engine oil GREAT WALL FLORID 2008 Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 217 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual210

Electromagnetic Clutch

Clutch composition

Electromagnetic clutch consists of an armature, a solenoid,

and a pulley.

Areas of importance during clutch usage

B e c a u s e t h e j o i n t o f t h e e l e c t r o m a g n e t i c c l u t c h

operates under high speeds, separation-joint marks on

the pulley and armature are completely normal, and do

not harm clutch usage.

The clutch's operating voltage must be consistent with

the specified voltage rating. Too high or too low will

affect its normal usage.

The clearance between the coil and the pulley is

very important. If too big, the effect of the magnetic

field reduces. If too small, the high speed pulley rubs

against the fixed coil, causing the clutch to burn.

The clearance between the armature and the pulley

is also very important. If too big, it leads to insufficient

clutch pull-in force. If too small, it may cause armature

damage.

Clutch removal

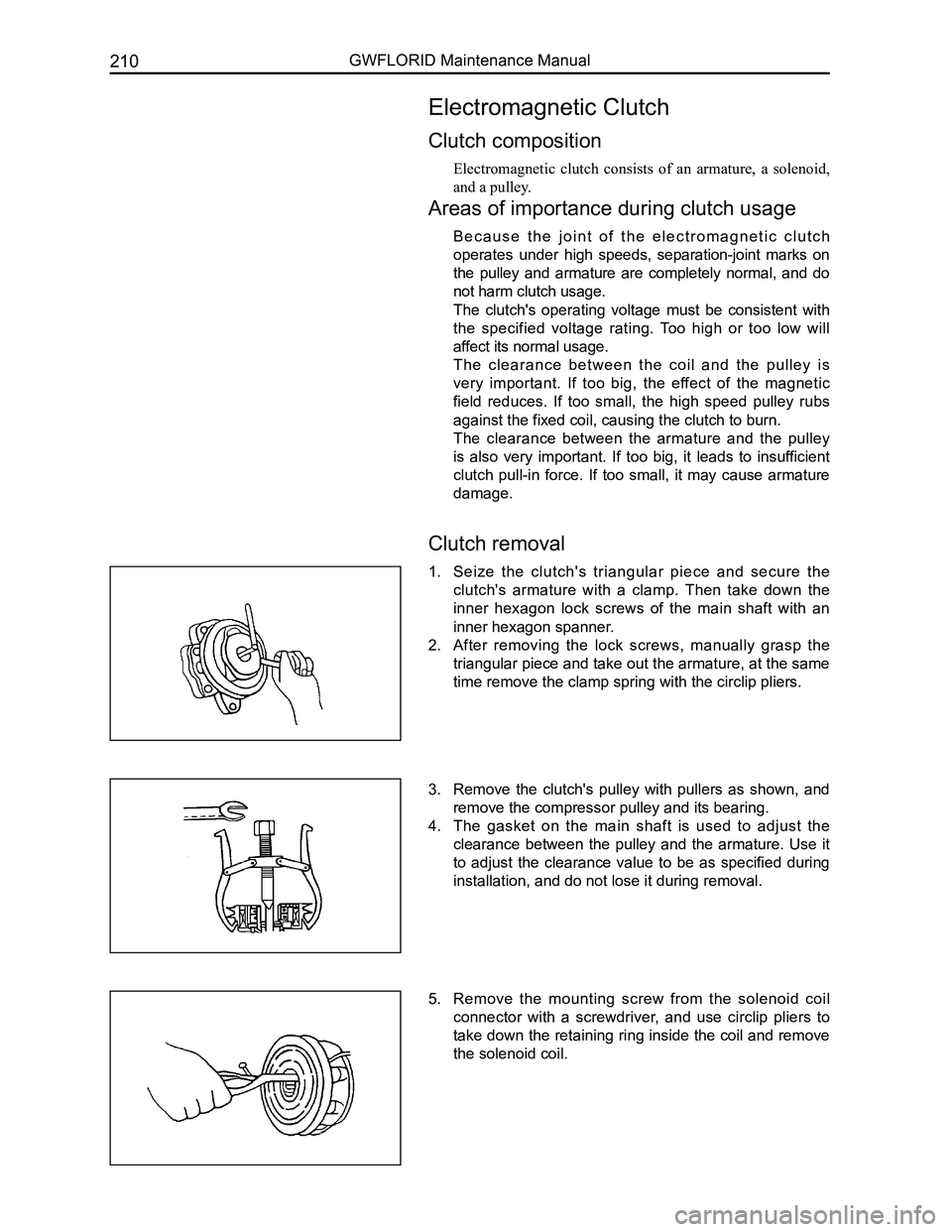

1. Seize the clutch's triangular piece and secure the

clutch's armature with a clamp. Then take down the

inner hexagon lock screws of the main shaft with an

inner hexagon spanner.

