engine oil GREAT WALL FLORID 2008 Workshop Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 161 of 281

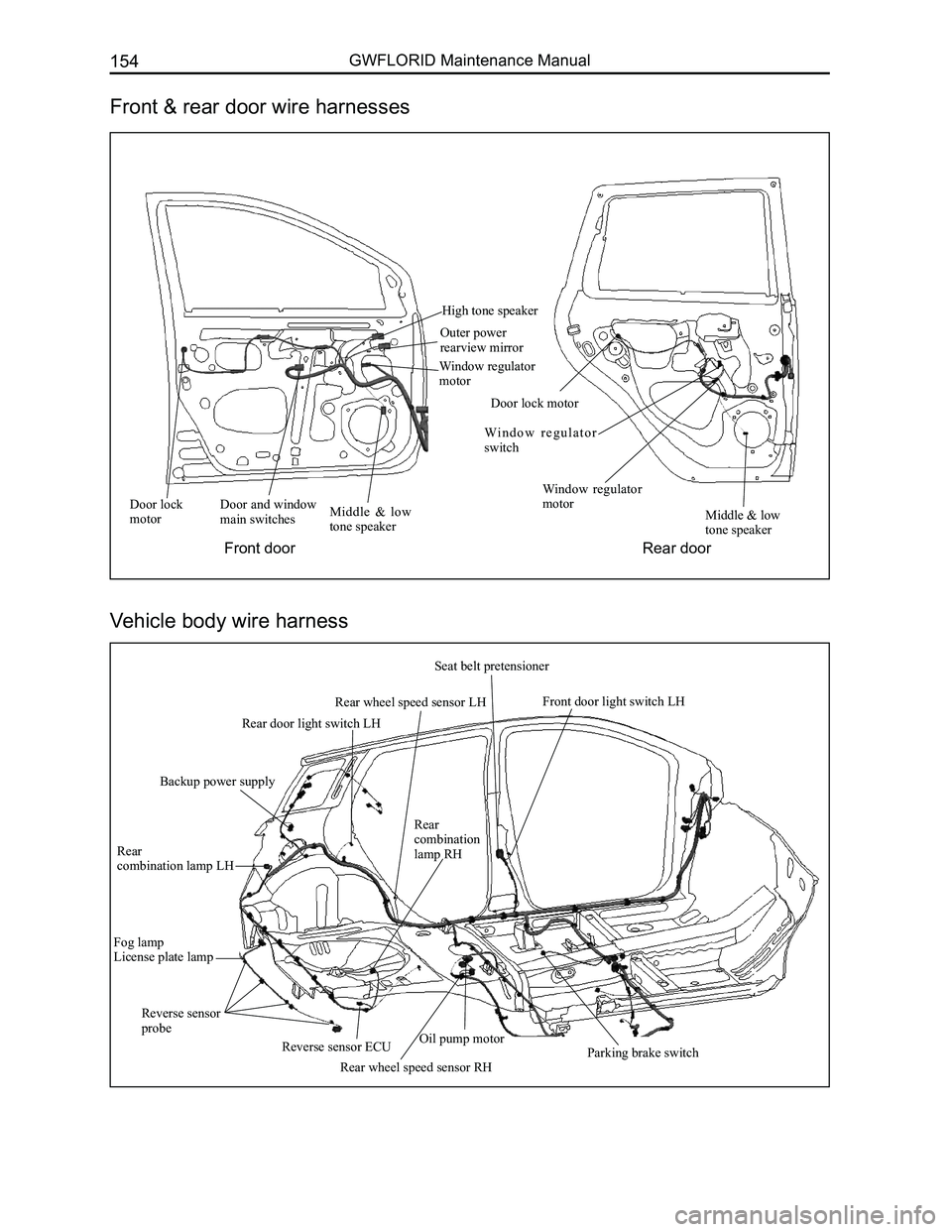

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual154

Door lock motorDoor and window main switchesMiddle & low tone speaker

High tone speaker

Outer power rearview mirror

Window regulator motor

Door lock motor

Wi n d o w r e g u l a t o r switch

Window regulator motorMiddle & low tone speaker

Fog lampLicense plate lamp

Rear

combination lamp LH

Rear combination lamp RH

Rear wheel speed sensor RHParking brake switch

Front door light switch LH

Seat belt pretensioner

Rear wheel speed sensor LH

Rear door light switch LH

Backup power supply

Front & rear door wire harnesses

Vehicle body wire harness

Front doorRear door

Reverse sensor ECU

Reverse sensor probeOil pump motor

Page 162 of 281

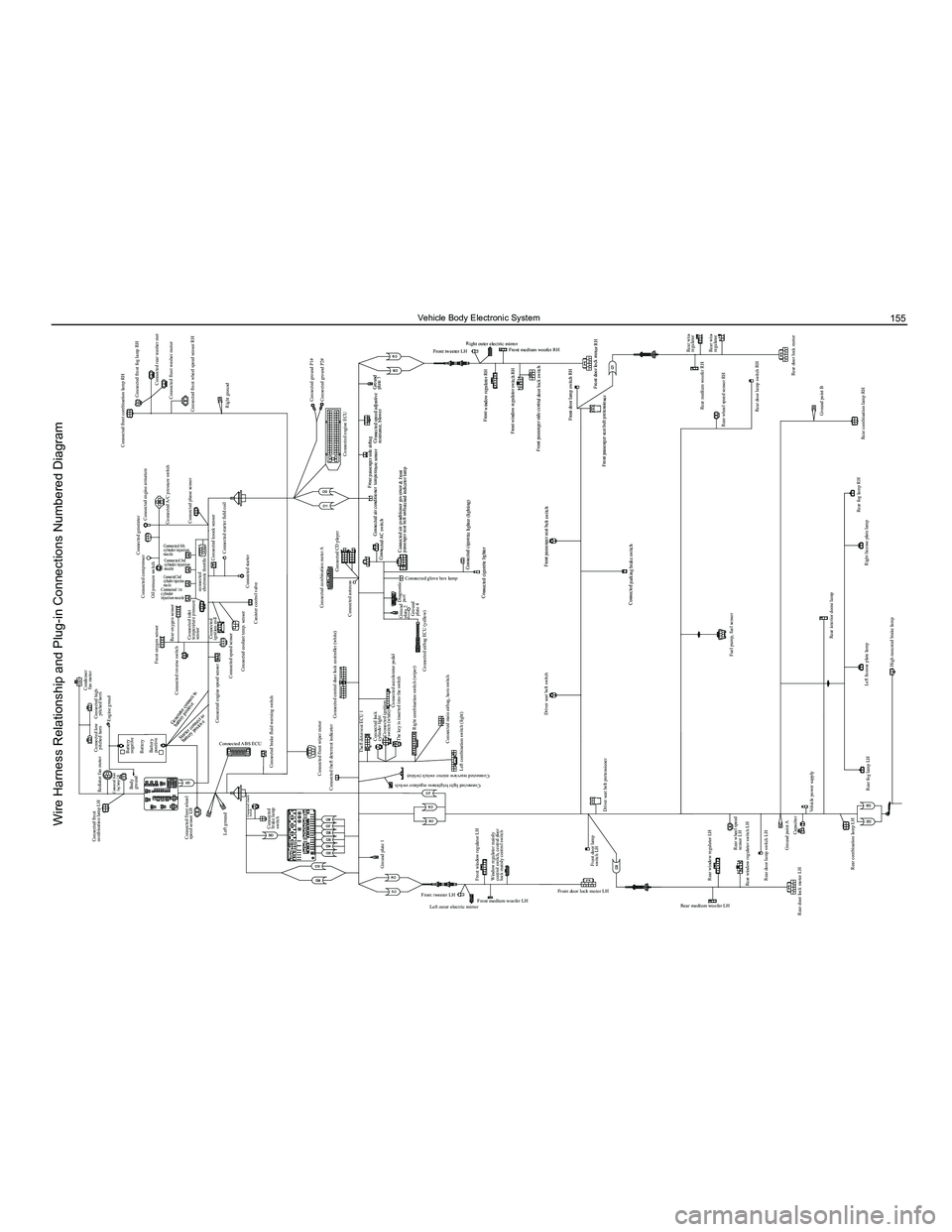

Downloaded from www.Manualslib.com manuals search engine 155Vehicle Body Electronic System

Condenser fan motor

Connected compressor

Oil pressure switch

Front oxygen sensor

Connected reverse switch

Connected engine speed sensor Connected

ignition coil

Connected speed sensor Connected coolant temp. sensor

Canister control valve

Connected combination meter A

Connected antenna

Diagnostic port

Connected AC switch Connected air conditioner temperature sensor

Front passenger side airbag

Connected speed adjustive resistance, blower

Front window regulator RH

Front window regulator switch RH

Front medium woofer RH

Front tweeter LH Right outer electric mirror

Front passenger side central door lock switch

Front door lamp switch RH

Front passenger seat belt pretensioner Front door lock motor RH

Ground

plate 3

Connected cigarette lighter (lighting)

Connected cigarette lighter

Front passenger seat belt switch

Connected parking brake switch Connected air conditioner governor & front

passenger seat belt unfastened indicator lamp

Connected CD player

Connected engine ECUConnected ground P1#

Connected ground P2#

Connected starter

Connected knock sensor

Connected starter field coil

Connected inlet

temperature pressure

sensor

connected

electronic throttle

Rear oxygen sensor

Connected 4th

