wheel GREAT WALL FLORID 2008 Workshop Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 145 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual138

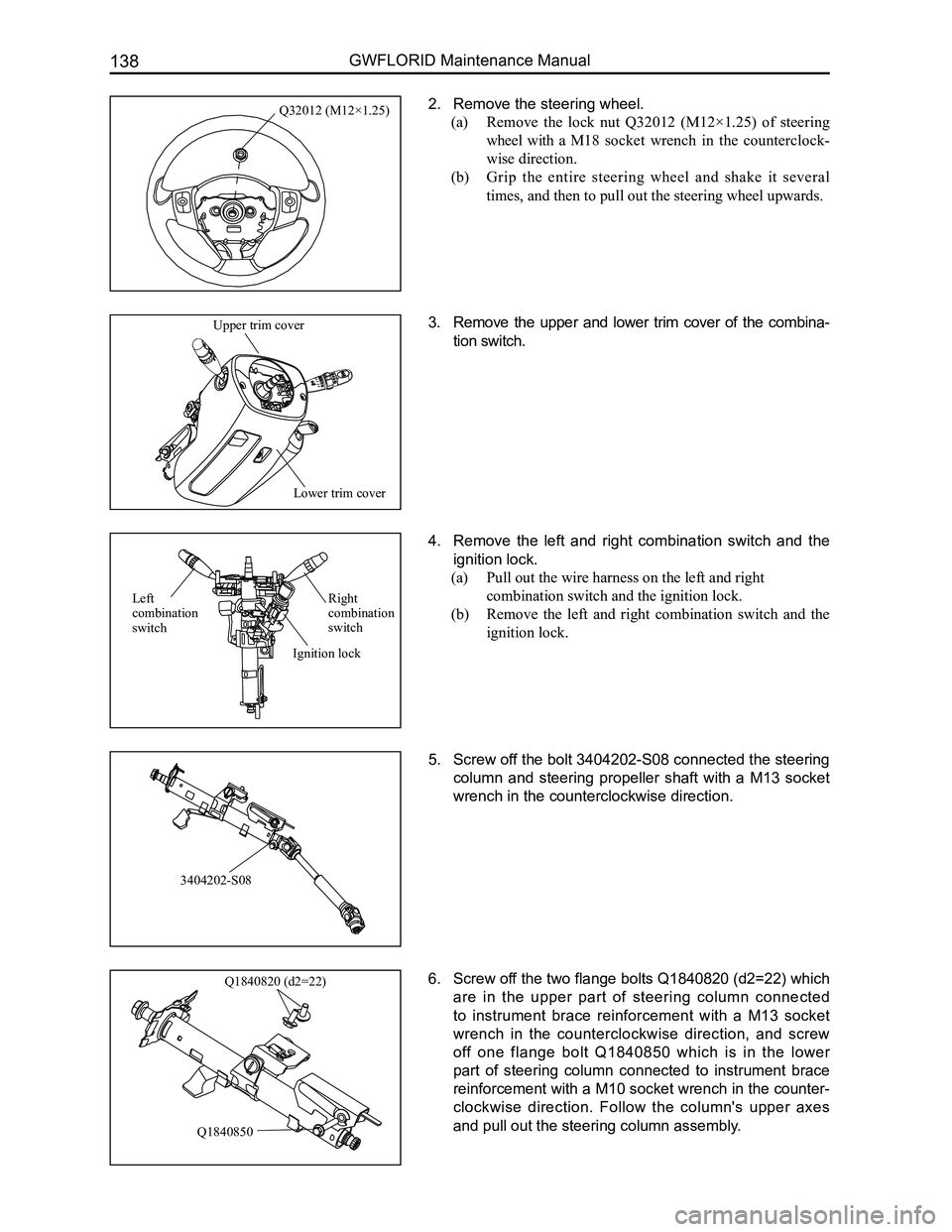

2. Remove the steering wheel.

(a) Remove the lock nut Q32012 (M12×1.25) of steering

wheel with a M18 socket wrench in the counterclock-

wise direction.

(b) Grip the entire steering wheel and shake it several

times, and then to pull out the steering wheel upwards.

3. Remove the upper and lower trim cover of the combina-

tion switch.

4. Remove the left and right combination switch and the

ignition lock.

(a) Pull out the wire harness on the left and right

combination switch and the ignition lock.

(b) Remove the left and right combination switch and the

ignition lock.

5. Screw off the bolt 3404202-S08 connected the steering

column and steering propeller shaft with a M13 socket

wrench in the counterclockwise direction.

6. Screw off the two flange bolts Q1840820 (d2=22) which

are in the upper part of steering column connected

to instrument brace reinforcement with a M13 socket

wrench in the counterclockwise direction, and screw

off one flange bolt Q1840850 which is in the lower

part of steering column connected to instrument brace

reinforcement with a M10 socket wrench in the counter-

clockwise direction. Follow the column's upper axes

and pull out the steering column assembly.

Q32012 (M12×1.25)

Lower trim cover

Upper trim cover

3404202-S08

Q1840820 (d2=22)