2. After removing the lock screws, manually grasp the

triangular piece and take out the armature, at the same

time remove the clamp spring with the circlip pliers.

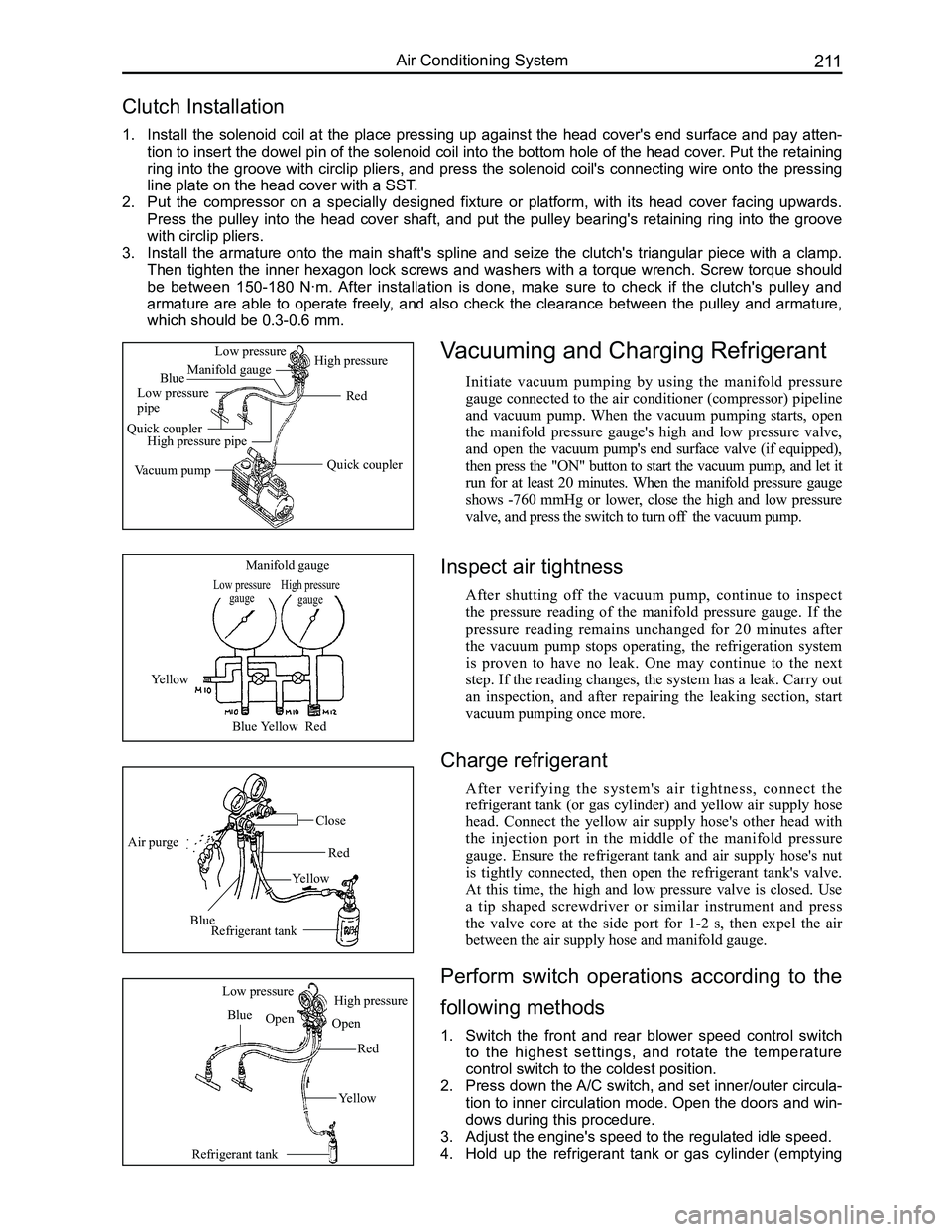

3. Remove the clutch's pulley with pullers as shown, and

remove the compressor pulley and its bearing.