cylinder injection

nozzle

Connected 3rd

cylinder injection

nozzle

Connected 2nd

cylinder injection

nozzle

Connected 1st

cylinder

injection nozzle

Connected generator

Connected engine armature Connected front combination lamp RH

Connected front fog lamp RH

Connected rear washer motor

Connected front washer motor

Connected front wheel speed sensor RH

Right ground

Connected A/C pressure switch

Connected phase sensor

Connected low

pitched horn

Connected front

combination lamp LH

Rediator fan motor

Connected front

fog lamp LH

Connected high pitched horn

Battery

negative

Body

ground

Battery

Left ground Connected

brake lamp

switch Connected brake fluid warning switch

Connected theft deterrent indicator Theft deterrent ECU 1Connected lock

cylinder lightConnected ignition

switch (white)

The key is inserted into the switch

Right combination switch (wiper) Connected airbag ECU (yellow)Ground

plate 2

Ground

plate 4

Connected accelerator pedal

Ground plate 1

Left outer electric mirror

Front medium woofer LH Front door lock motor LH

Rear medium woofer LH

Rear window regulator switch LH

Rear door lock motor LH Rear door lamp switch LH

Ground point ACapacitor

Vehicle power supply

Rear fog lamp LH Left license plate lamp

High mounted brake lamp

Ground point Trunk opener switch

Trunk motorRear wiper motor

Rear windshield defroster “-”

Trunk lamp switch Right license plate lamp

Rear fog lamp RH

Rear combination lamp RHRear wheel speed sensor RH

Rear window

regulator RH

Rear window

regulator switch RH

Rear door lock motor RH

Rear door lamp switch RH Rear medium woofer RH

Ground point B

Rear combination lamp LH

Rear windshield defroster “+”

Rear wheel speed

sensor LH

Rear window regulator LH

Fuel pump, fuel sensor

Rear interior dome lamp

Front door lamp

switch LH

Driver seat belt pretensioner Driver seat belt switch

Front tweeter LH

Connected light brightness regulator switch

Connected rearview mirror switch (white)

Connected glove box lamp

Front window regulator LH Left combination switch (light)

Connected main airbag, horn switch

Window regulator mainly

control switch, central door

lock mainly control switch Connected central door lock controller (white)