Q1840850

Right combination switch

Left combination switch

Ignition lock

Page 146 of 281

Downloaded from www.Manualslib.com manuals search engine 139Steering System

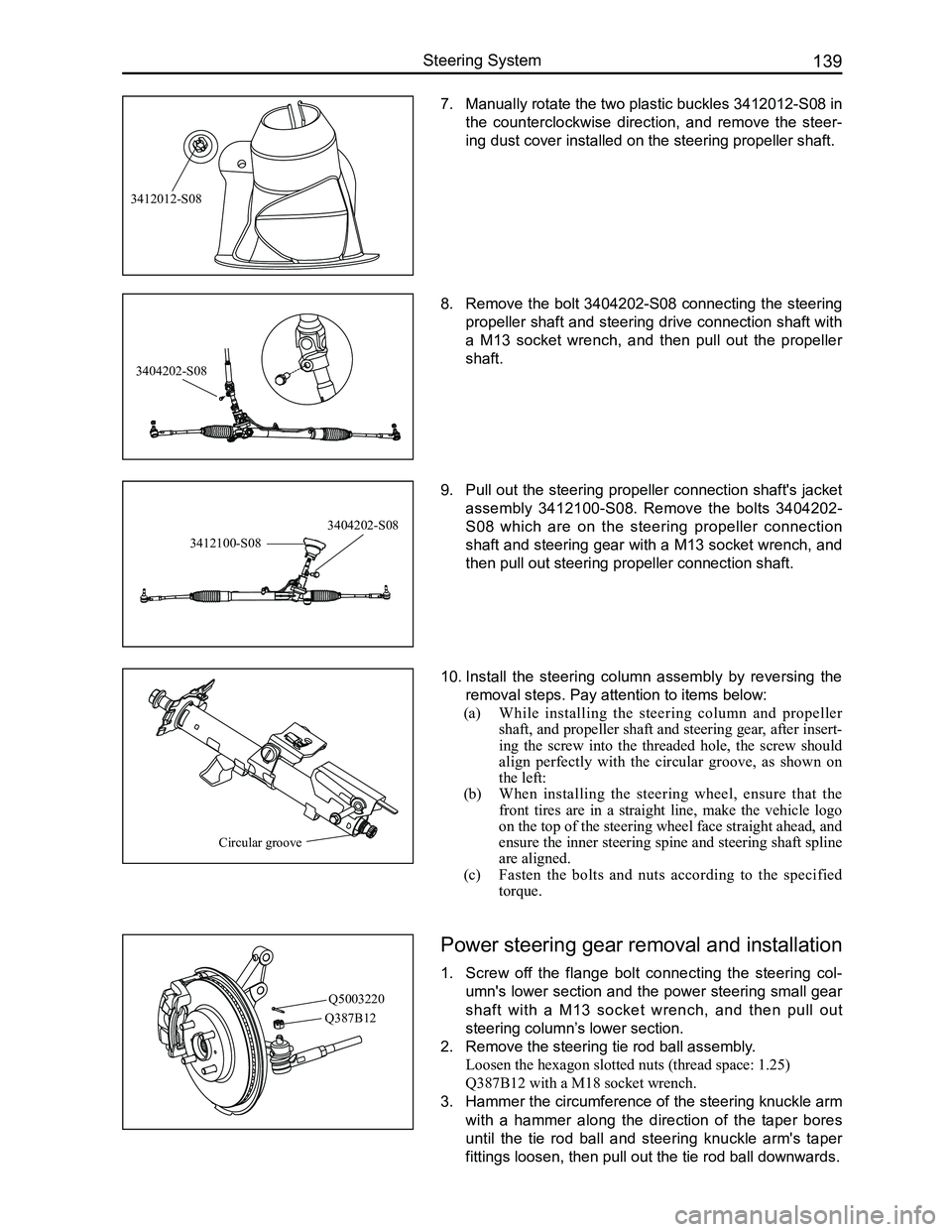

7. Manually rotate the two plastic buckles 3412012-S08 in

the counterclockwise direction, and remove the steer-

ing dust cover installed on the steering propeller shaft.

8. Remove the bolt 3404202-S08 connecting the steering

propeller shaft and steering drive connection shaft with

a M13 socket wrench, and then pull out the propeller

shaft.

9. Pull out the steering propeller connection shaft's jacket

assembly 3412100-S08. Remove the bolts 3404202-

S08 which are on the steering propeller connection

shaft and steering gear with a M13 socket wrench, and

then pull out steering propeller connection shaft.

10. Install the steering column assembly by reversing the

removal steps. Pay attention to items below:

(a) While installing the steering column and propeller

shaft, and propeller shaft and steering gear, after insert-

ing the screw into the threaded hole, the screw should

align perfectly with the circular groove, as shown on

the left:

(b) When installing the steering wheel, ensure that the

front tires are in a straight line, make the vehicle logo

on the top of the steering wheel face straight ahead, and

ensure the inner steering spine and steering shaft spline

are aligned.

(c) Fasten the bolts and nuts according to the specified

torque.

3412012-S08

Circular groove

3412100-S08

3404202-S08

Power steering gear removal and installation

1. Screw off the flange bolt connecting the steering col-

umn's lower section and the power steering small gear

shaft with a M13 socket wrench, and then pull out

steering column’s lower section.

2. Remove the steering tie rod ball assembly.

Loosen the hexagon slotted nuts (thread space: 1.25)

Q387B12 with a M18 socket wrench.

3. Hammer the circumference of the steering knuckle arm

with a hammer along the direction of the taper bores

until the tie rod ball and steering knuckle arm's taper

fittings loosen, then pull out the tie rod ball downwards.