4. The gasket on the main shaft is used to adjust the

clearance between the pulley and the armature. Use it

to adjust the clearance value to be as specified during

installation, and do not lose it during removal.

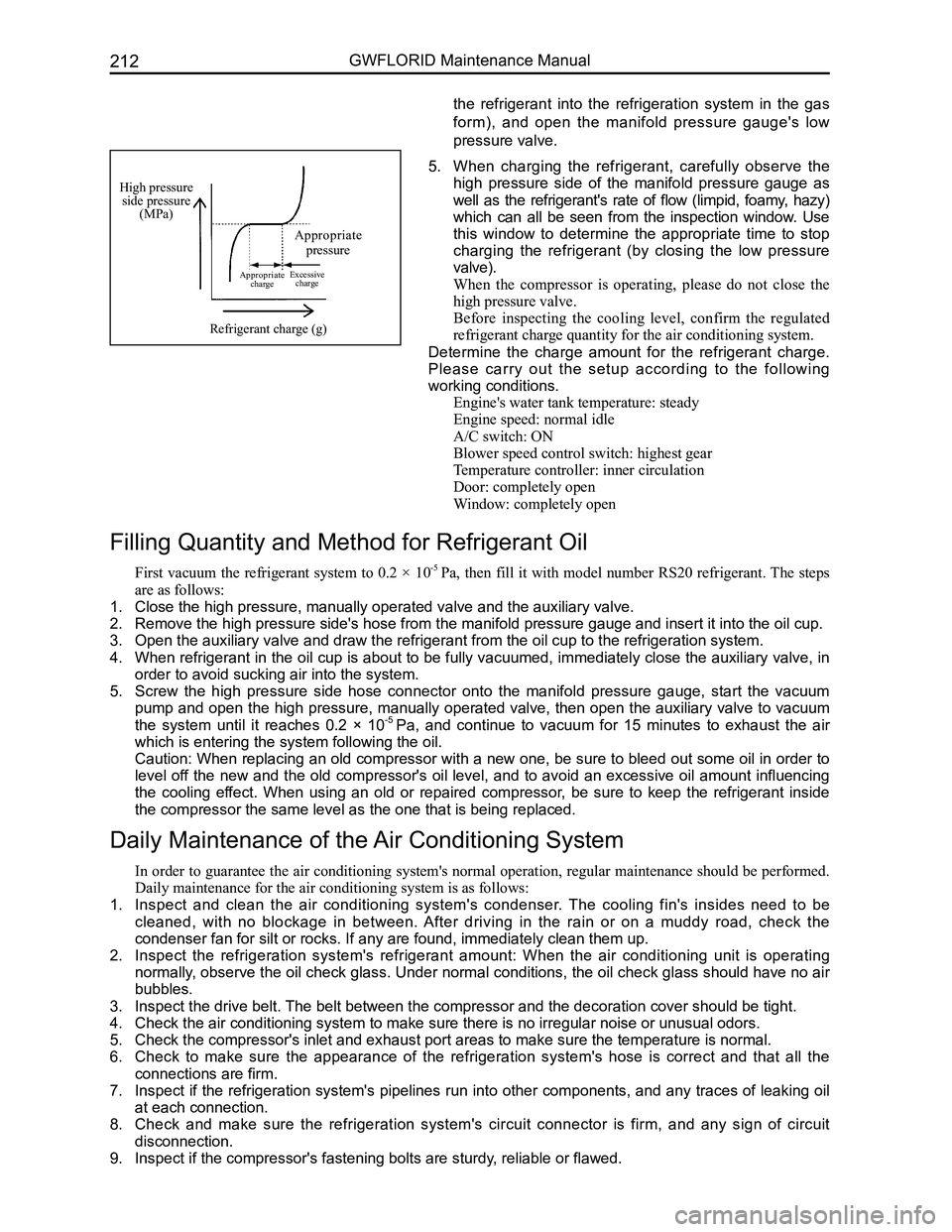

5. Remove the mounting screw from the solenoid coil

connector with a screwdriver, and use circlip pliers to

take down the retaining ring inside the coil and remove

the solenoid coil.

Page 218 of 281

Downloaded from www.Manualslib.com manuals search engine 211Air Conditioning System

Clutch Installation

1. Install the solenoid coil at the place pressing up against the head cover's end surface and pay atten-

tion to insert the dowel pin of the solenoid coil into the bottom hole of the head cover. Put the retaining

ring into the groove with circlip pliers, and press the solenoid coil's connecting wire onto the pressing

line plate on the head cover with a SST.