Connected front wiper motor

Connected clutch

switch

Connected ABS ECUBattery

positive

Connected front wheel

speed sensor LH Engine groud

Starter connect to

battery positive

Generator connect to

battery positive

Wire Harness Relationship and Plug-in Connections Numbered Diagram

Page 176 of 281

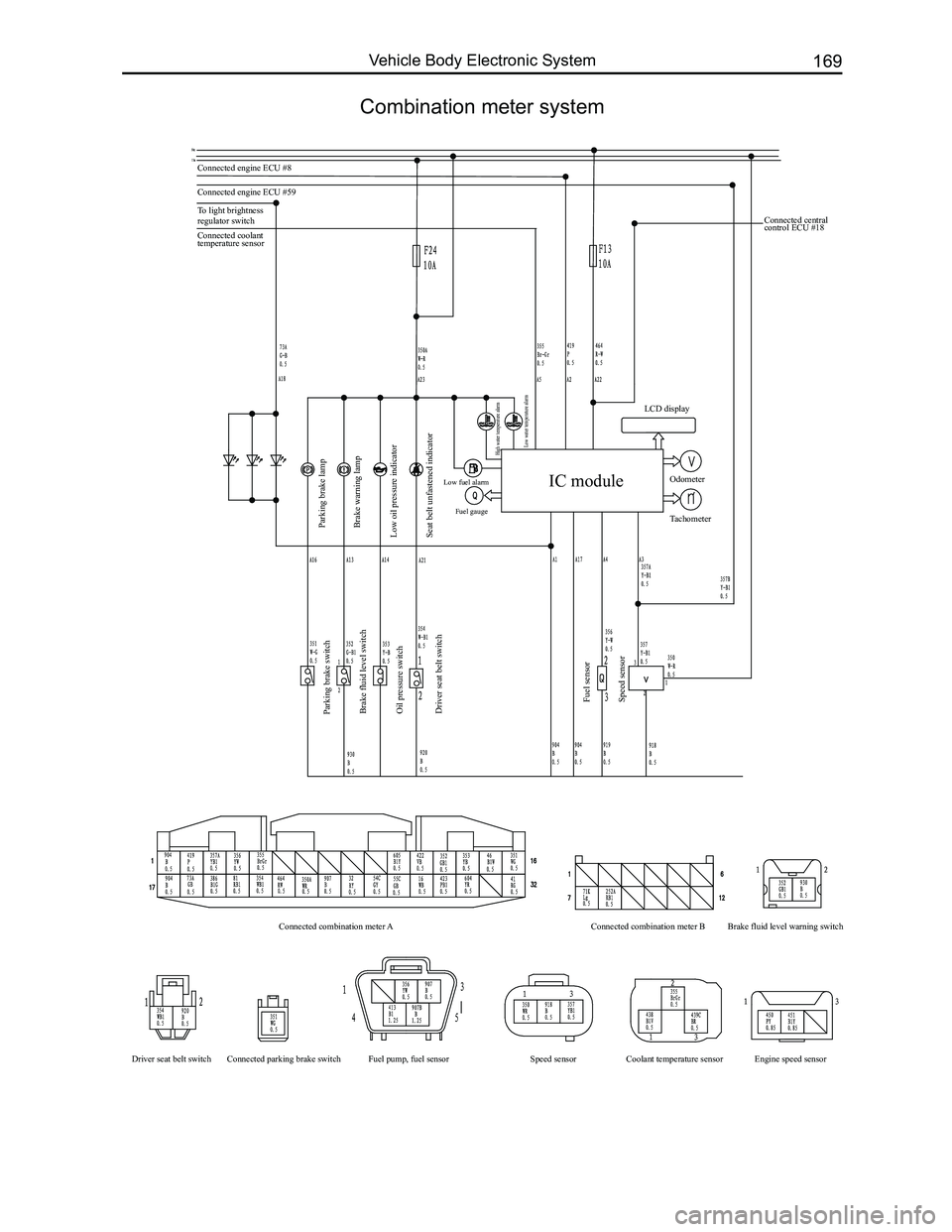

Downloaded from www.Manualslib.com manuals search engine 169Vehicle Body Electronic System

Combination meter system

Connected engine ECU #8

Connected engine ECU #59

To light brightness

regulator switch

Parking brake lamp

Parking brake switch

Brake fluid level switch

Oil pressure switch

Driver seat belt switch

Fuel sensor

Speed sensor

Connected combination meter A

Driver seat belt switch Connected parking brake switch Fuel pump, fuel sensor Coolant temperature sensor Engine speed sensor