Q5003220

Q387B12

3404202-S08

Page 148 of 281

Downloaded from www.Manualslib.com manuals search engine 141Steering System

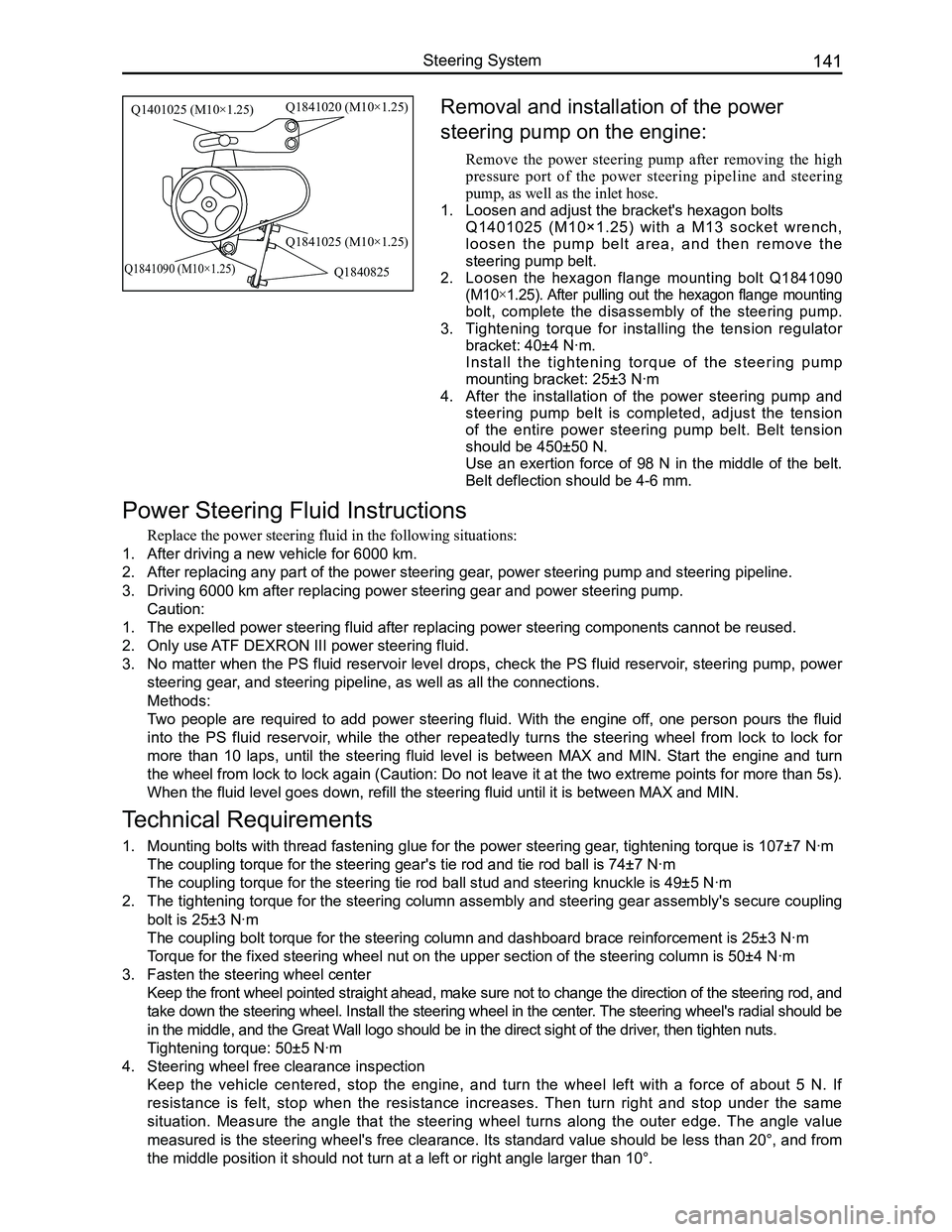

Removal and installation of the power

steering pump on the engine:

Remove the power steering pump after removing the high

pressure port of the power steering pipeline and steering

pump, as well as the inlet hose.

1. Loosen and adjust the bracket's hexagon bolts

Q1401025 (M10×1.25) with a M13 socket wrench,

l o o s e n t h e p u m p b e l t a r e a , a n d t h e n r e m o v e t h e

steering pump belt.

2. Loosen the hexagon flange mounting bolt Q1841090

(M10×1.25). After pulling out the hexagon flange mounting

bolt, complete the disassembly of the steering pump.

3. Tightening torque for installing the tension regulator

bracket: 40±4 N·m.

Install the tightening torque of the steering pump

mounting bracket: 25±3 N·m

4. After the installation of the power steering pump and

steering pump belt is completed, adjust the tension

of the entire power steering pump belt. Belt tension

should be 450±50 N.

Use an exertion force of 98 N in the middle of the belt.

Belt deflection should be 4-6 mm.

Power Steering Fluid Instructions

Replace the power steering fluid in the following situations:

1. After driving a new vehicle for 6000 km.

2. After replacing any part of the power steering gear, power steering pump and steering pipeline.

3. Driving 6000 km after replacing power steering gear and power steering p\

ump.

Caution:

1. The expelled power steering fluid after replacing power steering compone\

nts cannot be reused.

2. Only use ATF DEXRON III power steering fluid.

3. No matter when the PS fluid reservoir level drops, check the PS fluid reservoir, steering pump, power

steering gear, and steering pipeline, as well as all the connections.

Methods:

Two people are required to add power steering fluid. With the engine off, one person pours the fluid

into the PS fluid reservoir, while the other repeatedly turns the steering wheel from lock to lock for

more than 10 laps, until the steering fluid level is between MAX and MIN. Start the engine and turn

the wheel from lock to lock again (Caution: Do not leave it at the two extreme points for more than 5s).

When the fluid level goes down, refill the steering fluid until it is be\

tween MAX and MIN.

Technical Requirements

1. Mounting bolts with thread fastening glue for the power steering gear, tightening torque is 107±7 N·m

The coupling torque for the steering gear's tie rod and tie rod ball is \

74±7 N·m

The coupling torque for the steering tie rod ball stud and steering knuc\

kle is 49±5 N·m

2. The tightening torque for the steering column assembly and steering gear assembly's secure coupling

bolt is 25±3 N·m

The coupling bolt torque for the steering column and dashboard brace rei\

nforcement is 25±3 N·m

Torque for the fixed steering wheel nut on the upper section of the steer\

ing column is 50±4 N·m

3. Fasten the steering wheel center

Keep the front wheel pointed straight ahead, make sure not to change the direction of the steering rod, and

take down the steering wheel. Install the steering wheel in the center. The steering wheel's radial should be

in the middle, and the Great Wall logo should be in the direct sight of the driver, then tighten nuts.

Tightening torque: 50±5 N·m

4. Steering wheel free clearance inspection

Keep the vehicle centered, stop the engine, and turn the wheel left with a force of about 5 N. If

resistance is felt, stop when the resistance increases. Then turn right and stop under the same

situation. Measure the angle that the steering wheel turns along the outer edge. The angle value

measured is the steering wheel's free clearance. Its standard value should be less than 20°, and from

the middle position it should not turn at a left or right angle larger t\

han 10°.

