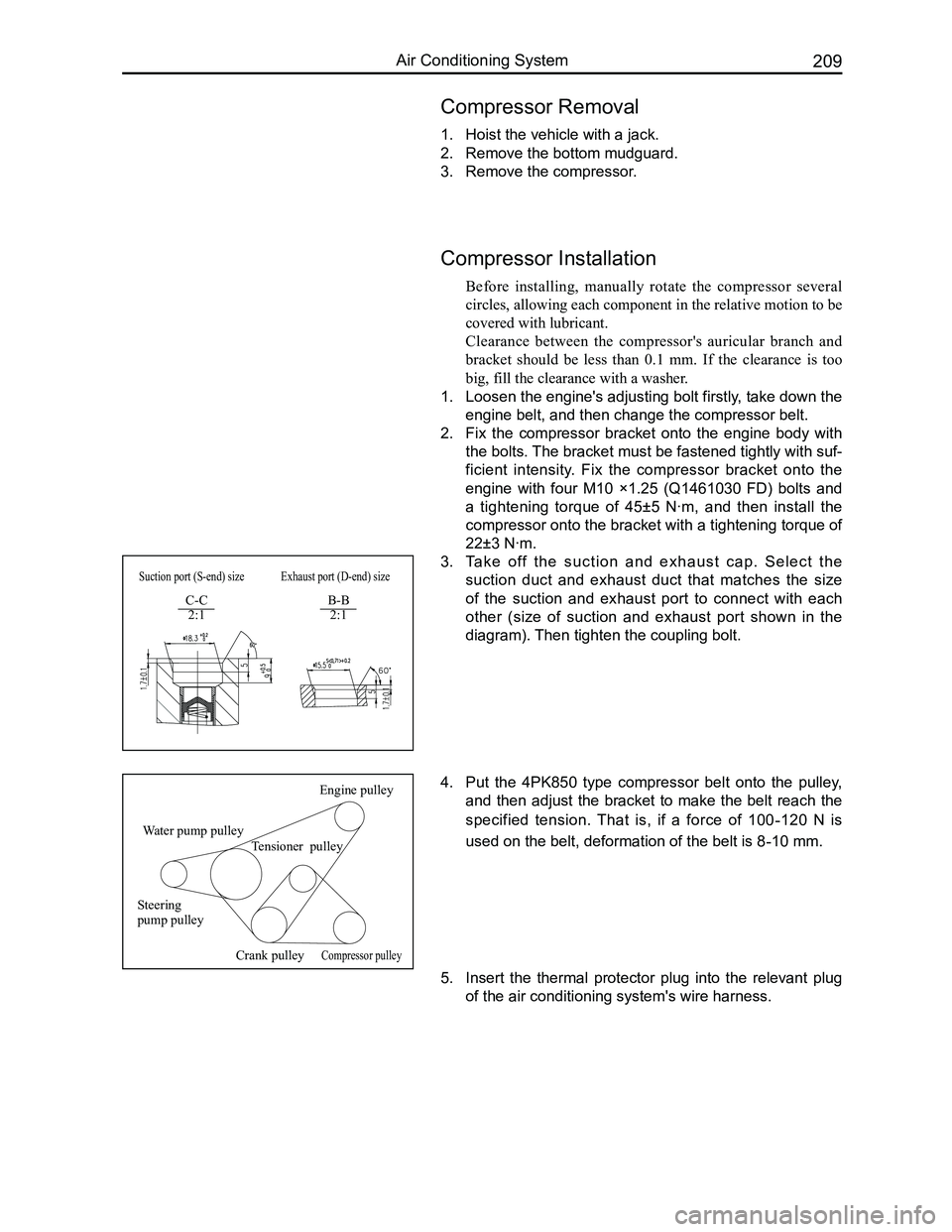

3. Ta k e o ff t h e s u c t i o n a n d e x h a u s t c a p . S e l e c t t h e

suction duct and exhaust duct that matches the size

of the suction and exhaust port to connect with each

other (size of suction and exhaust port shown in the

diagram). Then tighten the coupling bolt.

Water pump pulley

Engine pulley

Tensioner pulley

Steering pump pulley

Crank pulleyCompressor pulley

Suction port (S-end) sizeExhaust port (D-end) size

C-C 2:1B-B 2:1

4. Put the 4PK850 type compressor belt onto the pulley,

and then adjust the bracket to make the belt reach the

specified tension. That is, if a force of 100-120 N is

used on the belt, deformation of the belt is 8-10 mm.

5. Insert the thermal protector plug into the relevant plug

of the air conditioning system's wire harness.