Speed sensor Connected combination meter B

Brake fluid level warning switch

Brake warning lamp

Low oil pressure indicator

Seat belt unfastened indicator

Low fuel alarm Fuel gauge

High water temperature alarm

Low water temperature alarm

Connected coolant

temperature sensor Connected central

control ECU #18

IC module

LCD display

Odometer

Tachometer

Page 178 of 281

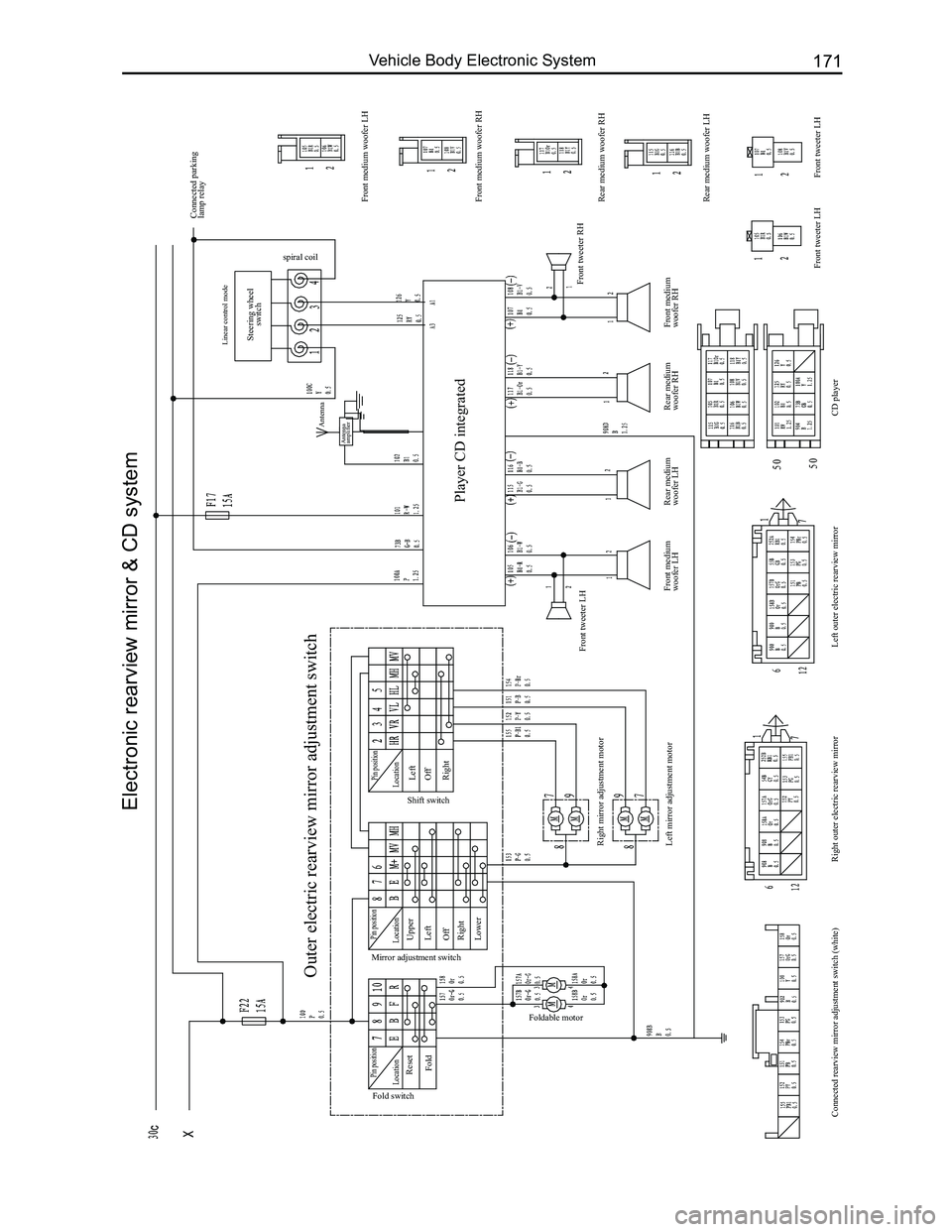

Downloaded from www.Manualslib.com manuals search engine 171Vehicle Body Electronic System

Electronic rearview mirror & CD system

Outer electric rearview mirror adjustment switch

Player CD integrated

Fold switch

Mirror adjustment switch

Foldable motor

Right mirror adjustment motor Steering wheel

switch Connected parking

lamp relay

Front medium woofer LH

Front medium woofer RH

Rear medium woofer RH

Rear medium woofer LH

Front tweeter LH Front tweeter LH

Front tweeter LH

Front medium

woofer LH Rear medium

woofer LH Rear medium

woofer RH Front medium

woofer RH Front tweeter RH

Linear control mode

Antenna

Antenna

amplifier

Left mirror adjustment motor

Connected rearview mirror adjustment switch (white) Right outer electric rearview mirror Left outer electric rearview mirror CD player

Shift switch

spiral coil

Location Reset

Upper

Left Left

Off Off

Right Right

Lower

Fold Pin position

Location

Location Pin position

Pin position

Page 180 of 281

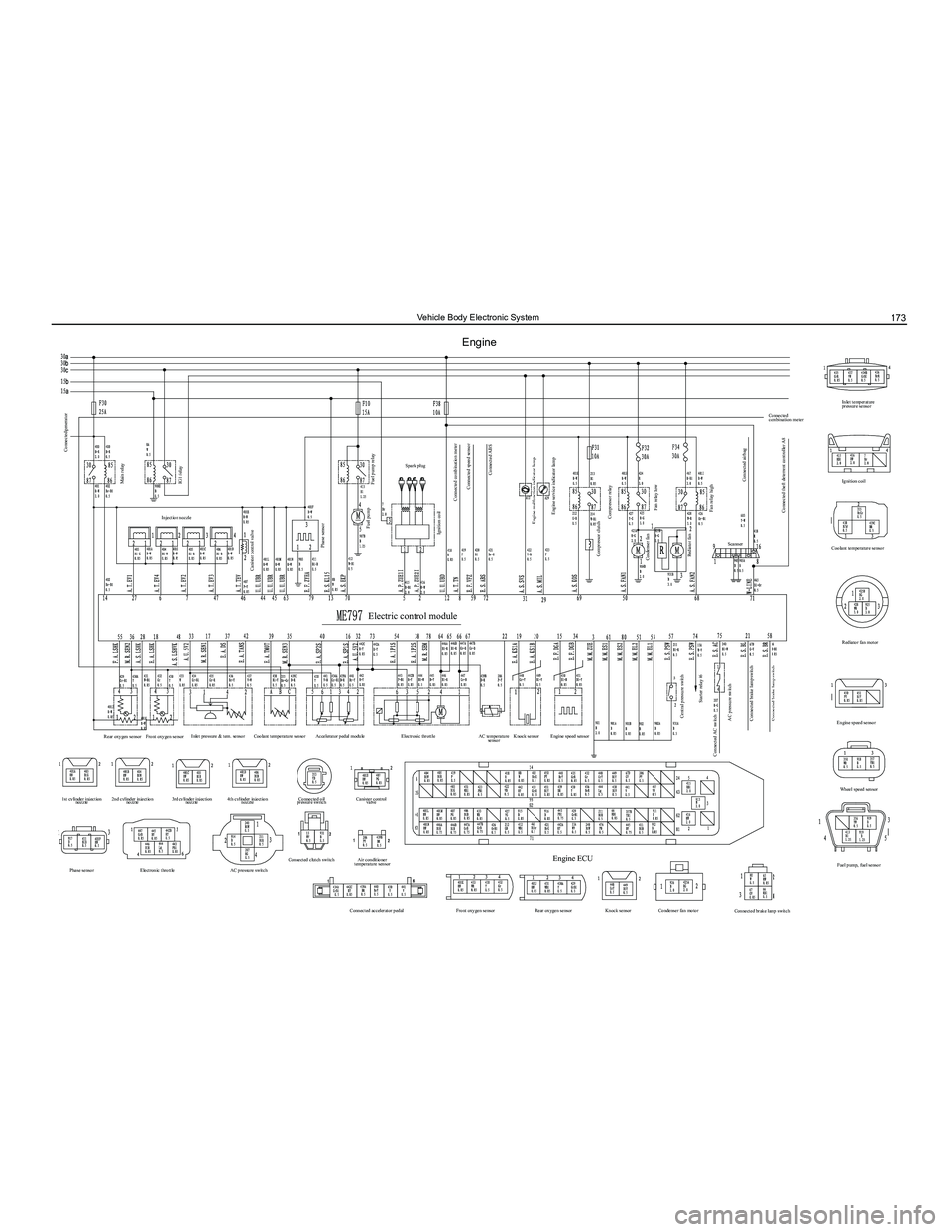

Downloaded from www.Manualslib.com manuals search engine 173Vehicle Body Electronic System

Engine

Connected generator

Canister control valve

Rear oxygen sensor

1st cylinder injection nozzle

Phase sensor Electronic throttle AC pressure switchConnected clutch switch

Air conditioner

temperature sensor

Connected accelerator pedal Front oxygen sensorRear oxygen sensorKnock sensorCondenser fan motor