Q1401025 (M10×1.25)Q1841020 (M10×1.25)

Q1841025 (M10×1.25)

Q1840825Q1841090 (M10×1.25)

Page 159 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual152

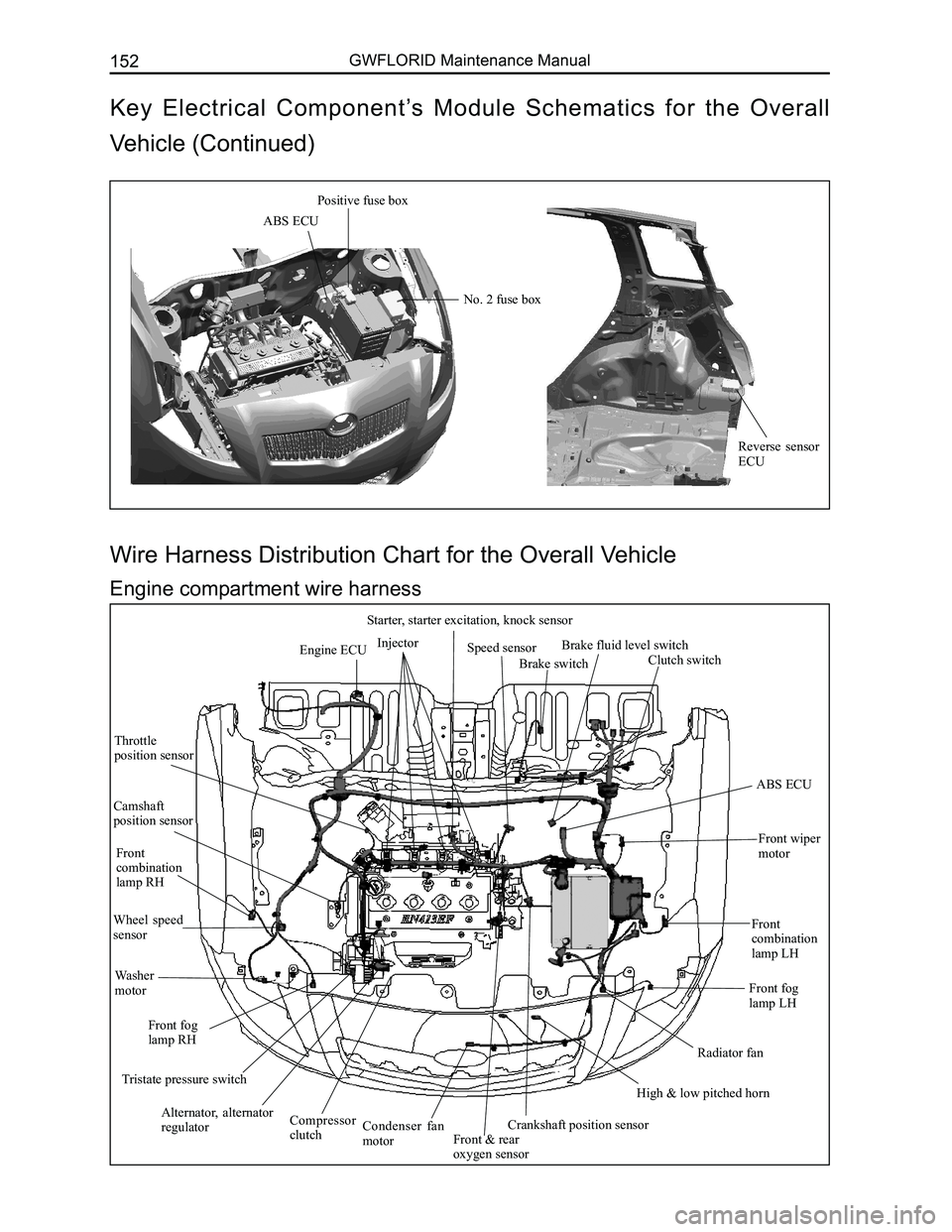

Engine ECUInjector

Starter, starter excitation, knock sensor

Speed sensor

Brake switch

Brake fluid level switch

Clutch switch

ABS ECU

Front wiper

motor

Front combination lamp LH

Front fog lamp LH

Radiator fan

High & low pitched horn

Crankshaft position sensorFront & rear oxygen sensor

Condenser fan motor

Compressor clutch

Alternator, alternator regulator

Tristate pressure switch

Front fog lamp RH

Washer motor

Wheel speed sensor

Front combination lamp RH

Camshaft position sensor

Throttle position sensor

Wire Harness Distribution Chart for the Overall Vehicle

Engine compartment wire harness

ABS ECU

Positive fuse box

No. 2 fuse box

Reverse sensor ECU

Key Electrical Component’s Module Schematics for the Overall

Vehicle (Continued)