2. Put the compressor on a specially designed fixture or platform, with its head cover facing upwards.

Press the pulley into the head cover shaft, and put the pulley bearing's retaining ring into the groove

with circlip pliers.

3. Install the armature onto the main shaft's spline and seize the clutch's triangular piece with a clamp.

Then tighten the inner hexagon lock screws and washers with a torque wrench. Screw torque should

be between 150-180 N·m. After installation is done, make sure to check if the clutch's pulley and

armature are able to operate freely, and also check the clearance between the pulley and armature,

which should be 0.3-0.6 mm.

Vacuuming and Charging Refrigerant

Initiate vacuum pumping by using the manifold pressure

gauge connected to the air conditioner (compressor) pipeline

and vacuum pump. When the vacuum pumping starts, open

the manifold pressure gauge's high and low pressure valve,

and open the vacuum pump's end surface valve (if equipped),

then press the "ON" button to start the vacuum pump, and let it

run for at least 20 minutes. When the manifold pressure gauge

shows -760 mmHg or lower, close the high and low pressure

valve, and press the switch to turn off the vacuum pump.

Low pressure gaugeHigh pressure gauge

Manifold gauge

Yellow

BlueYellowRed

Air purge

Blue

Yellow

Red

Close

Refrigerant tank

Refrigerant tank

Blue

Red

Yellow

Low pressureHigh pressure

OpenOpen

Quick coupler

Red

Manifold gauge

Low pressure pipe

Quick couplerHigh pressure pipe

Vacuum pump

Low pressureHigh pressure

Blue

Inspect air tightness

After shutting off the vacuum pump, continue to inspect

the pressure reading of the manifold pressure gauge. If the

pressure reading remains unchanged for 20 minutes after

the vacuum pump stops operating, the refrigeration system

is proven to have no leak. One may continue to the next

step. If the reading changes, the system has a leak. Carry out

an inspection, and after repairing the leaking section, start

vacuum pumping once more.

Charge refrigerant

After verifying the system's air tightness, connect the

refrigerant tank (or gas cylinder) and yellow air supply hose

head. Connect the yellow air supply hose's other head with

the injection port in the middle of the manifold pressure

gauge. Ensure the refrigerant tank and air supply hose's nut

is tightly connected, then open the refrigerant tank's valve.

At this time, the high and low pressure valve is closed. Use

a tip shaped screwdriver or similar instrument and press

the valve core at the side port for 1-2 s, then expel the air

between the air supply hose and manifold gauge.

Perform switch operations according to the

following methods

1. Switch the front and rear blower speed control switch

to the highest settings, and rotate the temperature

control switch to the coldest position.

2. Press down the A/C switch, and set inner/outer circula-

tion to inner circulation mode. Open the doors and win-

dows during this procedure.