Connected brake lamp switch

Engine ECU

2nd cylinder injection

nozzle 3rd cylinder injection

nozzle 4th cylinder injection

nozzle Connected oil

pressure switch Canister control

valve

Front oxygen sensor

Inlet pressure & tem. sensor

Coolant temperature sensor Accelerator pedal module Electronic throttle AC temperature

sensor Knock sensor

Engine speed sensor

Phase sensor

Fuel pump relay

Connected combination meter Connected speed sensor

Engine malfunction indicator lamp Engine service indicator lamp

Compressor relay

Compressor clutch

Central pressure switch Starter relay 86

Connected AC switch AC pressure switch

Connected brake lamp switch

Connected brake lamp switch Condenser fan

Rediator fan Fan relay lowScanner

Fan relay high

Connected airbag

Connected theft deterrent controller A8

Connected

combination meter

Ignition coil

Coolant temperature sensor

Rediator fan motor

Engine speed sensor Wheel speed sensor

Fuel pump, fuel sensor Inlet temperature

pressure sensor

Connected ABS

Spark plug

Fuel pump

Electric control module

Ignition coil

Main relay

Injection nozzle

IG1 relay

Page 183 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual176

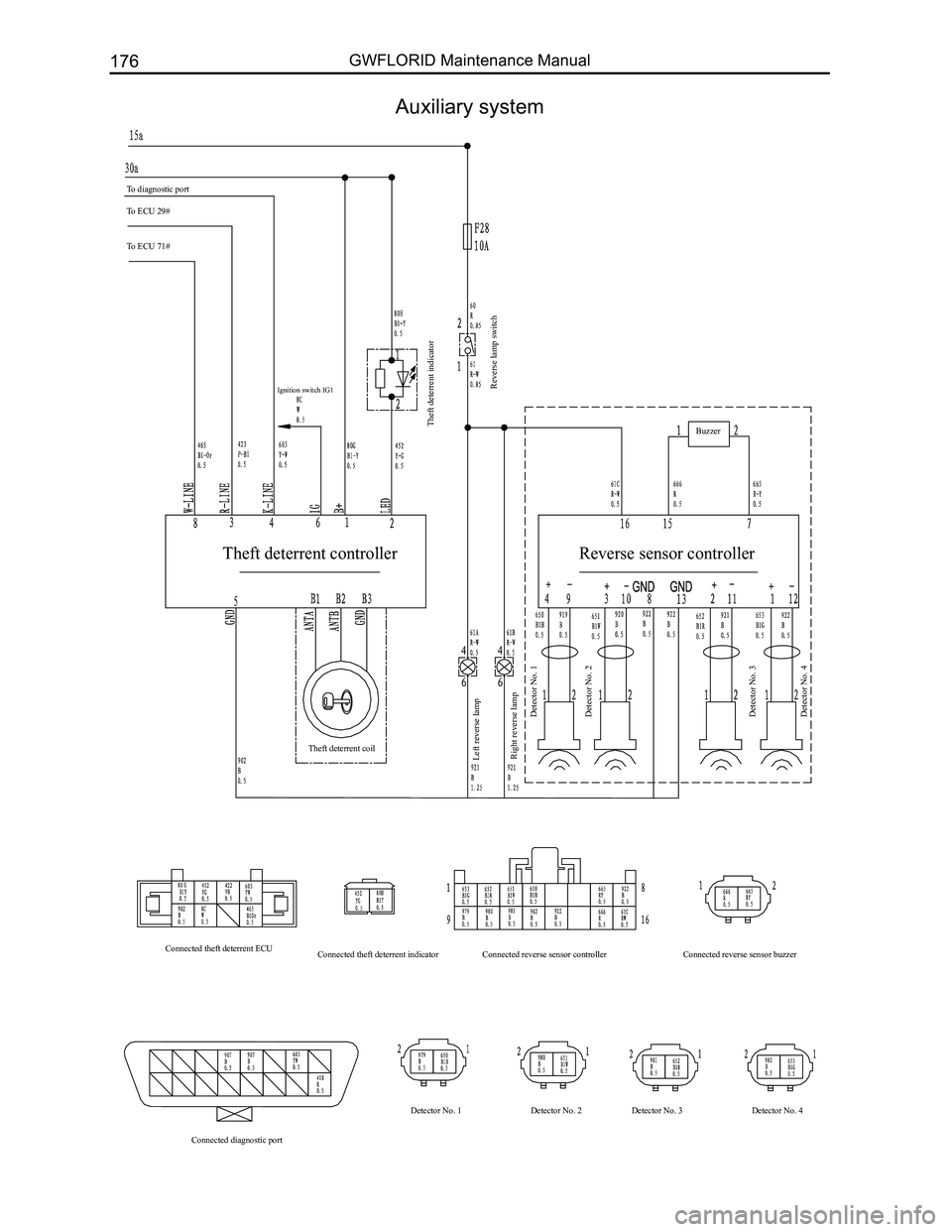

Auxiliary system

To diagnostic port

To ECU 29#

To ECU 71#

Theft deterrent indicatorReverse lamp switch

Left reverse lamp

Right reverse lamp Detector No. 1

Detector No. 2

Detector No. 3

Detector No. 4

Theft deterrent coil

Connected theft deterrent ECU Connected diagnostic port Detector No. 1

Detector No. 2Detector No. 3 Detector No. 4

Connected theft deterrent indicator

Connected reverse sensor controller Connected reverse sensor buzzerBuzzer

Ignition switch IG1

Theft deterrent controller

Reverse sensor controller

Page 187 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual180

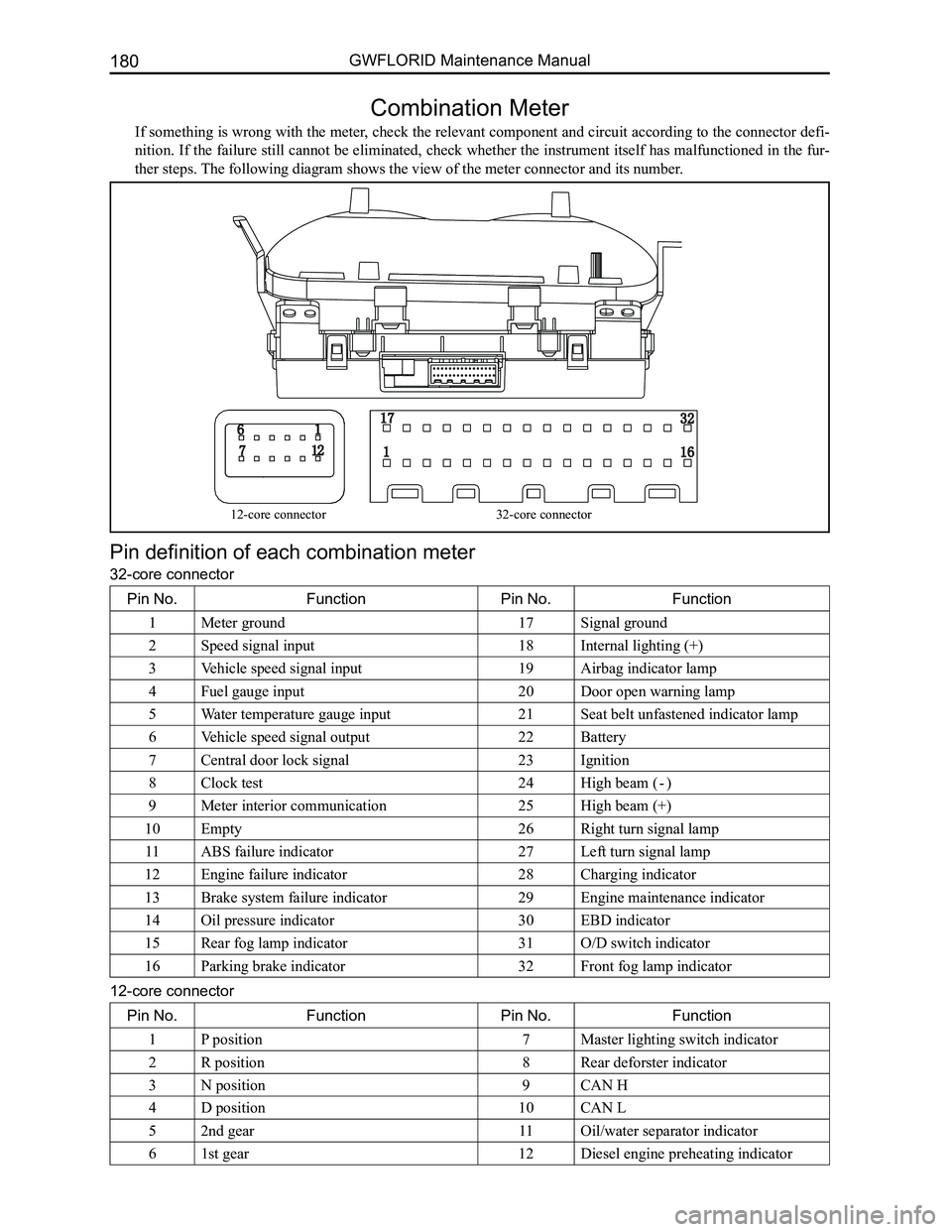

Combination Meter

If something is wrong with the meter, check the relevant component and circuit according to the connector defi-

nition. If the failure still cannot be eliminated, check whether the instrument itself has malfunctioned in the fur-

ther steps. The following diagram shows the view of the meter connector and its numb\

er.

Pin definition of each combination meter

32-core connector

Pin No.FunctionPin No.Function

1Meter ground17Signal ground

2Speed signal input18Internal lighting (+)

3Vehicle speed signal input19Airbag indicator lamp

4Fuel gauge input20Door open warning lamp

5Water temperature gauge input21Seat belt unfastened indicator lamp

6Vehicle speed signal output22Battery

7Central door lock signal23Ignition

8Clock test24High beam ( - )

9Meter interior communication25High beam (+)

10Empty26Right turn signal lamp

11ABS failure indicator27Left turn signal lamp

12Engine failure indicator28Charging indicator

13Brake system failure indicator29Engine maintenance indicator

14Oil pressure indicator30EBD indicator

15Rear fog lamp indicator31O/D switch indicator

16Parking brake indicator32Front fog lamp indicator

12-core connector