Page 161 of 281

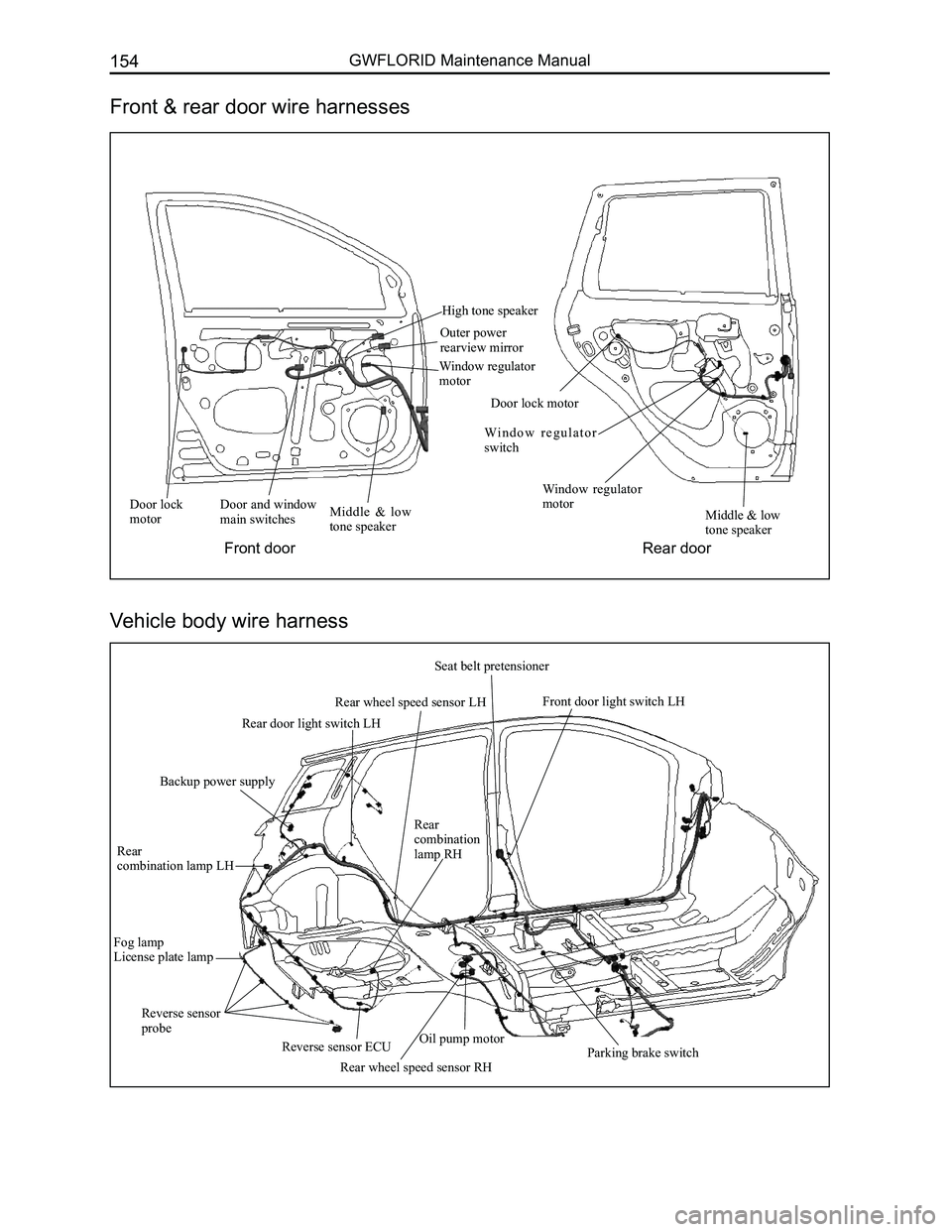

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual154

Door lock motorDoor and window main switchesMiddle & low tone speaker

High tone speaker

Outer power rearview mirror

Window regulator motor

Door lock motor

Wi n d o w r e g u l a t o r switch

Window regulator motorMiddle & low tone speaker

Fog lampLicense plate lamp

Rear

combination lamp LH

Rear combination lamp RH

Rear wheel speed sensor RHParking brake switch

Front door light switch LH

Seat belt pretensioner

Rear wheel speed sensor LH

Rear door light switch LH

Backup power supply

Front & rear door wire harnesses

Vehicle body wire harness

Front doorRear door

Reverse sensor ECU

Reverse sensor probeOil pump motor

Page 162 of 281

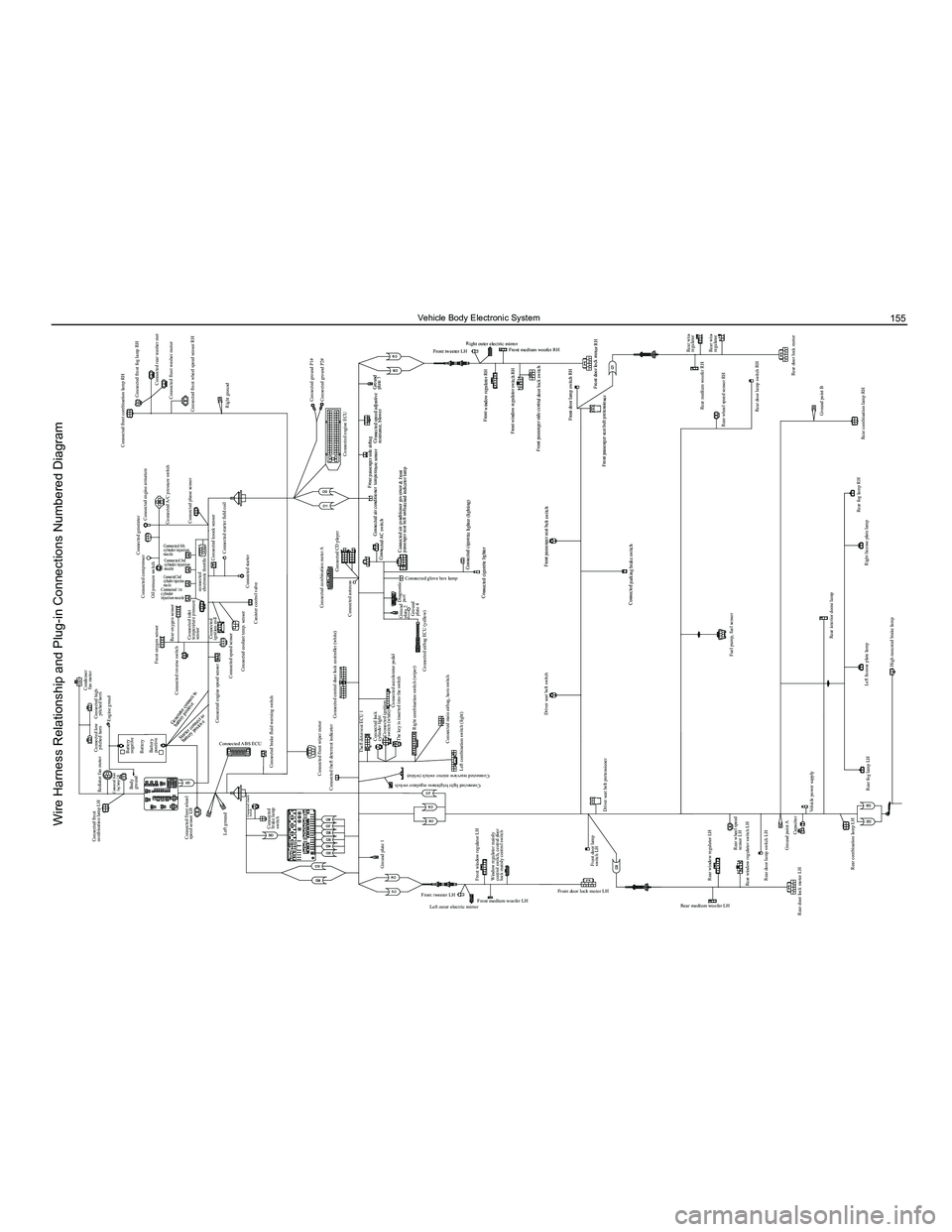

Downloaded from www.Manualslib.com manuals search engine 155Vehicle Body Electronic System

Condenser fan motor

Connected compressor

Oil pressure switch

Front oxygen sensor

Connected reverse switch

Connected engine speed sensor Connected

ignition coil

Connected speed sensor Connected coolant temp. sensor

Canister control valve

Connected combination meter A

Connected antenna

Diagnostic port

Connected AC switch Connected air conditioner temperature sensor

Front passenger side airbag

Connected speed adjustive resistance, blower

Front window regulator RH

Front window regulator switch RH

Front medium woofer RH

Front tweeter LH Right outer electric mirror

Front passenger side central door lock switch

Front door lamp switch RH

Front passenger seat belt pretensioner Front door lock motor RH

Ground

plate 3

Connected cigarette lighter (lighting)