3. Adjust the engine's speed to the regulated idle speed.

4. Hold up the refrigerant tank or gas cylinder (emptying

Page 219 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual212

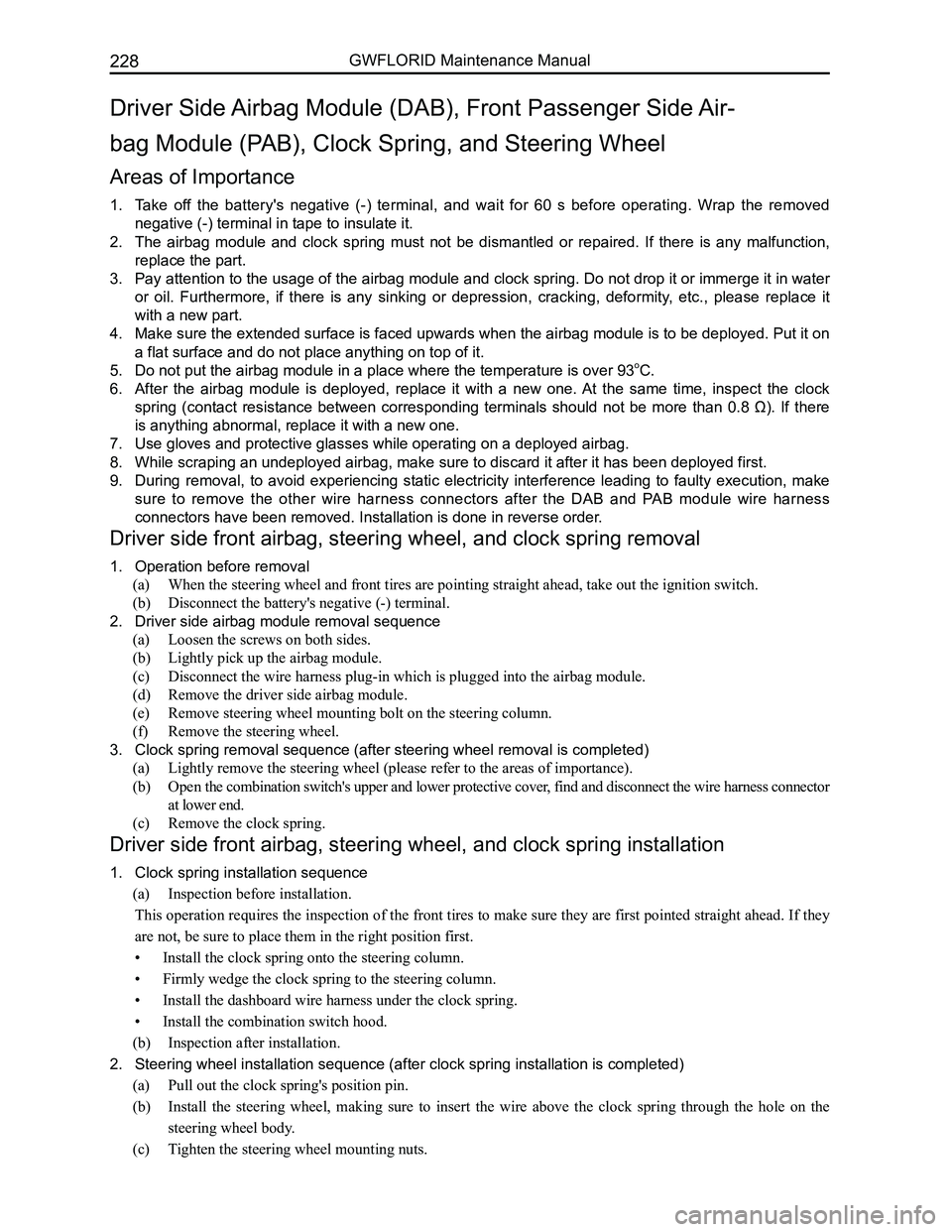

High pressure side pressure(MPa)

Appropriate pressure

Appropriate chargeExcessive charge

Refrigerant charge (g)

5. When charging the refrigerant, carefully observe the

high pressure side of the manifold pressure gauge as

well as the refrigerant's rate of flow (limpid, foamy, hazy)

which can all be seen from the inspection window. Use

this window to determine the appropriate time to stop

charging the refrigerant (by closing the low pressure

valve).

When the compressor is operating, please do not close the

high pressure valve.

Before inspecting the cooling level, confirm the regulated

refrigerant charge quantity for the air conditioning system.

Determine the charge amount for the refrigerant charge.

Please carry out the setup according to the following

working conditions.

Engine's water tank temperature: steady

Engine speed: normal idle

A/C switch: ON

Blower speed control switch: highest gear

Temperature controller: inner circulation

Door: completely open

Window: completely open

Filling Quantity and Method for Refrigerant Oil

First vacuum the refrigerant system to 0.2 × 10-5 Pa, then fill it with model number RS20 refrigerant. The steps

are as follows:

1. Close the high pressure, manually operated valve and the auxiliary valve\

.

2. Remove the high pressure side's hose from the manifold pressure gauge an\

d insert it into the oil cup.

3. Open the auxiliary valve and draw the refrigerant from the oil cup to th\

e refrigeration system.

4. When refrigerant in the oil cup is about to be fully vacuumed, immediately close the auxiliary valve, in

order to avoid sucking air into the system.

5. Screw the high pressure side hose connector onto the manifold pressure gauge, start the vacuum

pump and open the high pressure, manually operated valve, then open the auxiliary valve to vacuum

the system until it reaches 0.2 × 10-5 Pa, and continue to vacuum for 15 minutes to exhaust the air

which is entering the system following the oil.

Caution: When replacing an old compressor with a new one, be sure to bleed out some oil in order to

level off the new and the old compressor's oil level, and to avoid an excessive oil amount influencing

the cooling effect. When using an old or repaired compressor, be sure to keep the refrigerant inside

the compressor the same level as the one that is being replaced.