Pin No.FunctionPin No.Function

1P position7Master lighting switch indicator

2R position8Rear deforster indicator

3N position9CAN H

4D position10CAN L

52nd gear11Oil/water separator indicator

61st gear12Diesel engine preheating indicator

12-core connector32-core connector

Page 191 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual184

Power Windows

The GWFLORID electric power window actuator consist of a motor and module. Its functions include: jam

protection, centralized control rise, soft-stop, characterized by easy control, long life, etc.

The functions of electric power window actuator

1. Jam protection

Power windows have an jam protection function when manually or automatically rising after it has been

initialized. There is no limit on the amount of jam protections. When room temperature is 25±5oC, wire

resistance 150 mΩ and 14.5 V working voltage, the jam protection force risen glass is less than 100 N. When the

window is manually or electrically rising, once it encounters a force greater than the jam protection force, the glass

will immediately stop rising and make the motor rotate in reverse. Rever\

se rotation distance is about 125 mm.

2. Centralized control rise

The central door lock controller provides four lifters with a low level signal. The power windows will close until

they are completely closed. This enables the two power window actuators to start separately, which can avoid

hitting peak currents if they start up at the same time. As long as the centralized controller's rising pin receives

the low level signal, the motor will close the window until it is comple\

tely closed.

3. Soft-stop

If the motor suffers from an impacting block when the window is rolled all the way up or all the way down, it

would shorten the power window actuator's use life. In order to avoid this, the soft-stop function must be used,

in which both manual and automatic rolling up and down should have this \

function.

(a) Soft close function:

When the window is about to get to the top, that is to say, when it's rising to the soft-stop point, the engine's

power will cut off to make the motor stop working, meanwhile the rising inertia will continue to roll the

window up to the top. The soft-stop point is about 2 mm under the top limiting position.

(b) When the window is about to lower to the bottom, that is to say, when it's lowering to the soft-stop point,

the engine's power will cut off to make it stop working, meanwhile the lowering inertia will continue to roll

the window down to the bottom. The soft-stop point is about 12 mm above the bottom limiting position.

(c) Zero position calibration: This position takes the top limiting position as the zero position. In order to

guarantee reliable and safer system operation while in use, the zero pos\

ition will need constant calibration.

Manual calibration: When the window stops at the rising soft-stop position after rising for a period,

press the rise button so it will rise to the limiting position. Zero cal\

ibration is then complete.