Connected cigarette lighter

Front passenger seat belt switch

Connected parking brake switch Connected air conditioner governor & front

passenger seat belt unfastened indicator lamp

Connected CD player

Connected engine ECUConnected ground P1#

Connected ground P2#

Connected starter

Connected knock sensor

Connected starter field coil

Connected inlet

temperature pressure

sensor

connected

electronic throttle

Rear oxygen sensor

Connected 4th

cylinder injection

nozzle

Connected 3rd

cylinder injection

nozzle

Connected 2nd

cylinder injection

nozzle

Connected 1st

cylinder

injection nozzle

Connected generator

Connected engine armature Connected front combination lamp RH

Connected front fog lamp RH

Connected rear washer motor

Connected front washer motor

Connected front wheel speed sensor RH

Right ground

Connected A/C pressure switch

Connected phase sensor

Connected low

pitched horn

Connected front

combination lamp LH

Rediator fan motor

Connected front

fog lamp LH

Connected high pitched horn

Battery

negative

Body

ground

Battery

Left ground Connected

brake lamp

switch Connected brake fluid warning switch

Connected theft deterrent indicator Theft deterrent ECU 1Connected lock

cylinder lightConnected ignition

switch (white)

The key is inserted into the switch

Right combination switch (wiper) Connected airbag ECU (yellow)Ground

plate 2

Ground

plate 4

Connected accelerator pedal

Ground plate 1

Left outer electric mirror

Front medium woofer LH Front door lock motor LH

Rear medium woofer LH

Rear window regulator switch LH

Rear door lock motor LH Rear door lamp switch LH

Ground point ACapacitor

Vehicle power supply

Rear fog lamp LH Left license plate lamp

High mounted brake lamp

Ground point Trunk opener switch

Trunk motorRear wiper motor

Rear windshield defroster “-”

Trunk lamp switch Right license plate lamp

Rear fog lamp RH

Rear combination lamp RHRear wheel speed sensor RH

Rear window

regulator RH

Rear window

regulator switch RH

Rear door lock motor RH

Rear door lamp switch RH Rear medium woofer RH

Ground point B

Rear combination lamp LH

Rear windshield defroster “+”

Rear wheel speed

sensor LH

Rear window regulator LH

Fuel pump, fuel sensor

Rear interior dome lamp

Front door lamp

switch LH

Driver seat belt pretensioner Driver seat belt switch

Front tweeter LH

Connected light brightness regulator switch

Connected rearview mirror switch (white)

Connected glove box lamp

Front window regulator LH Left combination switch (light)

Connected main airbag, horn switch

Window regulator mainly

control switch, central door

lock mainly control switch Connected central door lock controller (white)

Connected front wiper motor

Connected clutch

switch

Connected ABS ECUBattery

positive

Connected front wheel

speed sensor LH Engine groud

Starter connect to

battery positive

Generator connect to

battery positive

Wire Harness Relationship and Plug-in Connections Numbered Diagram

Page 175 of 281

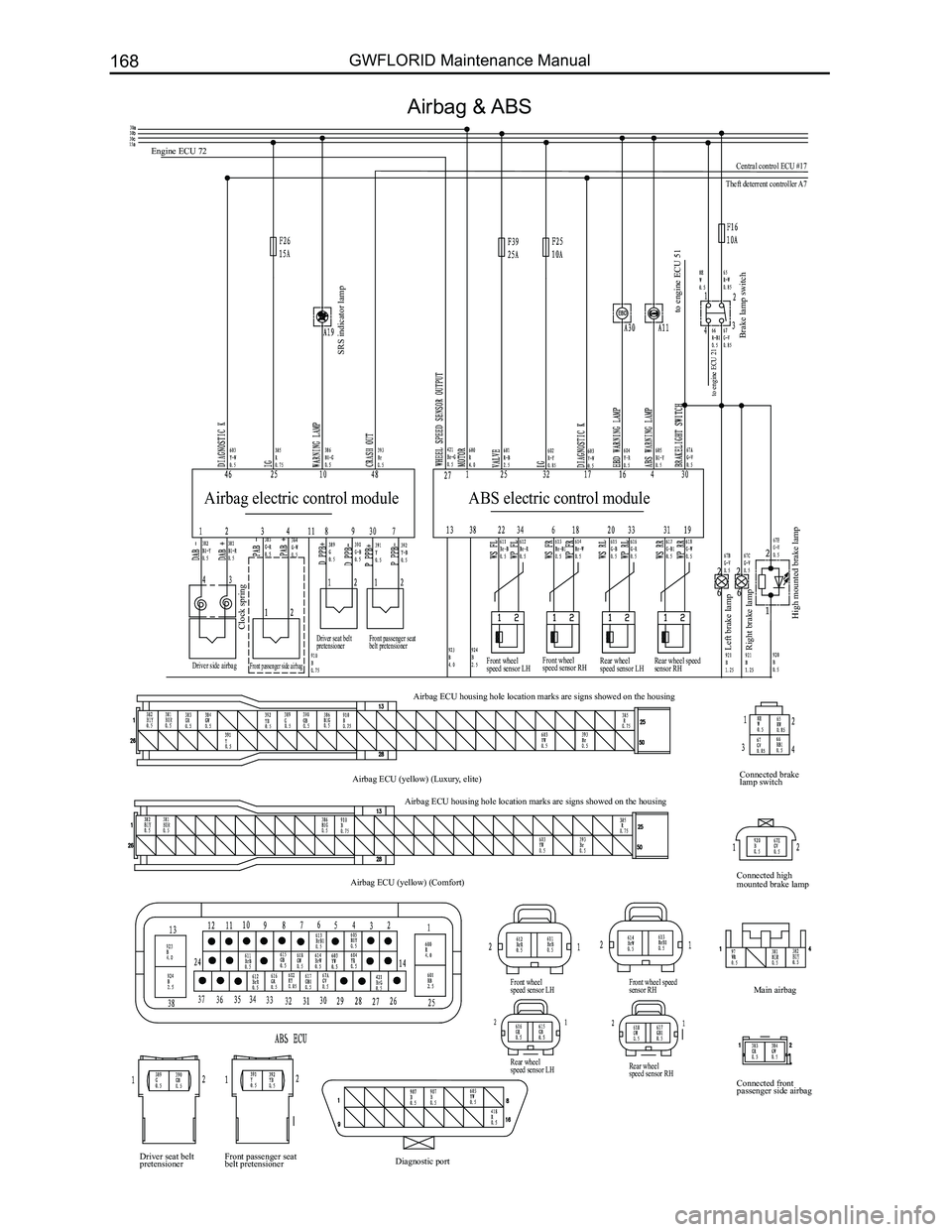

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual168

Airbag & ABS

SRS indicator lamp

Engine ECU 72

Central control ECU #17

Airbag ECU housing hole location marks are signs showed on the housing

Airbag ECU (yellow) (Luxury, elite)