Daily Maintenance of the Air Conditioning System

In order to guarantee the air conditioning system's normal operation, regular maintenance should be performed.

Daily maintenance for the air conditioning system is as follows:

1. Inspect and clean the air conditioning system's condenser. The cooling fin's insides need to be

cleaned, with no blockage in between. After driving in the rain or on a muddy road, check the

condenser fan for silt or rocks. If any are found, immediately clean the\

m up.

2. Inspect the refrigeration system's refrigerant amount: When the air conditioning unit is operating

normally, observe the oil check glass. Under normal conditions, the oil check glass should have no air

bubbles.

3. Inspect the drive belt. The belt between the compressor and the decoration cover should be tight\

.

4. Check the air conditioning system to make sure there is no irregular noi\

se or unusual odors.

5. Check the compressor's inlet and exhaust port areas to make sure the tem\

perature is normal.

6. Check to make sure the appearance of the refrigeration system's hose is correct and that all the

connections are firm.

7. Inspect if the refrigeration system's pipelines run into other components, and any traces of leaking oil

at each connection.

8. Check and make sure the refrigeration system's circuit connector is firm, and any sign of circuit

disconnection.

9. Inspect if the compressor's fastening bolts are sturdy, reliable or flawed.

the refrigerant into the refrigeration system in the gas

form), and open the manifold pressure gauge's low

pressure valve.

Page 235 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual228

Driver Side Airbag Module (DAB), Front Passenger Side Air-

bag Module (PAB), Clock Spring, and Steering Wheel

Areas of Importance

1. Take off the battery's negative (-) terminal, and wait for 60 s before operating. Wrap the removed

negative (-) terminal in tape to insulate it.

2. The airbag module and clock spring must not be dismantled or repaired. If there is any malfunction,

replace the part.

3. Pay attention to the usage of the airbag module and clock spring. Do not drop it or immerge it in water

or oil. Furthermore, if there is any sinking or depression, cracking, deformity, etc., please replace it

with a new part.

4. Make sure the extended surface is faced upwards when the airbag module is to be deployed. Put it on

a flat surface and do not place anything on top of it.

5. Do not put the airbag module in a place where the temperature is over 93\

oC.

6. After the airbag module is deployed, replace it with a new one. At the same time, inspect the clock

spring (contact resistance between corresponding terminals should not be more than 0.8 Ω). If there

is anything abnormal, replace it with a new one.

7. Use gloves and protective glasses while operating on a deployed airbag.

8. While scraping an undeployed airbag, make sure to discard it after it ha\

s been deployed first.

9. During removal, to avoid experiencing static electricity interference leading to faulty execution, make

sure to remove the other wire harness connectors after the DAB and PAB module wire harness

connectors have been removed. Installation is done in reverse order.

Driver side front airbag, steering wheel, and clock spring removal

1. Operation before removal

(a) When the steering wheel and front tires are pointing straight ahead, take out the ignition swit\

ch.

(b) Disconnect the battery's negative (-) terminal.

2. Driver side airbag module removal sequence

(a) Loosen the screws on both sides.

(b) Lightly pick up the airbag module.

(c) Disconnect the wire harness plug-in which is plugged into the airbag module.

(d) Remove the driver side airbag module.

(e) Remove steering wheel mounting bolt on the steering column.

(f) Remove the steering wheel.

3. Clock spring removal sequence (after steering wheel removal is complete\

d)

(a) Lightly remove the steering wheel (please refer to the areas of importance).

(b) Open the combination switch's upper and lower protective cover, find and disconnect the wire harness connector

at lower end.

(c) Remove the clock spring.

Driver side front airbag, steering wheel, and clock spring installation

1. Clock spring installation sequence

(a) Inspection before installation.

This operation requires the inspection of the front tires to make sure they are first pointed straight ahead. If they

are not, be sure to place them in the right position first.

• Install the clock spring onto the steering column.

• Firmly wedge the clock spring to the steering column.

• Install the dashboard wire harness under the clock spring.

• Install the combination switch hood.

(b) Inspection after installation.

2. Steering wheel installation sequence (after clock spring installation i\

s completed)

(a) Pull out the clock spring's position pin.

(b) Install the steering wheel, making sure to insert the wire above the clock spring through the hole on the

steering wheel body.

(c) Tighten the steering wheel mounting nuts.