Automatic calibration: After the motor runs forward and reverse more than 20 times, it will undergo

zero position calibration one time. That is to say, when it completely starts or stops operating, the motor will

be blocked one time. Currently, there is no soft close or start-up function. Zero position calibration is com-

pleted when the window is completely closed to the limiting position.

4. Motor locked protection

The control module will cut off the power supply to stop the motor from working within 250 ms of the l\

ocking.

5. Motor temperature protection

When the control module is powered on, the initial temperature of the motor is set at 40oC. There are two

temperature limits for the motor's thermal protection function. If the temperature of the coil exceeds the first

temperature limit (170oC), the motor will not respond to any new operation input, but it will still complete the present

operation. If the motor's temperature exceeds the first temperature limit during its operation, it will keep working until

the temperature of the motor coil reaches the second temperature limit (190oC), then the motor will not be limited by

the second temperature's threshold while reversing, so as to guarantee the safety of the users. Once the temperature of

the motor has lowered below the temperature limit, the motor will work normally.

6. Self-diagnostic protection function

So as to guarantee the system's reliability while improving the system's average non-failure time, self-diagnostic

protection measures are used: If the power supply voltage exceeds 16 V, the control module will close the auto-

rising function.

(a) Switch contact point adhesion:

If it is detected that the switch contact point adhesion has reached up to 10 m input instructions will no

longer be received. If later the switch contact is detected to be disconnected again, it's function will return

to normal.

(b) Relay contact point adhesion:

The power window actuator is controlled by two contact point relays.

After a shutoff command is sent to one of the relays, if the system detects that this relay is still on, then

the system will choose this relay contact point for adhesion. Thereupon, the system will send out another

command to make the other electric relay switch on as well, so as to guarantee the motor's power supply is

Page 193 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual186

Immobilizer System

Immobilizer system composition

This vehicle's engine immobilizer system consists of a theft deterrent ECU assembly, a theft deterrent coil as-

sembly, and two theft deterrent converter assemblies. The theft deterrent coil assembly is put on the head of

ignition lock cylinder, with the other end connected to the theft deterrent ECU assembly. The two theft deterrent

converter assemblies are separately installed inside the plastic handles\

of the two keys.

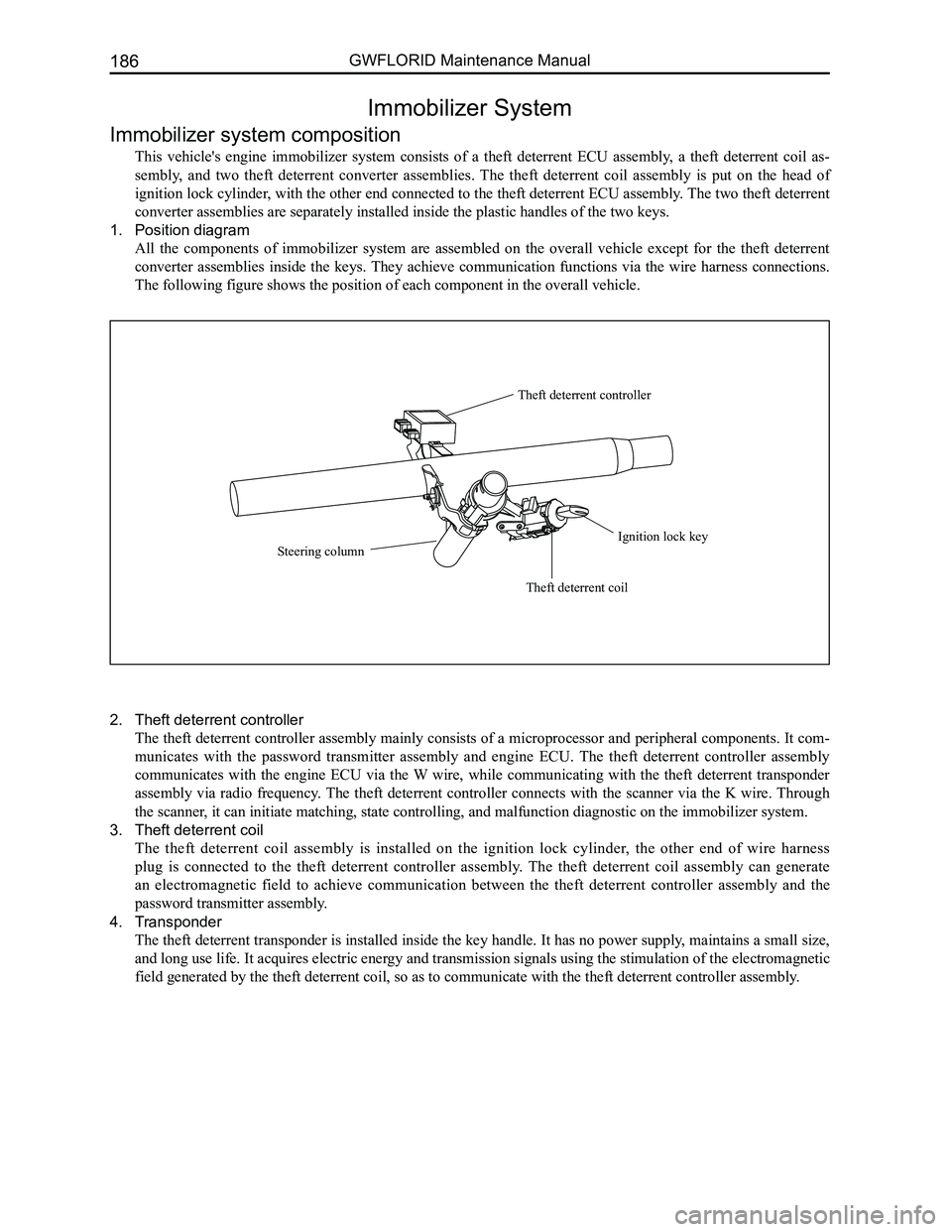

1. Position diagram

All the components of immobilizer system are assembled on the overall vehicle except for the theft deterrent

converter assemblies inside the keys. They achieve communication functions via the wire harness connections.

The following figure shows the position of each component in the overall\

vehicle.