Airbag ECU (yellow) (Comfort) Airbag ECU housing hole location marks are signs showed on the housing

Theft deterrent controller A7

Diagnostic port

Front passenger seat

belt pretensioner

Driver seat belt

pretensioner

Left brake lamp

Right brake lamp

High mounted brake lamp

Driver side airbagFront passenger side airbagFront wheel

speed sensor LH

Front wheel

speed sensor LH

Rear wheel

speed sensor LH Front wheel speed

sensor RH

Rear wheel

speed sensor RH

Front wheel

speed sensor RH

Rear wheel speed

sensor RH

Connected brake

lamp switch

Connected high

mounted brake lamp

Main airbag

Connected front

passenger side airbag

Rear wheel

speed sensor LH

Airbag electric control module ABS electric control module

Brake lamp switchto engine ECU 51

to engine ECU 21

Driver seat belt

pretensioner

Front passenger seat

belt pretensionerClock spring

Page 178 of 281

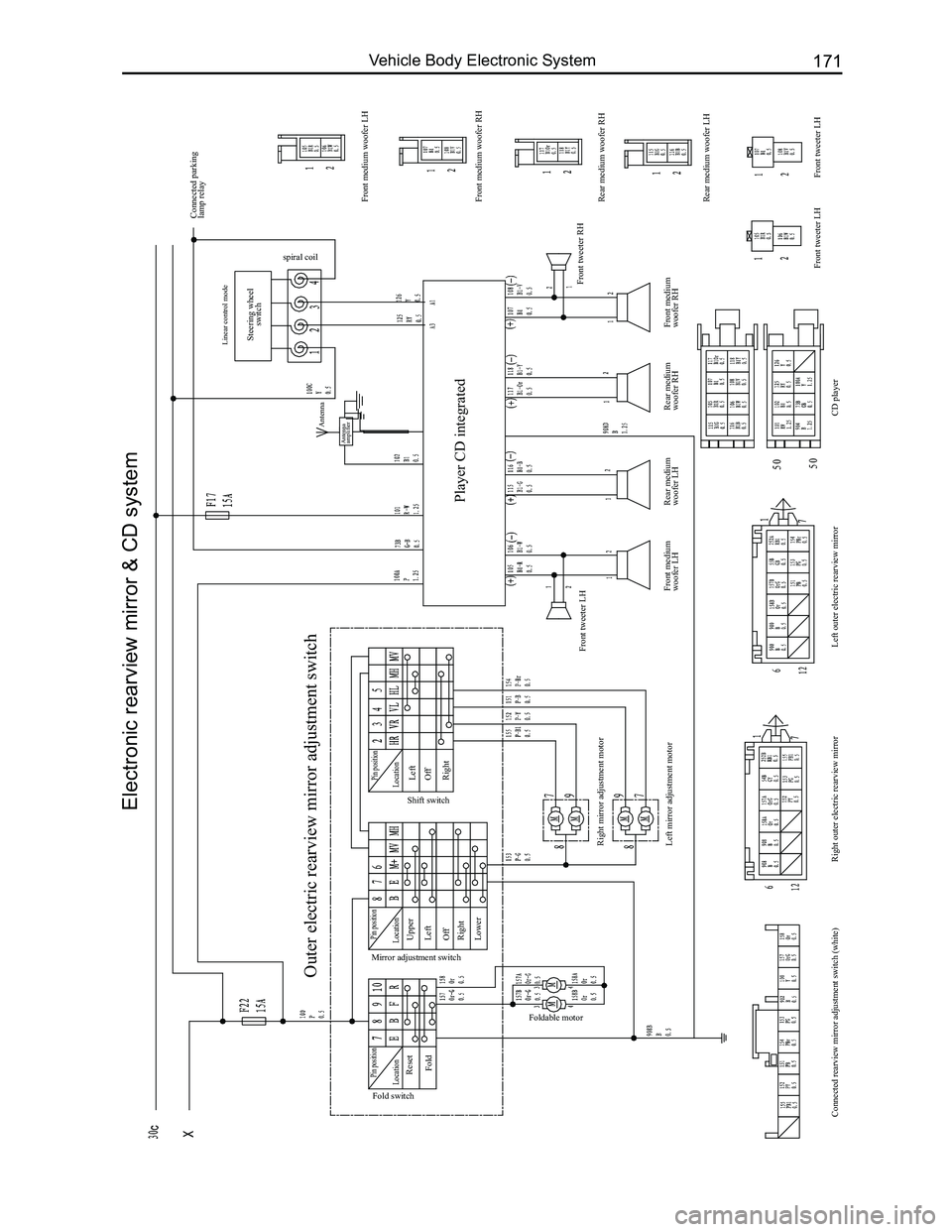

Downloaded from www.Manualslib.com manuals search engine 171Vehicle Body Electronic System

Electronic rearview mirror & CD system

Outer electric rearview mirror adjustment switch

Player CD integrated

Fold switch

Mirror adjustment switch

Foldable motor

Right mirror adjustment motor Steering wheel

switch Connected parking

lamp relay

Front medium woofer LH

Front medium woofer RH

Rear medium woofer RH

Rear medium woofer LH

Front tweeter LH Front tweeter LH

Front tweeter LH

Front medium

woofer LH Rear medium

woofer LH Rear medium

woofer RH Front medium

woofer RH Front tweeter RH

Linear control mode

Antenna

Antenna

amplifier

Left mirror adjustment motor

Connected rearview mirror adjustment switch (white) Right outer electric rearview mirror Left outer electric rearview mirror CD player