Page 261 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual254

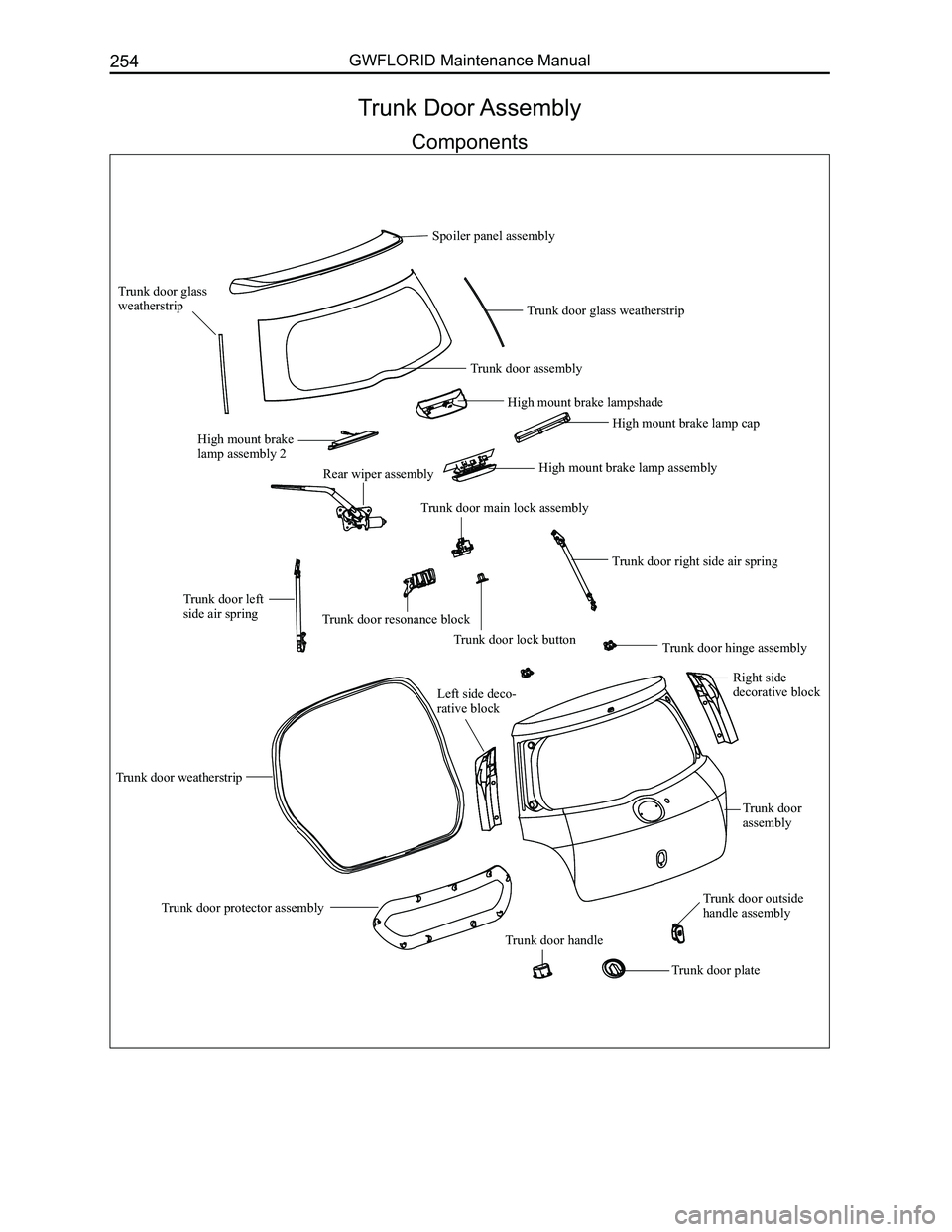

Trunk Door Assembly

Components

Right side decorative blockLeft side deco-rative block

High mount brake lamp cap

Spoiler panel assembly

Trunk door assembly

High mount brake lampshade

High mount brake lamp assembly

Trunk door main lock assembly

Trunk door right side air spring

Trunk door hinge assembly

Trunk door assembly

Trunk door outside handle assembly

Trunk door plate

Trunk door handle

Trunk door protector assembly

Trunk door weatherstrip

Trunk door left side air spring

Rear wiper assembly

Trunk door glass weatherstrip

Trunk door lock button

High mount brake lamp assembly 2

Trunk door resonance block

Trunk door glass weatherstrip