Theft deterrent controller

Ignition lock key

Theft deterrent coil

Steering column

2. Theft deterrent controller

The theft deterrent controller assembly mainly consists of a microprocessor and peripheral components. It com-

municates with the password transmitter assembly and engine ECU. The theft deterrent controller assembly

communicates with the engine ECU via the W wire, while communicating with the theft deterrent transponder

assembly via radio frequency. The theft deterrent controller connects with the scanner via the K wire. Through

the scanner, it can initiate matching, state controlling, and malfunction diagnosti\

c on the immobilizer system.

3. Theft deterrent coil

The theft deterrent coil assembly is installed on the ignition lock cylinder, the other end of wire harness

plug is connected to the theft deterrent controller assembly. The theft deterrent coil assembly can generate

an electromagnetic field to achieve communication between the theft deterrent controller assembly and the

password transmitter assembly.

4. Transponder

The theft deterrent transponder is installed inside the key handle. It has no power supply, maintains a small size,

and long use life. It acquires electric energy and transmission signals using the stimulation of the electromagnetic

field generated by the theft deterrent coil, so as to communicate with t\

he theft deterrent controller assembly.

Page 194 of 281

Downloaded from www.Manualslib.com manuals search engine 187Electrical Accessories

Diagnostic

scanner

Engine ECU

Battery

+-

Ignition switch

LED

620 Ω

LED

ON

ANTA

GND

ANTB

Battery

Ground

W wire

R wire

K wire

A4

A3

A1

A2

A8

A5

A7B3

B2

B1

Coil

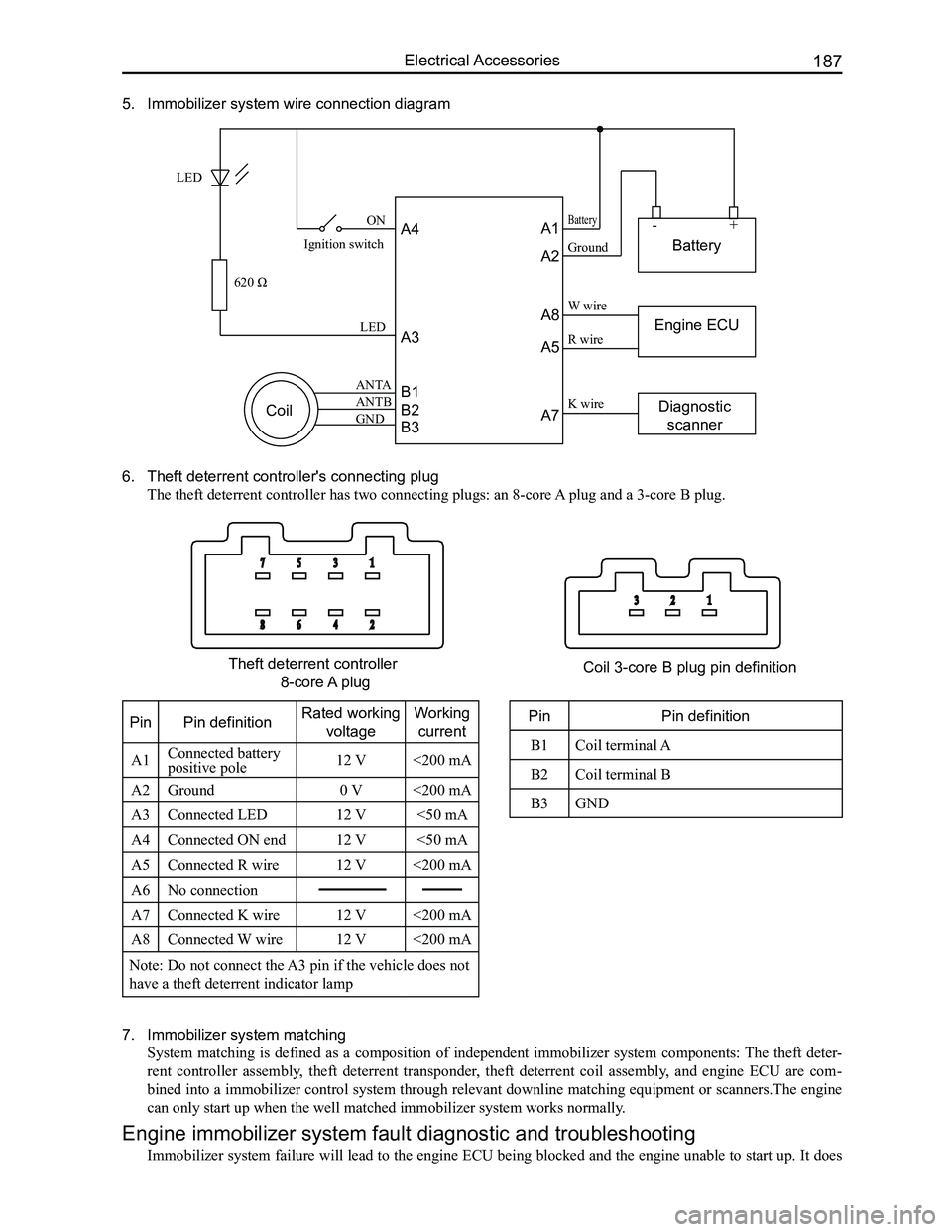

6. Theft deterrent controller's connecting plug

The theft deterrent controller has two connecting plugs: an 8-core A plug and a 3-core B plug.

PinPin definition

B1Coil terminal A

B2Coil terminal B

B3GND

Theft deterrent controller

8-core A plug

Coil 3-core B plug pin definition

7. Immobilizer system matching

System matching is defined as a composition of independent immobilizer system components: The theft deter-

rent controller assembly, theft deterrent transponder, theft deterrent coil assembly, and engine ECU are com-

bined into a immobilizer control system through relevant downline matching equipment or scanners.The engine

can only start up when the well matched immobilizer system works normall\

y.

Engine immobilizer system fault diagnostic and troubleshooting

Immobilizer system failure will lead to the engine ECU being blocked and the engine unable to start up. It does

PinPin definitionRated working

voltage

Working

current

A1Connected battery positive pole12 V<200 mA

A2Ground0 V<200 mA

A3Connected LED12 V<50 mA

A4Connected ON end12 V<50 mA

A5Connected R wire12 V<200 mA

A6No connection

A7Connected K wire12 V<200 mA

A8Connected W wire12 V<200 mA

Note: Do not connect the A3 pin if the vehicle does not

have a theft deterrent indicator lamp

5. Immobilizer system wire connection diagram