Shift switch

spiral coil

Location Reset

Upper

Left Left

Off Off

Right Right

Lower

Fold Pin position

Location

Location Pin position

Pin position

Page 180 of 281

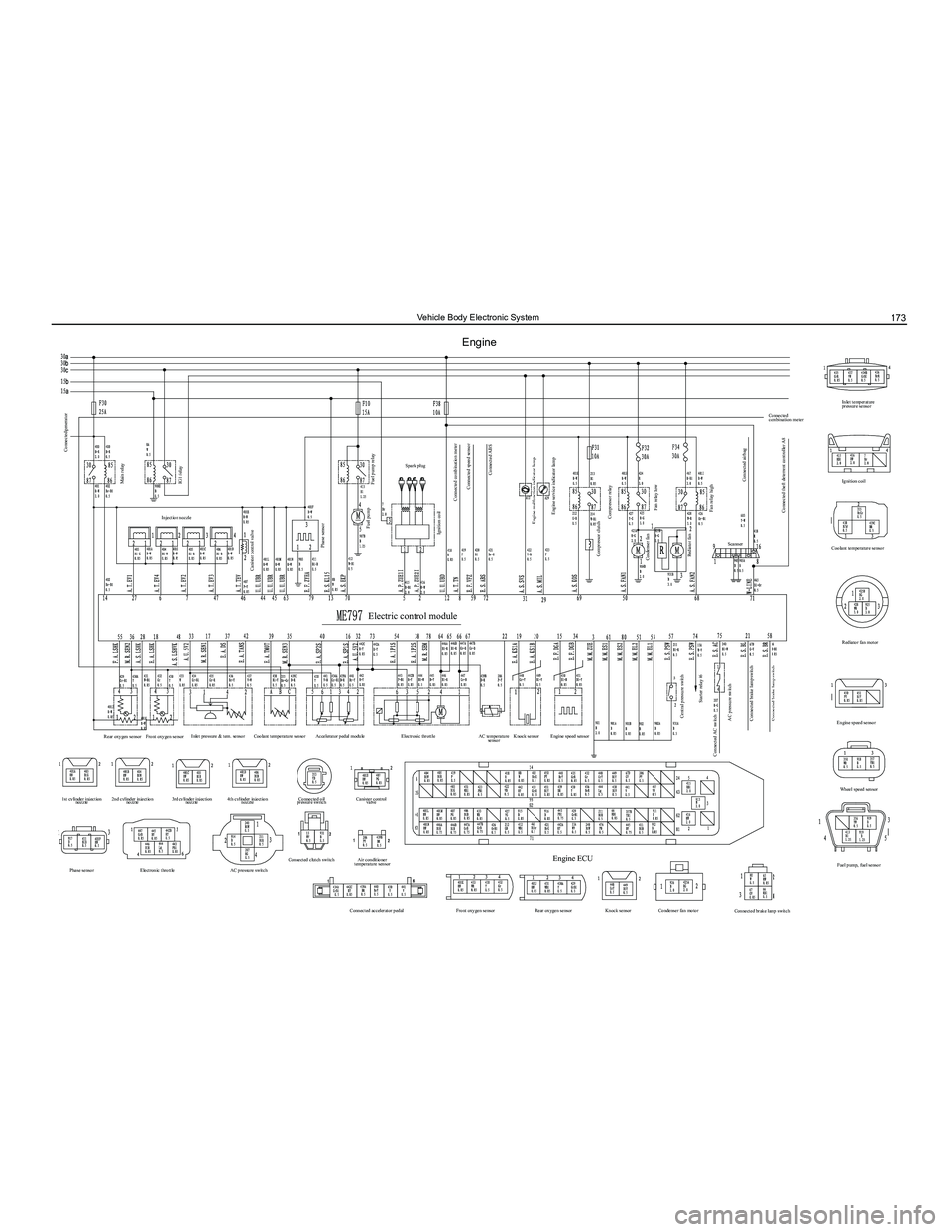

Downloaded from www.Manualslib.com manuals search engine 173Vehicle Body Electronic System

Engine

Connected generator

Canister control valve

Rear oxygen sensor

1st cylinder injection nozzle

Phase sensor Electronic throttle AC pressure switchConnected clutch switch

Air conditioner

temperature sensor

Connected accelerator pedal Front oxygen sensorRear oxygen sensorKnock sensorCondenser fan motor

Connected brake lamp switch

Engine ECU

2nd cylinder injection

nozzle 3rd cylinder injection

nozzle 4th cylinder injection

nozzle Connected oil

pressure switch Canister control

valve

Front oxygen sensor

Inlet pressure & tem. sensor

Coolant temperature sensor Accelerator pedal module Electronic throttle AC temperature

sensor Knock sensor

Engine speed sensor

Phase sensor

Fuel pump relay

Connected combination meter Connected speed sensor

Engine malfunction indicator lamp Engine service indicator lamp

Compressor relay

Compressor clutch

Central pressure switch Starter relay 86

Connected AC switch AC pressure switch

Connected brake lamp switch

Connected brake lamp switch Condenser fan

Rediator fan Fan relay lowScanner

Fan relay high

Connected airbag

Connected theft deterrent controller A8

Connected

combination meter

Ignition coil

Coolant temperature sensor

Rediator fan motor

Engine speed sensor Wheel speed sensor

Fuel pump, fuel sensor Inlet temperature

pressure sensor

Connected ABS

Spark plug

Fuel pump

Electric control module

Ignition coil

Main relay

Injection nozzle

IG1 relay

Page 220 of 281

Downloaded from www.Manualslib.com manuals search engine 213Airbags

Airbags

Airbag Electronic Control Unit ..........................................214

Diagnostic Scanner ..........................................................215

Troubleshooting ................................................................216

Vehicle Collision Diagnostics ............................................226

Removal Method for Individual Components....................227

Driver Side Airbag Module (DAB), Front Passenger Side

Airbag Module (PAB), Clock Spring, and Steering Wheel ....228

Airbag Module Disposal....................................................230

Airbag’s Diagnostic Methods Without a

Diagnostic Scanner ..........................................................232